Académique Documents

Professionnel Documents

Culture Documents

Cost Benefits of Using Ez Street Asphalt

Transféré par

Adjei Baldan0 évaluation0% ont trouvé ce document utile (0 vote)

32 vues4 pagesReistatement with asphalt

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentReistatement with asphalt

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

32 vues4 pagesCost Benefits of Using Ez Street Asphalt

Transféré par

Adjei BaldanReistatement with asphalt

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

A BETTER WAY FOR UTILITY CUT AND

TRENCH REINSTATEMENTS

Cost benefits of using EZ Street Asphalt

A Better Way for Utility Cut and

Trench Reinstatements

Cost benefits of using EZ Street Asphalt

Richard Hoare | Mainroad Maintenance Products LP

At the end of a normal day of operation for a

water service or utility cut repair, the practice is to

install a standard cold mix material in the partially

repaired trench to ensure it is serviceable and

trafficable overnight (or across a weekend). Once

the full service repair or replacement has been

completed, a paving / hotmix crew will traditionally

return to the site, remove all of the temporary cold

mix material and re-install asphalt through the

trench to create a permanent finished surface.

Removing the temporary cold mix material and

replacing it with asphalt adds a significant cost to

the utility repair. A standard asphalt crew (excluding

materials) can cost in the vicinity of $1,500 per

hour to operate. Of course every water service

reinstatement will be different in size and length

of time to complete. This does not even delve into

the realm of utility repairs in high traffic or metro/

downtown areas. In these instances the cost can

quickly skyrocket. The majority of the cost of any

trench reinstatement for utility services is carried in

the cost of the work crew and machinery. Installing

the asphalt and the cost of dumping the waste and

removed cold mix just helps the cost add up.

So, eliminating this step completely is money

in the bank. How many utility cuts, emergency

repairs, water main, sewer replacements, etc. are

completed by your municipality or company each

year and then try to add up the cost of the asphalt

re-visit? I would guarantee its a big number

although any wasted expenditure is inappropriate

in this day and age.

Using cold mix as a temporary trench repair

material presents a common problem of it failing

and coming out of the trench, especially in the

wheel tracks. This issue can be exacerbated during

wet and cold weather where potholes can grow

in a matter of hours causing driver complaints and

damage to vehicles. When temporary patching

materials fail, it also causes damage to the roadway

outside of the original trench excavation resulting

in additional saw cutting and repair work during

final asphalt surfacing.

What would you think about saving 90% of

that expenditureevery year?

Municipalities and the utility industry have

performed utility cut / trench reinstatement works

for so long that the added cost of this two part

completion method no longer seems to register

that it is wasted money. Municipal and utility

companies can literally save millions of dollars every

year if they are prepared to recognize that this

anticipated and expensive work method can be

replaced by a simpler and vastly more cost effective

method.

There seems to be no argument to the benefits of

fixing potholes once and not having to return to

repair them is the most economical, inexpensive

and best industry practice. The utilization of

materials such as EZ Street Asphalt as permanent,

immediate and the most inexpensive method

of dealing with potholes (especially during the

spring pothole season) has grown considerably as

contractors and government departments have

made the advancement to modern day methods.

already been asphalted. The use of EZ Street has

eliminated the full and very expensive second stage

of final asphalt surfacing.

This will also eliminate potholes appearing, causing

problems and requiring repair in the time prior to

the final asphalt repair.

There will always be arguments against this

method. But EZ Street has the ability to refute

them. In all cases EZ Street will still provide a cost

benefit against the traditional method.

1. Once the cold mix has been removed,

we like to compact the trench prior to

installing the asphalt.

This is pretty much an excuse for poor

workmanship. Without fail, all government

department specifications require specific

compaction requirements when utility

services are backfilled and brought to

surfacing level. Theses specifications are

designed to eliminate trench settlements and

surface defects. If the work crew performed

the job to the required specifications then

this will never be an issue.

Unfortunately the utility sector generally remains

in the dark ages when it comes to engaging

technology advancements. Repairing trenches

once and permanently is the proven future. There

are millions of dollars in saved expenditure and

profits to be made by one simple change to a work

method.

