Académique Documents

Professionnel Documents

Culture Documents

Case 77 Fiberglass PDF

Transféré par

Tushar NaikDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Case 77 Fiberglass PDF

Transféré par

Tushar NaikDroits d'auteur :

Formats disponibles

77

Fiberglass

Fire Water System on a LNG Plant

Stress and Surge Analysis

Introduction

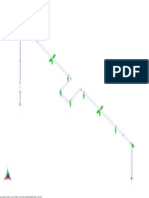

Stress Analysis

A stress and surge analysis has been performed for the firewater

The piping of the considered system is primarily buried and inclu-

piping system of a LNG Plant, located in South America. The system

des several connections to above ground fire hydrants and corres-

is constructed using Glassfiber Reinforced Epoxy (GRE) pipes. The

ponding equipment. System routing and pipe properties used for

largest and most critical unbalanced forces were used to perform a

the analysis are based on data provided by the client.

dynamic response analysis of the complete piping system.

The stresses are assessed conform ISO 14692, the standard for

GRE piping design. The software used to perform the stress analy-

Surge Analysis

sis is CAESAR II pipe stress software. This model incorporates the

The existing firewater plant contains two pump connections, a

unbalanced loads calculated using BOSfluids to perform the dyna-

fresh water and a seawater pump. During normal operation the

mic stress analysis, relevant for fatigue.

fresh water pump supplies the firewater, while the seawater pump

is used for backup in case of failure or when a large demand of

firewater is required.

A Transient flow analysis was performed using the software package BOSfluids. BOSfluids is a commercially available package that

has been developed by DRG to perform transient flow analysis. The

When performing a mechanical response

analysis, it is highly importance to identify

the most critical scenario resulting in the

largest unbalanced loads

pressure and flow distribution was calculated for steady state conditions as well as for four critical transient scenarios. These scena-

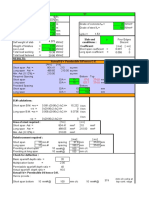

Results

rios include switching over from operating the fresh water pump

For given design conditions, several modifications were advised

to the seawater pump, the closing of all hydrants and monitors,

(with respect to the original design) to limit the static stresses

simulatuously opening of the LNG sprinklers (largest flow); and fi-

within the allowable envelopes, i.e. additional laminate reinforce-

nally the tripping of both fresh and seawater pump subsequently.

ments on top of the GRE wall thickness or application of flexible

These four scenarios were considered most important for the sys-

material. In addition to the static stress analysis, the unbalanced

tem in terms of generating the highest and lowest pressures pos-

loads were taken into account as a result of the pressure distribu-

sible and the largest unbalanaced loads.

tion of the transient flow in the system.

The maximum dynamic stresses were combined with the static

operational stresses and assessed against the ISO16492 long term

occasional envelope. It was found that none of the stresses were

greater than the occasional allowable.

More information on this subject? Contact us.

Houtsingel 95

2719 EB Zoetermeer

The Netherlands

Reg nr. 27320315

T

F

E

W

+31 79 361 5150

+31 79 361 5149

info@dynaflow.com

www.dynaflow.com

Vous aimerez peut-être aussi

- Plastics Pipe Institute Handbook of Polyethylene Pipe: Handbook Errata Sheet - March 2009Document1 pagePlastics Pipe Institute Handbook of Polyethylene Pipe: Handbook Errata Sheet - March 2009Alfonso José García LagunaPas encore d'évaluation

- Flowchart AIV FIVDocument1 pageFlowchart AIV FIVTushar NaikPas encore d'évaluation

- Frequently Asked Questions (FAQ)Document13 pagesFrequently Asked Questions (FAQ)Tushar NaikPas encore d'évaluation

- Title: Ref. No.:: Stress Analysis of Below Ground Chilled Water Pipe Work SLS-TCH-001-055-10-REV1Document1 pageTitle: Ref. No.:: Stress Analysis of Below Ground Chilled Water Pipe Work SLS-TCH-001-055-10-REV1Tushar NaikPas encore d'évaluation

- MIT16 07F09 Lec19Document10 pagesMIT16 07F09 Lec19spylogo3Pas encore d'évaluation

- DWG 1Document1 pageDWG 1Tushar NaikPas encore d'évaluation

- Tejas EngineerDocument3 pagesTejas EngineerTushar NaikPas encore d'évaluation

- WRC 107 - 297Document1 pageWRC 107 - 297Tushar NaikPas encore d'évaluation

- How A Bellows Works: Pressure ThrustDocument2 pagesHow A Bellows Works: Pressure ThrustTushar NaikPas encore d'évaluation

- SolvencyDocument1 pageSolvencyTushar NaikPas encore d'évaluation

- Pipe Design Basic MaterialDocument1 pagePipe Design Basic MaterialpandiangvPas encore d'évaluation

- Pipe Stress AnalysisDocument7 pagesPipe Stress AnalysisTushar NaikPas encore d'évaluation

- Selection of Air ValveDocument2 pagesSelection of Air ValveTushar NaikPas encore d'évaluation

- ExpDocument1 pageExpTushar NaikPas encore d'évaluation

- Heater Outlet Nozzle n4 LoadsDocument1 pageHeater Outlet Nozzle n4 LoadsTushar NaikPas encore d'évaluation

- Discharge Gas Cooler - Structure Views - Rev. 0Document1 pageDischarge Gas Cooler - Structure Views - Rev. 0Tushar NaikPas encore d'évaluation

- Modeling FRP and Plastic Piping-R11Document15 pagesModeling FRP and Plastic Piping-R11balas838541Pas encore d'évaluation

- Hot Sustained CaseDocument1 pageHot Sustained CaseTushar NaikPas encore d'évaluation

