Académique Documents

Professionnel Documents

Culture Documents

J8B Track - Check Adjust

Transféré par

catoperatorsCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

J8B Track - Check Adjust

Transféré par

catoperatorsDroits d'auteur :

Formats disponibles

Advanced Full Text Search - SEBU7763 - D8T Track-Type Tractor

Page 1 of 5

Shutdown SIS

Previous Screen

Product: NO EQUIPMENT SELECTED

Model: NO EQUIPMENT SELECTED

Configuration: NO EQUIPMENT SELECTED

Operation and Maintenance Manual

D8T Track-Type Tractor

Media Number -SEBU7763-03

Publication Date -01/07/2009

Date Updated -23/07/2009

i02877237

Track - Check/Adjust

SMCS - 4170-036

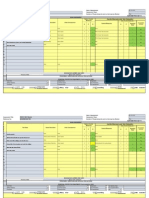

Illustration 1

g01015715

Check the track adjustment. Check the track for wear and for excessive dirt buildup.

Grease is under high pressure.

Grease coming out of the relief valve under pressure can penetrate the

body causing injury or death.

Do not watch the relief valve to see if grease is escaping. Watch the

track or track adjustment cylinder to see if the track is being loosened.

Loosen the relief valve only one turn.

1. Move the machine forward. Allow the machine to coast to a stop without the use of the service

https://sisweb.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 07/02/2011

Advanced Full Text Search - SEBU7763 - D8T Track-Type Tractor

Page 2 of 5

brakes. Adjust the tracks while you are in the machine's typical operating conditions. If

packing conditions prevail on the workplace, the tracks should be adjusted without removing

the packed material.

2. To measure the sag in the track, stretch a string over the grousers that are between the sprocket

and the front idler. Take the measurement from the string to the top of the grouser at the

maximum measurement. Dimension (A) is the maximum distance between the string and the

grouser.

Illustration 2

g01109482

If a machine does not have carrier rollers, the sag in the track is measured between the sprocket and

the front idler. The correct adjustment of dimension (A) for conventional undercarriage is 115 10

mm (4.5 .4 inch).

See the following tables for information on the SystemOne Undercarriage, if equipped.

Table 1

Track Sag

No Carrier Roller

Conventional

SystemOne (1)

(1)

Minimum

Target

Maximum

105 mm (4.1 inch)

115 mm (4.5 inch)

125 mm (4.9 inch)

80 mm (3.15 inch)

110 mm (4.30 inch)

120 mm (4.72 inch)

Machines with the SystemOne undercarriage have tighter dimensions for track sag.

https://sisweb.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 07/02/2011

Advanced Full Text Search - SEBU7763 - D8T Track-Type Tractor

Illustration 3

Page 3 of 5

g01118207

If the machine is equipped with a carrier roller, calculate the average of dimension (B) and

dimension (C) . The correct average value is 65 10 mm (2.6 0.4 inch) for the conventional

undercarriage.

Table 2

Track Sag

Carrier Roller

Conventional

SystemOne (1)

Minimum

Target

Maximum

55 mm (2.2 inch)

65 mm (2.6 inch)

75 mm (3.0 inch)

45 mm (1.80 inch)

60 mm (2.40 inch)

70 mm (2.8 inch)

Loose Track Adjustment

https://sisweb.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 07/02/2011

Advanced Full Text Search - SEBU7763 - D8T Track-Type Tractor

Illustration 4

Page 4 of 5

g01019107

NOTICE

Do not attempt to tighten track when dimension (D) is 152 mm (6.0

inch) or more. The hard bottom attachment can be tightened to the

point were (D) is no more than 152 mm (6.0 inch)Contact your

Caterpillar dealer for track service or instructions.

1. Remove the access cover.

Illustration 5

g01019116

https://sisweb.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 07/02/2011

Advanced Full Text Search - SEBU7763 - D8T Track-Type Tractor

Page 5 of 5

2. Add multipurpose grease (MPGM) through track adjustment valve (1) . Add the MPGM until

dimension (A, B, C) is correct.

3. Operate the machine back and forth in order to equalize the pressure. Allow the machine to

coast to a complete stop. Do not use the brakes.

4. Remeasure dimension (D) .

Tight Track Adjustment

1. Loosen relief valve (2) by one turn of 360 degrees. Allow the grease to escape.

2. Close the relief valve.

3. Add MPGM through track adjustment valve (1) . Add grease until dimension (A, B, C) is

correct.

4. Install the access cover.

Bolt Torque for Track Shoes

The torque requirement for track shoe bolts is 650 70 Nm (480 50 lb ft). Tighten the bolts for an

additional 120 degrees. If you are using bolts with a master link, tighten the bolts to a torque of 650

70 Nm (480 50 lb ft). Then, tighten the bolts for an additional 120 degrees.

Copyright 1993 - 2011 Caterpillar Inc.

