Académique Documents

Professionnel Documents

Culture Documents

1977 TSF Sputt

Transféré par

andresromero80Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1977 TSF Sputt

Transféré par

andresromero80Droits d'auteur :

Formats disponibles

Thin Solid Films, 42 (1977) 185 191

{~ Elsevier Sequoia S.A., Lausanne

Printed in the Netherlands

185

S P U T T E R I N G OF METALS IN T H E PRESENCE OF REACTIVE GASES

J. HRBEK

Czechoslovak Academy of Sciences, The J. Heyrovsk); Institute of Physical Chemistry and Electrochemistry, Mfichova 7, 12138 Praha 2, Vinohrady (Czechoslovakia)

(Received July 5, 1976; accepted October 15, 1976)

The sputtering yields of Ti, Ta, Mo and W bombarded by Ar ions were

measured in situ by a weight loss measurement as a function of the partial pressure

of reactive gas (02 or N2). The sputtering yields decreased to about 0.4-0.1 of the

initial value in the presence of a reactive gas for every gas-target combination

studied. All the curves were of sigmoidal shape with an inflection point that

depended on the primary ion current density.

The results were interpreted in terms of a monolayer chemisorption of the

reactive gas on the target surface using the assumption that the actual sputtering

yield can be expressed as a linear combination of the sputtering yield of the clean

target and the sputtering yield of the target covered with the adsorbed layer.

1. INTRODUCTION

The effect of gaseous impurities on the preparation of thin films by sputtering

was recognized a long time ago 1'2. More recently Wehner 3 and Yonts and

Harrison 4 found that the sputtering yield for both low and high energy was affected

by oxygen or reactive gas adsorption. In some recent papers the importance of the

physicochemical properties of the gas-target combination during reactive sputtering was discussed 5-12. The interaction between the reactive gas molecules and the

surface atoms of the target is of basic importance with respect to the nature and

mechanism of the sputtering process. This has been taken into account in recently

published models of reactive sputtering 10-12.

The various models of reactive sputtering can be verified by using the data from

experiments in which the deposition rate has been measured as a function of

different parameters, including the partial pressure of reactive gas. These measurements are complicated by the diversity of the interactions of both sputtered and

adsorbed particles with the substrate where the sputtered material is deposited.

Thus the sputtering yield is in general not proportional to the deposition rate 13.

A decrease in the deposition rate as the partial pressure of the reactive gas is

increased has been correlated by various authors with a decrease in sputtering

rate 6'1'12, with plasma characteristics 14 and with different physicochemical

processes on the substrate 15.

During the last fifteen years a large number of experimental data have been

published, and many models of reactive sputtering have been constructed. All these

186

J. HRBEK

models can be classified according to the position at which the interaction between

the reactive gas molecules and the target atoms takes place, e.g. on the target, in the

plasma or at the substrate 16.

Under certain experimental conditions the target surface can be considered as

the most probable interaction site 17. For this site, oxidation l, gettering 11 and

adsorption 12 were suggested as the mechanisms responsible for reactive sputtering.

In these papers the authors studied the changes in deposition rate as a function o f

the partial pressure and o f other parameters measured simultaneously, e.g. the mass

spectrum of the particles sputtered from the surface 1~ or the discharge characteristics ~o.

k

[ro,]

1.0

0.5

I

10

15

10

16

I

10

17

10

18

z(o21 [0~-2 ~~]

Fig. 1. The relative s p u t t e r i n g yield k as a function of the i m p i n g i n g rate Z (cm 2 s ~) of the reactive gas.

The Ti O2 target gas c o m b i n a t i o n was m e a s u r e d at p r i m a r y ion current densities of 250 p A cm 2 ( O )

a n d 30 p A cm -2 ().

15

10

[,e,]

16

10

17

zIN 2) [o-2 -I]

18

10

10

1.0 - -

0.5

--

I

10

15

I

10

16

I

10

17

I

1018

Fig. 2. The e x p e r i m e n t a l values o f the relative s p u t t e r i n g yield k as a function of the i m p i n g i n g rate Z of

the reactive gas for M o - O 2 ( 0 ) and M o N 2 (C)) t a r g e t - g a s c o m b i n a t i o n s . The p r i m a r y ion current

density was 150 laA cm - 2

S P U T T E R I N G OF METALS IN THE PRESENCE OF REACTIVE GASES

187

In the present work the sputtering yields o f T a , Ti, Mo and W were measured as

a function of the partial pressure of reactive gas ( 0 2, N2), and the experimental data

are explained in terms of an adsorption model.

