Académique Documents

Professionnel Documents

Culture Documents

Venturimeter Experiment

Transféré par

coutohahaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Venturimeter Experiment

Transféré par

coutohahaDroits d'auteur :

Formats disponibles

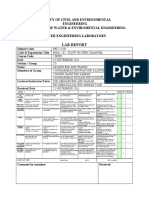

School of Civil and

Building Engineering

CVA002

FLUID MECHANICS

LABORATORY EXPERIMENT - FORMATIVE ASSESSMENT

VENTURI METER

Introduction

The venturimeter consists of a temporary reduction in the diameter of a pipe. The smaller pipe diameter is

called the Throat. The reduction in diameter forces the velocity to increase (continuity equation) which leads

to a corresponding lowering in pressure (Bernoulli equation).

It is mainly used for measuring the flow of fluids in pipes running full. It is also sometimes used to inject fluids

into the pipe. The venturimeter has a number of advantages over other flow measuring devices namely:

there is no obstruction to the fluid flow; and there are no moving parts so maintenance is minimal.

Theory:

The discharge through a venturimeter is given by:

Q1 CdA1

2( P1 P 2)

A12

2 1

A2

(Eq. 1)

or, in terms of piezometric head,

Q1 CdA1

where

2 g ( H 1 H 2)

A12

2 1

A2

Q = flow rate in m /s

(Eq. 2)

Cd = coefficient of discharge

A1 = main pipe area (Point 1 on Figure 2 and 4)

A2 = area of throat (Point 4 in Fig 2 / Point 3 in Fig 4)

P1 = pressure in pipe

P2 = pressure in throat

H1 = piezometer reading in main pipe at entrance

H2 = piezometer reading in throat.

or

This can be written as

where

K CdA1

2g

A12

2 1

A2

Dr Ian Pattison

(Eq. 3)

(Eq. 4)

Nov-14

CVA002 LABORATORY EXPERIMENTS

VENTURIMETER

Experiment

You will conduct a series of experiments at different flow rates to evaluate the performance of the

Venturimeter to measure discharge. The whole group should get experience of using the flow measurement

apparatus.

Objectives:

i)

To determine the overall value of Cd.

ii)

To examine the variation of Cd with discharge.

iii)

To compare measured pressure profile along the meter with the theoretical profile (for the

maximum and minimum flows only).

Apparatus:

You will be using the Venturimeter to measure the flow through the pipe. There are two different pieces of

equipment, but they both work on the same principles. However, the two equipment benches have slightly

different operating procedures.

Procedure:

Bench with ELEVEN manometer tapping points

Manometer manifold

Manifold air bleed

Manifold air inlet &

pump

Manometer tubes

Venturimeter

Flow control valve

Figure 1 Alternative manometer unit with eleven tappings

10

11

Direction of flow

Position

10

11

Distance (mm)

20.5

33.2

47.4

61.6

74.3

87.0

99.7

112.4

125.1

147.3

Diameter (mm)

25.4

23.3

18.5

15.9

16.5

17.9

19.2

20.6

21.9

23.3

25.4

Figure 2

Cross section through the venturimeter with 11 manometer tapping points.

CVA002 LABORATORY EXPERIMENTS

VENTURIMETER

Open the ON/OFF valve and close the control valve. Switch on the pump.

Gradually open the control valve until water starts to rise up the manometer tubes. Wait for all the air

bubbles to be evacuated from the system. Continue opening the control valve until the water level in one of

the tubes is near to the top of the measuring scale.

EITHER pump air into the top manifold using the cycle pump provided OR release air from the manifold by

loosening the manifold air bleed to depress/raise the surface levels in the tubes. Continue opening the valve

until the maximum range of manometer readings is reached. This corresponds with the maximum flow that

can be measured by the unit.

Take three sets of readings of all the water levels in the manometer tubes, each set being taken by a

different member of the group and write your results in Table 1. Compare the results to see if they agree. If

they dont agree take further sets until agreement is reached.