EZ Street will save you money...

guaranteed!!!

EZ Street is a high performance, polymer modified

asphalt. It has all the properties of asphalt and

more but has been designed to provide all of the

ease and workability that cold mix offers. Utilising

EZ Street for the reinstatement of a utility cut will

provide all of the benefits of the finished asphalt

surface with only the installation costs of the

temporary cold mix repair. EZ Street will allow the

work crew to place the material at the end of the

work day with the same labour and equipment

cost that would be used to install cold mix. Once

EZ Street Asphalt is in place, thats it, the trench

repair has been completed. There is no further

requirement for the eventual removal of the

cold mix and the replacement with asphalt. It has

2. The trench always needs to have an

asphalt finish for permanency.

EZ Street is high performance asphalt.

EZ Street is a material that has a minimum

of the same strengths, stabilities and

benefits as regular asphalt. In most

instances EZ Street outperforms asphalt.

Removing EZ Street to install regular

asphalt instead is the equivalent to using

cold mix to replace asphalt.

3. What if the trench sinks or settles due to

incomplete compaction.

As noted in point one, trench settlement

is a sign of poor workmanship and surface

reinstatement techniques should never

have to compensate for poor workmanship

on the backfill. That being said, EZ Street

loves bonding to EZ Street. If the trench

does settle, there is no need to cut out

and rebuild the effected section. EZ Street

can simply be placed directly on top of the

existing EZ Street surface and it will bind

cleanly to form one single deep layer.

EZ Street is not subject to the normal

slabbing effect commonly found when

placing new asphalt to patch on top of

existing asphalt.

4. We need to be able to asphalt over the

trench with a full road resurface.

EZ Street is not subject to diluent leaching

that can cause delamination of asphalt

layers. There are no issues or detrimental

effects to a new asphalt surface due to

paving over EZ Street.

5. I need to repair emergency water breaks

in the depths of winter.

EZ Street can be used in all temperatures

and weather conditions. We have successful

patch repairs that have installed when

the outside temperature has been -30 C.

EZ Street works best when the material is

at room temperature as this is when the

product has its best workability. Storing

EZ Street indoors or carrying bags inside

the cab of trucks will always maintain the

product at its best workability.

For a detailed report on cost benefits and savings

utilising EZ Street versus the traditional method,

please visit www.ezstreetasphalt.ca\technical. This

paper was put together for the City of Columbia,

Tennessee. All information in the document is

relevant for any utility service in North America

EZ Street is available in 1 tonne sacks, 22 kg bags,

or pallets (56 bags per pallet) and bulk* throughout

Canada. For more information visit us online at

www.ezstreetasphalt.ca or call toll free

1-877-575-7023.

*Available in bulk in some locations.

EZ Street and the EZ Street Logo are registered trademarks of Asphalt Research Technology, Inc. Copyright 2013.

Vous aimerez peut-être aussi

- Complaints, Compensation, Delayss181 110794bDocument11 pagesComplaints, Compensation, Delayss181 110794bAdjei BaldanPas encore d'évaluation

- An Evaluation and Pressure-Driven Design of Potable WaterJ - LADD - Thesis - June - 1Document195 pagesAn Evaluation and Pressure-Driven Design of Potable WaterJ - LADD - Thesis - June - 1Adjei BaldanPas encore d'évaluation

- Ductile Iron Pipe Pressure Test RecordsDocument2 pagesDuctile Iron Pipe Pressure Test RecordsAdjei BaldanPas encore d'évaluation

- Backfilling PDFDocument4 pagesBackfilling PDFAdjei BaldanPas encore d'évaluation

- Ppa2006 PDFDocument42 pagesPpa2006 PDFAdjei BaldanPas encore d'évaluation

- Peak Demands - Daily - HourlyDocument1 pagePeak Demands - Daily - HourlyAdjei BaldanPas encore d'évaluation

- Compaction Greater 100%Document2 pagesCompaction Greater 100%Adjei BaldanPas encore d'évaluation