2. EXPERIMENTAL

The experiments were carried out in an all-glass high vacuum apparatus

evacuated by oil diffusion and titanium sublimation pumps to an ultimate pressure

of less than 10 - s Pa. The residual gas, consisting mainly of CO, N 2 and H20, was

checked with a Centronic A I G 50 analytical ion gauge. The sputtering yields were

calculated from the weight losses of the metal targets caused by b o m b a r d m e n t with

Ar ions of energy 2.3 keV. The ion source with oscillating electrons and ion

extraction perpendicular to the electron beam axis was built according to the design

of K o e d a m 18. Secondary electron emission from the target was suppressed by a

combination of magnetic and electrostatic fields. The weight losses were measured

using a quartz spring balance with a sensitivity of 0.005 mg. The targets were

transferred magnetically in v a c u o from the target chamber to the balance or to the

heating cell for outgassing by electron bombardment.

The purity of the reactive gases used in this study was checked with an A I G 50.

The argon used as the inert gas for sputtering was spectroscopically pure. The metal

targets were 0.2-0.5 mm sheets of 99.7 ~o Ti, 99.9 ~o Mo, 99.99 /o Ta and 99.98 /o W.

The standard deviation of the measured sputtering yields was 13 ~ .

[re,]

15

10

I

16

10

I

17

10

I

18

10

I

1.0

0.5

10~5

1016

1017

1018

Z(O 2) [cm-2 s-1]

Fig. 3. The experimental values o f k as a f u n c t i o n o f Z f o r the Ta 0 2 ( 0 ) and T a - N 2 ( O ) target-gas

c o m b i n a t i o n s . The p r i m a r y ion current density was 150 laA cm - z.

3. RESULTS

The relative sputtering yields k (the ratio of the yield in the presence of the

reactive gas to that in the absence of the reactive gas) as a function of the impinging

rate Z of the reactive gas molecules are plotted in Figs. 1-4. The influence of the

188

[,e,]

J. HRBEK

15

10

16

10

17

10

Z(N 2) ~m-2 ~ ]

18

10

1.0

0.5

I

10

15

16

10

1

10

17

I

10

18

Z(O 2 ) ~ m - 2 ~ 1]

Fig. 4. T h e e x p e r i m e n t a l values o f k as a f u n c t i o n o f Z f o r the W 0 2 ( 0 ) a n d W N 2 ( C ) ) t a r g e t gas

combinations. The ~rimaryion current density was 150 ~Acm 2.

oxygen impinging rate on the Ti sputtering yield for primary ion current densities o f

250 laA c m - 2 and 30 ~tA cm 2 is shown in Fig. I. Figures 2, 3 and 4 show k r e r s u s Z

plots for M o O 2 and Mo N 2 target gas combinations, Ta O2 and Ta N 2

target gas combinations and W 02 and W N 2 target gas combinations respectively.

In all target gas combinations the sputtering yield was found to decrease to

about 0.4 0.1 o f the initial value. All the curves have a sigmoidal shape with an

inflection point that shifts to higher pressures when the primary ion current density

is increased.

4. DISCUSSION

With appropriate pressure and temperature conditions the reactive gas can be

chemisorbed onto the metal surface. If a target surface that is covered with a

chemisorbed layer is b o m b a r d e d by ions, the adsorbed particles will be removed

from the surface not only by desorption but also by sputtering.

The sputtered particles originate both from the surface and from the bulk of the

target. Most particles are sputtered from a very thin surface layer ~0. It is evident that

with an increasing surface coverage o f chemisorbed gas the probability that the

adsorbed particles will be sputtered will also increase 2 and simultaneously the

sputtering o f metal particles from the surface will be reduced. Thus the sputtering

yield o f gas-covered metal should be lower than the yield o f the clean metal because

part o f the primary ion energy will be used for sputtering the adsorbed layer. If this is

so, we might expect the metal sputtering yield to depend on the surface coverage, as

shown in Fig. 5.

Let us suppose that the adsorption is governed by the Langmuir isotherm.

SPUTTERING OF METALS IN THE PRESENCE OF REACTIVE GASES

e-o

o<e<l

189

o =1

Fig. 5. Two contributions to the sputtering yield can be distinguished: the surface contribution Fs and

the bulk contributionFa, Whenthe coverageO of the metal surfaceincreases, Fs is reducedand adsorbed

particles are also sputtered from the surface (contribution Fsa).