Calculate the actual flow rate through the venturimeter by measuring the time taken to collect a fixed volume

of water. Follow these steps:

Close the measuring tank outlet valve

Allow the water level in the measuring tank to rise to about 20 litres

Using the stopwatch provided measure the time (in seconds) to collect a fixed quantity of water. The

volume collected should take at least 60 seconds to collect. Write your results in the Table.

For very low flows, use the measuring jug.

Repeat the measurement at least three times or until you have three readings within one second of

each other.

Remember to empty the measuring tank periodically or your equipment will stop working.

Slightly reduce the flow rate and take another set of measurements. Continue until the flow is almost zero.

Take FIVE sets of reading between the maximum and zero.

You may have to add or remove air from the top of the manometer from time to time to keep the readings

within the range of the measuring scales but do not do this whilst taking a set of measurements

Bench with SIX manometer tapping points

Figure 3 Standard experimental bench with six manometer tappings

CVA002 LABORATORY EXPERIMENTS

Position

2

Area (mm )

VENTURIMETER

338.6

233.5

84.6

170.2

255.2

338.6

Figure 4

Cross section through the venturimeter with 6 manometer tapping points.

The following procedure is required for starting the venturimeter prior to taking readings:

CLOSE the ON/OFF valve

Switch on the water pump

Make sure the flow control valve is OPEN SLIGHTLY

OPEN the ON/OFF valve fully

OPEN the BLACK air bleed valve

Allow water to flow through the system until all the air is removed

CLOSE the BLACK air bleed valve

CLOSE the ON/OFF valve

OPEN the WHITE air bleed valve and allow the water levels in the manometer tubes to drop to the

zero mark

CLOSE the WHITE air bleed valve

OPEN the ON/OFF valve fully

Adjust the control valve until the maximum flow reading is achieved on the manometer.

You are now ready to start taking readings. Take three sets of readings of all the water levels in the

manometer tubes, each set being taken by a different member of the group and write your results in the

Table. Compare the results to see if they agree. If they dont agree take further sets until agreement is

reached.

Calculate the actual flow rate through the venturimeter by measuring the time taken to collect a fixed volume

of water. Follow these steps:

Close the measuring tank outlet valve

Allow the water level in the measuring tank to rise to about 20 litres

Using the stopwatch provided measure the time (in seconds) to collect a fixed quantity of water. The

volume collected should take at least 60 seconds to collect. Write your results in the Table.

For very low flows, use the measuring jug.

Repeat the measurement at least three times or until you have three readings within one second of

each other.

Remember to empty the measuring tank periodically or your equipment will stop working.

Slightly reduce the flow rate and take another set of measurements. Continue until the flow is almost zero.

Take FIVE sets of reading between the maximum and zero.

CVA002 LABORATORY EXPERIMENTS

VENTURIMETER

Results

Enter all your readings in the appropriate table below. An electronic copy of the Tables can be downloaded

from LEARN.

Table 1

Volume

(Litres)

Venturimeter results table for 11 manometer apparatus

Time

(secs)

Avg

time

(m /s)

Manometer readings

1

10

11

CVA002 LABORATORY EXPERIMENTS

Table 2

Volume

(Litres)

VENTURIMETER

Venturimeter results table for 6 manometer apparatus

Time

(Seconds)

Average

Time (s)

Discharge

3

(m /s)

Manometer Readings

1

CVA002 LABORATORY EXPERIMENTS

VENTURIMETER

Analysis

Plot Q (discharge) by H (difference in head between inlet and throat of Venturimeter). What is the

shape of the graph? What does this mean?

Take log10 of both axes. What is the shape of the line graph now? Fit a line of best fit to your data.

What type of relationship is it? What value of n did you expect?

HINT See Equation 3 in theory section of this handout, a plot of log10 Q vs log10 H should be a

straight line of slope n and intercept log K, i.e:

Log10 Q = log10 K + n log10 H

Log Q

Gradient = n

0

Log H

Intercept = Log K

Using Equation 4 in the theory section of this handout, calculate the average value of Cd

Calculate the value of Cd for each of the 5 discharges that you used using the value of n = 1/2 and

plot against Q.

