Académique Documents

Professionnel Documents

Culture Documents

Sae J 417 Fragment

Transféré par

simo96Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sae J 417 Fragment

Transféré par

simo96Droits d'auteur :

Formats disponibles

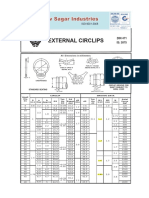

TECHNICAL DATA

CONVERSION TABLE OF HARDNESS

EXCERPT FROM SAE J 417

(1983)

(1)

Conversion table for approximate values for steel according to Rockwell hardness C scale

Rockwell

hardness

C scale

Vickers

hardness

(HRC) (HV)

Brinell hardnes(HB)

(3)

Standard ball

Tungsten

carbide

ball

A scale(HRA)

Load:60kgf

Diamond conical

penetrator

B scale

(HRB)

Load:100kgf

Ball of 1.6mm

(1/16")

dia.

Rockwell superficial hardness

Diamond conical penetrator

Tensile strength Rockwell

Shore (Approximate value)hardness

hardness

MPa

C scale(3)

D scale(HRD)

15-N Scale 30-N Scale 45-N Scale

2

Load:100kgf

)

(kgf/mm

Diamond conical

Load:15kgf Load:30kgf Load:45kgf (Hs)

(2)

penetrator

Rockwell hardness

Ball:10mm in

diameter/Load:3000kgf

68

67

66

65

64

940

900

865

832

800

(739)

(722)

85.6

85.0

84.5

83.9

83.4

76.9

76.1

75.4

74.5

73.8

93.2

92.9

92.5

92.2

91.8

84.4

83.6

82.8

81.9

81.1

75.4

74.2

73.3

72.0

71.0

97

95

92

91

88

68

67

66

65

64

63

62

61

60

59

772

746

720

697

674

(705)

(688)

(670)

(654)

(634)

82.8

82.3

81.8

81.2

80.7

73.0

72.2

71.5

70.7

69.9

91.4

91.1

90.7

90.2

89.8

80.1

79.3

78.4

77.5

76.6

69.9

68.8

67.7

66.6

65.5

87

85

83

81

80

63

62

61

60

59

58

57

56

55

54

653

633

613

595

577

615

595

577

560

543

80.1

79.6

79.0

78.5

78.0

69.2

68.5

67.7

66.9

66.1

89.3

88.9

88.3

87.9

87.4

75.7

74.8

73.9

73.0

72.0

64.3

63.2

62.0

60.9

59.8

78

76

75

74

72

2075 (212)

2015 (205)

58

57

56

55

54

53

52

51

50

49

560

544

528

513

498

(500)

(487)

(475)

(464)

525

512

496

481

469

77.4

76.8

76.3

75.9

75.2

65.4

64.6

63.8

63.1

62.1

86.9

86.4

85.9

85.5

85.0

71.2

70.2

69.4

68.5

67.6

58.5

57.4

56.1

55.0

53.8

71

69

68

67

66

1950 (199)

1880 (192)

1820 (186)

1760 (179)

1695 (173)

53

52

51

50

49

48

47

46

45

44

484

471

458

446

434

451

442

432

421

409

455

443

432

421

409

74.7

74.1

73.6

73.1

72.5

61.4

60.8

60.0

59.2

58.5

84.5

83.9

83.5

83.0

82.5

66.7

65.8

64.8

64.0

63.1

52.5

51.4

50.3

49.0

47.8

64

63

62

60

58

1635 (167)

1580 (161)

1530 (156)

1480 (151)

1435 (146)

48

47

46

45

44

43

42

41

40

39

423

412

402

392

382

400

390

381

371

362

400

390

381

371

362

72.0

71.5

70.9

70.4

69.9

57.7

56.9

56.2

55.4

54.6

82.0

81.5

80.9

80.4

79.9

62.2

61.3

60.4

59.5

58.6

46.7

45.5

44.3

43.1

41.9

57

56

55

54

52

1385 (141)

1340 (136)

1295 (132)

1250 (127)

1215 (124)

43

42

41

40

39

38

37

36

35

34

372

363

354

345

336

353

344

336

327

319

353

344

336

327

319

69.4

68.9

68.4

67.9

67.4

(109.0)

(108.5)

(108.0)