Using this approximation we can write 21

s Z ( l - O) = FAO

(1)

where s is the sticking probability, Z the impinging rate (cm- z s- 1) of gas molecules

on the surface, O the surface coverage and FA the rate (cm -2 s -1) of removal of

adsorbed particles from the surface.

If the actual sputtering rate Fe is a linear combination of the sputtering rates F1

atO=landF oatO=0weobtain

Fo = r o - ( r o - r O 0

(2)

Using F I / F o = m and F o / F o = k and rearranging eqn. (2) we can write

1-k

O= - 1-m

(3)

By substitution ofeqn. (3) into eqn. (1) we get

k=

sZ

sZ+F g(1-m)

(4)

This equation can readily be compared with the experimental data. The sputtering

yield and the sputtering rate are proportional so that the normalized sputtering

rates k and m can be determined from the measured sputtering yields together with

the values sZ. The value of the removal rate FA is determined from the condition

that k = (m + 1) because then F A = s Z .

As an example, the Ti-O 2 target-gas combination results are plotted together

with the model curve in Fig. 6. The experimental data for the W - O z and W - N z

target-gas combinations could be fitted reasonably well also. The decrease in

sputtering yield for the T a - O / a n d M o - N 2 systems is steeper than predicted by eqn.

(4). In contrast, for the Ta N z and M o - O 2 systems the inflection regions of the

experimental curves are elongated in comparison with the model curve.

The assumptions used for the derivation ofeqn. (1) are not completely fulfilled

in the sputtering process. In the course of the experiment the target is heated owing

to the ion bombardment; furthermore, when the impinging rate of oxygen or

nitrogen on the target is high, the surface coverage can be greater than unity. One of

the assumptions we made was that the surface was homogeneous with respect to

adsorption but this can be made invalid by ion bombardment 22. In spite of evident

190

J. HRBEK

[,e,]

1.0

0.5

15

10

16

10

1

10

17

10

18

Z(O 2) [cm-2 s-11

Fig. 6. The calculated k =./(Z) curves (eqn. (4)) compared with the experimental data for the Ti O z

target--gas combination : - , model: O, 250 gA cm a ; , 30 #A cm - 2.

violation o f the assumptions used in the derivation o f eqn. ( 1), this approximation is

widely used in the surface applications o f secondary ion mass spectroscopy 23, 2,,

The sputtering yield o f adsorbed gas will certainly be a function o f coverage.

Depending on the actual mechanism of adsorption and sputtering we expect that

when gas is adsorbed and sputtered in atomic form the sputtering yield o f the

adsorbed gas will be proportional to the coverage, whereas for atomic adsorption

and molecular sputtering the yield will be proportional to the second power o f the

coverage. F o r the latter mechanism we shall change the assumption o f a linear

c o m b i n a t i o n (eqn. (2)) to

fo = Fo-(fo-ft)O

(5)

and thus

sZ

k = 1-[sZ-+Z

\2

] (1-m)

(6)

This equation is a better approximation than eqn. (4) for the M o - O 2 and T a - N 2

target gas combinations.

F r o m sputtering theory it follows that the sputtered particles originating from

the bulk are characterized by a higher kinetic energy than the particles from the

surface region 19. We m a y thus expect that for the covered surface there will also be

changes in the energy distribution o f the sputtered metal particles. The m a x i m u m in

the energy distribution should be shifted to higher energy values because the

n u m b e r o f metal particles originating at the surface is reduced. So far, however,

there are no direct experimental data confirming this conclusion, but indirect

information concerning the energy spectra o f sputtered ions supports the prediction 2s.

The assumption that we have used concerning the combination of sputtering

rates has been used also in other models o f the reactive sputtering process 1 ~2.

SPUTTERING OF METALS IN THE PRESENCE OF REACTIVE GASES

191

Because there are so many other approximations there is no possibility of

comparison with the experimental data measured by other authors.

5. CONCLUSION

The influence that the partial pressure of the reactive gas exerts on metal

sputtering yields was measured and was interpreted by means of the Langmuir

isotherm using the assumption that the actual sputtering yields can be expressed as a

linear combination of the sputtering yield of the clean target and the sputtering yield

of the target covered with an adsorbed layer. Direct measurement of the sputtering

yields of the metal enabled us to exclude uncertainties about the nature of the

interaction of the substrate with the incoming particles.

