Académique Documents

Professionnel Documents

Culture Documents

Electrical WIP Test Form

Transféré par

Dick Anthony MabaoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Electrical WIP Test Form

Transféré par

Dick Anthony MabaoDroits d'auteur :

Formats disponibles

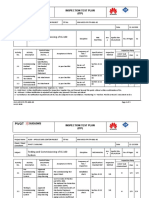

FORM NO.

: F-QM-EET-001

PROJECT :

ATTENUATORS TEST FORM

CONTROL NO. :

LOCATION :

DATE PREPARED :

TESTING DATE / TIME :

Functional Description :

Location Drawing No. :

Schematic Drawing No. :

Attenuator

Reference

Manufacturer

Type

TEST CARRIED OUT BY (Sub-contractor) :

(Name/Signature)

Non-Shedding Type, (YES/NO)

Installed Correctly, (YES/NO)

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

TEST WITNESSED BY :

(Date)

(Client Representative)

(MDCBP - MEFPS Field QC Engineer)

INSTALLATION INSPECTED AND DETAILS RECORDED BY :

(Sub-Contractor PIC / QAQC)

Size

INSTALLATION COMPLIES W/ DESIGN :

MDCBP - MEFPS Field QC Engineer

(Client Representative)

COMMENTS :

Note : Note:Refer to Room Performance Sheets

DECLARATION :

Data recorded above has been reviewed and found to be

satisfactory.

DISTRIBUTION :

Subcon

_____________________________

___________________________

(Client Representative)

(Date)

MDCBP Document Controller

Revision No. 002 (May 2014)

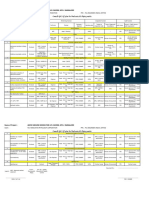

FORM NO. : F-QM-EET-002

PROJECT :

ILLUMINATION LEVEL TEST

FORM

CONTROL NO. :

LOCATION :

DATE PREPARED :

TESTING DATE / TIME :

Functional Description :

Location Drawing No. :

Schematic Drawing No. :

Location

Design

Lighting

Level

Distance

Measured

from floor

Average Lighting Level in LUX

No of Locations

Average

Emergency Lighting

Level

INSTALLATION INSPECTED AND DETAILS RECORDED BY :

(Sub-Contractor PIC / QAQC)

Tested

By

Date

INSTALLATION COMPLIES W/ DESIGN :

(MDCBP - MEFPS Field QC Engineer)

(Client Representative)

TEST CARRIED OUT BY :

TEST WITNSSED & RESULTS ACCEPTED BY :

(Sub-Contractor/Approved Testing Agency)

(MDCBP MEPFS Field QC Engr.)

COMMENTS :

DECLARATION :

Data recorded above has been reviewed and found to be

satisfactory.

DISTRIBUTION :

Subcon

_____________________________

Date :

______________________

(Client Representative)

MDCBP Document Controller

Revision No. 002 (May 2014)

FORM NO. : F-QM-EET-003

PROJECT :

CONDUCTIVITY CELL AND

TRANSMITTER TEST FORM

CONTROL NO. :

LOCATION :

TESTING DATE/TIME:

DATE PREPARED :

Functional Description :

Location :

Schematic :

1. Cell Details

a. Manufacturer

b. Connection

c. Signal Output*

d. Temperature Sensing, MA/MV*

e. Correct tag no.attached, YES/NO*

f. Removable for calibration, YES/NO*

g. Type

h. Material

i. Serial No.

j. Range, M

k. Calibration Certificate No.

l. Correction Factor

2. Transmitter Details

a. Manufacturer

b. Item of plant controlled

c. Range, M

d. Electrical Supply, V

e. Tag Label attached YES/NO *

f. Temp Compensation AUTO/MANUAL * INDICATING/RECORDING *

g. Type and form of Output 1 MA/MV * INDICATED/RECORDED *

h. Type and form of Output 2 MA/MV * INDICATED/RECORDED *

i. Combined Unit calibrated to SOP/Method Statement reference.

j. Results available in RAW DATA/SITE SYSTEM *

k. Type

l. Serial No.

m. Alarm relays

n. Sensor type

o. No. of Outputs:

Calibrated by:

__________________________________________________

______________________________

(Date)

(Name/Signature)

Test Instrument :

Serial No. :

INSTALLATION INSPECTED AND DETAILS RECORDED BY :

(Sub-Contractor PIC / QAQC)

INSTALLATION COMPLIES W/ DESIGN :

(MDCBP - MEFPS Field QC Engineer)

(Client Representative)

COMMENTS :

DECLARATION :

Data recorded above has been reviewed and found to be

satisfactory.

DISTRIBUTION :

Subcon

_____________________________

(Client Representative)

______________________________________

(Date)

MDCBP Document Controller

Revision No. 002 (May 2014)

FORM NO. : F-QM-EET-004

CONTINUITY OF RING METAL

CIRCUIT CONDUCTORS TEST

FORM

PROJECT :

CONTROL NO. :

LOCATION :

TESTING DATE/TIME:

DATE PREPARED :

Functional Description :

Location Drawing No. :

Schematic Drawing No. :

Type:

Distribution Board Reference No.:

A = Between Ends Of P (N) (C.P.C.) at Distribution Board

B = Test Lead

C = Closed Ends At Distribution Board & Mid Point Ring

Legend :

Circuit

No.

Resistance Phase (W)

A

B

C

Verification

B

Circuit

No.

Resistance C.P.C. (W)

A

B

C

Verification

B

Verification

A

Tested

INSTALLATION INSPECTED AND DETAILS RECORDED BY :

(Sub-Contractor PIC / QAQC)

Resistance Neutral (W)

A

B

C

By

Date

INSTALLATION COMPLIES W/ DESIGN :

(MDCBP - MEFPS Field QC Engr.)

(Client Representative)

COMMENTS :

DECLARATION :

Data recorded above has been reviewed and found to be

satisfactory.

DISTRIBUTION :

Subcon

_____________________________

___________________________

(Client Representative)

(Date)

MDCBP Document Controller

Revision No. 002 (May 2014)

FORM NO. : F-QM-EET-005

CONTROL NO. :

PROJECT :

CONTINUITY OF PROTECTIVE

CONDUCTOR TEST FORM

LOCATION :

TESTING DATE/TIME:

DATE PREPARED :

Functional Description :

Location Drawing No. :

Schematic Drawing No. :

1. Distribution Board Reference No:

2. Type:

3. Test Results :

Circuit No.

Design

R1 + R2

( W)

Test

R1 + R2

( W)

Verify

Zs

( )

Tested

By

INSTALLATION INSPECTED AND DETAILS RECORDED BY :

(Sub-Contractor PIC / QAQC)

Date

INSTALLATION COMPLIES W/ DESIGN :

(MDCBP - MEFPS Field QC Engineer)

(Client Representative)

COMMENTS :

DECLARATION :

Data recorded above has been reviewed and found to be

satisfactory.