53.8

53.1

52.3

51.5

50.8

79.4

78.8

78.3

77.7

77.2

57.7

56.8

55.9

55.0

54.2

40.8

39.6

38.4

37.2

36.1

51

50

49

48

47

1180 (120)

1160 (118)

1115 (114)

1080 (110)

1055 (108)

38

37

36

35

34

33

32

31

30

29

327

318

310

302

294

311

301

294

286

279

311

301

294

286

279

66.8

66.3

65.8

65.3

64.7

(107.5)

(107.0)

(106.0)

(105.5)

(104.5)

50.0

49.2

48.4

47.7

47.0

76.6

76.1

75.6

75.0

74.5

53.3

52.1

51.3

50.4

49.5

34.9

33.7

32.7

31.3

30.1

46

44

43

42

41

1025 (105)

1000 (102)

980 (100)

950 ( 97)

930 ( 95)

33

32

31

30

29

28

27

26

25

24

286

279

272

266

260

271

264

258

253

247

271

264

258

253

247

64.3

63.8

63.3

62.8

62.4

(104.0)

(103.0)

(102.5)

(101.5)

(101.0)

46.1

45.2

44.6

43.8

43.1

73.9

73.3

72.8

72.2

71.6

48.6

47.7

46.8

45.9

45.0

28.9

27.8

26.7

25.5

24.3

41

40

38

38

37

910 (

880 (

860 (

840 (

825 (

93)

90)

88)

86)

84)

23

22

21

20

(18)

254

248

243

238

230

243

237

231

226

219

243

237

231

226

219

62.0

61.5

61.0

60.5

-

100.0

99.0

98.5

97.8

96.7

42.1

41.6

40.9

40.1

-

71.0

70.5

69.9

69.4

-

44.0

43.2

42.3

41.5

-

23.1

22.0

20.7

19.6

-

36

35

35

34

33

805 (

785 (

770 (

760 (

730 (

82)

23

80)

22

79)

21

77)

20

75) (18)

(16)

(14)

(12)

(10)

( 8)

222

213

204

196

188

212

203

194

187

179

212

203

194

187

179

95.5

93.9

92.3

90.7

89.5

32

31

29

28

27

705 (

675 (

650 (

620 (

600 (

72)

69)

66)

63)

61)

(

(

(

(

180

173

166

160

171

165

158

152

171

165

158

152

87.1

85.5

83.5

81.7

26

25

24

24

580 (

550 (

530 (

515 (

59) (

56) (

54) (

53) (

6)

4)

2)

0)

Notes:(1) The figures in blue are based on Table 1 of ASTM E 140

(adjusted by SAE, ASM and ASTM in collaboration).

(2)

The values and units in parentheses have been converted from psi based on conversion tables of JIS Z 8413 and Z 8438.

2

1MPa=1N/mm

(3)

The figures in parentheses are less frequently used values and are for reference only.

28

27

26

25

24

(16)

(14)

(12)

(10)

( 8)

6)

4)

2)

0)

TECHNICAL DATA

INDICATIONS OF GEOMETRICAL TOLERANCE ON DRAWINGS

EXCERPT FROM

JIS B 0021

(1984)

Kinds and Symbols of Geometrical Tolerances

Definition of tolerance zone

Examples of diagrammatical indication and its interpretation

Where symbol F is attached before the numerical

value indicating a tolerance zone, this tolerance

zone is a zone in a cylinder of diameter t.

F0.08

Straightness

tolerance

Symbol

Ft

Kind of tolerance

The tolerance zone is a zone held

between two parallel planes a

distance t apart.

This surface shall be contained

between two parallel planes

0.08mm apart.

0.08

Flatness

tolerance

Where a tolerance frame is connected to

the dimension showing the diameter of a

cylinder, the axis of the cylinder shall be

contained a cylinder of 0.08mm diameter.

The tolerance zone in the considered

plane is a zone between two concentric

circles a distance t apart.

Circularity

tolerance

t

Form

tolerance

The tolerance zone is a zone

contained between two coaxial

cylinder surfaces a distance t apart.

Cylindricity

tolerance

Profile tolerance

of surface

In any cross-section parallel to the projection

plane the considered profile shall be contained

between two lines enveloping circles of 0.04mm

in diameter, the centers of which are situated on

a line having the theoretically exact profile.

