Académique Documents

Professionnel Documents

Culture Documents

Compressor Drive Allison 501-KB Gas Turbine

Transféré par

prabuCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Compressor Drive Allison 501-KB Gas Turbine

Transféré par

prabuDroits d'auteur :

Formats disponibles

ALLISON 501-KB GAS TURBINE

COMPRESSOR DRIVE

APPLICATION CONTROL PACKAGE

INC.

Rotating Machinery Controls

PRODUCT BULLETIN: 06004

JULY 2006

PETROTECH HOME PAGE

BLEED

VALVES

NGP

1

NGP

2

NGP

3

CIT

THERMO

COUPLES

CDP

TIT

CAPACITY

CONTROL

BYPASS

VALVE

GAS

FUEL

LIQUID

FUEL

STOP

VALVE

4-20 mA

4-20 mA

4-20 mA

FREQUENCY

FREQUENCY

FREQUENCY

FCV

STOP

VALVE

FUEL

PUMP

FUEL VALVE OUTPUT

STOP

VALVE

LCV VALVE OUTPUT

CDP INPUT

THERMOCOUPLE INPUTS

TC01-TC18

CIT INPUT

4-20 mA

mV

GP SPEED INPUT 3

4-20 mA

GP SPEED INPUT 2

LOAD SETPOINT INPUT

GP SPEED INPUT 1

BLEED VALVES OUTPUT

NOTE: GP SPEED

INPUTS 2oo3 VOTE

APPLICATION CONTROL PACKAGE 9500-501-KB-COMP

OPTIONAL

MMI

COMM PORT

TO PLANT INFORMATION SYSTEM

DCS/SCADA

PLC INTEGRATED CONTROL SYSTEM

Simplified schematic showing a Petrotech ALLISON 501-KB gas turbine compressor drive

application control package integrated into an advanced PLC-based control system.

97038 PG. 2

APPLICATION

SCOPE OF SUPPLY

The Allison 501-KB COMP gas turbine application control package

replaces older mechanical/hydraulic/electronic/pneumatic fuel

regulators with a modern, reliable application control package

which runs on an advanced PLC-based system. The control

package for the gas turbine provides fuel control and bleed valve

control.

The application control package for the Allison 501-KB gas turbine

generator drive system, includes:

Analog inputs, 4 - 20 mA:

Watts (load control).

Compressor discharge pressure (CDP).

Ambient temperature (CIT).

Analog inputs, frequency:

ADVANTAGES

Hardware independent system:

Application control packages portability allows customer choice

of platform, reducing need for additional spare parts and

training expenses. Available PLCs include General Electric,

Siemens/TI, Allen-Bradley, and Modicon.

Fault tolerant:

Control package is available on fault tolerant controllers for

critical control applications.

Simplified interface to DCS or SCADA:

Communication tasks are handled with a separate, dedicated

module in the PLC, increasing data rate and simplifying network

installation.

Improved fuel regulation:

Fast loop sampling rate, combined with modern digital control

techniques improve steady-state setpoint control, and reduce

overshoot during transients.

Improved start-up reliability:

Special lean lightoff procedure ignites all combustors with

essentially 100% reliability, and with greatly reduced thermal

stress.

Improved engine temperature monitoring and control:

Advanced statistical algorithms detect turbine hot/cold spots

and automatically reject failed thermocouples.

Fail-safe features:

Redundant overspeeds; open/short monitoring of mA and

thermocouples; readback monitoring of outputs, and special

self-check features improve safety.

Non-proprietary interfaces:

Simple 4- 20 mA, RTD, thermocouple, and dry contact I/O allow

simple interface to existing sequence/protection logic unit,

making low-cost partial upgrades practical, and system

troubleshooting simple.

Improved operator information with optional MMI:

Optional Man-Machine Interface MS Windows-based graphic

operator interface displays system status, trending and data

logging, which can be used as part of a preventative maintenance program.

Three (3) redundant NGP.