The reactive sputtering mechanism is controlled simultaneously by the

adsorption-sputtering mechanism of the reactive gas adsorbed, by changes in the

surface binding energy due to adsorption and finally by collision mechanics.

ACKNOWLEDGMENTS

The author gratefully acknowledges the helpful comments made by Drs. (~.

Jech and Z. Knor.

REFERENCES

1 C.J. Corbek, J. Opt. Soc. Am., 23 (1933) 109.

2 H. Koenig and L. Heisinger, Festschrift Hereaus Platinschmelze, Hereaus Platinschmelze, Hanau,

1947, p. 202.

3 G.K. Wehner, Phys. Rev., 108 (1957) 35.

4 O.C. Yonts and D. E. Harrison, J. Appl. Phys., 31 (1960) 1583.

5 R.E. Jones, H. F. Winters and L. I. Maissel, J. Vac. Sci. Technol., 5 (1967) 84.

6 E. Hollands and D. S. Campbell, J. Mater. Sci., 3 (1968) 544.

7 H.F. Winters, J. Vac. Sci. Technol., 8 (1971) 17.

8 M. Cantagrel and M. Marchal, J. Mater. Sci., 8 (1973) 1711.

9 M. Bernheim and G. Slodzian, Int. J. Mass Spectrom. Ion Phys., 12 (1973) 93.

10 J. Heller, Thin Solid Films, 17(1973) 163.

11 F. ShinokiandA. Itoh, J. Appl. Phys.~46(1975)3381.

12 T. Abe and T. Yamashina, Thin Solid Films, 30 (1975) 19.

13 R.E. Jones, C. L. Standley and L. I. Maissel, J. Appl. Phys., 38 (1967) 4656.

14 J.B. Llounsburry, J. Vac. Sci. Technol., 6 (1969) 838.

15 H.F. Winters, D. L. Raimondi and D. E. Horne, J. Appl. Phys., 40 (1969) 2996.

16 L. Holland and G. Siddall, Vacuum, 4 (1953) 375.

17 L.I. Maissel, in L. I. Maissel and R. Glang (eds.), Handbook of Thin Film Technology, McGrawHill, New York, 1970, Chap. 4.

18 M. Koedam, Philips Res. Rep., 16 (1961) 101.

19 P. Sigmund, Phys. Rev., 184 (1969) 383.

20 H.F. Winters and P. Sigmund, J. Appl. Phys., 45 (1974) 4760.

21 D.O. Hayward and B. M. W. Trapnell, Chemisorption, 2nd edn., Butterworths, London, 1964.

22 R.S. Gvosdover, V. M. Efremenkova, L. B. Shelyakin and V. E. Yurasova, Radiat. Effects, 27

(1976) 237.

23 A. Benninghoven, Surf. Sci., 35 (1973) 427.

24 G. Blaise and M. Bernheim, Surf. Sci., 47 (1975) 324.

25 T. Ishitani, H. Tamura and T. Shinmiyo, Surf. Sci., 55 (1976) 179.

Vous aimerez peut-être aussi

- Thermodynamic and Experimental Approach To Ceramic Materials: Gas - Solid/liquid EquilibriaDocument7 pagesThermodynamic and Experimental Approach To Ceramic Materials: Gas - Solid/liquid Equilibriafofia1955Pas encore d'évaluation

- A Virial Coefficient Analysis of Helium Adsorption IsothermsDocument10 pagesA Virial Coefficient Analysis of Helium Adsorption IsothermsYasir AliPas encore d'évaluation

- Kang Li, Hassan Javed, Guoqiang ZhangDocument6 pagesKang Li, Hassan Javed, Guoqiang ZhangAlbertoPas encore d'évaluation

- Tables of Coefficients for the Analysis of Triple Angular Correlations of Gamma-Rays from Aligned NucleiD'EverandTables of Coefficients for the Analysis of Triple Angular Correlations of Gamma-Rays from Aligned NucleiPas encore d'évaluation

- Jwri39 02 130Document4 pagesJwri39 02 130Abbas LkPas encore d'évaluation

- 1976-Morito - Transition From External To Internal Oxidation in Fe-Si Alloy As A Function of Oxygen Potential of The Ambient AtmosphereDocument4 pages1976-Morito - Transition From External To Internal Oxidation in Fe-Si Alloy As A Function of Oxygen Potential of The Ambient AtmosphereDavid Hernández EscobarPas encore d'évaluation

