Académique Documents

Professionnel Documents

Culture Documents

Multistage Distilation - Draft Protocol

Transféré par

Aubrey LuttrellCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Multistage Distilation - Draft Protocol

Transféré par

Aubrey LuttrellDroits d'auteur :

Formats disponibles

HEAT AND MASS TRANSFER LAB (DRAFT)

STEADY STATE MULTI-STAGE DISTILATION

Before performing this experiment, all students in the lab group should review this protocol in its entirety and also

the references provided. In addition to the measurement detailed out in the procedures, research and report other

data necessary to meet the experimental objectives in the prelab report.

Objectives

1.

To investigate steady state continuous distillation of a binary mixture with reflux.

2.

To determine the overall efficiency of separation by the distillation Column.

3.

Perform a stage by stage analysis of separation process in the Distillation Column.

Equipment Required

1.

Armfiled UOP3CC Continous Distillation Column

2.

Binary solution of composition 50 mol % ethanol/ 50 mol % water

3.

1 - 250 ml measuring cylinder graduated in mL.

4.

1 - stop watch

5.

1 -refractometer

Task

As part of your Prelab Report for this experiments, the Group should:

1.

calculate the volumes of ethanol and water required to prepare 10 Liters of binary solution

with a composition of 50 mole percent of ethanol and 50 mole percent of water.

2.

research and report the Vapor Liquid Equilibrium (VLE) data for ethanol/water system.

3.

plot a VLE curve for an ethanol/water binary system (molar composition) at 1 atm.

4.

Derive a general formulae relating the volumes of ethanol to water require to make up any

molar composition of an ethanol/water binary mixture.

5.

Research the McCabe-Thiele Method, the Lewis-Sorel Method and the Fenske Formula.

EXPERIMENTS

A.

1.

Refractometer Calibration Curve

Fill the 11 sample bottles with exact volumes of water and ethanol required to make 10mL

of a binary mixtures of different molar composition. Vary the volumes of ethanol in each

bottle from 0 mL to 10mL.

2.

Shake all the bottles vigorously for thorough mixing.

3.

Use the refractometer, to determine and record the refractive index (R.I.) of each sample.

Plot a calibration curve of the Molar Composition of Ethanol (xA) vs. Refractive index (R.I).

B.

Calibration curve for the feed pump

1.

Filled Feed Tank A with water to about 90% of its volume. Pass the feed tube over rollers

of the peristaltic pump and clamp it.

Turn on the Control console and turn the pump on.

Set the pump control dial to the 5-mark and allow the water flow to equilibrate.

Collect about 20 mL of water and note the time of collection noted.

Repeat the timed collection and determine the average discharge rate.

Repeat steps 3 through 5 for different pump control dial settings.

2.

3.

4.

5.

6.

Plot a calibration Curve of Pump Dial Settings versus Average Volumetric Flow Rate.

MULTISTAGE DISTILLATION

Armfiled UOP3CC Distillation Equipment Start up Procedure

The distillation the equipment should be turn on or off under the guidance of the Lab Manager.

1. Make up 10 liters of a mixture of 50 mole percent ethanol and 50 mole percent water.

Show all calculations to determine the volumes of ethanol and water used.

2. Ensure all valves on the equipment are closed.

3. Locate and open the filler cap on top of the reboiler. Load the 10 liters of prepared feed

mixture (the liquid to be distilled) directly into the reboiler. Make sure the filler cap is firmly

replaced.

4. Open valve V5 and set the cooling water flow rate on FI1 to approximately 3 liters/min.

5. Turn on the power to the control console.

6. Open valve V10 on the reflux pipe.

7. Switch off the reflux timer on the console so that the column operates at total reflux.

8. Set the temperature selector switch to T9 (the temperature in the reboiler).

9. Turn on the power switch of the heating element. (A red lamp will illuminate indicating the heating

element is on).

C.

Multistage Batch Distillation

Objectives: To determine the overall separation efficiency of the Distillation column

Procedure

1.

Perform steps 1 to 9 of the Equipment Start Up Procedure.

2.

Set the heat controller high to bring the binary mixture to a boil then reduce heat as reflux is

introduced to give a steady bubbling on all tray at total reflux.

3.

Leave the apparatus for at least 30 minutes so the system will reach equilibrium.

4.

Measure the boil-up rate by performing a timed volume collection:

Operate valve V3 so that all the condensate is diverted into a measuring cylinder.