DISTRIBUTION :

Subcon

_____________________________

Date :

______________________

(Client Representative)

MDCBP Document Controller

Revision No. 002 (May 2014)

FORM NO. : F-QM-EET-006

CONTROL NO. :

PROJECT :

MOTOR CONTROL

CENTERS TEST FORM

LOCATION :

TESTING DATE/TIME:

DATE PREPARED :

Functional Description :

Location :

Schematic :

I. Motor Control Centres

1. Manufacturer:

2. Type:

3. Serial No:.

4. Heater Size (W) :

5. Main Fuse Size (A) :

6. Control Fuse Size (A) :

II. Incomer Details

1. Fed From:

2. Voltage Rating:

3. Fault Rating:

4. Type No:

5. Earth Connection Type:

6. Ampere Rating:

7. Frame:

8. Thermal:

9. Cable Size:

III. Control Bus Section

Transformer

KVA

Volts Ratio Primary/Secondary

Fuse Size Primary/Secondary

/

/

No. 1

No. 2

IV. Instrument Details

Voltmeter Range:

Protection Detail Incl. CT Ratio:

/

/

Ammeter Range:

CT Ratio:

V. Check List ( if satisfactory )

Holding Bolts

Insulators in Place

Labels To Drawing Detail

Busbar Chamber

Locking Mechanism

Shutters Operate

Busbar Joints

Mechanical Check OK

Heater Operation OK

VI. Test Data

Insulation Resistance (M W )

R-E

S-E

T-E

R-S

S-T

T-R

* Phase Rotation Correct :

Yes

No

Earthloop (Zs), W:

Main Fuse Size, A :

Control Fuse Size, W :

INSTALLATION INSPECTED AND DETAILS RECORDED BY :

(Sub-Contractor PIC / QAQC)

INSTALLATION COMPLIES W/ DESIGN :

(MDCBP - MEFPS Field QC Engineer)

(Client Representative)

COMMENTS :

DECLARATION :

Data recorded above has been reviewed and found to

be satisfactory.

DISTRIBUTION :

Subcon

_____________________________

Date :

______________________

(Client Representative)

MDCBP Document Controller

Revision No. 002 (May 2014)

FORM NO. : F-QM-EET-007

PROJECT :

POWER TRANSFORMERS CAST RESIN TEST FORM

(PLANT INSPECTION)

CONTROL NO. :

LOCATION :

TESTING DATE/TIME:

DATE PREPARED :

Functional Description :

Location :

Schematic :

POWER TRANSFORMERS - CAST RESIN

Manufacturer:

Equipment No:

Serial No:

Type:

Weight:

App. Std:

Impedence:

Set points C:

Enclosure Type:

Vector Group:

Rating:

Voltage Ratio:

Amps HV:

LV:

Temp Class:

Temperature Monitoring:

Alarm Set Point C

Cooling Forced? Yes/No:

Yes

(Normal Tapping)

No

Frequency:

Trip Set Point C

Cable HT Reference:

Cable LV Reference:

SUPPLIERS/MANUFACTURER'S TEST DATA

Test Report Reference No. (Available in raw data/site

Impedance Voltage - Measured

Position

(Normal)

Uk(%)

No-Load

Losses(w)

Current

(%)

Ur(%)

Ux(%)

J(oC)

Short Circuit Losses Voltage

(W)

(%)

Rated

Measured

Check List ( if satisfactory) :

Resistance of winding at ______________C

R-S

S-T

T-R

H.V. Position

mW

L.V.

mW

system *)

Ur(%)

Uk(%)

J(oC)

Phase

Inception Voltage (...x Urated)

PD at 1,5 Usystem, 30 sec (pC)

PD at 1,1 Usystem, 3 min (pC)

Extinction Voltage (...x Urated)

Induced Voltage Test

L.V. Winding (Volt)

Excited by (Hz)

Frequency

Test Time (sec)

Applied Voltage Test

H.V.-L.V./Core (KV)

L.V.-Core (KV)

L.V. -Screen (KV)

Test Time (sec)

Sign :

Enclosure Interlocked with HV

Temperature Monitored

Phase

Date :

Tap Change Operation

Tap Change Lock-in - Pos

Phase Marking

Transformer Label

Sign :

Bonding

Date :

INSTALLATION INSPECTED AND DETAILS RECORDED BY :

(Sub-Contractor PIC / QAQC)

Phase

Partial Discharge

INSTALLATION COMPLIES W/ DESIGN :

(MDCBP - MEFPS Field QC Engineer)

The following were tested and found to be satisfactory:

Noise level at full load (dBA) :

Fans On (C) :

Fans Off (C) :

(Client Representative)

* Temperature trip:

* Temperature alarm:

* Cooling fans :

Yes

Yes

Yes

No

No

No

N/A

COMMENTS :

DECLARATION :

Data recorded above has been reviewed and found to

be satisfactory.

DISTRIBUTION :

Subcon

_____________________________

Date :

______________________

(Client Representative)

MDCBP Document Controller

Revision No. 002 (May 2014)

FORM NO. : F-QM-EET-008

PROJECT :

MOTOR DRIVE CIRCUITS

TEST FORM

CONTROL NO. :

LOCATION :

TESTING DATE/TIME:

DATE PREPARED :

Functional Description :

Location :

Schematic :

Motor Drive Circuits :

MCC Item Ref. No:

Drive Serving:

Type Of Starter: Star-Delta/Autotransformer/DOL/Soft/VSD/Other (specify)

Motor Details :

Manufacturer:

Model:

Voltage:

Serial No:

Frequency:

Enclosure:

Frame Size:

FLC:

KW:

RPM:

IP Rating:

For Certified Equipment Only :

Approving Body :

Certificate No :

Class :

Cable Details :

Motor Cable No:

Type:

Cores:

Size / Length:

* Cable No: Insulation Resistance. (Incl. Motor) Checked?

Yes

No

Check List :

* Direction Of rotation (Whilst Looking At Non Drive End):

Clockwise

Anticlockwise

* Checked Labelling @ MCC:

Yes

No

Terminations Check

Earthing Details

Motor

State Method and Earth Wire:

Control Interfaces

Earth Fault Loop Impedance (Zs):

Indication

* If serving a variable speed drive, separate certificate has been completed:

Emergency Stop

Yes

No

N/A

INSTALLATION INSPECTED AND DETAILS RECORDED BY :

(Sub-Contractor PIC / QAQC)

Test Data :

* Local Alarms Indication OK:

Running Current (Amps) :

INSTALLATION COMPLIES W/ DESIGN :

(MDCBP - MEFPS Field QC Engineer)

Yes

No

Test carried out by:

(Client Representative)

* Emergency Stop Operation OK:

* General Indication OK:

Yes

Yes

No

No

Test witnessed and results acccepted by :

____________________________________________________________

(Sub-Contractor / Approved Testing Agency)

_________________________________________________________________

(MDCBP MEPFS Field QC Engr.)

COMMENTS :

NOTE : * Delete as applicable.

DECLARATION :

Data recorded above has been reviewed and found to be

satisfactory.

DISTRIBUTION :

Subcon

_____________________________

Date :

______________________

(Client Representative)

MDCBP Document Controller

Revision No. 002 (May 2014)

FORM NO. : F-QM-EET-009

REPORT NO. :

PROJECT :

LOCATION :

LOAD TEST FORM

TESTING DATE/TIME:

DATE PREPARED :

Functional Description :

Location Drawing No. :

Schematic Drawing No.:

System No.