- Preferential Sputtering of OxidesDocument11 pagesPreferential Sputtering of OxidesGuilherme Wellington Alves CardosoPas encore d'évaluation

- The Mechanism of The Oxidation of Propene To AcroleinDocument9 pagesThe Mechanism of The Oxidation of Propene To AcroleinLeonardo BrunelliPas encore d'évaluation

- Oxigen ReducionDocument5 pagesOxigen ReducionRafael Ricardo Celin ManceraPas encore d'évaluation

- Instructions For Use: Hokkaido University Collection of Scholarly and Academic Papers: HUSCAPDocument25 pagesInstructions For Use: Hokkaido University Collection of Scholarly and Academic Papers: HUSCAPJulius Ferdinand TariganPas encore d'évaluation

- The Surface Tension of Molten Aluminum and Al-Si-Mg Alloy Under Vacuum and Hydrogen AtmospheresDocument6 pagesThe Surface Tension of Molten Aluminum and Al-Si-Mg Alloy Under Vacuum and Hydrogen AtmospheresBogdan AndriesPas encore d'évaluation

- Mining Science and Technology 1991 Vol.13 p.409 415Document7 pagesMining Science and Technology 1991 Vol.13 p.409 415Dicki SetiawanPas encore d'évaluation

- Австри 2010 БодлогоDocument13 pagesАвстри 2010 БодлогоGerel BayrmagnaiPas encore d'évaluation

- ArticleDocument12 pagesArticleASimilatrixPas encore d'évaluation

- Absorption of NOx in Packed ColumnDocument6 pagesAbsorption of NOx in Packed ColumnPauloValdiviesoPas encore d'évaluation

- Penetration by Gases To Sterilize Interior Surfaces of Confined SpacesDocument5 pagesPenetration by Gases To Sterilize Interior Surfaces of Confined Spacesmoresushant849643Pas encore d'évaluation

- Advanced Transport Phenomena Module 8 Lecture 37: Illustrative Example: Protective Oxide Dissolution On GT BladesDocument36 pagesAdvanced Transport Phenomena Module 8 Lecture 37: Illustrative Example: Protective Oxide Dissolution On GT BladesshashwatPas encore d'évaluation

- Simulation of Coal Combustion in A Bubbling Fluidized Bed by Distinct Element MethodDocument6 pagesSimulation of Coal Combustion in A Bubbling Fluidized Bed by Distinct Element Methodphemt84Pas encore d'évaluation

- Ftir Study of A Nanostructured Aluminum Nitride Powder Surface: Determination of The Acidic/Basic Sites by Co, Co2 and Acetic Acid AdsorptionsDocument11 pagesFtir Study of A Nanostructured Aluminum Nitride Powder Surface: Determination of The Acidic/Basic Sites by Co, Co2 and Acetic Acid AdsorptionsNurulAtirahNoroziPas encore d'évaluation

- A Comparative Study of The Bonding of N and CO To Ru (001) and The Role of 5 Orbital in Their Molecular Vibrational Frequency ChangesDocument3 pagesA Comparative Study of The Bonding of N and CO To Ru (001) and The Role of 5 Orbital in Their Molecular Vibrational Frequency ChangesTrần Duy TânPas encore d'évaluation

- On The Nature of The Phase Transition ..... Physica CDocument2 pagesOn The Nature of The Phase Transition ..... Physica CkjborkenPas encore d'évaluation

- Reith Oxidation of Na2so3Document7 pagesReith Oxidation of Na2so3cmegmhiPas encore d'évaluation

- Brambilla 1994Document8 pagesBrambilla 1994Esthefano Morales CampañaPas encore d'évaluation

- Adsorption of Chlorinated Volatile Organic Compounds in A Flxed Bed of Activated CarbonDocument7 pagesAdsorption of Chlorinated Volatile Organic Compounds in A Flxed Bed of Activated Carbonamir.m.norouzi95Pas encore d'évaluation

- RPCJPNV 33 P 041Document13 pagesRPCJPNV 33 P 041Irene 'septiriana'Pas encore d'évaluation

- The Size of Soluble Aerosol Particles As A Function of The Humidity of The Air. Application To The H U M A N Respiratory TractDocument17 pagesThe Size of Soluble Aerosol Particles As A Function of The Humidity of The Air. Application To The H U M A N Respiratory TractRigoberto CastroPas encore d'évaluation

