Académique Documents

Professionnel Documents

Culture Documents

Continuous Reliability Improvement (CRI) Goes Well Beyond TPM and RCM

Transféré par

ralphpetersCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Continuous Reliability Improvement (CRI) Goes Well Beyond TPM and RCM

Transféré par

ralphpetersDroits d'auteur :

Formats disponibles

Continuous Reliability Improvement:

Continuous Reliability Improvement (CRI) is a process developed by the founder of The Maintenance

Excellence Institute (TMEI) and it goes well beyond current reliability-centered maintenance (RCM)

and total productive maintenance (TPM) approaches. RCM for example is focused upon only the

assets within the total maintenance business process. CRI combines continuous improvement,

methods improvement and the principles of Alan Mogenson’s Work Simplification to outline a

continuous, integrated process for Working Smarter –Not Harder.

CRI is about improving total reliability of the following maintenance resources and within all types of

maintenance environments:

• Equipment/Facility Resources (Asset Care/Management and Maximum Uptime via

RCM Techniques)

• Craft and Operator Resources (Recognizing the most important resource: Crafts

People and Equipment/Process Operators)

• Maintenance Repair Operations (MRO) Resources (Establishing Effective Materials

Management Processes)

• Maintenance Information Resources (Effective Information Technology Applications

for Maintenance)

• Maintenance Technical Knowledge/Craft Skills Base (Closing the Technical

Knowledge Resource Gap)

• Hidden Resources and Synergistic Team Processes (Tapping the Value-Added

Resource of Effective Leadership-Driven Teams to Support Total Operations Success)

Continuous Reliability Improvement brings about a positive PRIDE-in-Maintenance culture and

proactive attitudes/actions for the synergy of TEAM efforts to improve each maintenance

resources area. All this is focused on contributing to gained value of all resources to support

total operations success. CRI applies to all types of public and private sector maintenance

organizations.

Going Beyond RCM and TPM: We understand and see the need for the RCM, TP) types of

improvement processes to include Six Sigma. On the shop floor we see today’s trend toward forgetting

about the basics of “blocking and tackling” while going for the long touchdown pass with some new

analysis paralysis scheme or buzzword. The CRI approach we use is built upon the basics and then

goes well beyond the traditional RCM/TPM approaches with Continuous Reliability Improvement (CRI)

of all maintenance resources. It is about improving the total maintenance process and all six

maintenance resource areas as shown in Figures on next pages.

The Maintenance Excellence Institute

6809 Foxfire Place, Raleigh, NC 27615 and 2625 East Beach Drive, Oak Island, NC 28465

Office: 919-270-1173 Direct Cell: 919-280-1253 SKYPE: PRIDEnWork Web: PRIDE-in-Maintenance.com

Improve Maintenance in Total and Go Beyond RCM and TPM

We strongly believe in basic maintenance best practices as the foundation for maintenance excellence.

Our improvement process includes all maintenance resources, equipment and facility assets as well as

the crafts people and equipment operators. It also includes MRO materials management assets,

maintenance informational assets and the added value resource of synergistic team-based processes.

Continuous Reliability Improvement improves the total maintenance operation.

The Maintenance Excellence Institute

6809 Foxfire Place, Raleigh, NC 27615 and 2625 East Beach Drive, Oak Island, NC 28465

Office: 919-270-1173 Direct Cell: 919-280-1253 SKYPE: PRIDEnWork Web: PRIDE-in-Maintenance.com

The Maintenance Excellence Institute

6809 Foxfire Place, Raleigh, NC 27615 and 2625 East Beach Drive, Oak Island, NC 28465

Office: 919-270-1173 Direct Cell: 919-280-1253 SKYPE: PRIDEnWork Web: PRIDE-in-Maintenance.com

The Maintenance Excellence Institute

6809 Foxfire Place, Raleigh, NC 27615 and 2625 East Beach Drive, Oak Island, NC 28465

Office: 919-270-1173 Direct Cell: 919-280-1253 SKYPE: PRIDEnWork Web: PRIDE-in-Maintenance.com

The Maintenance Excellence Institute

6809 Foxfire Place, Raleigh, NC 27615 and 2625 East Beach Drive, Oak Island, NC 28465

Office: 919-270-1173 Direct Cell: 919-280-1253 SKYPE: PRIDEnWork Web: PRIDE-in-Maintenance.com