- 11/23/2016 Upark Curtain Railings Width/m Height/m Support E.Cap Simple Cap Rem Kitchen Rod Length/mDocument9 pages11/23/2016 Upark Curtain Railings Width/m Height/m Support E.Cap Simple Cap Rem Kitchen Rod Length/mAdjei BaldanPas encore d'évaluation

- Math Formula Sheet AIEEEDocument93 pagesMath Formula Sheet AIEEETushar Saxena90% (21)

- Ing 4 - 01 - 03Document45 pagesIng 4 - 01 - 03awhk2006Pas encore d'évaluation

- 2013 Maths Resit QPDocument16 pages2013 Maths Resit QPAdjei BaldanPas encore d'évaluation

- Levelling ST Hubert - ST Hilaire Mains - Vol CalDocument178 pagesLevelling ST Hubert - ST Hilaire Mains - Vol CalAdjei BaldanPas encore d'évaluation

- Lir Sa Pasaz-La Ek Reponn Bann Kestion Ki Swiv.: Kont Tradisionel Lil MorisDocument6 pagesLir Sa Pasaz-La Ek Reponn Bann Kestion Ki Swiv.: Kont Tradisionel Lil MorisAdjei BaldanPas encore d'évaluation

- Cantilever Slab DesignDocument18 pagesCantilever Slab DesignSarah Huff67% (9)

- 2006 Trenchless TechnologyDocument17 pages2006 Trenchless TechnologyAdjei BaldanPas encore d'évaluation

- Lecture02 Pipeflow HandoutDocument3 pagesLecture02 Pipeflow HandoutAdjei BaldanPas encore d'évaluation

- Maths Mock STD V1 WiLLU Oct 2016Document12 pagesMaths Mock STD V1 WiLLU Oct 2016Adjei BaldanPas encore d'évaluation

- Metalwork: Rolled Steel Window and Door FramesDocument6 pagesMetalwork: Rolled Steel Window and Door FramesAdjei BaldanPas encore d'évaluation

- English Mock STD V1 WiLLU Oct 2016Document12 pagesEnglish Mock STD V1 WiLLU Oct 2016Adjei BaldanPas encore d'évaluation

- 851 10-001 AVK026 Eng v1-0Document2 pages851 10-001 AVK026 Eng v1-0Adjei BaldanPas encore d'évaluation

- ch4 PumpDocument12 pagesch4 PumpAdjei BaldanPas encore d'évaluation

- Fluid Flow in Pipes - Lecture 1Document4 pagesFluid Flow in Pipes - Lecture 1amin_corporationPas encore d'évaluation

- Water Tank DesignDocument58 pagesWater Tank DesignMoHaMmAd WaHeEd88% (17)

- Chapter-2 Understanding FlowDocument40 pagesChapter-2 Understanding FlowJR ZunigaPas encore d'évaluation

- BackfillingDocument4 pagesBackfillingAdjei BaldanPas encore d'évaluation

- Leeds University Fluid MechanicsDocument94 pagesLeeds University Fluid MechanicsAdjei BaldanPas encore d'évaluation

- Section 16 Road Pavements and SurfacingsDocument98 pagesSection 16 Road Pavements and SurfacingsAdjei BaldanPas encore d'évaluation

- The Hydraulic GradientDocument11 pagesThe Hydraulic GradientMamta SinghPas encore d'évaluation

- SoilMech Ch2 PhysProp and CompactionDocument10 pagesSoilMech Ch2 PhysProp and CompactionmargitorsiPas encore d'évaluation

- COMPACTION Soil Compact GaugeDocument132 pagesCOMPACTION Soil Compact GaugeAdjei BaldanPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- 1mrk508015-Ben B en Auxiliary Signalling and Trippning Relays Rxma 1 Rxma 2 Rxms 1 RXSF 1 Rxme 1 Rxme 18 RXMH 2 RXMDocument20 pages1mrk508015-Ben B en Auxiliary Signalling and Trippning Relays Rxma 1 Rxma 2 Rxms 1 RXSF 1 Rxme 1 Rxme 18 RXMH 2 RXMalaa6474794Pas encore d'évaluation