- THE OF OF Adsorbents: DubininDocument7 pagesTHE OF OF Adsorbents: DubininJ-queline NgPas encore d'évaluation

- Vg-. CV,: Eg NPG N (P + 2Z/R)Document3 pagesVg-. CV,: Eg NPG N (P + 2Z/R)cesardakoPas encore d'évaluation

- Detection Principle MOS-2Document3 pagesDetection Principle MOS-2Rajesh GudavalliPas encore d'évaluation

- 05 - Chapter 2 PDFDocument99 pages05 - Chapter 2 PDFUmme AbdullahPas encore d'évaluation

- School of Physics, Sydney University, Sydney, NSW 2006, AustraliaDocument14 pagesSchool of Physics, Sydney University, Sydney, NSW 2006, Australiahassan zohairPas encore d'évaluation

- Full TextDocument13 pagesFull TextYashi MalhotraPas encore d'évaluation

- CH-440 NanotechnologyDocument22 pagesCH-440 NanotechnologyAndrew SionPas encore d'évaluation

- 147 GiurannoDocument6 pages147 GiurannoV R SrinivasanPas encore d'évaluation

- Use of Ultra and Nanofiltration Ceramic Membranes For Desalination 2004 DesalinationDocument7 pagesUse of Ultra and Nanofiltration Ceramic Membranes For Desalination 2004 DesalinationIzzatIqbalPas encore d'évaluation

- The Choice of Cathode Material in A Hot CathodeDocument8 pagesThe Choice of Cathode Material in A Hot Cathodemahmoud22478Pas encore d'évaluation

- Amplification of Pressure Fluctuations Due To Fluid-Structure InteractionDocument11 pagesAmplification of Pressure Fluctuations Due To Fluid-Structure Interactionbaja2014Pas encore d'évaluation

- The Application of Potential - PH Diagrams To Solvent Extraction SystemsDocument14 pagesThe Application of Potential - PH Diagrams To Solvent Extraction SystemsandyPas encore d'évaluation

- The Adsorption of Non-Polar Gases On Alkali Halide CrystalsDocument19 pagesThe Adsorption of Non-Polar Gases On Alkali Halide CrystalsMGNMPas encore d'évaluation

- Catalytic Dehydrogenation of Z-Butanol With Zno and CuoDocument4 pagesCatalytic Dehydrogenation of Z-Butanol With Zno and CuoRosy Vargas CaroPas encore d'évaluation

- Interplay Between O and Sno: Oxygen Ionosorption and Spectroscopic Evidence For Adsorbed OxygenDocument12 pagesInterplay Between O and Sno: Oxygen Ionosorption and Spectroscopic Evidence For Adsorbed OxygenGiovana SantosPas encore d'évaluation

- Chemical Reaction of Fly Ash: H.J.H. Brouwers and R.J. Van EijkDocument10 pagesChemical Reaction of Fly Ash: H.J.H. Brouwers and R.J. Van Eijkvasireddy balasaikrishnaPas encore d'évaluation

- Liebhafsky1932 PDFDocument15 pagesLiebhafsky1932 PDFK K LoachPas encore d'évaluation

- II. Vacuum Apparatus and Auxiliaries: Bookpubld by Nauky, Moscow 1969,432 P (In Russian)Document1 pageII. Vacuum Apparatus and Auxiliaries: Bookpubld by Nauky, Moscow 1969,432 P (In Russian)juan carlosPas encore d'évaluation

- Fi-Artigo 2Document4 pagesFi-Artigo 2Pedro VieiraPas encore d'évaluation

- Exercises Mtk2Document5 pagesExercises Mtk2Rina Pebriana SiregarPas encore d'évaluation

- Surface Oxidation of Liquid SN: A, B A A, B C D e e e eDocument18 pagesSurface Oxidation of Liquid SN: A, B A A, B C D e e e eV R SrinivasanPas encore d'évaluation

- Trends in Catalytic Activity For SOFC Anode MaterialsDocument7 pagesTrends in Catalytic Activity For SOFC Anode MaterialssharatPas encore d'évaluation

- Otto 1968Document13 pagesOtto 1968Devi Taufiq NurrohmanPas encore d'évaluation

- Ab Initio DFT Study of Urea Adsorption and Decomposition On The ZnO SurfaceDocument8 pagesAb Initio DFT Study of Urea Adsorption and Decomposition On The ZnO SurfaceAlex FaudoaPas encore d'évaluation

