Académique Documents

Professionnel Documents

Culture Documents

Art:10 1007/BF02483137

Transféré par

Tarek ChikerTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Art:10 1007/BF02483137

Transféré par

Tarek ChikerDroits d'auteur :

Formats disponibles

Materials and Structures/Materiaux et Constructions, Vol.

35, September-October2002, pp 495-503

Optimization of ternary cementitious mortar blends

using factorial experimental plans

M. L. Nehdi andJ. Sumner

Department of Civil and Environmental Engineering, The University of Western Ontario, London, Ontario, Canada, N6A 5B9

Paper received:March 11, 2002; Paperaccepted:July3, 2002

A B S T R A C T

R I~ S U M I~

Producing cements incorporating high-volume

replacement of ordinary portland cement (OPC) by recycled industrial by-products is perceived as the most

promising venture for the cement and concrete industry

to meet its environmental obligations. However, the twocomponent (binary) cements thus produced are often

associated with shortcomings such as the need for

extended moist-curing, increased use of chemical admixtures, low early age strength, increased cracking tendency

due to drying shrinkage, and de-icing salt scaling problems. There is need for research to investigate whether

high-volume replacement multi-component (ternary and

quaternary) cements could be optimized with synergistic

effects allowing component ingredients to compensate for

any mutual shortcomings. This study uses factorial experimental plans to investigate the performance of OPC-silica

fume (SF)-class F fly ash (FA) and OPC-SF-ground granulated blast furnace slag (GBFS) ternary cementitious

blends. Response surfaces for the superplasticizer requirement to achieve a constant flow, setting time, drying

shrinkage up to 112 days, compressive strength at 1, 7, 28

and 56 days, and for the sulfate expansion up to 9-months

were obtained for up to 20%, 60%, and 60% replacement

levels of OPC by SF, FA and GBFS, respectively. A multiparametric optimization is used to establish response surfaces for a desirability function, which is used to rate

ternary cementitious blends. Results indicate that when

rheological, mechanical, durability and cost requirements

are combined; the use of costly mineral admixtures such

as silica fume is not economic in ternary OPC-SF-FA or

OPC-SF-GBFS blends beyond levels of about 3 to 5%.

Moreover, it is shown that the major hurdle for high-volume replacement of OPC with class F fly ash is compromising the early age performance. Results also indicate

that a good quality high-fineness GBFS can be used at

replacement levels of OPC up to 60% without major disadvantages.

La production de ciments incluant de hautes proportions

de d&hets industriels est consid(r(e comme l'entreprise la plus

prometteuse afin que I'industrie du ciment et du bdton reinplisse ses devoirs environnementaux. Cependant, les ciments

binaires (2 composants) ainsi produits sont souvent associ~s

des inconv~nients tels que le besoin de m~rissement humide

plus prolong( et un dosage d'adjuvants ckimiques plus dlevd,

une faible rdsistance en compression au jeune @e, vulndrabilit( accrue ~ la fissuration par retrait de s&hage et une plus

faible r(sistance 21 l'&aillage par les sels de d~glafage. Il est

ne~cessairede savoir si des ciments ~ plusieurs composants (ternaires et quatemaires) ont des effets synergiques de fa(on ~ ce

que leurs ingrddients compensent pour leurs faiblesses

mutuelles. Cette 8tude utilise des plans factoriels pour examiner la pe~rmance de ciments temaires incluant du ciment

Portland, de la fum~e de silice, des cendres volantes de dasse

F ou du laitier de hautfoumeau. Des courbes d'iso-@onses

pour le dosage de superplastifiant requis pour donner un e'coulement constant, le temps de prise, le retrait de s(chage jusqu '~