0.04

The tolerance zone is a zone held

between the two surfaces enveloping

the spheres of diameter t, the centers

of which are situated on a theoretically

exact profile surface.

The considered surface shall be contained

between two surfaces enveloping the

spheres of diameter 0.02mm, the centers

of which are situated on a surface having

the theoretically exact profile.

0.02

The tolerance zone is a zone held

between two parallel planes parallel

to the datum plane and a distance t

apart from each other.

Parallelism

tolerance

SF t

The considered surface shall be

contained between two coaxial

cylinder surfaces 0.1mm apart.

0.1

The tolerance zone is a zone held

between two lines enveloping circles of

diameter t, the centers of

which are situated on a theoretically

exact profile line.

Profile tolerance

of line

The circumference in any section

normal to the axis shall be contained

between two concentric circles

0.1mm apart on the same plane.

0.1

The surface shown by the arrow of the leader

line shall be contained between two planes

parallel to the datum plane A and 0.01mm

apart from each other in the direction of the

arrow of the leader line.

0.01 A

A

Where symbol Fis attached before the numerical

value indicating the tolerance, the tolerance zone

is a zone within a cylinder of diameter t

perpendicular to the datum plane.

Ft

Orientation Perpendicularity

tolerance

tolerance

t

Angularity

tolerance

A

The tolerance zone is a zone held between

0.08 A

two parallel planes inclined at the specified

angle to the datum plane and a distance t 40B

apart from each other.

The surface shown by the arrow of the leader line

shall be contained between two parallel planes

which are inclined at 40Bwith theoretical exactness

to the datum plane A and which are

0.08mm apart from each other in the direction

of the arrow of the leader line.

Total run-out

tolerance

The tolerance zone is a zone between two

coaxial cylinders having axes agreeing with

the datum axial straight line and a distance

t apart from each other in the radial direction.

0.08 A

0.1 A-B

The tolerance is a zone between two concentric

circles whose centers agree

with the datum axial straight line on any

measuring plane normal to the datum axial

Toleranced straight line and which are a distance t apart

surface from each other in the radial direction.

B

0.1 A-B

The point shown by the arrow of the leader

line shall be contained within a circle of

0.03mm diameter having its center at the

true location 60mm and 100mm apart,

respectively,from the datum straight line

A and from the datum straight line B.

F0.01 A The axis shown by the arrow of the

leader line shall be contained within

a cylinder of 0.01mm diameter

whose axis agrees with the

datum axial straight line A.

Run-out

tolerance

Measuring plane

The tolerance zone is a zone held between

two parallel planes a distance t apart from

each other and arranged symmetrically about

the datum median plane.

Symmetry

tolerance

Circular run-out

tolerance

100

Where symbol F is attached before the numerical

value indicating the tolerance, the tolerance zone

is a zone within a cylinder of diameter t whose

axis agrees with the datum axial straight line.

Ft

Location

tolerance

Coaxiality

tolerance

or

concentricity

tolerance

True

location

F0.03 AB

Positional

tolerance

B

60

A

The tolerance zone is a zone within a circle or

sphere of diameter t having its center at the

theoretically exact location, hereinafter referred to

as thetrue location".

The axis of the cylinder shown by

the arrow of the leader line shall

be contained within a cylinder of

diameter 0.01mm perpendicular

to the datum plane A.

F0.01 A

The median surface shown by the arrow of

the leader line shall be contained between

two parallel planes 0.08mm apart from

each other and arranged symmetrically

about the datum median plane A.

The run-out in the radial direction of the cylinder

surface shown by the arrow of the leader line

shall not exceed 0.1mm on any measuring plane

normal to the datum axial straight line when the

cylinder is rotated by one rotation about the

datum axial straight line A-B.

The total radial run-out of the cylinder surface

shown by the arrow of the leader line shall not

exceed 0.1mm at any point on the cylinder

surface when the cylinder part is rotated about

the datum axial straight line A-B with a relative

movement in the axial direction.