The actual pressure at each piezometer tapping is not simply equal to gh, as the pressure above the

piezometers is not atmospheric. Comparative pressure is thus used, i.e., from Bernoulli,

Where the suffix n denotes the piezometer positions from 1 to 11, or 1 to 6 depending on the apparatus you

used

Reducing to dimensionless terms by dividing by the velocity head in the throat,

Using this equation, the dimensionless pressure head

OR

is derived for each piezometer position along the venturimeter.

Plot the observed values of H along the length of the venturimeter tube for the maximum and

minimum discharges. (Both lines should on same axes)

CVA002 LABORATORY EXPERIMENTS

Also on the same graph plot the theoretical value

VENTURIMETER

( )

( )

or

for comparison.

Important Note:

Tabulate all your calculations before plotting each graph and present a full specimen calculation of each

element of the analysis.

An accurate analysis requires accurate data (itself subject to observational error) and accurate plots.

Discussion

1. Comment on your original data, do you think it was accurate, how might you improve it if you were to

repeat the experiment?

2. What is your calculated value of n and how does it compare with what you expected?

3. What is your average Cd value and how does it compare with published values. Provide references

for your sources of information.

4. How does Cd vary with discharge? Is this what you would expect? If not, what should you have

expected? Provide references for your information.

5. Compare the dimensionless pressure heads plotted on the same graph and explain what they mean.

Explain any deviation between the theoretical and the two observed values.

Evaluation

-

Were the projects aims and objectives achieved?

Discuss the limitations of your experiment and any errors these may have caused.

How could your series of experiments be improved?

Report Presentation

The report must be structured. Be sure to include:

Title page (title, authors and date);

Methods

Results and Analysis;

Discussion, references and appendices.

The report must be typed using Arial 10 or Times Roman 12 fonts. Lines should be single spaced with a

single line space between paragraphs. Pages should have 2.5 cm margins all round. Graphical items should

be generated using a spreadsheet and electronically pasted into the report.

All pages should be numbered except the title page. All tables, figures and graphs must be properly labelled

and referred to in the text.

All units must follow the MKS system.

Calculations may be done by hand, computer or programmable calculator. If programs are used a sample

hand calculation must be presented. This allows the reader to check for errors.

Numbers should be displayed to three significant figures.

Any information obtained from other sources must be referenced in the text at the point where it is used and

given in full at the end in a reference section.

Marks will be deducted for poor spelling and poor grammar. Use the spell checker!

The original hand written data must be included as appendices.

8

CVA002 LABORATORY EXPERIMENTS

VENTURIMETER

Assessment

Group Report = 100%

Group Report

-

Method = 10%

Outline method used, justify decisions made and assumptions included.

Quality of Results = 20%

Data collected from the whole range of flow in uniform spacing, no anomalies, and sufficient

iterations to obtain good averages.

Analysis = 30%

Tables clearly presented for each analysis, specimen calculations provided, graphs drawn

accurately

Discussion/Evaluation = 30%

All parts of the experiment and analysis discussed, results of analysis summarised, expected values

presented

Report Presentation / References = 10%

Presentation of figures/graphs, structure of report, use of references

Further reading:

Douglas, Gasiorek and Swaffield: Fluid Mechanics. Ch.6.10.

Douglas and Matthews: Solving Problems in Fluid Mechanics, Vol 1, Ch. 6.1.