Analog inputs, mV:

TIT (up to 18 thermocouples).

Analog outputs, 4-20 mA:

Fuel control valve position setpoint.

Bleed valve position setpoint.

Operating states:

Firing.

Warm-up.

Accelerate.

Load.

Status, alarms, and shutdowns:

Fault .

GP overspeed alarm.

GP underspeed shutdown.

GP overspeed shutdown.

Redundant GP overspeed shutdown.

UGP alarm.

High TIT alarm.

High TIT shutdown.

Low TIT shutdown.

Low TIT delayed alarm.

Rejected thermocouple.

Too few thermocouples shutdown.

UT alarm.

UT shutdown.

Thermocouple spread alarm.

Thermocouple spread shutdown.

Turbine maximum limit.

97038 PG. 3

Turbine minimum limit.

GP speed #1.

GP speed #2.

OPTIONS FOR COMPLETE

CONTROL SYSTEM UPGRADE

GP speed #3.

Gas turbine sequencing and protection discrete logic.

GP speed #4.

Compressor sequencing and protection discrete logic.

GP speed #5.

Communication interface to DCS or SCADA.

TIT switch #1.

PLC hardware.

Manual.

Man machine interface unit with WonderWare InTouch licensed

software package.

High firing fuel pressure shutdown.

Transmitter failure alarms.

Complete custom engineered control panel, factory tested and

ready to install.

Transmitter failure shutdowns.

Fuel control valve system upgrade.

Output failure shutdowns.

Bleed valve actuator system upgrade.

Control mode.

Thermocouple upgrade.

Controllers/special features:

Synchronizing and regulation equipment.

Start-up controller for fuel valve.

Vibration system upgrade.

NGP controller for fuel valve.

Installation and commissioning.

TIT controller for fuel valve.

Training

TIT rate of rise controller.

Fuel acceleration schedule.

Fuel deceleration schedule.

Deceleration rate limiter.

Corrected speed (CNGP) override.

Bleed valve controller.

Combustion monitoring system.

Stagnation detection system.

Ramps:

Firing (lean lightoff) ramp.

Start-up ramp.

Loading ramp.

Cooldown ramp.

Does not include:

PLC hardware.

Gas turbine sequencing and protection discrete logic.

Compressor sequencing and protection discrete logic.

Compressor anti-surge control application package.

End elements.

97038 PG. 4

THIS PAGE LEFT BLANK

Petrotech, Inc

141 James Drive West

St. Rose, Louisiana 70087

USA

Phone:

Fax:

Email:

Web Site:

(504) 620-6600

(504) 620-6601

info@petrotechinc.com

www.petrotechinc.com

INC.

Rotating Machinery Controls

This document is a Petrotech, Inc. copyrighted intellectual property

and may be changed at anytime without notice.

Vous aimerez peut-être aussi

- Datasheet Industrial 501 Kb7sDocument2 pagesDatasheet Industrial 501 Kb7sNebojsa100% (1)

- TRM0371 GAP TrainingDocument77 pagesTRM0371 GAP TrainingRolfred50% (2)

- SGT600Document2 pagesSGT600fabyanoPas encore d'évaluation

- Liburdi Ruston TB5000 Tornado PresentationDocument27 pagesLiburdi Ruston TB5000 Tornado PresentationRoberto Cuadros67% (3)

- CT Inspection IntervalsDocument19 pagesCT Inspection IntervalsSantiago67% (3)

- 2015 Masonry Codes and Specifications Compilation, MCAA StoreDocument1 page2015 Masonry Codes and Specifications Compilation, MCAA StoreMuhammad MurtazaPas encore d'évaluation

- Restructuring ScenariosDocument57 pagesRestructuring ScenariosEmir KarabegovićPas encore d'évaluation

- Limiting and Excess Reactants Lesson PlanDocument3 pagesLimiting and Excess Reactants Lesson Planapi-316338270100% (3)

- Lm2500 InstrumentationDocument4 pagesLm2500 InstrumentationDenis JimenezPas encore d'évaluation