Lines used in the drawings in the column ofdefinition of tolerance zone"indicate the following meanings:

Thick solid line or broken line:Feature

Thin alternate long and short dash line:Center line

Thick alternate long and short dash line:Datum

Thin alternate long and two short dashes line:Supplementary projection plane or sectional plane

Thin solid line or broken line:Tolerance zone

Thick alternate long and two short dashes line:Projection of a feature to supplementary Projection plane or sectional plane

Vous aimerez peut-être aussi

- 2841 - 2842 Hardness Conversion and Metric Coarse ThreadsDocument1 page2841 - 2842 Hardness Conversion and Metric Coarse ThreadsNatthawut CheencharoenPas encore d'évaluation

- Wilsons LTD Nickel Alloy AMS 5662 Alloy 718 450Document3 pagesWilsons LTD Nickel Alloy AMS 5662 Alloy 718 450Ray Mark De TorresPas encore d'évaluation

- Spline Program Ver 1.1Document7 pagesSpline Program Ver 1.1Ozeias CardosoPas encore d'évaluation

- Gear Grades EquivalenttablesDocument1 pageGear Grades Equivalenttablesamir_fortunatePas encore d'évaluation

- ISO M ThreadDocument2 pagesISO M ThreaddineshkshirsagarPas encore d'évaluation

- Miller - Joint Design and Weld TypeDocument8 pagesMiller - Joint Design and Weld Typed_beachboyzPas encore d'évaluation

- Nomenclature of The Hob's PartsDocument13 pagesNomenclature of The Hob's PartssilviolcPas encore d'évaluation

- As 3779-1990 Height Setting Micrometers and Riser BlocksDocument7 pagesAs 3779-1990 Height Setting Micrometers and Riser BlocksSAI Global - APACPas encore d'évaluation

- Standards Book 2002Document129 pagesStandards Book 2002oliveiralauroPas encore d'évaluation

- Interlloy 440C MartensiticDocument4 pagesInterlloy 440C MartensiticGuillaume BoyerPas encore d'évaluation

- Astm Structural Steel DefinitionsDocument2 pagesAstm Structural Steel DefinitionsCARLOS ACOSTAPas encore d'évaluation

- Source: Https://assist - Dla.mil - Downloaded: 2017-12-05T21:08Z Check The Source To Verify That This Is The Current Version Before UseDocument6 pagesSource: Https://assist - Dla.mil - Downloaded: 2017-12-05T21:08Z Check The Source To Verify That This Is The Current Version Before UseJoey ThomannPas encore d'évaluation

- Welding Hardox and Weldox PDFDocument4 pagesWelding Hardox and Weldox PDFEnoc AndradePas encore d'évaluation

- Uddeholm Heat Treatment Eng 1710 E9Document20 pagesUddeholm Heat Treatment Eng 1710 E9Sinan YıldızPas encore d'évaluation

- Grades of Steel ChartDocument3 pagesGrades of Steel ChartKimPas encore d'évaluation

- St52 Material STD PDFDocument7 pagesSt52 Material STD PDFsardhan.rajender84Pas encore d'évaluation

- 13 Symbols DrawingsDocument13 pages13 Symbols DrawingsAlie AlbantaniPas encore d'évaluation

- Norma 1691 DIN 1691 1985 Flake Graphite Cast Iron Grey Cast Iron PropertiesDocument13 pagesNorma 1691 DIN 1691 1985 Flake Graphite Cast Iron Grey Cast Iron PropertiesJuan Rivera100% (1)

- AN818 Rev-20 PDFDocument5 pagesAN818 Rev-20 PDFaldiPas encore d'évaluation

- Process Specification For The Heat Treatment of Aluminum Alloys PDFDocument8 pagesProcess Specification For The Heat Treatment of Aluminum Alloys PDFashokksamy100% (1)

- Steel GradesDocument2 pagesSteel GradesAmit Rajmane100% (1)

- SWRCH18ADocument2 pagesSWRCH18AHari SuthanPas encore d'évaluation

- Sae J500 EstriadosDocument2 pagesSae J500 EstriadosMarcel Dandaro100% (1)

- External CirclipDocument2 pagesExternal CirclipDivyang MistryPas encore d'évaluation

- Din 5480-2 - 2006-05Document40 pagesDin 5480-2 - 2006-05Luiz Munari100% (2)

- Numerical Analysis - I. Jacques and C. Judd PDFDocument109 pagesNumerical Analysis - I. Jacques and C. Judd PDFMaria AquisePas encore d'évaluation

- BoilerTubes - TechnitubeDocument24 pagesBoilerTubes - TechnitubeMMPAPPas encore d'évaluation