British Standard 5167 4:2003

Vous aimerez peut-être aussi

- The Van Conversion Bible - The Ultimate Guide To Converting A CampervanDocument170 pagesThe Van Conversion Bible - The Ultimate Guide To Converting A CampervanPil100% (3)

- Advanced Machining User Guide PDFDocument250 pagesAdvanced Machining User Guide PDFDaniel González JuárezPas encore d'évaluation

- GTT NO96 LNG TanksDocument5 pagesGTT NO96 LNG TanksEdutamPas encore d'évaluation

- V Notch PracticalDocument13 pagesV Notch PracticalAnushaBheenuck0% (2)

- Report Hydraulic JumpsDocument11 pagesReport Hydraulic JumpsMayLeongPas encore d'évaluation

- Pelton Turbine LabDocument12 pagesPelton Turbine LablufimanPas encore d'évaluation

- Project of Consumer BehaviourDocument28 pagesProject of Consumer BehaviourNaveed JuttPas encore d'évaluation

- V-Notch ExperimentDocument5 pagesV-Notch ExperimentKheshav Jhundoo100% (2)

- Material LaboratoryDocument14 pagesMaterial LaboratoryAnonymous tLXKwTPas encore d'évaluation

- Energy Losses in Pipes: Experiment # 4Document4 pagesEnergy Losses in Pipes: Experiment # 4محمد جوادPas encore d'évaluation

- Hydraulic Laboratory Civil Engineering Department Sultan Azlan Shah PolytechnicDocument12 pagesHydraulic Laboratory Civil Engineering Department Sultan Azlan Shah PolytechnicSyafiq Roslan75% (4)

- 3-Matic 14 - User Manual 15Document169 pages3-Matic 14 - User Manual 15Oliver RuizPas encore d'évaluation

- MouthpieceDocument5 pagesMouthpieceAshish VermaPas encore d'évaluation

- Duhok Polytechnic University Technical College of Engineering Petrochemical Department Transport Phenomena Fourth Year-2018-2019Document10 pagesDuhok Polytechnic University Technical College of Engineering Petrochemical Department Transport Phenomena Fourth Year-2018-2019Bryar XalilPas encore d'évaluation

- Consumer Research ProcessDocument78 pagesConsumer Research ProcessShikha PrasadPas encore d'évaluation

- Lab 4-Friction Losses and Minor LossesDocument7 pagesLab 4-Friction Losses and Minor LossesJJ Sean CruzPas encore d'évaluation

- Venturi Meter 1Document13 pagesVenturi Meter 1Da Champ CenaPas encore d'évaluation

- Lab Soil-Hydrometer TestDocument6 pagesLab Soil-Hydrometer TestSyed Zulfaizzuan AljufriPas encore d'évaluation

- Theory VenturiDocument7 pagesTheory VenturiMahendranath RamakrishnanPas encore d'évaluation

- Venturi MeterDocument15 pagesVenturi MeterFatimah BadruddinPas encore d'évaluation

- 5 Calibration of Triangular NotchDocument8 pages5 Calibration of Triangular Notchkanavan monPas encore d'évaluation

- Centre of Hidrostatic PressureDocument16 pagesCentre of Hidrostatic PressureVanithaa Ponnaiah0% (1)

- Liquid and Plastic LimitDocument13 pagesLiquid and Plastic LimitDariusAngelitoPas encore d'évaluation

- Lab 2 Mini FLow ChannelDocument16 pagesLab 2 Mini FLow ChannelIr Fik TPas encore d'évaluation

- FULL REPORT Flow Over WeirDocument18 pagesFULL REPORT Flow Over WeirShahrul Ikram0% (1)

- Flow Visualization ExperimentDocument9 pagesFlow Visualization ExperimentPei Shan ChoongPas encore d'évaluation

- Lab7-Phelton Turbine Experiment-UpdatedDocument7 pagesLab7-Phelton Turbine Experiment-Updatedtomtoms92Pas encore d'évaluation

- Report Buckling of StructsDocument7 pagesReport Buckling of StructsAnonymous 59kjvq4OLBPas encore d'évaluation

- Final Experiment HydraulicsDocument12 pagesFinal Experiment HydraulicsKevin OngjuncoPas encore d'évaluation

- Venturimeter Exp. 250412Document4 pagesVenturimeter Exp. 250412abhishekpatil21Pas encore d'évaluation

- Venturimeter 28Document10 pagesVenturimeter 28Agyeman EmmanuelPas encore d'évaluation