- Acidity and Basicity of Metal Oxide Surfaces 1 II. Determination by Catalytic Decomposition of IsopropanolDocument9 pagesAcidity and Basicity of Metal Oxide Surfaces 1 II. Determination by Catalytic Decomposition of Isopropanolnguyennha1211Pas encore d'évaluation

- Electronic and Chemical Interactions at Aluminum/Tio, (110) InterfacesDocument10 pagesElectronic and Chemical Interactions at Aluminum/Tio, (110) Interfacessujatasingh786Pas encore d'évaluation

- Oxygen Vacancies As Active Sites For Water Dissociation On Rutile TioDocument4 pagesOxygen Vacancies As Active Sites For Water Dissociation On Rutile TioiprateekPas encore d'évaluation

- General Combustion Equation PDFDocument39 pagesGeneral Combustion Equation PDFMohanad El-HarbawiPas encore d'évaluation

- Ellingham DiagramsDocument8 pagesEllingham DiagramschantaiahPas encore d'évaluation

- Wend Land T 1966Document4 pagesWend Land T 1966Rama Rós LahhamPas encore d'évaluation

- Thin Film Deposition From Hexamethyldisiloxane Fed Glow DischargesDocument18 pagesThin Film Deposition From Hexamethyldisiloxane Fed Glow DischargesYoucef FermiPas encore d'évaluation

- Problem Set 4 SolutionDocument3 pagesProblem Set 4 SolutionRod De GuzmanPas encore d'évaluation

- Numerical Simulation of An Oxygen-Fed Wire-To-Cylinder Positive Corona DischargeDocument5 pagesNumerical Simulation of An Oxygen-Fed Wire-To-Cylinder Positive Corona DischargeYoucef MyoucefPas encore d'évaluation

- Analytical Theory of Coalbed Methane Recovery by Gas InjectionDocument9 pagesAnalytical Theory of Coalbed Methane Recovery by Gas Injectionmsmsoft90Pas encore d'évaluation

- 2372 Travel Tracker enDocument1 page2372 Travel Tracker enandresromero80Pas encore d'évaluation

- Problem # 4 (20 Points) : (3 Points) (Except The Shaded Cells) and DetermineDocument1 pageProblem # 4 (20 Points) : (3 Points) (Except The Shaded Cells) and Determineandresromero80Pas encore d'évaluation

- Problem #5 (20 Points)Document1 pageProblem #5 (20 Points)andresromero80Pas encore d'évaluation

- Opalphy@academie-Sciences - FR: 23, Quai de Conti, 75006 Paris, France Tél. (+33) (0) 1 44 41 43 72Document2 pagesOpalphy@academie-Sciences - FR: 23, Quai de Conti, 75006 Paris, France Tél. (+33) (0) 1 44 41 43 72andresromero80Pas encore d'évaluation

- I-3 Technology Start-Up Competition 2013-2014: Information Kit September 2013 WWW - Innovacorp.caDocument11 pagesI-3 Technology Start-Up Competition 2013-2014: Information Kit September 2013 WWW - Innovacorp.caandresromero80Pas encore d'évaluation

- Crown Corporation: Business PlansDocument12 pagesCrown Corporation: Business Plansandresromero80Pas encore d'évaluation

- Formulario GrowLabDocument5 pagesFormulario GrowLabandresromero80Pas encore d'évaluation

- Energy Security BackgroundDocument1 pageEnergy Security Backgroundandresromero80Pas encore d'évaluation

- Gear Process OptimizationDocument5 pagesGear Process Optimizationandresromero80Pas encore d'évaluation

- Technical Data: Relative Humidity SensorDocument4 pagesTechnical Data: Relative Humidity Sensorandresromero80Pas encore d'évaluation

- Elementary Inorganic Nomenclature PDFDocument2 pagesElementary Inorganic Nomenclature PDFPrecious Mae Cuerquis BarbosaPas encore d'évaluation

- D 4278 - 02 Rdqynzg - PDFDocument3 pagesD 4278 - 02 Rdqynzg - PDFRufo CascoPas encore d'évaluation

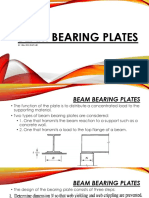

- 7-B. Beam Bearing PlatesDocument14 pages7-B. Beam Bearing PlatesMelchizedek EllPas encore d'évaluation

- HPLC RS Method DevelopmentDocument175 pagesHPLC RS Method Developmentnew inspire100% (2)