- A 108 - 03 - Qtewoa - PDFDocument7 pagesA 108 - 03 - Qtewoa - PDFHanifiantoPas encore d'évaluation

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)Deepak ChaurasiaPas encore d'évaluation

- Angle Section DimensionsDocument4 pagesAngle Section DimensionsAnonymous q0irDXlWAmPas encore d'évaluation

- UHMW-PE (Ultra High Molecular Weight - Polyethylene)Document2 pagesUHMW-PE (Ultra High Molecular Weight - Polyethylene)Gaurav PatilPas encore d'évaluation

- 12l14 Bright Mild SteelDocument2 pages12l14 Bright Mild SteelStefany Carolina Chavez DavidPas encore d'évaluation

- Thread Pitch ChartDocument2 pagesThread Pitch ChartGeorgeMtyPas encore d'évaluation

- ARPCatalog PDFDocument128 pagesARPCatalog PDFAnonymous wpUyixsjPas encore d'évaluation

- DIN 17100 TablasDocument2 pagesDIN 17100 Tablasanonimarium100% (3)

- AISI 440 Martensit PDFDocument4 pagesAISI 440 Martensit PDFJimmyVargasPas encore d'évaluation

- 6885 1Document1 page6885 1ajeshPas encore d'évaluation

- 4-Machining Fundamentals Ams May01 13Document87 pages4-Machining Fundamentals Ams May01 13mjdaleneziPas encore d'évaluation

- Polygon Shafts and HubsDocument6 pagesPolygon Shafts and HubskicklOpPas encore d'évaluation

- Mil S 13165Document20 pagesMil S 13165Francisco Ribeiro FernandesPas encore d'évaluation

- Surface Vehicle Standardsta Ndard: Rev. DEC83Document11 pagesSurface Vehicle Standardsta Ndard: Rev. DEC83san moedano100% (1)

- Caterpillar: Confidential Green - Reproduction Constitutes An Uncontrolled DocumentDocument14 pagesCaterpillar: Confidential Green - Reproduction Constitutes An Uncontrolled DocumentDinar OjakPas encore d'évaluation

- Weight Per Meter of WeldDocument1 pageWeight Per Meter of Weldreza329329Pas encore d'évaluation

- Hollow Bars (ISO2938)Document8 pagesHollow Bars (ISO2938)suku maranPas encore d'évaluation

- SIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Document5 pagesSIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Rajoo PrajapatiPas encore d'évaluation

- Introduction To Gear DesignDocument35 pagesIntroduction To Gear DesignAsela Bollegala100% (1)

- pr1169 1170Document1 pagepr1169 1170renebbPas encore d'évaluation

- Form TolerancesDocument4 pagesForm Tolerancesvskumar4uPas encore d'évaluation

- GD&T PosterDocument1 pageGD&T Posterssaramail100% (1)

- GD&T Form and Position TolerancesDocument1 pageGD&T Form and Position TolerancesSaulo TrejoPas encore d'évaluation

- Feature Axis To Datum SurfaceDocument5 pagesFeature Axis To Datum Surfacegthulasi787126Pas encore d'évaluation

- Chapter 3: Angular Measurements: Definition of AngleDocument10 pagesChapter 3: Angular Measurements: Definition of AngleMohsin Munawar100% (1)

- 5dimensioning and TolerancingDocument43 pages5dimensioning and TolerancingPavan RaghavPas encore d'évaluation

- GD & TDocument43 pagesGD & TMahender Kumar100% (1)

- Geometric Dimensioning & TolerancingDocument67 pagesGeometric Dimensioning & TolerancingAmolPagdal100% (1)

- Examples On How To Interpret GD&T: Form, Orientation, Location and Run-Out TolerancesDocument28 pagesExamples On How To Interpret GD&T: Form, Orientation, Location and Run-Out TolerancesSUDHIR SINGH PATYALPas encore d'évaluation

- METROLOGYDocument5 pagesMETROLOGYGangadhar TallaPas encore d'évaluation

- Elearning - Vtu.ac - in 18 Enotes 10ME42 Unit3-PRVDocument10 pagesElearning - Vtu.ac - in 18 Enotes 10ME42 Unit3-PRVLokesh NarasimhaiahPas encore d'évaluation

- Maths FrameworkDocument1 pageMaths FrameworkSamion AwaldinPas encore d'évaluation