- L2 Full PDFDocument22 pagesL2 Full PDFMas Idayu RosliPas encore d'évaluation

- Flow in Open ChannelDocument24 pagesFlow in Open ChannelSue IlaPas encore d'évaluation

- StabilityDocument5 pagesStabilityJenelia Jojo50% (2)

- Sieve AnalysisDocument7 pagesSieve AnalysisMarc Anthony de VillaPas encore d'évaluation

- Atterberg LimitsDocument6 pagesAtterberg LimitsMuhammadZAmjadPas encore d'évaluation

- Orifice and Free Jet Flow Experiment: Updated 8/9/06Document3 pagesOrifice and Free Jet Flow Experiment: Updated 8/9/06shaneshaneshaneshanePas encore d'évaluation

- Experiment 2 - Basic HydrologyDocument18 pagesExperiment 2 - Basic HydrologySYaz WAni100% (1)

- Stability of Floating Bodies: Hydraulic Lab Practical - 2Document7 pagesStability of Floating Bodies: Hydraulic Lab Practical - 2tarumPas encore d'évaluation

- Experiment 1: Flow Over A NotchDocument15 pagesExperiment 1: Flow Over A NotchLai YenPas encore d'évaluation

- CE 2020 - Fluid Mechanics LaboratoryDocument67 pagesCE 2020 - Fluid Mechanics LaboratoryMd.Tarequl IslamPas encore d'évaluation

- C2-Consistency Cement PasteDocument4 pagesC2-Consistency Cement PasteMuhamad FarhanPas encore d'évaluation

- Open Channel LabDocument27 pagesOpen Channel Labஅருண்ராஜ் கிருஷ்ணன்சாமிPas encore d'évaluation

- FM05 Pitot Static Tube PDFDocument2 pagesFM05 Pitot Static Tube PDFAnonymous thaRdEcpD100% (2)

- Flow Over WeirsDocument4 pagesFlow Over WeirsZAXPas encore d'évaluation

- Experiment 2, Flow Over A Broad Crested WeirDocument4 pagesExperiment 2, Flow Over A Broad Crested WeirRayanPas encore d'évaluation

- Lab Report 2Document16 pagesLab Report 2Limmy Yingran0% (1)

- Venturi Meter Experiment ProceduresDocument2 pagesVenturi Meter Experiment ProceduresAnonymous mRBbdopMKf100% (1)

- Center of PressureDocument3 pagesCenter of PressureTemoteo L Pupa IIIPas encore d'évaluation

- Structure Lab-Three Hinge ArcDocument13 pagesStructure Lab-Three Hinge ArcFendi Roon100% (1)

- Lab Report For Venturi MeterDocument9 pagesLab Report For Venturi MeterRichard Puni92% (12)

- Hydraulic Laboratory Civil Engineering Department Sultan Azlan Shah Polytechnic Experiment: 2 Title: Impact of Jet TestDocument8 pagesHydraulic Laboratory Civil Engineering Department Sultan Azlan Shah Polytechnic Experiment: 2 Title: Impact of Jet TestAzrol Azmir Long100% (3)

- Hydraulics Sniper ReportDocument8 pagesHydraulics Sniper ReportKhumo Ezekiel MoraPas encore d'évaluation

- Cussons: TechnologyDocument2 pagesCussons: TechnologyhaudeitbaPas encore d'évaluation

- Experiment 6 Hydraulics LabDocument6 pagesExperiment 6 Hydraulics LabTinaPas encore d'évaluation

- Full As Contoh Member AkashahDocument29 pagesFull As Contoh Member AkashahWayen Bulat100% (1)

- Centre of Pressure Level 1Document12 pagesCentre of Pressure Level 1Mohd Azeem RizalPas encore d'évaluation

- Venturimeter Report PDFDocument7 pagesVenturimeter Report PDFAhmed M. El-DyastyPas encore d'évaluation

- Concrete Mix Design Report PDFDocument32 pagesConcrete Mix Design Report PDFMohamed AhmedPas encore d'évaluation

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985D'EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Pas encore d'évaluation