%RH

1. Room Design Conditions :

PQ

2. External Design Conditions :

a. summer

%RH

o

C

%RH

b. winter

3. Room Loads :

a. Solar load, kW

b. Fabric load, kW

c. Corrective load, kW

d. Equipment load

- latent

- Sensible

e. Total Room load

- latent

- Sensible

f. Occupancy load

- latent

- Sensible

Entrance

1) Heater positions to be agreed with Glaxo prior to testing, and shown on plan thus +

2) Chart recorder positions to be agreed with Glaxo prior to testing, units to be installed 1m above FFL,

Show positions on plan thus o.

4. Test Format

The test should last for a minimum of 48 hours to an agreed method statement including:

a. No load conditions

b. Progressive increase to simulated peak summer load conditions (i.e. part load).

c. 8 hour period at simulated peak summer load conditions.

d. Period at reduced conditions (i.e.part load).

e. Period at no load conditions.

f. Period at no load conditions.

The result should be bound into Raw Data, with each chart marked to show; location and room reference, start and completion time and

date, Protocol No., equipment type and serial numbers and latent and sensible loads applied.

5. Test Instrument :

Serial No.:

Note: Lights to be left on during testing

Test carried out by : Subcontractor

______________________

Subcontractor PIC / QAQC

Test witnessed and results accepted by : MDCBP Field QC Engineer

________________

(Date)

______________________

_________________

(Name/Signature)

(Date)

COMMENTS :

NOTE : * Delete as applicable.

DECLARATION :

Data recorded above has been reviewed and found to

be satisfactory.

DISTRIBUTION :

Subcon

_____________________________

Date :

______________________

(Client Representative)

MDCBP Document Controller

Revision No. 002 (May 2014)

FORM NO. : F-QM-EET-0010

PROJECT :

PROTECTION RELAYS

TEST FORM

CONTROL NO.

LOCATION :

DATE/TIME TESTING:

DATE PREPARED :

Functional Description :

Location :

Schematic :

PROTECTION RELAYS :

Manufacturer:

Model No:

Serial No:

current transformer

details

Unit Type:

Frequency:

Ass. Switchboard/Mcc Ref:

Systems Voltage:

Settings Range:

serial numbers

R

Neutral

ratio

manufacturer

accuracy

INSTALLATION INSPECTED AND DETAILS RECORDED BY :

(Subcontractor)

(MDCBP-MEFPS Field QC Engineer)

INSTALLATION COMPLIES WITH THE DESIGN :

___________________________

(MDCBP-MEFPS Supervisor)

Date :

SECONDARY INJECTION TESTS :

Phase

Element

Relay

R

Over-Current

S

T

Earth/Ground

Instantaneous O/C Relay

Relay Setting

%

Pick-Up

Current

Operating Time @ Time Setting

2

5

10

Time Multiplier

Setting

1

0.5

1

0.5

1

0.5

1

0.5

100

100

100

100

100

100

25 or 50

25 or 50

Relay Setting

R Phase

Tripping Current

S Phase

T Phase

TEST CARRIED OUT BY :

TEST WITNESSED AND RESULTS ACCEPTED BY :

________________________________________

(Sub-Contractor / Approved Testing Agency)

__________________________________________

(MDCBP-MEPFS Field QC Engineer)

COMMENTS :

DECLARATION :

Data recorded above has been reviewed and found to

be satisfactory.

DISTRIBUTION :

Subcon

___________________________

(Client Representative)

Date :

MDCBP Document Controller

Revision No. 002 (May 2014)

FORM NO. : F-QM-EET-011

PROJECT :

CIRCUIT BREAKER TEST

FORM

CONTROL NO. :

LOCATION :

DATE/TIME TESTING:

DATE PREPARED :

Functional Description :

Location Drawing No. :

Schematic Drawing No. :

1. Data

Manufacturer:

Type:

Switchboard Ref:

Rating:

No. Poles:

Frequency:

V.T. Ratio: / V Rated Breaking Capacity: kA for secs.

Description Of Open/Close/Trip Mechanisms & Operations:

2. Check List ( if satisfactory)

General Labelling

Status Indication

Ammeter

Voltmeter

Kwhr Meter

Other Instruments:

Serial No.

Voltage:

General Operation

Intertripping

Key Interlocks

Shuttering

Protective Relay (See Below)

Pad Locking Facilities

3. Current Transformers

Function

4. Protective Relays Tests

Ratio

Note : For Detailed Results See Separate forms

Titled "Protection Relays". (IOTC/E/011, Item Ref.

No. _______________ ) This is confirmation only.

E/L

Type Of Relay :

Primary Injection

Secondary Injection

Instantaneous.

Overcurrent

Earth Fault

YES/NO*

YES/NO*

YES/NO*

YES/NO*

5. Protective Devices

Function

Manufacturer

Type

Setting

Range

INSTALLATION INSPECTED AND DETAILS RECORDED BY :

Subcontractor PIC / QAQC

No

Connected ()

R

E/F

INSTALLATION COMPLIES W/ DESIGN :

(MDCBP - MEFPS Field QC Engineer)

(Client Representative)

COMMENTS :

Note : * Delete as applicable

DECLARATION :

Data recorded above has been reviewed and found to be

satisfactory.

DISTRIBUTION :

Subcon

_____________________________

___________________________

(Client Representative)

(Date)

MDCBP Document Controller

Revision No. 002 (May 2014)

FORM NO. : F-QM-EET-012

PROJECT :

DISTRIBUTION BOARD

TEST FORM

CONTROL NO. :

LOCATION :

TESTING DATE/TIME:

DATE PREPARED :

Functional Description :

Location Drawing No. :

Schematic Drawing No. :

Manufacturer :

Type:

Supplied From:

Back-Up Fuse Rating

Size Of Supply Cable :

Test Results Verification:

a. Circuit Description List Provided*

b. Blanks Fitted On Outgoing Ways*

c. Adequate Warning & Identification Labelling Fitted*

Circuit No.

Circuit No.

Protective Device

Type

Size (A)

Ring Continuity

Yes

Yes

Yes

No

No

No

Load Current (A)

kA

Verification Of Tests Carried Out ()

CPC Conti-nuity

IR

INSTALLATION INSPECTED AND DETAILS RECORDED BY :

(Sub-Contractor PIC / QAQC)

Cable Size (mm2)

Polarity

Zs

RCD

Earth Cable Size

(mm2)

Inspected

By

Date

INSTALLATION COMPLIES W/ DESIGN :

(MDCBP - MEFPS Field QC Engineer)

(Client Representative)

COMMENTS :

Note : * Delete as applicable

DECLARATION :

Data recorded above has been reviewed and found to be

satisfactory.

DISTRIBUTION :

Subcon

_____________________________

___________________________

(Client Representative)

(Date)

MDCBP Document Controller

Revision No. 002 (May 2014)

FORM NO. : F-QM-EET-013

PROJECT :

INSULATION RESISTANCE

TEST FORM

CONTROL NO:

LOCATION :

TESTING DATE/TIME:

DATE PREPARED :

Functional Description :

Location Drawing No. :

Schematic Drawing No. :

Distribution Board Reference No :

Type :

Insulation Resistance

Circuit No.

