Académique Documents

Professionnel Documents

Culture Documents

Stealth 14

Transféré par

CV JoeCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Stealth 14

Transféré par

CV JoeDroits d'auteur :

Formats disponibles

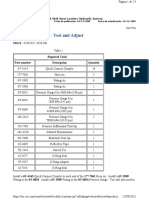

HYTORC

TOOL MODEL:HY-STEALTH 14 with HEX LINK

PRESSURE/TORQUE CONVERSION CHART

Standard Torque Chart

PRESSURE IN

PSI

1500

1600

1800

2000

2200

2400

2600

2800

3000

3200

3400

3600

3800

4000

4200

4400

4600

4800

5000

5200

5400

5600

5800

6000

6200

6400

6600

6800

7000

7200

7400

7600

7800

8000

8200

8400

8600

8800

9000

9200

9400

9600

9800

10000

* ISO DOCUMENT 9000

FT. LBS.

2105

2247

2532

2817

3102

3386

3671

3955

4240

4525

4810

5094

5379

5664

5948

6232

6517

6801

7085

7372

7659

7945

8232

8519

8805

9091

9377

9663

9949

10237

10525

10814

11102

11390

11676

11962

12248

12534

12820

13107

13394

13681

13968

14255

TORQUE IN

KGM

291

311

350

390

429

468

508

547

586

626

665

705

744

783

823

862

901

941

980

1020

1059

1099

1139

1178

1218

1257

1297

1336

1376

1416

1456

1496

1535

1575

1615

1654

1694

1733

1773

1813

1852

1892

1932

1971

NM

2854

3047

3433

3819

4205

4590

4976

5362

5748

6134

6520

6906

7292

7678

8063

8449

8834

9219

9604

9993

10382

10771

11160

11548

11936

12324

12711

13099

13487

13878

14268

14659

15050

15440

15828

16216

16603

16991

17379

17768

18157

18546

18935

19324

PRESSURE IN

BAR

104

110

124

138

152

165

179

193

207

220

234

248

262

276

290

303

317

331

345

358

372

386

400

414

427

441

455

468

482

496

510

524

538

552

565

579

593

607

620

634

648

662

676

690

REV. 03/03

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Your HYTORC TORQUE MACHINE is a power tool, and as with any power tool, certain safety precautions should be

observed to avoid accidents or personal injury. The following tips will assist you.

READ ALL INSTUCTIONS.

KEEP WORK AREA CLEAN AND WELL LIT.

CONSIDER WORK AREA ENVIRONMENT.

Electrical Pumps should never be used in an atmosphere which can be

considered potentially volatile. If there is any doubt, use an air pump. Also Note: metal to metal contact can cause sparks, precautions

should be taken.

AVOID PREMATURE TOOL STARTING. The Pump Remote Control is for the TOOL OPERATOR only.

STAY CLEAR DURING OPERATION. In most cases, the tool will allow hands free operation. If the tool must be held or steadied

during operation, use alternative means of securing the tool to the application

GUARD AGAINS ELECTRIC SHOCK. Ensure the pump is properly grounded and the proper voltage is being used.

STORE IDLE TOOLS. When not in use, tool sand accessories should be properly stored to avoid deterioration

USE RIGHT TOOL. Dont force small tools or attachments to do the job of a larger tool. Dont use a tool for purposes not intended.

PROPER SAFETY ATTIRE. When handling/operating hydraulic equipment use work gloves, hard hats, safety shoes and other

applicable clothing.

USE SAFETY GLASSES.

MOVING EQUIPMENT. Do not use hydraulic hoses, uni-swivels, pump power or remote cords as means of moving the equipment.

MAINTAIN TOOLS WITH CARE. For top performance, inspect tools, powerpack and accessories for visual damage frequently and

always prior to use. Always follow instruction for proper tool and pump maintenance. Refer to the Operations Maintenance Section for

further clarification

STAY ALERT. Watch what you are doing. Use Common sense. Do not use power equipment under the influence of any mood altering

substances.