- 3rd Party PSM Ansaldo - Energia PDFDocument30 pages3rd Party PSM Ansaldo - Energia PDFkp pk100% (1)

- Advanced Compressor Less Purge ControlsDocument32 pagesAdvanced Compressor Less Purge ControlsMaha BluePas encore d'évaluation

- I A G T C: Ndustrial Pplication OF AS Urbines OmmitteeDocument13 pagesI A G T C: Ndustrial Pplication OF AS Urbines Ommittee'Izzad AfifPas encore d'évaluation

- GE Power Systems 7F Users Conference PresentationsDocument27 pagesGE Power Systems 7F Users Conference Presentationsatfrost4638Pas encore d'évaluation

- Report on blade failure of LP last stages in a 210 MW steam turbineDocument5 pagesReport on blade failure of LP last stages in a 210 MW steam turbinemanojpuru100% (1)

- IPL Saturn 20Document56 pagesIPL Saturn 20Ranjan Shankar100% (3)

- APA DOC No. 2014 PDFDocument67 pagesAPA DOC No. 2014 PDFThanapaet RittirutPas encore d'évaluation

- Mars 100 PlantDocument9 pagesMars 100 PlantabelsgPas encore d'évaluation

- Ansaldo Thomassen - CMU (2014)Document4 pagesAnsaldo Thomassen - CMU (2014)guerrezPas encore d'évaluation

- Variable Inlet Guide Vane System: GE Power SystemsDocument4 pagesVariable Inlet Guide Vane System: GE Power Systemsanggita gigih wahyu iriawan100% (1)

- Solar 5.2MVADocument15 pagesSolar 5.2MVAsohaila7Pas encore d'évaluation

- Seal Oil System Modifications Instability in The Seal Oil SystemDocument67 pagesSeal Oil System Modifications Instability in The Seal Oil SystemJONATHAN100% (1)

- Coatings Guide: Air Intake Air Intake Exhaust Compressor Compressor Combustor Combustor Turbine TurbineDocument1 pageCoatings Guide: Air Intake Air Intake Exhaust Compressor Compressor Combustor Combustor Turbine TurbinefrdnPas encore d'évaluation

- Gas TurbineDocument16 pagesGas TurbinehusnainyasirPas encore d'évaluation

- C10518078 PDFDocument20 pagesC10518078 PDFJessica ChandlerPas encore d'évaluation

- 10.1115 1.3240303Document6 pages10.1115 1.3240303ali a100% (1)

- 7FAAirfoils 50HzDocument2 pages7FAAirfoils 50Hzgassem208920Pas encore d'évaluation

- GT Gas Fuel and Air FlowDocument38 pagesGT Gas Fuel and Air FlowhinaPas encore d'évaluation

- Maintenance Manual: Order N: 827Document528 pagesMaintenance Manual: Order N: 827Luis SilvaPas encore d'évaluation

- Gas Turbines Technical PerformanceDocument2 pagesGas Turbines Technical PerformanceRoozbeh PPas encore d'évaluation

- General Electric Power Business Unit: Strategic Analysis Tools and Techniques - Coursework 2Document13 pagesGeneral Electric Power Business Unit: Strategic Analysis Tools and Techniques - Coursework 2Ibilola IbisankalePas encore d'évaluation

- Thermal Peaking PDFDocument26 pagesThermal Peaking PDFkhozaqiPas encore d'évaluation

- Turbine BladesDocument11 pagesTurbine BladesTheWorrior ChayranPas encore d'évaluation

- Ge Industrial Aeroderivative Gas TurbinesDocument2 pagesGe Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZ0% (1)

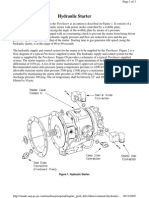

- Figure 1. Hydraulic StarterDocument3 pagesFigure 1. Hydraulic StarterDenis JimenezPas encore d'évaluation