112 jours, la r(sistance en compression ~ 1, 7, 28 et 56

jours, et pour l' expansion due aux sulfates jusqu'~ 9 mois

ont (td obtenues pour des niveaux de remplacement du ciment

Portland de 20%, 60% et 60% avec, respectivement, de la

fum(e de silice, des cendres volantes et du laitier de haut fourneau. Une optimisation multi-param(trique a dtd utilisde

pour (tablir une (,fonction de d(sirabilit( }}permettant de dassifter des ciments temaires par ordre de pr~firence. Les r(sultats indiquent que lorsque les exigences rh~ologiques, mScaniques, de durabilitd ainsi qu'(conomiques sont prises en

compte, l'utilisation d'ajouts mindraux ~ co~t (let,( comme la

fumde de silice clans les ciments temaires examine's n'est pas

justifi(e au-del~ d'environ 3 ~ 596. De plus, il semble que

l'obstade majeur pour l'utilisation des ciments 27 haut dosage

en cendres volantes de classe F est leur faible pe~rmance au

jeune dge. Les laitiers de haut foumeau de bonne qualit( et

haute finesse par contre, peuvent 8tre utilis(s ~ des dosages

aussi hauts que 60% sans inconv~nients majeurs.

1359-5997/02 9

495

Materials and Structures/Mat6riaux et Constructions,Vol.3S, September-October2002

phates up to 9 months for the OPC-SF-FA and OP-SFGBFS ternary cementitious mortars.

1. INTRODUCTION

While civil infrastructure is already failing to keep up in

many parts of the world, the planet must prepare to

accommodate another 4 billion people within the next 50

years [1]. Moreover, a substantial part of existing civil infrastructure is reaching its design life and requiring repair or

replacement. Therefore, demand for construction materials is expected to continue to increase. Portland cement

concrete is already the most consumed material by humans

after water. The annual global production of portland

cement could reach 2 billion tonnes by year 2010 [2],

which could translate into 2 billion tonnes of CO 2 released

into the atmosphere each year, exacerbating the threat of

global warming and air pollution. If the current trends of

growing catastrophic losses due to extreme weather continue, public resistance to greenhouse gas emissions will

likely grow, and environmental regulations will consequently become much more stringent.

The cement and concrete industry is well advised to

be part of a concerted, internationally supported strategy

to meet sustainable development and environmental goals

[3]. So far this industry responded to this challenge mostly

by the production of two-component (binary) cements

incorporating various dosages of recycled industrial byproducts (some ternary cements are also being experimented and commercialized in some places). These

cements often deliver additional benefits such as lower

heat of hydration, increased resistance to alkali-silica reaction, sulphate attack, and chloride ion penetration.

Indeed, it is inconceivable nowadays to construct a concrete structure in an aggressive environment with only

pure OPC as the cementitious material. Binary cements,

however, are often associated with shortcomings such as

the need for extended moist-curing, increased use of

chemical admixtures, low-early-age strengths, increased

cracking tendency due to plastic shrinkage, and de-icing

salt scaling problems. Although research on multi-component cements had existed for several years, there is currently growing belief that such cements can be optimized

with synergistic effects, allowing component ingredients

to compensate for any mutual shortcomings [3].

Therefore, resource-efficient low-CO 2 emission cements

with tailor made properties can be developed.

It is believed that synergistic action in multi-component cements could be significant if the blend could have

wider particle size distribution and contains simultaneously a highly reactive pozzolan that would consume the

calcium hydroxide (CH) released by the early hydration of

OPC and a latent pozzolan that would consume the CH

rdeased at a later stage. Therefore, this study investigates

the performance of OPC-SF-FA and OPC-SF-GBFS

ternary cementitious blends. Factorial experiments that

provide response surfaces for the parameters under study

were used because they proved efficient as prediction

tools in previous investigations [4-6]. This study provides

a statistical modeling for the superplasticizer requirement

to achieve a constant mortar flow, setting time, drying

shrinkage up to 112 days, compressive strength at 1, 7, 28

and 56 days, and for the expansion due to exposure to sul-

2. MATERIALS

Ordinary ASTM Type I portland cement (OPC), silica fume (SF), class F fly ash (FA), and ground granulated blast furnace slag (GBFS) were used in this study.