No. of

Points

R+S+T+N To Earth

P/N

R/STN

S/RTN

INSTALLATION INSPECTED AND DETAILS RECORDED BY :

(Sub-Contractor PIC / QAQC)

Tested

Between Poles

T/RSN

N/RST

By

Date

INSTALLATION COMPLIES W/ DESIGN :

(MDCBP - MEFPS Field QC Engineer)

(Client Representative)

COMMENTS :

DECLARATION :

Data recorded above has been reviewed and found to be

satisfactory.

DISTRIBUTION :

Subcon

_____________________________

(Client Representative)

Date :

______________________

MDCBP Document Controller

Revision No. 002 (May 2014)

FORM NO. : F-QM-EET-014

PROJECT :

CABLES AND CONDUCTORS

TEST FORM

CONTROL NO. :

LOCATION :

TESTING DATE/TIME:

DATE PREPARED :

Functional Description :

Location Drawing No. :

Schematic Drawing No. :

Cable Details

Circuit

Cable No.

From

Cable No.

Cores

To

Used

Size

(mm2)

Spare

Grade

Conductor,

Cu/Al

Type (see Key

Below)

Volts

Tested

Insulation Resistance Test (M)

Core-Core

To Earth

By

Date

Key to Cable Type

1 = PVC/PVC

4 = XLPE/SWA/PVC

7 = XLPE/AWA/LSF

10 = * *

2 = PVC/SWA/PVC

5 = XLPE/AWA/PVC

8 = MICC

11 = * *

3 = PVC/AWA/PVC

6 = XLPE/SWA/LSF

9= **

INSTALLATION INSPECTED AND DETAILS RECORDED BY :

(Sub-Contractor PIC / QAQC)

INSTALLATION COMPLIES W/ DESIGN :

(MDCBP - MEFPS Field QC Engineer)

(Client Representative)

COMMENTS :

DECLARATION :

Data recorded above has been reviewed and found to be

satisfactory.

DISTRIBUTION :

Subcon

_____________________________

___________________________

(Client Representative)

(Date)

MDCBP Document Controller

Revision No. 002 (May 2014)

FORM NO. : F-QM-EET-015

CONTROL NO. :

PROJECT :

EARTH FAULT LOOP

IMPEDANCE TEST FORM

LOCATION :

TESTING DATE/TIME:

DATE/TIME PREPARED:

Functional Description :

Location Drawing No. :

Schematic Drawing No. :

1. Distribution Board Reference No.:

Type:

2. Earth Loop Impedance (Ze) at Distribution Board, W :

3. Type of Earthing System : TN-C/TN-S/TN-c-S/IT/TT*

Circuit

No.

Design

Zs ()

Test Zs ()

Tested

By

Date

Circuit No.

INSTALLATION INSPECTED AND DETAILS RECORDED BY :

( Sub-Contractor / QAQC )

COMMENTS :

DECLARATION :

(MDCBP - MEFPS Field QC Engineer)

Design Zs

(W)

Test Zs

(W)

Tested

By

INSTALLATION COMPLIES W/ DESIGN :

(Client Representative)

Date

Data recorded above has been reviewed and found to be

satisfactory.

DISTRIBUTION :

Subcon

_____________________________

Date :

______________________

(Client Representative)

MDCBP Document Controller

Revision No. 002 (May 2014)

FORM NO. : F-QM-EET-016

PROJECT :

VARIABLE SPEED DRIVE

TEST FORM

REPORT NO. :

LOCATION :

DATE PREPARED:

INSPECTION DATE/TIME:

Functional Description :

Location Drawing No. :

Schematic Drawing No. :

1. VARIABLE SPEED DRIVE

a. Manufacturer :

b. Type:

c. Serial No.:

d. Drive Ref::

e. MCC Ref:

f. Method of Operation : PWM/VVC/Other (Please Specify) :

g. Frequency, Hz :

h.Continuous Rated Output Power, kVA :

i. Mains Supply - Voltage:

j. Continuous Rated Output Current, A :

2. CHECK LIST ( if satisfactory or N/A if not applicable) :

a. Overall Operation

b. Security Measure

c. Labelling

d. EMC Compatability

e. Terminations

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

N/A

N/A

N/A

N/A

N/A

3. SETTINGS :

Description

Range

Set

Point

Description

Range

Set

Point

Description

Jogging Frequency

Lower Frequency Limit, (Hz)

PI Feedback Scaling

Output Frequency

PI Integrate Time

PI Band Width

Motor Voltage

Reset After Trip

Rated Motor Current

Analogue Reference

PI Prop. Amplification

SW. Freq. Range

Motor Current

No Load Monitoring (a)

SW. Freq. Range

Start/Stop Mode

PI Feedback Type

Res. Bypass 1

U/F Characteristic

Thermal Motor Protection

Res. Bypass 2

Relay Function

Current Limit (a)

Res. Bypass 3

Local/Remote Operation

Ramp-Down Time

Res. Bypass 4

Digital Input Function

Rated Motor Output (kW)

Switching Frequency

Local Reference (Hz)

Read-Out Factor

Ramp-Up Time

Analogue Output

Upper Frequency Limit, (Hz)

Rated Motor Voltage (v)

INSTALLATION INSPECTED AND DETAILS RECORDED BY :

(Sub-Contractor PIC / QAQC)

(MDCBP - MEFPS Field QC Engineer)

Range

Set

Point

INSTALLATION COMPLIES W/ DESIGN :

(Client Representative)

COMMENTS :

DECLARATION :

Data recorded above has been reviewed and found to be satisfactory.

DISTRIBUTION :

Subcon

_____________________________ ___________________________

(Client Representative)

(Date)

MDCBP Document Controller

Revision No. 002 (May 2014)

FORM NO. : F-QM-EET-017

CONTROL NO. :

PROJECT :

THERMOSTAT TEST FORM

LOCATION :

DATE / TIME TESTING:

DATE / TIME PREPARED:

Functional Description :

Location Drawing No. :

Schematic Drawing No. :

THERMOSTAT

a. Manufacturer :

b. Type :

c. Serial No. :

d. Range, ( o C) :

e. Constant rating, A :

f. Length, mm :

g. Voltage, AC/DC * :

h. Body material :

i. Spring Design :

j. Positioned correctly, YES/NO * :

k. Item of plant being controlled :

l. Tag label attached, YES/NO * :

m. Calibrated to Sop/Method Statement * reference

Calibrated by:

Results in Raw Data/Site System *

Signature :

Date :

Functional test satisfactory, YES/NO * :

Set point :

Test Instrument :

Serial No :

TEST CARRIED OUT BY (Subcontractor) :

______________________

(Name/Signature)

TEST WITNESSED & RESULTS ACCEPTED BY : MDCBP-Field QC Engr.

________________

(Date)

INSTALLATION INSPECTED AND DETAILS RECORDED BY :

(Sub-Contractor PIC / QAQC)

______________________

_________________

(Name/Signature)

(Date)

INSTALLATION COMPLIES W/ DESIGN :

(MDCBP - MEFPS Field QC Engineer)

(Client Representative)

COMMENTS :

Note : * Delete as applicable

DECLARATION :

Data recorded above has been reviewed and found to be

satisfactory.