- Ok TC FlotationDocument4 pagesOk TC FlotationWilliam SalcedoPas encore d'évaluation

- R0221120 - Salsabilla Cindy Pratama - Daily ActivityDocument15 pagesR0221120 - Salsabilla Cindy Pratama - Daily Activitysalsabilla cindy pratamaPas encore d'évaluation

- T - Cell DifferentiationDocument24 pagesT - Cell DifferentiationAnand Prakash YadavPas encore d'évaluation

- Feeg2003 L21Document9 pagesFeeg2003 L21jiales225Pas encore d'évaluation

- Newton Interviews - Tookie AngusDocument12 pagesNewton Interviews - Tookie AngusPeter BellPas encore d'évaluation

- Esab Ok 55 (3.2 MM)Document1 pageEsab Ok 55 (3.2 MM)DHANEESH VELLILAPULLIPas encore d'évaluation

- Ao+ WDM12 R40DDocument8 pagesAo+ WDM12 R40DPedro Igor Oliveira CarvalhoPas encore d'évaluation

- 5980 10143 1 SM PDFDocument11 pages5980 10143 1 SM PDFfaustinaPas encore d'évaluation

- Enzymes MCQsDocument2 pagesEnzymes MCQsNobody's PerfectPas encore d'évaluation

- The Tenth House in AstrologyDocument6 pagesThe Tenth House in AstrologytratakPas encore d'évaluation

- Grade 8 MAPEH ReviewerDocument4 pagesGrade 8 MAPEH ReviewerVictoria DelgadoPas encore d'évaluation

- Risk Assesment FOR PIPING WORKDocument1 pageRisk Assesment FOR PIPING WORKsunil100% (2)

- 49728393Document17 pages49728393MarcoPas encore d'évaluation

- 21 Century Mind ControlDocument7 pages21 Century Mind ControltrswartzPas encore d'évaluation

- Morning Star Cafe Menu Revised 08-14-2019 On Line Menu 1Document2 pagesMorning Star Cafe Menu Revised 08-14-2019 On Line Menu 1api-471935951Pas encore d'évaluation

- The Symbols Found in TarotDocument17 pagesThe Symbols Found in TarotPEdro100% (1)

- Cantece Copii in EnglezaDocument10 pagesCantece Copii in EnglezaGeorgi Neacşa100% (1)

- Sabas fOR THE FRCR 2aDocument9 pagesSabas fOR THE FRCR 2aMohammad Shafiq0% (1)

- 1965 Elio R. Freni - Electrolytic Lead Refining in SardiniaDocument9 pages1965 Elio R. Freni - Electrolytic Lead Refining in SardiniaGeorgettaPas encore d'évaluation

- BR Safetymatrix enDocument12 pagesBR Safetymatrix enHamidreza MoaddeliPas encore d'évaluation

- Papr114 SpectralDocument4 pagesPapr114 Spectrallilivaca28Pas encore d'évaluation

- Tubular Flow ReactorDocument24 pagesTubular Flow ReactorluismiguelmmercadoPas encore d'évaluation

- International Standard Paper SizesDocument34 pagesInternational Standard Paper SizesAman KumarPas encore d'évaluation

- AidsDocument22 pagesAidsVicky Singh100% (2)

- Stellite 6 DS01-21708 (S R0808)Document2 pagesStellite 6 DS01-21708 (S R0808)bwv1006Pas encore d'évaluation

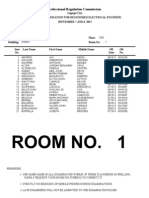

- REE0913ra LegazpiDocument6 pagesREE0913ra LegazpiScoopBoyPas encore d'évaluation

- Book of Bible Answers (Volume 1) - by Doug-BatchelorDocument138 pagesBook of Bible Answers (Volume 1) - by Doug-BatchelorAdventist_Truth100% (3)

- L 7 Thermal Death Time DataDocument21 pagesL 7 Thermal Death Time DataVaibhav GuptaPas encore d'évaluation