PRIOR TO OPERATION

Ensure that all hydraulic connections are securely connected and there is no leakage

Verify that the Hydraulic hoses are not kinked or otherwise damaged.

Ensure the square drive and its retainer are fully and securely engaged.

Be certain that all connectors, elbows, fitting and swivels are not bent, loose or damaged.

PRIOR TO USE.

Check sockets for size, quality and flaws. (Do not use if questionable)

Cycle tool to ensure proper function.

Locate a solid, secure reaction point.

Be sure the reaction arm retaining clamp is fully engaged.

Be sure the hydraulic hoses are free of the reaction point.

Pressurize the system momentarily; if the tool tends to ride up or to creep, stop and re-adjust the reaction arm to a more solid and

secure position.

NOTE: Remain clear of the reaction arm during operation and never put body parts between reaction arm and reaction surfaces.

ALWAYS USE QUALITY ACCESSORIES. Always use top quality impact sockets in good condition which are the correct size and

fully engage the nut. Hidden flaws, however, remain a possibility which could cause breakage, so stay clear of sockets during operation

DO NOR USE other equipment to enhance performance (Hammer on Socket/Tool)

NOTE: Hytorc Pumps are designed to operate Hytorc Tools only. Damage may occur to the pump or the product that is being operated

due to misuse.

SAVE THESE INSTRUCTIONS FOR FUTURE USE!

Vous aimerez peut-être aussi

- XLCT 14Document2 pagesXLCT 14carlosPas encore d'évaluation

- mxt10 PDFDocument2 pagesmxt10 PDFTaufikPas encore d'évaluation

- AVANTI 3 Torque Conversion ChartDocument2 pagesAVANTI 3 Torque Conversion ChartJovani SecrettiPas encore d'évaluation

- Tool Model: Hy-5Xlt: Standard Torque ChartDocument2 pagesTool Model: Hy-5Xlt: Standard Torque ChartFabioPas encore d'évaluation

- Tool Model: HY-3MXT: Pressure/Torque Conversion ChartDocument2 pagesTool Model: HY-3MXT: Pressure/Torque Conversion ChartBhavin GamiPas encore d'évaluation

- Captura de Pantalla 2022-03-30 A La(s) 20.30.14Document2 pagesCaptura de Pantalla 2022-03-30 A La(s) 20.30.14Manuel CaipoPas encore d'évaluation

- STEALTH 2 Torque Conversion ChartDocument2 pagesSTEALTH 2 Torque Conversion Chartluisantoniojimenezperez31Pas encore d'évaluation

- Hytorc Avanti 3 Torque ChartDocument2 pagesHytorc Avanti 3 Torque ChartDarwin Tovar ZuriquePas encore d'évaluation

- MXT 1 Pressure/Torque Conversion Chart & Safety InstructionsDocument2 pagesMXT 1 Pressure/Torque Conversion Chart & Safety InstructionsWahyu WidiyantoPas encore d'évaluation

- ICE 1 Torque Conversion ChartDocument2 pagesICE 1 Torque Conversion ChartDeivid BezerraPas encore d'évaluation

- RT10 Torque ChartDocument2 pagesRT10 Torque ChartRoy Ramos100% (1)

- Satuan GDocument1 pageSatuan GWoro IndrianiPas encore d'évaluation

- Stealth Torque Pressure ChartDocument3 pagesStealth Torque Pressure Chartnarft narftPas encore d'évaluation

- XLCTTorqueDocument4 pagesXLCTTorqueSebastin DrignyPas encore d'évaluation

- HTL DS Series Torque Pressure ChartDocument1 pageHTL DS Series Torque Pressure ChartElmo JuicePas encore d'évaluation

- EDGE 6 - Torque - Conversion - ChartDocument1 pageEDGE 6 - Torque - Conversion - ChartindunilPas encore d'évaluation

- Hazen William Formula PDFDocument4 pagesHazen William Formula PDFMac ShaikPas encore d'évaluation