Their physical and chemical properties are summarized

in Table 1. A naphthalene sulfonate superplasticizer having 42% solid content and tap water were used for the

mixing. The different mortars were made with standard

Ottawa sand (ASTM C778-91 Standard Specification

for Standard Sand).

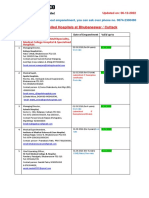

3. EXPERIMENTAL PLAN AND TEST

METHODS

3.1 Experimental plan

The experiments were designed according to a 32

factorial experimental plan (2 factors at 3 levels) as

shown in Fig. 1. This approach was selected to limit the

total number of cement mortars investigated while firstand second-order models could be used to fit the data.

In addition, this method highlights not only the significance of the experimental variables but also that of their

interactions, and has predictive capability for the

responses of other experimental points located within

the experimental domain. The experimental variables

were (i) the replacement rate of OPC by SF and (ii) the

replacement rate of OPC by either FA or GBFS.

Appropriate commercial software was used for the statistical analysis of the results [7].

FAor GBFS[%]

(0,60)

(10,60)

Q (20,6o)

(10,30)

(0,30) ~

(0,0)

@@

(10,0)

Q (20,3o)

(20,0)

Fig. l - I l l u s t r a t i o n o f t h e 3 2 factorial experimental plan used for

the ternary cementitious mixtures (13 mortar mixtures for each

ternary system).

3.2 Test methods

Twenty-six ternary-cement mortar mixtures (Fig. 1)

were conducted in a planetary paddle mixer according to

ASTM C305-82 guidelines (Practice for Mechanical

Mixing of Hydraulic Cement Pastes and Mortars of

496

Nehdi, Sumner

Table 1- Physical and chemical properties of materials used

ASTMType I ClassF

Cement

Fly Ash

Physical tests

Specific gravity

Passing 45 p m [%1

Specific surface [cm2/g]

f'cat l d [MPa]

7 d [MPa]

28 d [MPa]

Water requirement [%]

Pozzol. activity index [%]

7d

28d

Initial set, Vicat test [min]

Final set, Vicat test [min]

Air content of mortar [%]

Chemical analysis

Silicon oxide (Si02)

Aluminum oxide (AI203)

Ferric oxide (Fe203)

Calcium oxide (CaO)

Free calcium oxide (CaO)

Magnesium oxide (MgO)

Sodium oxide (Na20)

Potassium oxide (K20)

Eq. AIk. (Na20+0.658 K20)

Phosphorous oxide (P205)

Titanium oxide (Ti02)

Sulfur trioxide (S03)

Loss on ignition

(C3S)

(c2s)

(C3A)

(C4AF)

3.17

83.9

3950

17.2

32.1

38.8

GBFS Silica

Fume

2.08

83.6

2800

2.90

93.9

4680

2.06

-22920

99.2

102.4

114

79

87

91

102

96

105

92

242

7.6

19.5

5.2

2.4

61.3

1.1

0.3

1.1

1.0

1.8

4.2

2.0

2.5

51

18

10

7

52.4

23.4

4.7

13.4

1.3

3.6

0.6

4.0

0.2

0.8

0.2

0.3

2.2

34.8

94.0

9.8

0.1

0.6

0.1

38.3

0.4

. . . .

9.6

0.4

0.4

0.1

0.4

0.9

0.7

0.7

-<0.01

0.8

0.3

2.4

1.3

-2.7

Compressive Strength of Hydraulic Cement Mortars). In

addition, six prisms (25x25x285-mm) were cast for each

mortar mixture to test its drying shrinkage according to

ASTM C596-89 (Standard Test Method for Drying

Shrinkage of Mortar Containing Portland Cement).

Drying started after 1 day of curing the bar specimens

under more than 95% relative humidity and 2 days of

submersion in lime saturated water.