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Infinique Structured Cabling Installation ChecklistDocument2 pagesInfinique Structured Cabling Installation Checklistroot75% (4)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Columns: Advance of Computation Since These Codes FallDocument2 pagesColumns: Advance of Computation Since These Codes FallAbhimanyu RavindranathPas encore d'évaluation

- Física Práctica 1 MRUDocument5 pagesFísica Práctica 1 MRUPolet BarrionuevoPas encore d'évaluation

- Instruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0750 ADocument32 pagesInstruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0750 AYunisPas encore d'évaluation

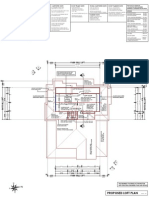

- LoftplanDocument1 pageLoftplanapi-228799117Pas encore d'évaluation

- Computation For Concrete Mix 120221Document3 pagesComputation For Concrete Mix 120221MASGRO BUILDERSPas encore d'évaluation

- Carte Tehnica Excavator VolvoDocument12 pagesCarte Tehnica Excavator VolvoCiufudean AdrianPas encore d'évaluation

- Ee BD ManualDocument37 pagesEe BD Manualsergey62Pas encore d'évaluation

- Operation Manual - A Table of ContentsDocument506 pagesOperation Manual - A Table of ContentsErvin PregPas encore d'évaluation

- Gear Selector CableDocument3 pagesGear Selector CableojopodoabePas encore d'évaluation

- Empaque Espirometalicos PDFDocument50 pagesEmpaque Espirometalicos PDFgregorioPas encore d'évaluation

- Conformity Assessment For The Execution of Steel & Aluminium StructuresDocument14 pagesConformity Assessment For The Execution of Steel & Aluminium StructuresJevgenijsKolupajevsPas encore d'évaluation

- Biogas Technology: Construction, Utilization and Operation ManualDocument52 pagesBiogas Technology: Construction, Utilization and Operation ManualDwi Cahyo NugrohoPas encore d'évaluation

- Day 1 Borehole Geophysics WDocument21 pagesDay 1 Borehole Geophysics Waliy2k4uPas encore d'évaluation

- SVT-RM10: Remote Control UnitDocument2 pagesSVT-RM10: Remote Control UnitJOGITELEPas encore d'évaluation

- Pentex Gas OvenDocument5 pagesPentex Gas OvenRahman PashariPas encore d'évaluation

- Fastening SystemsDocument74 pagesFastening SystemsskyvanePas encore d'évaluation

- CDMA APPLICATION FOR Child Name Inclusion-Before 1 Year PDFDocument2 pagesCDMA APPLICATION FOR Child Name Inclusion-Before 1 Year PDFAnonymous C0pl6hPas encore d'évaluation

- Knowledge Based SystemsDocument57 pagesKnowledge Based SystemsRodel MoralesPas encore d'évaluation

- Gama Dimat Catalog Be17Document16 pagesGama Dimat Catalog Be17ELMIR ADILPas encore d'évaluation

- Magnum Dxi13 Engine Torque Settings PDFDocument67 pagesMagnum Dxi13 Engine Torque Settings PDFbuchniyPas encore d'évaluation

- New Premium ListDocument10 pagesNew Premium ListAshwani SainiPas encore d'évaluation

- Ionic Equations & Redox ReactionsDocument6 pagesIonic Equations & Redox ReactionsAyaanNashidPas encore d'évaluation

- Verilog Implementation of Reed - Solomon CodeDocument16 pagesVerilog Implementation of Reed - Solomon CodeManik Prabhu ChillalPas encore d'évaluation

- Welder and Welding Operator Qualification Test Record (Asme Ix Code)Document1 pageWelder and Welding Operator Qualification Test Record (Asme Ix Code)Neil TaneoPas encore d'évaluation

- Valbart: API 6D & 6A Trunnion Mounted Ball ValvesDocument36 pagesValbart: API 6D & 6A Trunnion Mounted Ball Valvesbabis1980Pas encore d'évaluation

- February 2016Document104 pagesFebruary 2016Cleaner MagazinePas encore d'évaluation

- Sika PDS - E - Sikagard - 705 LDocument3 pagesSika PDS - E - Sikagard - 705 Llwin_oo2435Pas encore d'évaluation

- Swimming Pool Pump & Filter SystemDocument8 pagesSwimming Pool Pump & Filter SystemDedy KristiantoPas encore d'évaluation

- WSTP Week 10-13Document6 pagesWSTP Week 10-13Christian John Paul LijayanPas encore d'évaluation