First take a small discarding sample (about 5 to 10 ml) of condensate in beaker and

discard in the RECYCLE BOTTLE.

Use a stopwatch to measure the time required to collect a set volume of

condensate.

Ensure equilibrium conditions in the column are not disrupted by maintaining a

liquid level in the condensate feeding pipe. When taking a sample, partially open

valve V3 and drain the condensate (in a separate measuring cylinder) from the reflux

system until a steady flow is obtained. (Ensure that liquid remains in the flexible

connecting tube to prevent vapour from escaping.)

Start sample collection and timing at the same time, and collect a sizeable amount.

5.

Repeat the timed collection of condensate three times and take an average value to determine

the boil-up rate.

6.

Measure and record the refractive index for the overhead samples and determine the

condensate composition (xD).

7.

Following a similar procedure, take a sample of the bottom through valve V2.

CAUTION! THIS SAMPLE WILL BE HOT!

8.

Record the refractive index, and determine the bottom fraction composition (xW).

9.

Repeat this procedure every ten minutes until 3 samples of overhead and bottom are obtained.

10.

Record the temperatures T8 and T1 and calculate the average column temperature.

11.

Record the temperatures T11 and T12 and determine the condenser load.

Use the Refractometer Calibration Curve from Experiment A to determine all sample composition.

As part of your report for this experiment:

1.

Note the number of actual plates of separation in the column.

2.

Determine the number of theoretical stage of separation:

i.

using the McCabe Thiele Method (graphical Method).

ii.

using the Fenske Formula.

iii.

by a stage-by-stage analysis of the separation using the Lewis-Sorel Method.

iv.

Determine the overall efficiency of separation by each of these method.

D.

Steady State Multistage Continuous Distillation With Reflux

Objectives: To determine the overall separation efficiency of the Distillation column

Procedure

1.

Perform steps 1 to 9 of the Equipment Start Up Procedure.

2.

Ensure the reflux timer on the console is switched off so that the column operates at total

reflux.

3.

Connect the feed tube to the column at the mid-point (onto tray 5). Set the feed flow to 2

litres/hr (Using the feed pump calibration graph). Turn off the Feed Pump.

4.

On the control panel turn the power controller for the reboiler heating element fully anticlockwise and Turn on the power switch of the heating element. A red lamp will illuminate

indicating the heating element is on. Turn the power controller clockwise until a reading of

approximately 1.5 kW is obtained on the digital wattmeter. The contents of the reboiler will

begin to warm up and this can be observed on the temperature readout for T9.

5.

Eventually, vapor will begin to rise up the column and the progress of this can be observed

by the increasing temperature readouts when the temperature selector is set on T8, T7, T6,

T5, T4, T3, T2 and T1.

The vapor will be condensed and reappear as droplets into the glass walled distillate receiver

vessel. The distillate will build up a small level in the receiver and eventually overflow to

the reflux regulator valve. The cooled distillate will return to the top of the column and

cascade down the trays forming liquid level on each trays and bubbling of vapor through

the liquid.

The system will have reached an equilibrium condition when the temperatures T1, T2, T3,

T4, T5, T6, T7 and T8 have reached an average steady temperature (but note cycling due to

the intermittent reflux).

6.

Before turning the reflux switch on, set the reflux ratio to 5:1. This means 5 sec condensed

distillate will return back to the column and 1 sec to top product receiver. On the Reflux

Controller LCD screen, C- means back to column and C+ means to top product receiver.

When this is done, switch the reflux valve on (on the control panel). You should now hear

a click, meaning the reflux valve is working. You should also see condensed vapor flowing

to the top product receiver.

7.

When the column has stabilized at total reflux (it takes 15 to 30 minutes), the Feed Pump

and the reflux timer can be started at the same time.

8.

As the flow into the column becomes established, more vapor will rise up the column and

appear as condensate in the distillate receiver, allow this to flow to the top product receiver.

9.

After pumping approximately 3 liters of Feed, take a discarding sample of about 5-10 mL

of the overheads through valve V3. Be careful never to drain the condensate return line ie.

partially open valve V3 to leave a small amount of liquid in the line all the time. Take a

further four samples. Discard the discarding sample in a safe manner.

10.

Take a condensate sample. Start collection and timing at the same time, and collect a

sizeable amount.

11.

In a similar manner and preferably at the same time as step 11, take a timed sample of

the bottom through valve V2.

