Académique Documents

Professionnel Documents

Culture Documents

Investigation of The Corrosion Behavior of Electroless Nickel Coatings in Basic Solutions

Transféré par

Faz Zachary0 évaluation0% ont trouvé ce document utile (0 vote)

16 vues1 page099

Titre original

0119

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce document099

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

16 vues1 pageInvestigation of The Corrosion Behavior of Electroless Nickel Coatings in Basic Solutions

Transféré par

Faz Zachary099

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

Abs. 119, 205th Meeting, 2004 The Electrochemical Society, Inc.

Investigation of the Corrosion Behavior of

Electroless Nickel Coatings in Basic Solutions

Nazila Dadvand1, William Caly and Georges Kiporous

Mining and Metallurgical Engineering Department, Dalhousie

University, 1360 Barrington Street, Halifax (NS) B3J 2X2,

Canada

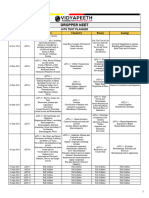

Figure 1 shows XRD spectra for EN-B coated samples

with different heat treatment durations. It can be seen that

by increasing the heat treatment time at 220 oC, more

peaks of Ni3B appears and the transition from amorphous

to crystalline states occurs. This may explain the decrease

in corrosion resistance with an increase in heat treatment

time.

(a)

Now at: National Research Council Canada

Industrial Materials Institute, 75 de Mortagne Blvd.

Boucherville (QC) J4B 6Y4, Canada

Electroless nickel (EN) is a barrier coating which protects a

substrate by preventing contact of the alloy with the

environment. The corrosion resistance of the coating is

excellent and in many environments is better than that of

traditional nickel or chromium alloys. This level of

corrosion resistance can be explained by the amorphous and

passive nature of EN. For example, the corrosion resistance

of amorphous alloys is better than for equivalent

polycrystalline materials, both because there are no grain or

phase boundaries and because of the glassy surface films

which form [1,2].

(b)

EN plating produces a Ni-P or Ni-B or pure nickel deposits

depending on whether sodium hypophosphite or dimethyl

amine borane / borohydride or hydrazine hydrate

respectively are used as the chemical reducing agent.

The corrosion behavior of electroless nickel phosphorous

(EN-P) coatings with phosphorous (P) contents ranging

from 2 to 12.5 w% was investigated using potentiodynamic

and cyclic voltammetry techniques in 0.5 M sodium

hydroxide.

It was found that although the corrosion resistance of EN-P

coatings generally increased with an increase in P content

the trend was observed only for samples where the

difference in the P content was large. For example, a very

low P EN coating (2 w%) was more resistant in alkaline

solution than two medium P (6.5, 8 w%) samples, and these

in turn were more resistant than the high P (12.5 w% P)

coated samples. However, when comparing the 6.5 and 8

w% samples the higher P content showed more resistance.

This behavior may be explained in terms of the two

counteracting effects, activating and inhibiting of

phosphorous on corrosion resistance. The activating effect

is due to the lower protectiveness of the passivating film

because of its lower thickness. As the P content increases,

the inhibiting effect increases as a result of phosphate

formation.

The corrosion behavior of electroless nickel-boron (EN-B)

coatings with boron content of 6 w% was also investigated

using a potentiodynamic technique in 0.5 M sodium

hydroxide, and the results were compared with those of a

EN-P coating with P content of 6 w%. Comparison

between potentiodynamic polarization behaviors of EN-B

coated sample with that of EN-P coated sample showed less

corrosion resistance of EN-B.

As well, the effect of heat treatment on the corrosion

resistance of the EN-B coating was investigated. X-ray

diffraction (XRD) spectra were taken from various Ni-B

coatings on the brass substrate with various heat treatment

duration conditions.

Fig. 1 XRD spectra of various Ni-B coatings at 220 oC:

(a) 5 h heat treatment, (b) 48 h heat treatment

Acknowledgements: The authors wish to acknowledge

financial assistance from the Natural Science and

Engineering Research Council of Canada.

.

[1] R. L. Zeller and L. Salvati, Corrosion Science,

50(1994)457.

[2] Y. Z. Zhang, and M. Yao, Trans IMF, 77(1999)78.