- Experiment No 7Document7 pagesExperiment No 7Faizan Ahmed67% (3)

- Page For Main Menu: Typical Results Using The Equipment Below. Return To Lab Experiments PageDocument13 pagesPage For Main Menu: Typical Results Using The Equipment Below. Return To Lab Experiments PagepaniuatuiPas encore d'évaluation

- Ce422l E5 4eg2Document5 pagesCe422l E5 4eg2Christine Joyce A. CortezPas encore d'évaluation

- Lab 4 (Thermofluids Lab)Document32 pagesLab 4 (Thermofluids Lab)Adnan Nanda0% (1)

- Energy Losses in BendsDocument8 pagesEnergy Losses in BendsVikramSingh0% (3)

- Flowmeter DEMONSTRATIONDocument20 pagesFlowmeter DEMONSTRATIONAfiq IkhwanPas encore d'évaluation

- PWD BlueRoofs One SheetDocument1 pagePWD BlueRoofs One SheetcoutohahaPas encore d'évaluation

- RANGARAJAN 2008 - New Directions in Real-Time and Dynamic Control For Stormwater ManagementDocument7 pagesRANGARAJAN 2008 - New Directions in Real-Time and Dynamic Control For Stormwater ManagementcoutohahaPas encore d'évaluation

- TORAN 2016 - Water Level Loggers As A Low-Cost Tool For Monitoring of Stormwater Control MeasuresDocument10 pagesTORAN 2016 - Water Level Loggers As A Low-Cost Tool For Monitoring of Stormwater Control MeasurescoutohahaPas encore d'évaluation

- PWD BlueRoofs One SheetDocument1 pagePWD BlueRoofs One SheetcoutohahaPas encore d'évaluation

- Innovation in Stormwater Management in Canada - The Way FowardDocument6 pagesInnovation in Stormwater Management in Canada - The Way FowardcoutohahaPas encore d'évaluation

- The Potential of Green Infrastructure Application in Urban Runoff Control ForDocument10 pagesThe Potential of Green Infrastructure Application in Urban Runoff Control ForcoutohahaPas encore d'évaluation

- Rooftop DetentionDocument2 pagesRooftop DetentioncoutohahaPas encore d'évaluation

- Urban Drainage in Developing CountriesDocument4 pagesUrban Drainage in Developing CountriescoutohahaPas encore d'évaluation

- VERSINI 2018 - A Distributed Modelling Approach To Assess The Use of Blue and GreenInfrastructures To Ful L Stormwater Management RequirementsDocument4 pagesVERSINI 2018 - A Distributed Modelling Approach To Assess The Use of Blue and GreenInfrastructures To Ful L Stormwater Management RequirementscoutohahaPas encore d'évaluation

- On-Site Stormwater Detention Guide: Document Current at 21 August 2014Document7 pagesOn-Site Stormwater Detention Guide: Document Current at 21 August 2014shafiqPas encore d'évaluation

- BROWN 2006 - Implementation Impediments To Institutionalising The Practice of Sustainable Urban Water Management PDFDocument8 pagesBROWN 2006 - Implementation Impediments To Institutionalising The Practice of Sustainable Urban Water Management PDFcoutohahaPas encore d'évaluation

- Optimization of Waste Collection and TransportDocument11 pagesOptimization of Waste Collection and TransportcoutohahaPas encore d'évaluation

- Green Stormwater Infrastructure Use and Perception On Related Smart ServicesDocument10 pagesGreen Stormwater Infrastructure Use and Perception On Related Smart ServicescoutohahaPas encore d'évaluation

- Practical Hydraulics (240-266) PDFDocument266 pagesPractical Hydraulics (240-266) PDFcoutohahaPas encore d'évaluation

- BARBOSA 2012 - Key Issues For Sustainable Urban Stormwater Management PDFDocument12 pagesBARBOSA 2012 - Key Issues For Sustainable Urban Stormwater Management PDFcoutohahaPas encore d'évaluation