- Technical Information Letter: Dangers of Bearing RefurbishmentDocument7 pagesTechnical Information Letter: Dangers of Bearing RefurbishmentJJPas encore d'évaluation

- GearboxDocument16 pagesGearboxMehul zarePas encore d'évaluation

- GT Mtc. PracticesDocument59 pagesGT Mtc. PracticesAbhishek Prakash SrivastavaPas encore d'évaluation

- Gas Turbines Drive Pipelines CompressorsDocument20 pagesGas Turbines Drive Pipelines CompressorsRoozbeh PPas encore d'évaluation

- V005t15a001 88 GT 150Document13 pagesV005t15a001 88 GT 150Antonio CilindroPas encore d'évaluation

- Repair Document RD-51-B1-1001 Rev: BDocument13 pagesRepair Document RD-51-B1-1001 Rev: BCiro MontielPas encore d'évaluation

- EPS GT Base PrinciplesDocument32 pagesEPS GT Base PrinciplescdbeardsallPas encore d'évaluation

- Gas Transport-Mallnow-Natural-Gas-Compressor-Station PDFDocument8 pagesGas Transport-Mallnow-Natural-Gas-Compressor-Station PDFJaswindersingh BhatiaPas encore d'évaluation

- Mechanical Interview Questions & Answers (Gas Turbine)Document14 pagesMechanical Interview Questions & Answers (Gas Turbine)ChiduPas encore d'évaluation

- 2.4 MBM Combustor Dilution Air SystemDocument6 pages2.4 MBM Combustor Dilution Air SystemmiladPas encore d'évaluation

- Solar Turbines - Centifugal Gas Compressor BookletDocument48 pagesSolar Turbines - Centifugal Gas Compressor Bookletsetyo ardiPas encore d'évaluation

- DescriptionDocument21 pagesDescriptionengine5Pas encore d'évaluation

- File No.5 - GT Operating ManualDocument27 pagesFile No.5 - GT Operating ManualMani Kandan0% (1)

- Siemens GTDocument8 pagesSiemens GThbalu007Pas encore d'évaluation

- Protection and Condition Monitoring of The LM5000 Gas TurbineDocument9 pagesProtection and Condition Monitoring of The LM5000 Gas TurbineSudeshPas encore d'évaluation

- Gt13e2 Gas Turbine PosterDocument1 pageGt13e2 Gas Turbine PosterHeri SetyantoPas encore d'évaluation

- GE LM2500, LM5000, LM6000 and LMS100 Gas Turbine Engines GuideDocument35 pagesGE LM2500, LM5000, LM6000 and LMS100 Gas Turbine Engines GuidesppramPas encore d'évaluation

- Ansaldo Energia AE94.2 Upgrading ProjectDocument20 pagesAnsaldo Energia AE94.2 Upgrading Projectvincent8295547100% (1)

- 03 GT13E2 Users Conference 2008 - Technical UpdateDocument26 pages03 GT13E2 Users Conference 2008 - Technical UpdateFabienne DemolPas encore d'évaluation

- 01 - SSE Academy BoolDocument65 pages01 - SSE Academy BoolAmmar AltamimyPas encore d'évaluation

- Wood Group - Gts Products Services Jan 08Document16 pagesWood Group - Gts Products Services Jan 08Jin Hern100% (1)

- Wet Seal System: Solar Gas CompressorDocument39 pagesWet Seal System: Solar Gas CompressoraputraPas encore d'évaluation

- Gek97310 File0001Document2 pagesGek97310 File0001Mendez Francisco33% (3)

- Design and Analysis of Centrifugal CompressorsD'EverandDesign and Analysis of Centrifugal CompressorsPas encore d'évaluation

- Modelling and Control of Electric Power Plants: Proceedings of the IFAC Workshop, Como, Italy, 22-23 September 1983D'EverandModelling and Control of Electric Power Plants: Proceedings of the IFAC Workshop, Como, Italy, 22-23 September 1983C. MaffezzoniPas encore d'évaluation