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Carbon Disulphide PlantDocument8 pagesCarbon Disulphide PlantDipanjanSarkarPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Welding ReportDocument3 pagesWelding ReportChanten NanPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Heat of Vaporization and Heat of FusionDocument17 pagesHeat of Vaporization and Heat of FusionJASIS JULIA NOELYN V.Pas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Tugas BingDocument9 pagesTugas Bingulilnajwa0Pas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Atoms, Elements, Compounds and MixturesDocument15 pagesAtoms, Elements, Compounds and MixturesRajat AnandPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Soil Conditions On Earthworm ActivityDocument2 pagesSoil Conditions On Earthworm ActivityRahul RoopchandPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Akcc - 1Document2 pagesAkcc - 1intel pcPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Artigo Nova Metodologia-PqcDocument19 pagesArtigo Nova Metodologia-PqcDaniely Carlos Henrique Carlos HenriquePas encore d'évaluation

- Cainta Senior High School G11 - Physical Sciences: Quarter 3 - Third Week March 01. 2022Document4 pagesCainta Senior High School G11 - Physical Sciences: Quarter 3 - Third Week March 01. 2022gerald martos100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Technical Data Sheet: EPIKURE™ Curing Agent 3046Document4 pagesTechnical Data Sheet: EPIKURE™ Curing Agent 3046Maha MuflehPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Chemistry Project Work: TopicDocument12 pagesChemistry Project Work: TopicNABIN DHAKALPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Post Lab-4Document4 pagesPost Lab-4Gaffar KhanPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Astm-D3846 2008 355215838138Document3 pagesAstm-D3846 2008 355215838138Malik AzeemPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Health Risk Assessment and Analysis of Nitrosamine Impurities in Drugs AssDocument35 pagesHealth Risk Assessment and Analysis of Nitrosamine Impurities in Drugs AssYegezu MebratuPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Chem 1 Week 4 Stoichiometry CompilerDocument7 pagesChem 1 Week 4 Stoichiometry CompilerMelcorr MontesclarosPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Astm G 35 - 98 - RZM1LTK4Document3 pagesAstm G 35 - 98 - RZM1LTK4Cordova RaphaelPas encore d'évaluation

- Schmincke Horadam Aquarell Material Safety Data SheetDocument11 pagesSchmincke Horadam Aquarell Material Safety Data SheetCherylPas encore d'évaluation

- PW Test Planner 2024Document1 pagePW Test Planner 2024Neel MirchandaniPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- DCG Recording With Red LightDocument10 pagesDCG Recording With Red LightMaximoPas encore d'évaluation

- ( (2004) Yamamuro & Wood) - Effect of Depositional Method On The Undrained Behavior and Microstructure of Sand With SiltDocument10 pages( (2004) Yamamuro & Wood) - Effect of Depositional Method On The Undrained Behavior and Microstructure of Sand With SiltLAM TRAN DONG KIEMPas encore d'évaluation

- Model Question To Aptitude Test: Manoj Kumar Rout BiitmDocument35 pagesModel Question To Aptitude Test: Manoj Kumar Rout BiitmBikash Kumar DashPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- CTR Pillar 61037-38 MIKOMI StatusDocument2 pagesCTR Pillar 61037-38 MIKOMI StatusMuhammad UsmanPas encore d'évaluation

- Avogadro Exam 2019 - With AnswersDocument12 pagesAvogadro Exam 2019 - With AnswersDENIZ SURURPas encore d'évaluation

- Local Media5124777314878222530Document6 pagesLocal Media5124777314878222530Joforce Karl MalanaPas encore d'évaluation

- Formic AcidDocument23 pagesFormic AcidAMS100% (1)

- Review Table of Surface TensionDocument4 pagesReview Table of Surface TensionmariyanaPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Stoichiometry 1Document4 pagesStoichiometry 1hey mama don’t stress your mindPas encore d'évaluation

- Chapter 4Document48 pagesChapter 4alex tomsonPas encore d'évaluation

- Spinel Ferrite Nanoparticles Synthesis, Characterization and ApplicationsDocument6 pagesSpinel Ferrite Nanoparticles Synthesis, Characterization and ApplicationsEditor IJTSRDPas encore d'évaluation

- MCQ in General Chemistry Part 1 ECE Board ExamDocument10 pagesMCQ in General Chemistry Part 1 ECE Board ExamEllaine Joy PecsonPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)