- MSW Incineration Decision Makers Guide 2000 PDFDocument18 pagesMSW Incineration Decision Makers Guide 2000 PDFMaximiliano MarineroPas encore d'évaluation

- Definition of Sustainable Packaging PDFDocument10 pagesDefinition of Sustainable Packaging PDFProf C.S.PurushothamanPas encore d'évaluation

- MC 10226555 0001Document7 pagesMC 10226555 0001Hema IbraPas encore d'évaluation

- ADAMDocument12 pagesADAMreyPas encore d'évaluation

- Odontogenic CystsDocument5 pagesOdontogenic CystsBH ASMRPas encore d'évaluation

- Methods of ResearchDocument12 pagesMethods of ResearchArt Angel GingoPas encore d'évaluation

- Oxford Handbooks Online: From Old To New Developmentalism in Latin AmericaDocument27 pagesOxford Handbooks Online: From Old To New Developmentalism in Latin AmericadiegoPas encore d'évaluation

- Juegos PPCDocument8 pagesJuegos PPCikro995Pas encore d'évaluation

- Emancipation Fact SheetDocument2 pagesEmancipation Fact SheetKeelie SmithPas encore d'évaluation

- Bridging: Transportation: Chapter 3: The Transportation Planning ProcessDocument28 pagesBridging: Transportation: Chapter 3: The Transportation Planning ProcesspercyPas encore d'évaluation

- AutoCAD Civil 3D Performance Optimization 2Document5 pagesAutoCAD Civil 3D Performance Optimization 2Renukadevi RptPas encore d'évaluation

- Baterías YuasaDocument122 pagesBaterías YuasaLuisPas encore d'évaluation

- Peace Corps Guatemala Welcome Book - June 2009Document42 pagesPeace Corps Guatemala Welcome Book - June 2009Accessible Journal Media: Peace Corps DocumentsPas encore d'évaluation

- Mysuru Royal Institute of Technology. Mandya: Question Bank-1Document2 pagesMysuru Royal Institute of Technology. Mandya: Question Bank-1chaitragowda213_4732Pas encore d'évaluation

- Important Questions Mba-Ii Sem Organisational BehaviourDocument24 pagesImportant Questions Mba-Ii Sem Organisational Behaviourvikas__ccPas encore d'évaluation

- Human Resource Management - Introduction - A Revision Article - A Knol by Narayana RaoDocument7 pagesHuman Resource Management - Introduction - A Revision Article - A Knol by Narayana RaoHimanshu ShuklaPas encore d'évaluation

- Financial Analysis of OGDCLDocument16 pagesFinancial Analysis of OGDCLsehrish_sadaqat7873100% (1)

- JQuery Interview Questions and AnswersDocument5 pagesJQuery Interview Questions and AnswersShailesh M SassPas encore d'évaluation

- Gcse Economics 8136/1: Paper 1 - How Markets WorkDocument19 pagesGcse Economics 8136/1: Paper 1 - How Markets WorkkaruneshnPas encore d'évaluation

- Digirig Mobile 1 - 9 SchematicDocument1 pageDigirig Mobile 1 - 9 SchematicKiki SolihinPas encore d'évaluation

- 11 - Savulescu Et Al (2020) - Equality or Utility. Ethics and Law of Rationing VentilatorsDocument6 pages11 - Savulescu Et Al (2020) - Equality or Utility. Ethics and Law of Rationing VentilatorsCorrado BisottoPas encore d'évaluation

- Poverty Eradication Cluster HLPF Position Paper With Case StudiesDocument4 pagesPoverty Eradication Cluster HLPF Position Paper With Case StudiesJohn Paul Demonteverde ElepPas encore d'évaluation

- What Is Bitcoin MiningDocument4 pagesWhat Is Bitcoin MiningCarmen M Leal CurielPas encore d'évaluation

- Roundup WG Bula MonsantoDocument16 pagesRoundup WG Bula MonsantodandanyddPas encore d'évaluation

- Chapter 1Document2 pagesChapter 1Reymond Homigop GalarpePas encore d'évaluation