DISTRIBUTION :

Subcon

_____________________________

___________________________

(Client Representative)

(Date)

MDCBP Document Controller

Revision No. 002 (May 2014)

FORM NO. : F-QM-EET-018

CONTROL NO. :

PROJECT :

PRESSURE SWITCH TEST

FORM

LOCATION :

DATE / TIME TESTING :

DATE PREPARED:

Functional Description :

Location Drawing No. :

Schematic Drawing No. :

PRESSURE SWITCH

a. Manufacturer :

b. Type :

c. Differential :

d. Action DA/RA * :

e. Electrical Supply V,AC/DC * :

f. Location to Design, YES/NO * :

g. Tag label attached YES/NO * :

h. Results in Raw Data/Site System * :

i. Calibrated to Sop/Method Statement * :

Reference :

Functional test satisfactory YES/NO * :

Set Point :

Test Instrument :

Serial No :

TEST CARRIED OUT BY: Subcontractor

______________________

(Name/Signature)

TEST WITNESSED & RESULTS ACCEPTED BY : MDCBP-Field Engr.

________________

(Date)

______________________

_________________

(Name/Signature)

(Date)

INSTALLATION INSPECTED AND DETAILS RECORDED BY :

INSTALLATION COMPLIES W/ DESIGN :

_______________________

(Sub-Contractor PIC / QAQC)

(MDCBP - MEFPS Field QC Engineer)

(Client Representative)

COMMENTS :

Note : * Delete as applicable

DECLARATION :

Data recorded above has been reviewed and found to be

satisfactory.

DISTRIBUTION :

Subcon

_____________________________

___________________________

(Client Representative)

(Date)

MDCBP Document Controller

Revision No. 002 (May 2014)

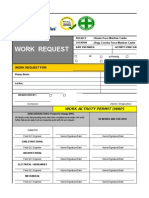

FORM NO. : F-QM-EET-019

PROJECT

LOCATION :

MANDRELLING

TEST

Structural

Sanitary/Plumbing

Architectural

FDAS/BAS

Elec'l/Auxiliaries

FIRE PRO

Mechanical

Others

Site Location :

Brand

Equipment No. :

Model/Serial No. :

Type/ Rating

Asset No.

LINE

ITEM

NO.

FROM

PREPARED BY:

(Subcon PIC / QAQC)

DISTRIBUTION :

INSPECTED BY:

(MDCBP Field QC Engineer)

Subcon

Control No. :

:

:

MANDRELLING TEST

Primary

Secondary

Ductline

Ductline

No. of Length, No. of Length,

Runs

Runs

m

m

TO

Date Conducted :

PIPES

Material

Diameter, mm

REMARKS

APPROVED BY:

(MDCBP Supervisor / Superintendent)

MDCBP Document Controller

Revision No. : 002 (May 2014)

FORM NO. : F-QM-EET-020

PROJECT

LOCATION :

CONTINUITY

ELECTRICAL

TESTING

Structural

Sanitary/Plumbing

Architectural

FDAS/BAS

Elec'l/Auxiliaries

FIRE PRO

Mechanical

Others

Site Location :

Brand

Equipment No. :

Model/Serial No. :

Type/ Rating

Asset No.

I. Type of Test:

Date Conducted :

Control No. :

:

:

II. Equipment/Instrument Used:

Continuity

Brand

Resistance

Serial No. :

Other/s

Range

III. Location / Item of Test :

IV. Continuity Test :

CIRCUIT

NO.

DESCRIPTION

PREPARED BY:

(Subcon PIC / QAQC)

DISTRIBUTION :

L1-L2

L2-L3

L3-L1

L1-N

L2-N

INSPECTED BY:

(MDCBP Field QC Engineer)

Subcon

L3-N

L1-G

L2-G

L3-G

N-G

WIRE

SIZE

REMARKS

APPROVED BY:

(MDCBP Supervisor / Superintendent)

MDCBP Document Controller

Revision No. : 002 (May 2014)

FORM NO. : F-QM-EET-021

PROJECT

ELECTRICAL

GROUNDING

TESTING

LOCATION :

Structural

Sanitary/Plumbing

Architectural

FDAS/BAS

Elec'l/Auxiliaries

FIRE PRO

Mechanical

Others

Site Location :

Brand

Equipment No. :

Model/Serial No. :

Type/ Rating

Asset No.

ITEM

NO.

Control No. :

:

:

EARTH RESISTANCE READINGS(MEGA-OHMS)

LOAD DESCRIPTION

PREPARED BY:

(Subcon PIC/ QAQC)

DISTRIBUTION :

Date Conducted :

QTY.

PT.1

PT.2

PT.3

INITIAL FINAL INITIAL FINAL INITIAL FINAL

INSPECTED BY:

(MDCBP Field QC Engineer)

Subcon

WIRE SIZE

REMARKS

APPROVED BY:

(MDCBP Supervisor / Superintendent)

MDCBP Document Controller

Revision No. : 002 (May 2014)

FORM NO. : F-QM-EET-022

PROJECT

LOCATION :

ELECTRICAL

FUNCTIONAL

TESTING

Structural

Sanitary/Plumbing

Architectural

FDAS/BAS

Elec'l/Auxiliaries

FIRE PRO

Mechanical

Others

Site Location :

Brand

Equipment No. :

Model/Serial No. :

Type/ Rating

Asset No.

CIRCUIT

NO.

DESCRIPTION

PREPARED BY:

(Subcon PIC / QAQC)

DISTRIBUTION :

L1-L2

L2-L3

L3-L1

(MDCBP Field QC Engineer)

Subcon

Control No. :

:

:

VOLTAGE READINGS

L1-N

L2-N

L3-N

L1-G

INSPECTED BY:

Date Conducted :

L2-G

L3-G

N-G

WIRE

SIZE

CIRCUIT

BREAKER

REMARKS

APPROVED BY:

(MDCBP Supervisor / Superintendent)

MDCBP Document Controller

Revision No. : 002 (May 2014)

FORM NO. : F-QM-EET-023

PROJECT

LOCATION :

TRANSFORMER TEST

Structural

Date Conducted :

Architectural

Sanitary/Plumbing

FDAS/BAS

Elec'l/Auxiliaries

Mechanical

FIRE PRO

Others ___________________

Site Location :

Brand

Equipment No. :

Model/Serial No. :

Type/ Rating

Asset No.

Control No. :

:

:

A. Insulation Resistance Test

TIME

Pri-Ground (megaohms)

Pri-Secondary

(megaohms)

Sec-Ground (megaohms)

Test Voltage:

Test Voltage:

Test Voltage:

30sec.

Test Instrument Used :

1min.

Name/Type

10min.

Model/Serial No.

Limit (Rdg>)

Remarks

Manufacturer

Calibration Date

:

:

B. Winding Resistance Test

TAP POSITION

VOLTAGE

Primary Winding (Mohm)

Secondary Winding

(Milliohm)

VOLTAGE

H(1)-(2) H(2)-(3) H(3)H(1)

X(0)-X(1) X(0)-X(2) X(0)-X(3)

Test Instrument Used :

1min.

Name/Type

10min.

Model/Serial No.