- Hazen-Williams Formula PDFDocument4 pagesHazen-Williams Formula PDFyehuoy100% (1)

- TableBookErrata PDFDocument4 pagesTableBookErrata PDFIbnuyusoff77Pas encore d'évaluation

- TableBookErrata PDFDocument4 pagesTableBookErrata PDFLutfi LailaPas encore d'évaluation

- Pressure Vs Torque Conversion Chart: Titan T Series ToolsDocument1 pagePressure Vs Torque Conversion Chart: Titan T Series ToolsHanselPerezAguirrePas encore d'évaluation

- TR0040dh4 Centrifuge SpeedDocument1 pageTR0040dh4 Centrifuge SpeedrofiqsnPas encore d'évaluation

- 3MXT Torque ConversionDocument2 pages3MXT Torque ConversionRodrigo SanzPas encore d'évaluation

- RTX04_torque_chartDocument1 pageRTX04_torque_chartYang Kyo OhPas encore d'évaluation

- Sitio WebDocument15 pagesSitio WebRoberto RodriguezPas encore d'évaluation

- Pressure Versus Torque - S-Series Torque WrenchesDocument5 pagesPressure Versus Torque - S-Series Torque WrenchesManga MinPas encore d'évaluation

- Datasheet LR 13000Document13 pagesDatasheet LR 13000RasoolKhadibi100% (1)

- 1 May 2019 Avocab New LP New March W.E.F - May 1stDocument1 page1 May 2019 Avocab New LP New March W.E.F - May 1stKaushal JhaPas encore d'évaluation

- DD-140 Parts ManualDocument162 pagesDD-140 Parts ManualClaudinei Marcos SilvaPas encore d'évaluation

- DIN 2215 V Belt SpecificationDocument1 pageDIN 2215 V Belt SpecificationumeshPas encore d'évaluation

- Br. Naziv Prostorije Gubici (W) Tip Radijatora Dužina (CM) Izaberi Tip 0 Temp (°C) Površina (m2) Po Radijatoru Protok Grijanje (KG/H)Document5 pagesBr. Naziv Prostorije Gubici (W) Tip Radijatora Dužina (CM) Izaberi Tip 0 Temp (°C) Površina (m2) Po Radijatoru Protok Grijanje (KG/H)Damir ĆavarPas encore d'évaluation

- HighTensileFastners PDFDocument24 pagesHighTensileFastners PDFMallika SahniPas encore d'évaluation

- catchment area to runoff yield 2 ١Document1 pagecatchment area to runoff yield 2 ١Ahmed NabilPas encore d'évaluation

- Kode HS Deskripsi HS January Nil/Val (US $) January BRT/WGT (KG)Document7 pagesKode HS Deskripsi HS January Nil/Val (US $) January BRT/WGT (KG)eniPas encore d'évaluation

- Laboratory Exercise No. 5 Rheological PropertiesDocument16 pagesLaboratory Exercise No. 5 Rheological PropertiesANIME CHANPas encore d'évaluation

- Alliance 533 Implement TireDocument2 pagesAlliance 533 Implement TireJosé Rojas AlvaradoPas encore d'évaluation

- Atlas Copco TFX08 Torque ChartDocument1 pageAtlas Copco TFX08 Torque Chartgauthamac07Pas encore d'évaluation

- Marine Chain DataDocument7 pagesMarine Chain DataIrwan SyahPas encore d'évaluation

- Draft Calibration Chart of SKO Tank # T-104 IPF LAP 19-01-2019Document1 pageDraft Calibration Chart of SKO Tank # T-104 IPF LAP 19-01-2019Muhammad Usman MirzaPas encore d'évaluation

- Hytorc Pressure/Torque Conversion Chart For MXT Hydraulic Torque Wrenches Hytorc Pressure/Torque Conversion Chart For MXT Hydraulic Torque WrenchesDocument2 pagesHytorc Pressure/Torque Conversion Chart For MXT Hydraulic Torque Wrenches Hytorc Pressure/Torque Conversion Chart For MXT Hydraulic Torque WrenchesMarcello LaraPas encore d'évaluation