All Rights Reserved.

Private Network For SIS Licensees.

Mon Feb 7 16:21:12 EST 2011

https://sisweb.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 07/02/2011

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Poka Yoke BDocument31 pagesPoka Yoke BjaymuscatPas encore d'évaluation

- Financial Market and Portfolio Management Assignment 2Document6 pagesFinancial Market and Portfolio Management Assignment 2leeroy mekiPas encore d'évaluation

- Line Sets in Oracle Order ManagementDocument9 pagesLine Sets in Oracle Order ManagementS S PatelPas encore d'évaluation

- Task Based Risk Assesment FormDocument2 pagesTask Based Risk Assesment FormKolluri SrinivasPas encore d'évaluation

- Lecture Notes in Airport Engineering PDFDocument91 pagesLecture Notes in Airport Engineering PDFMaya RajPas encore d'évaluation

- Company Name Email Id Contact Location: 3 Praj Industries Limited Yogesh960488815Pune-Nagar Road, SanaswadiDocument65 pagesCompany Name Email Id Contact Location: 3 Praj Industries Limited Yogesh960488815Pune-Nagar Road, SanaswadiDhruv Parekh100% (1)

- Volvo Ingles ResolverDocument12 pagesVolvo Ingles ResolvercatoperatorsPas encore d'évaluation

- Motor Volquete VolvoDocument4 pagesMotor Volquete VolvocatoperatorsPas encore d'évaluation

- Sistemas Del VolqueteDocument3 pagesSistemas Del VolquetecatoperatorsPas encore d'évaluation

- CONTROL Y LOS INDICADORES RDocument3 pagesCONTROL Y LOS INDICADORES RcatoperatorsPas encore d'évaluation

- Colores en Seguridad InglesDocument21 pagesColores en Seguridad InglescatoperatorsPas encore d'évaluation

- Motor Volquete Volvo PDFDocument4 pagesMotor Volquete Volvo PDFcatoperatorsPas encore d'évaluation

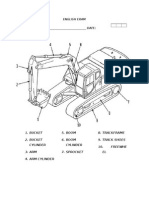

- Examen de Ingles Tractor OrugaDocument4 pagesExamen de Ingles Tractor OrugacatoperatorsPas encore d'évaluation

- Rodillo Ingles 2 PDFDocument8 pagesRodillo Ingles 2 PDFcatoperatorsPas encore d'évaluation

- Montacarga InglesDocument3 pagesMontacarga InglescatoperatorsPas encore d'évaluation

- Rodillo Ingles 2 PDFDocument8 pagesRodillo Ingles 2 PDFcatoperatorsPas encore d'évaluation

- Boost PortDocument3 pagesBoost PortcatoperatorsPas encore d'évaluation

- English Exam Surnames and NAMES: - DATE: I. TranslateDocument4 pagesEnglish Exam Surnames and NAMES: - DATE: I. TranslatecatoperatorsPas encore d'évaluation

- Rodillo Ingles 3Document14 pagesRodillo Ingles 3catoperatorsPas encore d'évaluation

- Rodillo InglesDocument5 pagesRodillo InglescatoperatorsPas encore d'évaluation

- Rodillo Ingles 2 PDFDocument8 pagesRodillo Ingles 2 PDFcatoperatorsPas encore d'évaluation

- Control y Los Indicadores PDFDocument9 pagesControl y Los Indicadores PDFcatoperatorsPas encore d'évaluation

- Rodillo Ingles 2Document9 pagesRodillo Ingles 2catoperatorsPas encore d'évaluation

- EXAMEN DE INGLES MontacargaDocument3 pagesEXAMEN DE INGLES MontacargacatoperatorsPas encore d'évaluation

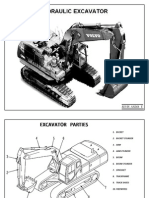

- Excavadora Ingles 2 PDFDocument13 pagesExcavadora Ingles 2 PDFcatoperatorsPas encore d'évaluation

- Minicargador Scooper Resolver PDFDocument7 pagesMinicargador Scooper Resolver PDFcatoperatorsPas encore d'évaluation

- Minicargador Scooper ResolverDocument7 pagesMinicargador Scooper ResolvercatoperatorsPas encore d'évaluation

- English Exam Surnames and NAMES: - DATE: I. TranslateDocument4 pagesEnglish Exam Surnames and NAMES: - DATE: I. TranslatecatoperatorsPas encore d'évaluation

- Excavadora InglesDocument14 pagesExcavadora InglescatoperatorsPas encore d'évaluation