CAUTION! THIS SAMPLE WILL BE HOT.

12.

Record the refractive index and composition for the condensate (xD) and the bottom (xW).

13.

Draw samples from each stage. Determine the Refractive index and compositions of each

sample.

14.

Record the temperature of the liquid on each stage

15.

Repeat the sample taking (steps 10-13) three more times at 10 15 minutes time intervals

before feed runs out.

16.

Record the temperatures T11 and T12.

17.

Record the feed temperature T14 and temperature of liquid from the top stages of the

column, T10.

As part of your report for this experiment:

1.

Perform total material and component balances around the whole column and the top and

bottoms parts to determine the Feed, Condensate and Bottoms.

2.

Use the McCabe Thiele Method (graphical Method) to analyze the operations of the

column.

3.

By performing a stage-by-stage analysis of the separation using the Lewis-Sorel Method.

4.

Use temperatures T11 and T12 and to determine the condenser load.

5.

Use the feed temperature T14 and temperature of liquid from the top stages of the column,

T10, and determine how much heat was used to heat and vaporize the feed.

RESULTS AND DATA ANALYSIS

In addition to all measurements detailed in the procedures, research and report:

1. Molecular weights of ethanol and water.

2. Refractive indices of ethanol and water at room temperature.

3. Densities of ethanol and water at room ambient temperature.

1. Number of actual stages in the distillation column.

2. Top temperature (C)

3. Bottom temperature (C).

Use the refractometer and the calibration curve to obtain the RI and compositions of all samples obtained

during in the experiments.

Column and process temperatures and reboiler power can be obtained from the control console.

Determine and report the compositions of the all Feed (xF), Condensate (xD) and Bottoms (xB)

products.

Discussions/ Conclusion

Is there any relationship between boil-up rate and column efficiency?

Compare your result from the McCabe-Thiele Method and the Lewis-Sorel Method.

Useful Reference

1)

Geankoplis, Christie J. Transport Processes and Separation Process Principles: (includes

Unit Operations). Prentice Hall Professional Technical Reference, 2003. Upper Saddle

River, NJ 07458.

2)

McGraw-Hill Book Company. Chemical Engineers Handbook (5th. Ed.). Perry H. R.

(Consultant) and Chilton H. C. (Senior Advisor).

3)

Armfield Distillation Column UOP3CC Instruction Manual.

Useful Information

Vous aimerez peut-être aussi

- Lesson Three Environmental Ethics and Equity Howard University, Spring Semester 2015Document18 pagesLesson Three Environmental Ethics and Equity Howard University, Spring Semester 2015Aubrey LuttrellPas encore d'évaluation

- Physics Lab Report Example PDFDocument17 pagesPhysics Lab Report Example PDFFara Diba100% (1)

- Solving Linear Differential Equations with Constant CoefficientsDocument2 pagesSolving Linear Differential Equations with Constant CoefficientsAubrey LuttrellPas encore d'évaluation

- Self ReflectionDocument1 pageSelf ReflectionAubrey LuttrellPas encore d'évaluation

- Interpretations of CirceDocument10 pagesInterpretations of CirceAubrey LuttrellPas encore d'évaluation

- Chemical Engineering PRe Lab 2Document6 pagesChemical Engineering PRe Lab 2Aubrey LuttrellPas encore d'évaluation

- Interpretations of CirceDocument10 pagesInterpretations of CirceAubrey LuttrellPas encore d'évaluation

- The Adventures of HimDocument1 pageThe Adventures of HimAubrey LuttrellPas encore d'évaluation

- CBE 461L 1 Multistage DistillationDocument7 pagesCBE 461L 1 Multistage DistillationAubrey LuttrellPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Allison Transmision Om3753en, 3000-4000 SP Series Operators ManualDocument111 pagesAllison Transmision Om3753en, 3000-4000 SP Series Operators ManualHernan Reyes Carbonell100% (1)

- Engineering Services LTD: CalculationDocument29 pagesEngineering Services LTD: CalculationtomPas encore d'évaluation

- Homework 03Document4 pagesHomework 03PARVATHY ANILPas encore d'évaluation

- The Determination of The Icl and Icc of Material To Be Stabilised. 1 ScopeDocument3 pagesThe Determination of The Icl and Icc of Material To Be Stabilised. 1 ScopeBruno Ramírez PoncePas encore d'évaluation