- Gas Turbine Pump Drive Integrated Control System: Petrotech Home PageDocument4 pagesGas Turbine Pump Drive Integrated Control System: Petrotech Home Pagescribdkhatn100% (1)

- Surge ProtectedDocument42 pagesSurge ProtectedRaul Roque Yujra100% (2)

- Gas EngineDocument6 pagesGas EngineMRizwanSadiq313Pas encore d'évaluation

- Manual-Motor de Gasolina Cm11 MkiiDocument4 pagesManual-Motor de Gasolina Cm11 MkiiNallely MassoPas encore d'évaluation

- TeSys D - LC1D09F7 (AC Power Contactor)Document6 pagesTeSys D - LC1D09F7 (AC Power Contactor)Electrical DistributionPas encore d'évaluation

- CT-X9000IN Manual 1B EN PDFDocument147 pagesCT-X9000IN Manual 1B EN PDFChristian Nirmal Satya & ValarmathiPas encore d'évaluation

- 5SL42167 Datasheet enDocument4 pages5SL42167 Datasheet enprabuPas encore d'évaluation

- AC Motors: Frames 180 449 API 610 Style (P Base) Vertical Mount Solid ShaftDocument18 pagesAC Motors: Frames 180 449 API 610 Style (P Base) Vertical Mount Solid ShaftTito FebriantoPas encore d'évaluation

- Saral Jeevan Bima Brochure-BRDocument10 pagesSaral Jeevan Bima Brochure-BRprabuPas encore d'évaluation

- AC Motors: Frames 180 449 API 610 Style (P Base) Vertical Mount Solid ShaftDocument18 pagesAC Motors: Frames 180 449 API 610 Style (P Base) Vertical Mount Solid ShaftTito FebriantoPas encore d'évaluation

- Jun'22 - On Road Price - JazzDocument1 pageJun'22 - On Road Price - JazzprabuPas encore d'évaluation

- SBI Life - Smart Annuity Plus - Brochure 1Document15 pagesSBI Life - Smart Annuity Plus - Brochure 1prabuPas encore d'évaluation

- Nema MG P4-2020 Watermarked - 2021-07-25Document4 pagesNema MG P4-2020 Watermarked - 2021-07-25prabuPas encore d'évaluation

- C++ Data Types GuideDocument2 pagesC++ Data Types GuideprabuPas encore d'évaluation

- Cold vs. Flu vs. Allergies vs. COVID-19Document1 pageCold vs. Flu vs. Allergies vs. COVID-19prabuPas encore d'évaluation

- 5SL43327 Datasheet enDocument4 pages5SL43327 Datasheet enprabuPas encore d'évaluation

- XH3-HE User'S Manual: Self-Contained, Single Pump Wellhead Control Panel For Harsh EnvironmentsDocument9 pagesXH3-HE User'S Manual: Self-Contained, Single Pump Wellhead Control Panel For Harsh EnvironmentsprabuPas encore d'évaluation

- S.N NOTEBOOK Specification Unit Price (KD.) : 14-Ax000neDocument9 pagesS.N NOTEBOOK Specification Unit Price (KD.) : 14-Ax000neprabuPas encore d'évaluation

- CAT EMCP 3 3 Control Systems Operation Manual PDFDocument19 pagesCAT EMCP 3 3 Control Systems Operation Manual PDFprabuPas encore d'évaluation

- CONTRACT SPECSDocument12 pagesCONTRACT SPECSprabuPas encore d'évaluation

- Set PointsDocument12 pagesSet PointsprabuPas encore d'évaluation

- Self-Contained Wellhead Control Panel User's ManualDocument9 pagesSelf-Contained Wellhead Control Panel User's ManualprabuPas encore d'évaluation

- Buy APC Smart-UPS RT 2000VA 230V For China - Technical Specifications and Information - APCDocument3 pagesBuy APC Smart-UPS RT 2000VA 230V For China - Technical Specifications and Information - APCprabuPas encore d'évaluation