- Pet Cons 821ker Dcu Nus ADocument4 pagesPet Cons 821ker Dcu Nus AShrekPas encore d'évaluation

- Partial Horizontal Tank Volumes: ParametersDocument4 pagesPartial Horizontal Tank Volumes: ParametersSagar DhuriPas encore d'évaluation

- GC-3000 Torque ChartDocument1 pageGC-3000 Torque Chartgerryocnahron86Pas encore d'évaluation

- DDDDDDDDDDDDDDDDocument2 pagesDDDDDDDDDDDDDDDfredjbps@gmail.comPas encore d'évaluation

- Datasheet PTC 140 DsDocument10 pagesDatasheet PTC 140 Dsasdasd asdasdPas encore d'évaluation

- 6 - Cost Estimate SimulationDocument9 pages6 - Cost Estimate SimulationVENSAR CONSTRUCTIONPas encore d'évaluation

- Posedroniche MatrixDocument572 pagesPosedroniche MatrixAnonymous vDi0LMxPas encore d'évaluation

- CRS Manual - PPPU PumpDocument27 pagesCRS Manual - PPPU PumpRishabh VermaPas encore d'évaluation

- 1-Rev Pay Scale - Army (New-2022)Document3 pages1-Rev Pay Scale - Army (New-2022)Syed Asif BadshahPas encore d'évaluation

- Load Inertia TablesDocument7 pagesLoad Inertia TablesgabrielaPas encore d'évaluation

- Collaboration ChartDocument1 pageCollaboration Chartlubnayaqoob0808Pas encore d'évaluation

- Phone:-Director Office FAX WWW - Kerala.gov - in 0471-2305230 0471-2305193 0471-2301740Document2 pagesPhone:-Director Office FAX WWW - Kerala.gov - in 0471-2305230 0471-2305193 0471-2301740Rajesh RamachandranPas encore d'évaluation

- Real Street PlotsDocument33 pagesReal Street PlotsSarmientoPas encore d'évaluation

- Interim Relief Rates Table from 15% to 34Document2 pagesInterim Relief Rates Table from 15% to 34V Khasim SaidhaPas encore d'évaluation

- Loadsheet b737Document1 pageLoadsheet b737David PlichtaPas encore d'évaluation

- Hydraulic Torque Wrench Operation ManualDocument18 pagesHydraulic Torque Wrench Operation Manualahmad fahmeyPas encore d'évaluation

- Polycab Price List 16th October 2021Document2 pagesPolycab Price List 16th October 2021Kushal DixitPas encore d'évaluation

- United States Census Figures Back to 1630D'EverandUnited States Census Figures Back to 1630Pas encore d'évaluation

- Technical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionD'EverandTechnical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionPas encore d'évaluation

- Important Safeguards: Danger!Document4 pagesImportant Safeguards: Danger!Carmen FosterPas encore d'évaluation

- Pressure Sensor MPS20N0040DDocument14 pagesPressure Sensor MPS20N0040DDharmi JaviyaPas encore d'évaluation

- Pressure Relief Devices ASME PTe 25-2001Document90 pagesPressure Relief Devices ASME PTe 25-2001HaziqPas encore d'évaluation

- Manual Montaje Mural Su-Pw2 Sony TVDocument32 pagesManual Montaje Mural Su-Pw2 Sony TVQuinoGallardoGomezPas encore d'évaluation

- Wire Ropes: Wire Rope Variety InstructionsDocument6 pagesWire Ropes: Wire Rope Variety InstructionsALEX-UKRPas encore d'évaluation

- PLT Line Thrower: Restech Norway AsDocument21 pagesPLT Line Thrower: Restech Norway AsFreddy José CastroPas encore d'évaluation