:

:

Limit (Rdg>)

Remarks: Resistance value of each winding should not be far from each (small variance only)

Manufacturer

Calibration Date

:

:

C. Turns Ration Test

WINDING

TERMINALS

TAP

EXPECTED AS FOUND

RATIO

RATIO

PERCENT DIFFERENCE

(%)

REMARKS

LIMITS +

Test Instrument Used :

Name/Type

Model/Serial No.

Manufacturer

Calibration Date

:

:

D. Excitation Current Test

WINDING

TERMINALS

TAP

TEST

VOLTAGE

EXCITATION CURRENT

(Ma)

REMARKS LIMITS +

Test Instrument Used :

Name/Type

Model/Serial No.

Manufacturer

Calibration Date

:

:

E. Diaelectric Breakdown Voltage Test of Insulating Oil

TYPE

TRIALS

3

AVERAGE in

kV

REMARKS

Limits > 24KV

Remarks:

1. The limits for the winding resistance test are 5% difference with the other windings or compare with the manufacturer's test values.

2. The insulation resistance readings are corrected to 20 degrees Celsius with a multiplier of 1.98

3. The insulation resistance readings for the secondary windings should reached the equipment maximum range at a given test voltage.

4. Test results must be within the limits.

PREPARED BY:

(Subcon PIC / QAQC)

DISTRIBUTION :

INSPECTED BY:

(MDCBP Field QC Engineer)

Subcon

APPROVED BY:

(MDCBP Supervisor / Superintendent)

MDCBP Document Controller

Revision No. : 002 (May 2014)

FORM NO. : F-QM-EET-024

AUTOMATIC

TRANSFER

SWITCH (ATS)

TESTING

PROJECT

LOCATION :

Structural

Sanitary/Plumbing

Architectural

FDAS/BAS

Elec'l/Auxiliaries

FIRE PRO

Mechanical

Others

Date Conducted :

Site Location :

Brand

Equipment No. :

Model/Serial No. :

Type/ Rating

Asset No.

:

DATA

AUTOMATIC

MANUAL

Control No. :

:

:

PASSED

FAILED

REMARKS

1. Power Transfer

2. Load Sharing

3. Syncronization

4. Normal to Emergency Time (sec.)

5. Emergency to Normal Time (sec.)

6. Cool Down Time (sec.)

PREPARED BY:

(SubCon PIC / QAQC)

DISTRIBUTION :

INSPECTED BY:

(MDCBP Field QC Engineer)

Subcon

APPROVED BY:

(MDCBP Supervisor / Superintendent)

MDCBP Document Control

Revision No. : 002 (May 2014)

FORM NO. : F-QM-EET-025

PROJECT

LOCATION :

CAPACITOR TEST

Structural

Sanitary/Plumbing

Architectural

FDAS/BAS

Elec'l/Auxiliaries

FIRE PRO

Mechanical

Others

Site Location :

Brand

Equipment No. :

Model/Serial No. :

Type/ Rating

Asset No.

:

DATA

Date Conducted :

Control No. :

:

:

NO. OF STEPS

1

REMARKS

1. Power Factor %

2. Time(sec)

3. Circuit Breaker Rating

4. Ampere Trip

5. Kvar rating

6. Kvar rating/bank

7. Capacitor Brand

8. Feeder Type

9. Feeder Size

10. Feed Size(G)

11. No. of steps

12. Voltage reading

L1

L2

L3

L1-G

L2:G

L3-G

13. Ampere reading:

L1

L2

L3

14. Frequency:

15. Fed From:

PREPARED BY:

DISTRIBUTION :

INSPECTED BY:

Subcon

APPROVED BY:

MDCBP Document Controller

Revision No. : 002 (May 2014)

FORM NO. : F-QM-EET-026

PROJECT

LOCATION :

FIRE ALARM TESTING

Structural

Elec'l/Auxiliaries

Sanitary/Plumbing

FIRE PRO

Architectural

Mechanical

FDAS/BAS

Others ___________________________

Site Location :

Equipment No. :

Type/ Rating

NAME TAG

Control No. :

Brand

:

Model/Serial No. :

Asset No.

DEVICE TYPE

ITEM

NO.

Date Conducted :

LOCATION

SERIAL

NUMBER

SMOKE

HEAT

BELL

INTERFACING

ANNUNCIATO

R

MANUAL

PULL

STATION

FLOW

SWITCH

INSTALLATION

SMOKE

SUPERVISOR PRESSURIZ

EVACUATION

Y SWITCH

ATION FAN

FAN

LPG LEAK

ON SLAB

DROP

CEILING

REMARKS

TOTAL

PREPARED BY:

(Subcon PIC / QAQC)

DISTRIBUTION :

INSPECTED BY:

(MDCBP Field QC Engineer)

Subcon

APPROVED BY :

(MDCBP Supervisor / Superintendent)

MDCBP Document Controller

Revision No. : 002 (May 2014)

FORM NO. : F-QM-EET-027

PROJECT

BACKGROUND

MUSIC/PUBLIC

ADDRESS SYSTEM

TESTING

LOCATION :

Structural

Sanitary/Plumbing

Architectural

FDAS/BAS

Elec'l/Auxiliaries

FIRE PRO

Mechanical

Others

Date Conducted :

Site Location :

Brand

Equipment No. :

Model/Serial No. :

Type/ Rating

Asset No.

ITEM

NO.

:

:

FUNCTIONAL

TEST

DECIBEL (db)

EQUIPMENT / DEVICE

PREPARED BY:

(Subcon PIC / QAQC)

DISTRIBUTION :

LOCATION

DESIGN

INSPECTED BY:

(MDCBP Field QC Engineer)

Subcon

Control No. :

ACTUAL

INITIAL FINAL

REMARKS

PASSED

APPROVED BY:

(MDCBP Supervisor / Superintendent)

MDCBP Document Controller

Revision No. : 002 (May 2014)

Vous aimerez peut-être aussi

- Essentials Electrical Quality Control Plan Sample PDFDocument13 pagesEssentials Electrical Quality Control Plan Sample PDFSalman HameedPas encore d'évaluation

- LV Panel ChecklistDocument1 pageLV Panel ChecklistvaradharajanPas encore d'évaluation

- Testing and Commissioning Certificate: Details of ProjectDocument1 pageTesting and Commissioning Certificate: Details of ProjectUmar FarooqPas encore d'évaluation

- Building Electrical Installation Level - I: Based On March, 2022 CURRICULUM Version - 1Document36 pagesBuilding Electrical Installation Level - I: Based On March, 2022 CURRICULUM Version - 1kassa mamoPas encore d'évaluation

- Gravity Test Report Water SupplyDocument1 pageGravity Test Report Water SupplygaineyskPas encore d'évaluation

- ITP For MV Power Cables & Accessories InstallationDocument1 pageITP For MV Power Cables & Accessories InstallationAdil HasanovPas encore d'évaluation

- Attachment E - UPS Checklist PDFDocument1 pageAttachment E - UPS Checklist PDFnandaanujPas encore d'évaluation

- MEP Engineer Job DescriptionDocument1 pageMEP Engineer Job DescriptionMaher MahgoubPas encore d'évaluation

- User Manual - Online Wiring Certificates-Rev3Document12 pagesUser Manual - Online Wiring Certificates-Rev3Tony Ras Mwangi100% (1)

- Clas Ohlson ReadingDocument22 pagesClas Ohlson ReadingJennifer BradyPas encore d'évaluation