- Buy APC Smart-UPS RT 2000VA 230V For China - Technical Specifications and Information - APCDocument3 pagesBuy APC Smart-UPS RT 2000VA 230V For China - Technical Specifications and Information - APCprabuPas encore d'évaluation

- All India Chess Federation: Player Registration Form For The Year: 2013 2014Document1 pageAll India Chess Federation: Player Registration Form For The Year: 2013 2014prabuPas encore d'évaluation

- Buy APC Smart-UPS RT 2000VA 230V For China - Technical Specifications and Information - APCDocument3 pagesBuy APC Smart-UPS RT 2000VA 230V For China - Technical Specifications and Information - APCprabuPas encore d'évaluation

- J - MTS - 2012 - 12-7189 - Electrical - ACSUPPLY D PDFDocument1 pageJ - MTS - 2012 - 12-7189 - Electrical - ACSUPPLY D PDFprabuPas encore d'évaluation

- Manual CGPower DT Installation Instructions ENG 29-10-10Document24 pagesManual CGPower DT Installation Instructions ENG 29-10-10prabuPas encore d'évaluation

- Laws of Chess 1 July 2014Document31 pagesLaws of Chess 1 July 2014prabuPas encore d'évaluation

- All India Chess Federation: Player Registration Form For The Year: 2013 2014Document1 pageAll India Chess Federation: Player Registration Form For The Year: 2013 2014prabuPas encore d'évaluation

- CorporateDocument7 pagesCorporateprabuPas encore d'évaluation

- Ay 2014 Elec Systems EbookDocument26 pagesAy 2014 Elec Systems EbookprabuPas encore d'évaluation

- All India Chess Federation: Player Registration Form For The Year: 2013 2014Document1 pageAll India Chess Federation: Player Registration Form For The Year: 2013 2014prabuPas encore d'évaluation

- 2009 WORD White Paper TemplateDocument4 pages2009 WORD White Paper Templateomegalpha777Pas encore d'évaluation

- People V Gona Phil 54 Phil 605Document1 pagePeople V Gona Phil 54 Phil 605Carly GracePas encore d'évaluation

- Apola Ose-Otura (Popoola PDFDocument2 pagesApola Ose-Otura (Popoola PDFHowe JosephPas encore d'évaluation

- KG Technologies Inc Metric: K119X-DX024P-1AT-90A-C399Document2 pagesKG Technologies Inc Metric: K119X-DX024P-1AT-90A-C399Bhushan PAwarPas encore d'évaluation

- Safe Handling of Solid Ammonium Nitrate: Recommendations For The Environmental Management of Commercial ExplosivesDocument48 pagesSafe Handling of Solid Ammonium Nitrate: Recommendations For The Environmental Management of Commercial ExplosivesCuesta AndresPas encore d'évaluation

- REBECCA SOLNIT, Wanderlust. A History of WalkingDocument23 pagesREBECCA SOLNIT, Wanderlust. A History of WalkingAndreaAurora BarberoPas encore d'évaluation

- Junior Instructor (Computer Operator & Programming Assistant) - Kerala PSC Blog - PSC Exam Questions and AnswersDocument13 pagesJunior Instructor (Computer Operator & Programming Assistant) - Kerala PSC Blog - PSC Exam Questions and AnswersDrAjay Singh100% (1)