- Edoc - Pub - Canon mp750 780 Service ManualDocument132 pagesEdoc - Pub - Canon mp750 780 Service ManualKarim KarimmPas encore d'évaluation

- MY16 Madone Assembly ManualDocument38 pagesMY16 Madone Assembly ManualEdis HercegovacPas encore d'évaluation

- 18 Hofmann Hofnuts Brochure A4Document2 pages18 Hofmann Hofnuts Brochure A4Jorge VillalobosPas encore d'évaluation

- Description: Unit QTY Unit Price Amount SRDocument10 pagesDescription: Unit QTY Unit Price Amount SRvin ssPas encore d'évaluation

- Go With Your Safety! GO IN-AC-TION!: Science 7Document15 pagesGo With Your Safety! GO IN-AC-TION!: Science 7Core GirlPas encore d'évaluation

- G Nuovo Pignone: STD-ET-114 Pre-Commissioning Form Checks On The Lighting and M.P. SystemsDocument1 pageG Nuovo Pignone: STD-ET-114 Pre-Commissioning Form Checks On The Lighting and M.P. Systemscvg ertdPas encore d'évaluation

- Novex B Serie English v4Document6 pagesNovex B Serie English v4phandang_tPas encore d'évaluation

- BJ-Q1 Range Quarter-Turn Intelligent Electric Valve Actuator GuideDocument20 pagesBJ-Q1 Range Quarter-Turn Intelligent Electric Valve Actuator GuideRudi AlfadliPas encore d'évaluation

- N2 Generator Atlas Copco - NGM+7-70 - EN For SBK1Document2 pagesN2 Generator Atlas Copco - NGM+7-70 - EN For SBK1Taufan JustvandsPas encore d'évaluation

- Bedlift 271.92.XXXDocument8 pagesBedlift 271.92.XXXMarcus BarberPas encore d'évaluation

- CCTV Pole EarthingDocument2 pagesCCTV Pole EarthingJoselin Leo100% (2)

- TM - 698 Tech Manual AusP PES - V2 - Compressed PDFDocument42 pagesTM - 698 Tech Manual AusP PES - V2 - Compressed PDFSaswita SaktiPas encore d'évaluation

- Tws101 Emergency BatternDocument2 pagesTws101 Emergency BatternIkie Barie0% (1)

- ANSI Device NumbersDocument4 pagesANSI Device NumbersMohamed ShafeyPas encore d'évaluation

- Hydrostatic System - Test and AdjustDocument23 pagesHydrostatic System - Test and AdjustSanchez Gamarra AndyPas encore d'évaluation

- 12V Wiring Diagram for KSB Water Pump Temperature SwitchDocument1 page12V Wiring Diagram for KSB Water Pump Temperature SwitchM. Shaat100% (2)

- Woodworking Presentation 040518-1Document60 pagesWoodworking Presentation 040518-1Ssilva silvaPas encore d'évaluation

- Mob LedDocument12 pagesMob LedUsht0% (1)

- GEZE Operating Instructions User Manual en 808279Document24 pagesGEZE Operating Instructions User Manual en 808279Yudha P MPas encore d'évaluation

- In-Line Multi Fit: IrripodDocument2 pagesIn-Line Multi Fit: Irripodrightnow1000Pas encore d'évaluation

- Proportional Valve Group: Service and Parts ManualDocument142 pagesProportional Valve Group: Service and Parts ManualMilos BubanjaPas encore d'évaluation

- Ybbys Analiz Yazilimi IsmxlsxDocument54 pagesYbbys Analiz Yazilimi IsmxlsxALİPas encore d'évaluation

- Prince Prince Prince Prince Prince: Pressure SwitchesDocument2 pagesPrince Prince Prince Prince Prince: Pressure Switchesersanjeeb_456100% (1)

- Black Blue Red Pink Green White Violet Orange Yellow Brown Sky Blue Light Green GrayDocument25 pagesBlack Blue Red Pink Green White Violet Orange Yellow Brown Sky Blue Light Green GrayToua Yaj100% (1)