- Uranium Mining in Tanzania - Are We ReadyDocument31 pagesUranium Mining in Tanzania - Are We ReadyStephen MsechuPas encore d'évaluation

- Investigations On Transient Dynamic Response of Functionally Graded MaterialsDocument5 pagesInvestigations On Transient Dynamic Response of Functionally Graded MaterialsInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- KKI Series 1200 and 7200Document18 pagesKKI Series 1200 and 7200Tabiquera Guadalupe Victoria Texcoco De Mora100% (1)

- Minor Project For Civil EngineeringDocument52 pagesMinor Project For Civil EngineeringRupesh GenesisPas encore d'évaluation

- Hysteresis in Ferromagnetic Materials ExperimentDocument8 pagesHysteresis in Ferromagnetic Materials ExperimentbpmurtaPas encore d'évaluation

- Some Reduction and Transformation Formulas For The Appell Hypergeometric Function F2Document16 pagesSome Reduction and Transformation Formulas For The Appell Hypergeometric Function F2peppas4643Pas encore d'évaluation

- Chloroplast Structure and FunctionDocument19 pagesChloroplast Structure and FunctionFizul HelmiPas encore d'évaluation

- 952 - Comparative Statement - Electrical - Rev 00Document8 pages952 - Comparative Statement - Electrical - Rev 00clickanant4171Pas encore d'évaluation

- Siemens Rayos X Multix Swing Datasheet 1 PDFDocument8 pagesSiemens Rayos X Multix Swing Datasheet 1 PDFAlejandro FaveroPas encore d'évaluation

- Analysis and Design of Multistoreyed ApartmentDocument92 pagesAnalysis and Design of Multistoreyed ApartmentAmeer JoshiPas encore d'évaluation

- Mahasudarshan ChurnaDocument6 pagesMahasudarshan Churnadrsa2100% (1)

- Lab Pid Motor ControlDocument17 pagesLab Pid Motor ControlacajahuaringaPas encore d'évaluation

- Uniform Flow 2Document33 pagesUniform Flow 2Vaishnavi SingrePas encore d'évaluation

- Design Manual for Ethiopia's Low-Volume Rural RoadsDocument45 pagesDesign Manual for Ethiopia's Low-Volume Rural RoadsMichael Kazi100% (1)

- Readme File of Ynogkm: Yun-Nan Observatory Geodesics in A Kerr-Newmann Spacetime For Massive ParticlesDocument3 pagesReadme File of Ynogkm: Yun-Nan Observatory Geodesics in A Kerr-Newmann Spacetime For Massive Particleschewbacca1409Pas encore d'évaluation

- Ohm's Law: Current is Directly Proportional to VoltageDocument5 pagesOhm's Law: Current is Directly Proportional to VoltageLawrence DecanoPas encore d'évaluation

- Ultimate Bearing Capacity of Foundation On Clays Meyerhof PDFDocument3 pagesUltimate Bearing Capacity of Foundation On Clays Meyerhof PDFNadherPas encore d'évaluation

- Christopher Cervino - Resume and ReferencesDocument2 pagesChristopher Cervino - Resume and Referencesapi-468873427Pas encore d'évaluation

- Maths 7 Quarterly ExamDocument3 pagesMaths 7 Quarterly ExamCee Jay AbanillaPas encore d'évaluation

- 2019 Cre Ii L24-26Document32 pages2019 Cre Ii L24-26Aman PrasadPas encore d'évaluation

- Soalan Smart Coaching 2 (2 Ogos 2017) Edited With SchemaDocument9 pagesSoalan Smart Coaching 2 (2 Ogos 2017) Edited With SchemaNORHIDAYAH50% (2)

- Master Thesis S BuysseDocument141 pagesMaster Thesis S Buyssemichael KetselaPas encore d'évaluation

- Golden SearchDocument14 pagesGolden Searchrahulsaini855Pas encore d'évaluation

- CH12Document52 pagesCH12blackhawk00001Pas encore d'évaluation

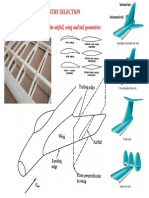

- Aircraft Design: Airfoil and Geometry SelectionDocument94 pagesAircraft Design: Airfoil and Geometry SelectionYak100% (10)

- 09 M1 Silver 4Document13 pages09 M1 Silver 4RoshPas encore d'évaluation