- Ward A. Thompson v. City of Lawrence, Kansas Ron Olin, Chief of Police Jerry Wells, District Attorney Frank Diehl, David Davis, Kevin Harmon, Mike Hall, Ray Urbanek, Jim Miller, Bob Williams, Craig Shanks, John Lewis, Jack Cross, Catherine Kelley, Dan Ward, James Haller, Dave Hubbell and Matilda Woody, Frances S. Wisdom v. City of Lawrence, Kansas Ron Olin, Chief of Police David Davis, Mike Hall, Jim Miller, Bob Williams, Craig Shanks, John L. Lewis, Jack Cross, Kevin Harmon, Catherine Kelley, Dan Ward and James Haller, Jr., 58 F.3d 1511, 10th Cir. (1995)Document8 pagesWard A. Thompson v. City of Lawrence, Kansas Ron Olin, Chief of Police Jerry Wells, District Attorney Frank Diehl, David Davis, Kevin Harmon, Mike Hall, Ray Urbanek, Jim Miller, Bob Williams, Craig Shanks, John Lewis, Jack Cross, Catherine Kelley, Dan Ward, James Haller, Dave Hubbell and Matilda Woody, Frances S. Wisdom v. City of Lawrence, Kansas Ron Olin, Chief of Police David Davis, Mike Hall, Jim Miller, Bob Williams, Craig Shanks, John L. Lewis, Jack Cross, Kevin Harmon, Catherine Kelley, Dan Ward and James Haller, Jr., 58 F.3d 1511, 10th Cir. (1995)Scribd Government DocsPas encore d'évaluation

- Dance Manual W. Learning Outcomes PDFDocument8 pagesDance Manual W. Learning Outcomes PDFJoshua Quijano LamzonPas encore d'évaluation

- Kerala Dinesh Beedi - WikipediaDocument12 pagesKerala Dinesh Beedi - Wikipediaaymanamna2016Pas encore d'évaluation

- Evoe Spring Spa Targeting Climbers with Affordable WellnessDocument7 pagesEvoe Spring Spa Targeting Climbers with Affordable WellnessKenny AlphaPas encore d'évaluation

- 02-Procedures & DocumentationDocument29 pages02-Procedures & DocumentationIYAMUREMYE EMMANUELPas encore d'évaluation

- Importance of Time Management To Senior High School Honor StudentsDocument7 pagesImportance of Time Management To Senior High School Honor StudentsBien LausaPas encore d'évaluation

- Alberta AwdNomineeDocs Case Circle BestMagazine NewTrailSpring2016Document35 pagesAlberta AwdNomineeDocs Case Circle BestMagazine NewTrailSpring2016LucasPas encore d'évaluation

- Siege by Roxane Orgill Chapter SamplerDocument28 pagesSiege by Roxane Orgill Chapter SamplerCandlewick PressPas encore d'évaluation

- BRT vs Light Rail Costs: Which is Cheaper to OperateDocument11 pagesBRT vs Light Rail Costs: Which is Cheaper to Operatejas rovelo50% (2)

- LEGAL STATUs of A PersonDocument24 pagesLEGAL STATUs of A Personpravas naikPas encore d'évaluation

- Something About UsDocument18 pagesSomething About UsFercho CarrascoPas encore d'évaluation

- Fluid MechanicsDocument46 pagesFluid MechanicsEr Suraj Hulke100% (1)

- Sawmill Safety 3-Trim SawsDocument51 pagesSawmill Safety 3-Trim SawsramptgdPas encore d'évaluation

- E.Coli Coliforms Chromogenic Medium: CAT Nº: 1340Document2 pagesE.Coli Coliforms Chromogenic Medium: CAT Nº: 1340Juan Manuel Ramos ReyesPas encore d'évaluation

- Standard Chartered BackgroundDocument6 pagesStandard Chartered BackgroundAwesum Allen MukiPas encore d'évaluation

- Chrome Settings For CameraDocument6 pagesChrome Settings For CameraDeep BhanushaliPas encore d'évaluation

- Reviewer in Intermediate Accounting IDocument9 pagesReviewer in Intermediate Accounting ICzarhiena SantiagoPas encore d'évaluation

- Ra 1425 Rizal LawDocument7 pagesRa 1425 Rizal LawJulie-Mar Valleramos LabacladoPas encore d'évaluation

- Module 1: Overview of Implementation of The NSTP (Activities)Document3 pagesModule 1: Overview of Implementation of The NSTP (Activities)RonnelPas encore d'évaluation

- Mendoza CasesDocument66 pagesMendoza Casespoiuytrewq9115Pas encore d'évaluation