- Electrical Method of T&C ProcedureDocument35 pagesElectrical Method of T&C ProceduresasikalaPas encore d'évaluation

- Mandrelling Test / Checklist: Pmqs Construction Solutions, IncDocument1 pageMandrelling Test / Checklist: Pmqs Construction Solutions, IncAbnar KumplishaPas encore d'évaluation

- Power Cable Magger TEST PROCEDUREDocument1 pagePower Cable Magger TEST PROCEDUREkamilPas encore d'évaluation

- 16139-Cable TraysDocument4 pages16139-Cable TraysNATHANPas encore d'évaluation

- Itp For Electrical WorksDocument22 pagesItp For Electrical Worksirfan vpPas encore d'évaluation

- HG Power Transmission Sdn. BHD.: Method StatementDocument6 pagesHG Power Transmission Sdn. BHD.: Method StatementNabil MazelanPas encore d'évaluation

- Method Stament For Street Pole LightDocument16 pagesMethod Stament For Street Pole Lightمقاول تكييف كهرباء وصحيPas encore d'évaluation

- ATS Test Report 34Document3 pagesATS Test Report 34Rami Badran63% (8)

- Doha Petroleum Construction Co. LTD Inspection & Test Plan: 1 Material ReceivingDocument1 pageDoha Petroleum Construction Co. LTD Inspection & Test Plan: 1 Material ReceivingmeePas encore d'évaluation

- Mels Constuction Limitada: Commercial Management Mechanical Completion CertificateDocument1 pageMels Constuction Limitada: Commercial Management Mechanical Completion CertificateDeonPas encore d'évaluation

- Methodology For Installation of Fire Pro PDFDocument4 pagesMethodology For Installation of Fire Pro PDFswamyPas encore d'évaluation

- LV Panel ReportDocument71 pagesLV Panel ReportMudassirPas encore d'évaluation

- Quality Assurance PlanDocument2 pagesQuality Assurance PlanSAGARPas encore d'évaluation

- Testing and Commissioning of IG 100 System: Inspection Test Plan (ITP)Document3 pagesTesting and Commissioning of IG 100 System: Inspection Test Plan (ITP)Samboy DionisioPas encore d'évaluation

- Itp Electrical CableDocument2 pagesItp Electrical CablekamlPas encore d'évaluation

- Precommissioning ChecklistDocument2 pagesPrecommissioning ChecklistPankaj PandeyPas encore d'évaluation

- Pipeline StandardDocument50 pagesPipeline Standardsofianina05Pas encore d'évaluation

- Street Light Inspection: Cscec-Tata JODocument1 pageStreet Light Inspection: Cscec-Tata JOdoly damanik50% (2)

- Commissioning Observation and Testing Report: 1. General Project InformationDocument1 pageCommissioning Observation and Testing Report: 1. General Project InformationHumaid ShaikhPas encore d'évaluation

- Aviation Light BOQDocument6 pagesAviation Light BOQkkjha31Pas encore d'évaluation

- MQP of PanelDocument1 pageMQP of Panelrahulchitrakoot123Pas encore d'évaluation

- QAP For Overall Mechanical ActivitiesDocument2 pagesQAP For Overall Mechanical ActivitiesMaheshwar polepallyPas encore d'évaluation

- SG Cable Colour Code ChangesDocument4 pagesSG Cable Colour Code ChangesOA AooPas encore d'évaluation

- Electrical Technical SpecificationDocument37 pagesElectrical Technical SpecificationKamal KhanPas encore d'évaluation

- Electrical Works (Cable Pulling, Termination, Jointing and Conduit) Inspection ChecklistDocument1 pageElectrical Works (Cable Pulling, Termination, Jointing and Conduit) Inspection ChecklistUtku Can KılıçPas encore d'évaluation

- Factory Acceptance Test Procedure For DCS - Part 6Document1 pageFactory Acceptance Test Procedure For DCS - Part 6kapsarcPas encore d'évaluation

- 08.2 Method StatementDocument3 pages08.2 Method StatementelbaraniPas encore d'évaluation

- Annual Building Maintenance ChecklistDocument9 pagesAnnual Building Maintenance ChecklistNur MajPas encore d'évaluation

- FA QCDD Exam Questions KIC by TrekaDocument7 pagesFA QCDD Exam Questions KIC by TrekaSHERIF KHATTABPas encore d'évaluation

- 13 Fan Coil Unit: Location: - No.Document1 page13 Fan Coil Unit: Location: - No.JIJUPas encore d'évaluation

- Underground Electrical Infrastructure Open Trench Audit Report Civil Electrical and Cable HaulingDocument7 pagesUnderground Electrical Infrastructure Open Trench Audit Report Civil Electrical and Cable HaulingBadhur Zaman100% (1)

- Project: Samsun CCPP: Title: ITP of SwitchgearsDocument4 pagesProject: Samsun CCPP: Title: ITP of SwitchgearsUtku Can Kılıç100% (1)

- Methos of Statement For Startup WorkDocument6 pagesMethos of Statement For Startup WorkMahesh MirajkarPas encore d'évaluation

- Check List For Erection of Switch Gear-FieldDocument3 pagesCheck List For Erection of Switch Gear-Fieldsantoshkumar100% (1)

- Testing and Commissioning Procedure For Moving WalksDocument14 pagesTesting and Commissioning Procedure For Moving WalksWinPas encore d'évaluation

- Itp Architectural WorkDocument6 pagesItp Architectural WorkBenjamin Chavez100% (2)

- NSC-400-CE-3230-Transmission Line Checklist MasterlistsDocument2 pagesNSC-400-CE-3230-Transmission Line Checklist MasterlistsElisco Pher SalmasanPas encore d'évaluation

- 022 - Leak Test FormDocument1 page022 - Leak Test FormAngela YumangPas encore d'évaluation

- Video Intercom Solution and Cabling SpecificationsDocument20 pagesVideo Intercom Solution and Cabling SpecificationsSaid GedeonPas encore d'évaluation

- Inspection and Test Plan For Bus DuctDocument4 pagesInspection and Test Plan For Bus Ductsamuraivicky0% (1)

- Excel Bill of Materials Bom TemplateDocument8 pagesExcel Bill of Materials Bom TemplateRavi ChhawdiPas encore d'évaluation

- Types of Artificial Lighting: Architectural Acoustics and LightingDocument12 pagesTypes of Artificial Lighting: Architectural Acoustics and LightingRashid MujahidPas encore d'évaluation

- Material Submittal - Checklist PDFDocument1 pageMaterial Submittal - Checklist PDFDanish AhamadPas encore d'évaluation

- Cable MeggeringDocument12 pagesCable MeggeringaeliusmanoPas encore d'évaluation

- Electrical Test Report FormatDocument1 pageElectrical Test Report Formatzee159100% (3)

- MDB & SMDBDocument3 pagesMDB & SMDBnazi1945Pas encore d'évaluation

- Appendix E - Material Submission For Approval FormDocument1 pageAppendix E - Material Submission For Approval FormSyerifaizal Hj. MustaphaPas encore d'évaluation