- EXAMEN DE INGLES ScoopDocument3 pagesEXAMEN DE INGLES ScoopcatoperatorsPas encore d'évaluation

- Control y Los IndicadoresDocument8 pagesControl y Los IndicadorescatoperatorsPas encore d'évaluation

- Excavadora Ingles PDFDocument12 pagesExcavadora Ingles PDFcatoperatorsPas encore d'évaluation

- Excavadora Ingles 2 PDFDocument13 pagesExcavadora Ingles 2 PDFcatoperatorsPas encore d'évaluation

- English exam translationDocument4 pagesEnglish exam translationcatoperatorsPas encore d'évaluation

- Excavadora Ingles 2Document14 pagesExcavadora Ingles 2catoperatorsPas encore d'évaluation

- Camion Minero Ingles PDFDocument13 pagesCamion Minero Ingles PDFcatoperatorsPas encore d'évaluation

- Service Manual: DCR-DVD150E/DVD450E/DVD650/ DVD650E/DVD850/DVD850EDocument71 pagesService Manual: DCR-DVD150E/DVD450E/DVD650/ DVD650E/DVD850/DVD850EJonathan Da SilvaPas encore d'évaluation

- TMS Software ProductsDocument214 pagesTMS Software ProductsRomica SauleaPas encore d'évaluation

- Marking SchemeDocument8 pagesMarking Schememohamed sajithPas encore d'évaluation

- COA Full Syllabus-CSEDocument3 pagesCOA Full Syllabus-CSEAMARTYA KUMARPas encore d'évaluation

- Ap22 FRQ World History ModernDocument13 pagesAp22 FRQ World History ModernDylan DanovPas encore d'évaluation

- Open Recruitment Member Kejar Mimpi Periode 2023 (Responses)Document22 pagesOpen Recruitment Member Kejar Mimpi Periode 2023 (Responses)Sophia Dewi AzzahraPas encore d'évaluation

- The Mpeg Dash StandardDocument6 pagesThe Mpeg Dash Standard9716755397Pas encore d'évaluation

- Parents Day Script - PDF - Schools - LeisureDocument17 pagesParents Day Script - PDF - Schools - LeisureNAIDU SHAKEENAPas encore d'évaluation

- SUTI Report - Metro ManilaDocument87 pagesSUTI Report - Metro ManilaIvan Harris TanyagPas encore d'évaluation

- Leader in CSR 2020: A Case Study of Infosys LTDDocument19 pagesLeader in CSR 2020: A Case Study of Infosys LTDDr.Rashmi GuptaPas encore d'évaluation

- Create Email Alerts For Mulitple People or Group - XpoDocument79 pagesCreate Email Alerts For Mulitple People or Group - XponiravmodyPas encore d'évaluation

- Stock Futures Are Flat in Overnight Trading After A Losing WeekDocument2 pagesStock Futures Are Flat in Overnight Trading After A Losing WeekVina Rahma AuliyaPas encore d'évaluation

- Draft SemestralWorK Aircraft2Document7 pagesDraft SemestralWorK Aircraft2Filip SkultetyPas encore d'évaluation

- IPR GUIDE COVERS PATENTS, TRADEMARKS AND MOREDocument22 pagesIPR GUIDE COVERS PATENTS, TRADEMARKS AND MOREShaheen TajPas encore d'évaluation

- GSR Azure High Level ArchitectureDocument4 pagesGSR Azure High Level ArchitectureCSKPas encore d'évaluation

- CS547Document11 pagesCS547Usman Suleman AhmadPas encore d'évaluation

- Frequently Asked Questions (And Answers) About eFPSDocument10 pagesFrequently Asked Questions (And Answers) About eFPSghingker_blopPas encore d'évaluation

- Vaccination Management System of Brgy 6 (Table of Contents)Document8 pagesVaccination Management System of Brgy 6 (Table of Contents)Ryan Christian MenorPas encore d'évaluation

- E. Market Size PotentialDocument4 pagesE. Market Size Potentialmesadaeterjohn.studentPas encore d'évaluation

- 9643 SoirDocument38 pages9643 SoirpolscreamPas encore d'évaluation

- Motorola l6Document54 pagesMotorola l6Marcelo AriasPas encore d'évaluation

- Management principles and quantitative techniquesDocument7 pagesManagement principles and quantitative techniquesLakshmi Devi LakshmiPas encore d'évaluation

- 136 ADMU V Capulong (Roxas)Document2 pages136 ADMU V Capulong (Roxas)Trisha Dela RosaPas encore d'évaluation

- GPL 12800 (80) AhDocument1 pageGPL 12800 (80) AhismailPas encore d'évaluation