- BID105 - Basic DesignDocument108 pagesBID105 - Basic Designcharmi shahPas encore d'évaluation

- Mesh-Intro 14.5 L04 Meshing MethodsDocument55 pagesMesh-Intro 14.5 L04 Meshing MethodsalfredozegarraPas encore d'évaluation

- CATIA V5 R19 204 - Intermediate SurfacingDocument3 pagesCATIA V5 R19 204 - Intermediate Surfacingsp_escherPas encore d'évaluation

- Axis Symmetric Analysis in ANSYSDocument3 pagesAxis Symmetric Analysis in ANSYSkabinPas encore d'évaluation

- 1-Crystal Symmetry and Classification-1Document7 pages1-Crystal Symmetry and Classification-1Cazimir BostanPas encore d'évaluation

- Crystallography 2Document3 pagesCrystallography 2Akshay KumarPas encore d'évaluation

- Cricket Bat Thesis - 2006 SymesDocument297 pagesCricket Bat Thesis - 2006 SymesAnonymous unj3NHW82vPas encore d'évaluation

- 284 PDFDocument23 pages284 PDFSamah SamahPas encore d'évaluation

- Lensometro Eq 6405 ManualDocument19 pagesLensometro Eq 6405 Manualanon_431405544Pas encore d'évaluation

- Mineralogy 1Document50 pagesMineralogy 1Karla Fermil SayenPas encore d'évaluation

- Crystal SystemsDocument99 pagesCrystal SystemsTristram KeatsPas encore d'évaluation

- Module 1: Nature of Mathematics: Patterns and Numbers in Nature and The WorldDocument8 pagesModule 1: Nature of Mathematics: Patterns and Numbers in Nature and The WorldNeil MonteroPas encore d'évaluation

- Plaxis 2D ManualDocument320 pagesPlaxis 2D ManualAndreas Fendisa Putra100% (3)

- Basic Crystallography PDFDocument81 pagesBasic Crystallography PDFJavier Andres UrreaPas encore d'évaluation

- Chemistry 445 Lecture 8 The Determination of Point GroupsDocument33 pagesChemistry 445 Lecture 8 The Determination of Point GroupsUmair ZulfiqarPas encore d'évaluation

- Basics of CrystallographyDocument60 pagesBasics of Crystallographylmanna454Pas encore d'évaluation

- Chapter1 - Symmetry and Point GroupDocument111 pagesChapter1 - Symmetry and Point GroupChia Wee Keat100% (1)

- Wu Et Al 1989 Validity of Smith Model in Pile Driving AnalysisDocument18 pagesWu Et Al 1989 Validity of Smith Model in Pile Driving Analysis叶晓平Pas encore d'évaluation

- AnsysDocument76 pagesAnsysazerai2000Pas encore d'évaluation

- Maths Rotational Symmetry Worksheets TemplateDocument9 pagesMaths Rotational Symmetry Worksheets Templatelisandro reyesPas encore d'évaluation

- Two Mark QuestionsDocument12 pagesTwo Mark QuestionsAbishekPas encore d'évaluation

- Core and Cavity ExtractionDocument129 pagesCore and Cavity ExtractionSaggam Narasimharaju100% (1)

- Study of Symmetry Elements of Normal Class of Isometric and Tetragonal SystemsDocument21 pagesStudy of Symmetry Elements of Normal Class of Isometric and Tetragonal SystemsAshutosh BosePas encore d'évaluation

- Chapter 1 Molecular SymmetryDocument55 pagesChapter 1 Molecular SymmetrySyxfiqxh NjwaPas encore d'évaluation

- Creating Feathers in ZBrushDocument14 pagesCreating Feathers in ZBrushzanibab100% (6)

- Visual Pattern Recognition by Moment Invariants"Document9 pagesVisual Pattern Recognition by Moment Invariants"Carlos Patiño GómezPas encore d'évaluation

- Me 6603 - Finite Element Analysis: Part A Questions With Answers Unit 1Document14 pagesMe 6603 - Finite Element Analysis: Part A Questions With Answers Unit 1Karthik SubramaniPas encore d'évaluation

- Finite Element Method Magnetics - FEMM 4.2 Electrostatics TutorialDocument7 pagesFinite Element Method Magnetics - FEMM 4.2 Electrostatics TutorialKamila KPas encore d'évaluation