- CC 7502 - INSTRUMENT INSTALLATION & HOOK-UP INSPECTION CHECKLIST - Rev 3Document2 pagesCC 7502 - INSTRUMENT INSTALLATION & HOOK-UP INSPECTION CHECKLIST - Rev 3samboopathiPas encore d'évaluation

- Mep WirDocument69 pagesMep WirAnuj KjoyPas encore d'évaluation

- Commissioning Procedure EngrDocument11 pagesCommissioning Procedure EngrkumarPas encore d'évaluation

- Amaia Trece - CheckListDocument32 pagesAmaia Trece - CheckListDick Anthony MabaoPas encore d'évaluation

- Basic Plumbing SymbolsDocument1 pageBasic Plumbing SymbolsBrandon Borromeo75% (4)

- Book 1Document6 pagesBook 1Dick Anthony MabaoPas encore d'évaluation

- Asnp OsmDocument19 pagesAsnp OsmDick Anthony MabaoPas encore d'évaluation

- Mabs Diet!!!Document2 pagesMabs Diet!!!Dick Anthony MabaoPas encore d'évaluation

- Asnp MDC-BP Subcon Monitoring (053014)Document45 pagesAsnp MDC-BP Subcon Monitoring (053014)Dick Anthony MabaoPas encore d'évaluation

- Qty Take Off Boq2Document55 pagesQty Take Off Boq2Dick Anthony MabaoPas encore d'évaluation

- Project Execution Plan: Sector 1 MDC BP - Cog South LuzonDocument2 pagesProject Execution Plan: Sector 1 MDC BP - Cog South LuzonDick Anthony MabaoPas encore d'évaluation

- Qty Take Off Boq2Document55 pagesQty Take Off Boq2Dick Anthony MabaoPas encore d'évaluation

- ASTMC Actual S-Curve Erwin 01-20-15Document69 pagesASTMC Actual S-Curve Erwin 01-20-15Dick Anthony MabaoPas encore d'évaluation

- Rebar For AstmDocument5 pagesRebar For AstmDick Anthony MabaoPas encore d'évaluation

- Question Excerpt: "Size of Water Piping Shall Be Based On The TotalDocument8 pagesQuestion Excerpt: "Size of Water Piping Shall Be Based On The TotalDick Anthony MabaoPas encore d'évaluation

- Testing - Updated October 18, 2014Document162 pagesTesting - Updated October 18, 2014Dick Anthony MabaoPas encore d'évaluation

- Durations (DAYS) Activity Preceding CostDocument2 pagesDurations (DAYS) Activity Preceding CostDick Anthony MabaoPas encore d'évaluation

- NT 29 - Para-Raios - EngDocument109 pagesNT 29 - Para-Raios - EngMarcos SerrãoPas encore d'évaluation

- Energy Recovery Ventilation Technical Service Manaul PDFDocument40 pagesEnergy Recovery Ventilation Technical Service Manaul PDFjdanastasPas encore d'évaluation

- Substation Off Line and Hot Line CommissioningDocument3 pagesSubstation Off Line and Hot Line CommissioningMohammad JawadPas encore d'évaluation

- Service: ManualDocument88 pagesService: ManualMarceloAndradePas encore d'évaluation

- T 6760 67120 67240 67350 67500 PDFDocument14 pagesT 6760 67120 67240 67350 67500 PDFZayar Min ThanPas encore d'évaluation

- Corix 70 Plus-USV: Installation ManualDocument40 pagesCorix 70 Plus-USV: Installation Manualuriel vazquezPas encore d'évaluation

- Ime34070m 2 Far FR2835SDocument80 pagesIme34070m 2 Far FR2835Ssrinu1984Pas encore d'évaluation

- ClearHyb Heating Unit User ManualDocument13 pagesClearHyb Heating Unit User ManualDumitrescu CosminPas encore d'évaluation

- RCD PDFDocument6 pagesRCD PDFsanjay975Pas encore d'évaluation

- Siprotec4 Manual b9 enDocument530 pagesSiprotec4 Manual b9 enShamik PurkayasthaPas encore d'évaluation

- Manual Del Modulo de Una Entrada KIDDE GSA-CT1 PDFDocument2 pagesManual Del Modulo de Una Entrada KIDDE GSA-CT1 PDFAnderson CastañedaPas encore d'évaluation

- Sun MRC 400Document153 pagesSun MRC 400Pavel ManolovPas encore d'évaluation

- Omega Resistivity Meter ManualDocument16 pagesOmega Resistivity Meter ManualLouie Raymond Abbas FernandezPas encore d'évaluation

- Osteoporosis MeterDocument68 pagesOsteoporosis MeterHoang Ngoc TyPas encore d'évaluation

- 42,0410,2115Document52 pages42,0410,2115David Aguirre BurneoPas encore d'évaluation

- Bill of Quantities - Feb29Document15 pagesBill of Quantities - Feb29Elmer Soroan BarrerasPas encore d'évaluation

- Supplementary Specification To IEC 62040-3 AC Uninterruptible Power Systems (UPS)Document27 pagesSupplementary Specification To IEC 62040-3 AC Uninterruptible Power Systems (UPS)Jose LopezPas encore d'évaluation

- Electrical Design CriteriaDocument38 pagesElectrical Design Criteriaengmswilam100% (1)

- BS-2 (2. Building Wiring System) PDFDocument10 pagesBS-2 (2. Building Wiring System) PDFNaman JainPas encore d'évaluation

- CEC JA Solar PV Bifacial Double-Glass Modules Inatallation ManualDocument18 pagesCEC JA Solar PV Bifacial Double-Glass Modules Inatallation ManualTim ZHANGPas encore d'évaluation

- Sirona Cerec Dental Milling Machine - Service ManualDocument122 pagesSirona Cerec Dental Milling Machine - Service ManualRancer BaezPas encore d'évaluation

- Air Conditioner: Installation ManualDocument33 pagesAir Conditioner: Installation ManualromelrPas encore d'évaluation

- MHS E000 El CC 107 05Document24 pagesMHS E000 El CC 107 05sivasan10006098Pas encore d'évaluation

- Field of Application: Welding ProcessDocument2 pagesField of Application: Welding ProcessJoshuaPas encore d'évaluation

- SVERKER 750 - 780 Relay Test Unit. User S ManualDocument76 pagesSVERKER 750 - 780 Relay Test Unit. User S ManualaleksandarlaskovPas encore d'évaluation

- Benning MM12 User ManualDocument20 pagesBenning MM12 User ManualPWPRO3 PWPRO3Pas encore d'évaluation

- PCS-985G - X - Instruction Manual - EN - Domestic General - X - R1.00 - (EN - YJBH2641.0086.0001) PDFDocument316 pagesPCS-985G - X - Instruction Manual - EN - Domestic General - X - R1.00 - (EN - YJBH2641.0086.0001) PDFDoan BaoPas encore d'évaluation

- Guideline Chlorine Gas Pipeline 10032019 RevisedDocument40 pagesGuideline Chlorine Gas Pipeline 10032019 RevisedDarshan PatelPas encore d'évaluation

- 3054E and 3056E Industrial Engines-Maintenance IntervalsDocument36 pages3054E and 3056E Industrial Engines-Maintenance IntervalsprabumnPas encore d'évaluation

- Test ReportDocument4 pagesTest Reportmfm saventphilsPas encore d'évaluation