- Viking Pump Nozzle Load DetailsDocument1 pageViking Pump Nozzle Load DetailsTushar Naik0% (1)

- EC-Newsletter-Wind and Seismic Design in Brazil-09Document2 pagesEC-Newsletter-Wind and Seismic Design in Brazil-09Tushar NaikPas encore d'évaluation

- RF PadsDocument1 pageRF PadsTushar NaikPas encore d'évaluation

- Trunnion Calculation SheetDocument3 pagesTrunnion Calculation Sheetsudhisnair67% (3)

- Steam GeneratorDocument1 pageSteam GeneratorTushar NaikPas encore d'évaluation

- Proposal Sketch - Discharge Gas Cooler - Rev. 1Document1 pageProposal Sketch - Discharge Gas Cooler - Rev. 1Tushar NaikPas encore d'évaluation

- Calc SheetDocument1 pageCalc SheetTushar NaikPas encore d'évaluation

- Equivalent Length of Common Fittings Like PDFDocument2 pagesEquivalent Length of Common Fittings Like PDFFelix BadillaPas encore d'évaluation

- Net Positive Suction Head or NPSHDocument4 pagesNet Positive Suction Head or NPSHsateesh chandPas encore d'évaluation

- Boiler PlantDocument1 pageBoiler PlantTushar NaikPas encore d'évaluation

- Calc SheetDocument1 pageCalc SheetTushar NaikPas encore d'évaluation

- Steam GeneratorDocument1 pageSteam GeneratorTushar NaikPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- CML TML FancoilokDocument52 pagesCML TML FancoilokIstván GabrovitsPas encore d'évaluation

- NTF Aalborg HK 2Document5 pagesNTF Aalborg HK 2Ruben PauwelsPas encore d'évaluation

- The CrystalDocument2 pagesThe CrystalДима ВасканPas encore d'évaluation

- AntiferroelectricDocument6 pagesAntiferroelectricCristina ChirilaPas encore d'évaluation

- All Slab - LSDocument15 pagesAll Slab - LSTechnical OrilitePas encore d'évaluation

- Pressure Relief Valves Operating Instructions: Supplemental ProtectionDocument2 pagesPressure Relief Valves Operating Instructions: Supplemental ProtectionlorenzoPas encore d'évaluation

- Asme IxDocument98 pagesAsme IxNam KhansomboonPas encore d'évaluation

- DS11S1 - (1970) An Evaluation of The Elevated Temperature Tensile and Creep-Rupture Properties of Wrought Carbon Steel PDFDocument102 pagesDS11S1 - (1970) An Evaluation of The Elevated Temperature Tensile and Creep-Rupture Properties of Wrought Carbon Steel PDFJacques StrappePas encore d'évaluation

- Cagsawa, Ryan I. (Sce101-10 Problems)Document7 pagesCagsawa, Ryan I. (Sce101-10 Problems)Ryan CagsawaPas encore d'évaluation

- Alternative Building MaterialsDocument12 pagesAlternative Building Materialslakshmi achayathPas encore d'évaluation

- PBT - Lanxess Pocan B3235 000000Document3 pagesPBT - Lanxess Pocan B3235 000000armandoPas encore d'évaluation

- Iso 5817Document34 pagesIso 5817ElenaGozunovaPas encore d'évaluation

- Blockice6p PDFDocument6 pagesBlockice6p PDFLouie Fajardo AbadPas encore d'évaluation

- Self Compacting ConcreteDocument48 pagesSelf Compacting Concreteshweta sharmaPas encore d'évaluation

- Titanium Grade 5 ASTM B 265 / 348Document2 pagesTitanium Grade 5 ASTM B 265 / 348DarkedgePas encore d'évaluation

- Price ScheduleDocument9 pagesPrice SchedulePlofang BlokangPas encore d'évaluation

- Bomba Gorman RuppDocument15 pagesBomba Gorman RuppdenisPas encore d'évaluation

- Users Manual - Axial Flow Fan - 2020Document26 pagesUsers Manual - Axial Flow Fan - 2020Nguyễn Quốc ĐạtPas encore d'évaluation

- #2 Philosophy Rating Tools Rev-2 37Document37 pages#2 Philosophy Rating Tools Rev-2 37dina lisaPas encore d'évaluation

- CYCOLOY™ Resin - XCY620 - Asia - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - XCY620 - Asia - Technical - Data - SheetAthiwat TriwattanapornPas encore d'évaluation

- Vernacular Terms Used in ConstructionDocument6 pagesVernacular Terms Used in ConstructionJe CiroPas encore d'évaluation

- Mil HDBK 697a PDFDocument122 pagesMil HDBK 697a PDFkulto_kultoPas encore d'évaluation

- Control Tower ResearchDocument7 pagesControl Tower ResearchJannah ArandaPas encore d'évaluation

- Tenmat Feroform t14 DatasheetDocument1 pageTenmat Feroform t14 DatasheettungPas encore d'évaluation

- Sheet - 2-Iternal Incompressible Viscous FlowDocument1 pageSheet - 2-Iternal Incompressible Viscous FlowS.A. BeskalesPas encore d'évaluation

- WM3535 1Document4 pagesWM3535 1aguileraenrique0505Pas encore d'évaluation

- Liquid Retaining Structures HandoutsDocument17 pagesLiquid Retaining Structures Handoutsmaria talibPas encore d'évaluation

- Me 1303 Gas Dynamics and Jet Propulsion: Presented byDocument24 pagesMe 1303 Gas Dynamics and Jet Propulsion: Presented byArul SankaranPas encore d'évaluation

- GST-250 PSI Vertical Storage Tanks: 1500 Gallons Through 20,000 GallonsDocument33 pagesGST-250 PSI Vertical Storage Tanks: 1500 Gallons Through 20,000 GallonsPham LanphuongPas encore d'évaluation