- Geochemical Characteristics of Igneous Rocks As Petrogenetic IndicatorsDocument2 pagesGeochemical Characteristics of Igneous Rocks As Petrogenetic IndicatorsFrank Hoyos CubasPas encore d'évaluation

- BS en 682-2002 Elastomeric Seals-Materials Requirements For Seals Used in PipesDocument22 pagesBS en 682-2002 Elastomeric Seals-Materials Requirements For Seals Used in PipesM Alim Ur RahmanPas encore d'évaluation

- Mullion Transom Connector BS-EN-1991-1-1 V2.0Document2 pagesMullion Transom Connector BS-EN-1991-1-1 V2.0Giri DharanPas encore d'évaluation

- Lopez PrefiDocument5 pagesLopez PrefiCarl Adrienne LopezPas encore d'évaluation

- AED Design Requirements:: Breaker and Conductor SizingDocument4 pagesAED Design Requirements:: Breaker and Conductor SizingRicky Respondo TindocPas encore d'évaluation

- Mcqs On HeatDocument13 pagesMcqs On HeatParshantKumarBajajPas encore d'évaluation

- Assignment: Submitted by R.Deepa 116011001503 Ii Yr / Iv SemDocument6 pagesAssignment: Submitted by R.Deepa 116011001503 Ii Yr / Iv SemR. Deepa - APas encore d'évaluation

- PCL BiomedicalDocument6 pagesPCL BiomedicalCynthia CastroPas encore d'évaluation

- GPCDOC Local TDS Canada Shell Tellus S2 V 100 (en-CA) TDSDocument3 pagesGPCDOC Local TDS Canada Shell Tellus S2 V 100 (en-CA) TDSRoger ObregonPas encore d'évaluation

- AWC WCD5 HeavyTimber ViewOnly 0402Document24 pagesAWC WCD5 HeavyTimber ViewOnly 0402Sand'sZaoldyeckPas encore d'évaluation

- The Passivated Emitter and Rear Cell (PERC) PDFDocument8 pagesThe Passivated Emitter and Rear Cell (PERC) PDFShadab AhmedPas encore d'évaluation

- Buffer Solutions .Docx 1Document8 pagesBuffer Solutions .Docx 1H.M. AriyanPas encore d'évaluation

- Vessel Nozzle PDFDocument30 pagesVessel Nozzle PDFEugenia LorenzaPas encore d'évaluation

- Lesson Plan 8Document9 pagesLesson Plan 8princesdianedelectorPas encore d'évaluation

- TDS Hydrazine HydrateDocument1 pageTDS Hydrazine HydrateMarthinus BoxyPas encore d'évaluation

- Allen CCP 25.7.21 Jee Main Unit Test Nurture Ques Jee 2023Document13 pagesAllen CCP 25.7.21 Jee Main Unit Test Nurture Ques Jee 2023sounitbPas encore d'évaluation

- Hardness Conversion ChartDocument10 pagesHardness Conversion ChartAshutosh SinghPas encore d'évaluation

- Experiment 8Document4 pagesExperiment 8api-252952453100% (3)

- Thermocouple: From Wikipedia, The Free EncyclopediaDocument18 pagesThermocouple: From Wikipedia, The Free EncyclopediaM.A. NANTHAKUMARPas encore d'évaluation

- Handbook Best Practice Dropped Object Management - Engelsk - GodkjentDocument108 pagesHandbook Best Practice Dropped Object Management - Engelsk - Godkjentmiguel angelPas encore d'évaluation

- Design and Development of SMA-actuated CPR SystemDocument11 pagesDesign and Development of SMA-actuated CPR SystemHarsh NigamPas encore d'évaluation

- Study On The Second Stage of Chalcocite Leaching in Column With RedoxDocument12 pagesStudy On The Second Stage of Chalcocite Leaching in Column With RedoxFrancisco CampbellPas encore d'évaluation

- Gunstone 61 eDocument0 pageGunstone 61 esusu222000Pas encore d'évaluation

- Cal OSHA Handbook 2022Document92 pagesCal OSHA Handbook 2022Russell SadlerPas encore d'évaluation

- 04 Melt Indexer Primer PDFDocument4 pages04 Melt Indexer Primer PDFNia SyafiqqPas encore d'évaluation

- All in One - 10th Class em - Fa-2Document35 pagesAll in One - 10th Class em - Fa-2sai ramxeroxPas encore d'évaluation