For each mortar mixture, 8 bars (25x25x285-mm)

were also made. The test specimens were stored in limesaturated water in a curing room at 23 + 1.7~ until they

reached a compressive strength of 20.0 + 1.0 MPa, as

measured using cubes made from the same mortar. The

bar specimens were then immersed in a sulphate solution

(5% by weight of Na2SO4). The containers in which the

bars were immersed are made of plastic and a means for

supporting the bars was included so that no end or side

of a bar specimen rests against the container. The pH

value of the sulphate solution was maintained in the

range of 6 to 8 by replacing the solution with a fresh one

when needed.

Before placing the specimens in the sulphate solution, their length was measured using a high accuracy

digital length comparator. The length change of the

specimens was then monitored at 1, 2, 3, 4, 8, 13, and 15

weeks after they were placed in the sulphate solution. If

slight, gradual, and uniform length change was taking

place, the next measurements were made at 4, 6, and 9

months. When expansion was occurring rapidly at any

stage of the test, the interval between readings was adequately shortened.

4. RESULTS AND DISCUSSION

4.1 Superplasticizer requirement

The superplasticizer dosage (expressed as ratio of the

Plastic Consistency). All mixtures had a constant

weight of liquid superplasticizer to that of cement in

water/binder (w/b) ratio of 0.40. A proportion of sand 2.5

percent) required to achieve a flow table value of 110% _+

times the mass of the binder was used. Flow for each mor5% is illustrated in Fig. 2 for the various OPC-SF-FA

tar mixture was measured using a flow table according to

and OPC-SF-GBFS ternary cement mortars. Increasing

ASTM C230-90 guidelines (Specifications for Flow Table

for Use in Tests of Hydraulic

Cement). The amount of superplasticizer added in each mixture was

designed to achieve a flow value of

110% + 5% (flow results are calculated

as [(d-do)/d o x 100] where d o is the initial

diameter and d is the diameter after

spread). The initial setting time for

each mortar mixture was measured

using ASTM C191-82 (Test Method

for Time of Setting of Hydraulic

C e m e n t Using the Vicat Needle).

Standard 5 0 - m m cubes were cast,

demoulded after 24 hours and cured in

lime-saturated water until testing for

uniaxial compressive strength as per

Fig. 2 - Response surfaces of superplasticizer requirement for (a) OPC-SF-FA and (b),

ASTM C349-82 (Test Method for OPC-SF-GBFS ternary cement mortars.

497

Materials and Structures/Mat~riaux et Constructions,Vol.3S, September-October

2002

the GBFS replacement rate from 0 to 60% seemed to

significantly reduce the required superplasticizer dosage

when high SF dosages are also used, while within a similar range of replacement of OPC by fly ash, the required

dosage of superplasticizer seemed to decrease in a less

significant fashion. Since the fly ash is coarser than the

GBFS, this may be due to the presence of carbon in fly

ash, which could reduce the efficiency of the superplasticizer. However, for both types of ternary cementitious

blends, silica fume seemed to be the major cause of

increasing the superplasticizer dosage, likely due to its

very high surface area.

4.2 Setting time

Response surfaces for the initial setting time are illustrated in Fig. 3 for the OPC-SF-FA and OPC-SF-GBFS

ternary cement mortars. The setting time increased as

the dosage of both GBFS and FA increased because of

their low reactivity. However, this effect was more drastic for ternary blends containing class F fly ash, likely

because GBFS is richer in calcium, has a significantly

higher surface area and would thus react faster than the

class F fly ash. For both OPC-SF-FA and OPC-SFGBFS ternary cement mortars, the initial setting time

also increased as the dosage of silica fume increased. This

is apparently caused by the higher superplasticizer

dosages used in high-SF content mortars (Fig. 2), which

are known to cause set-retarding problems. It was not

possible to use a constant superplasticizer dosage for all

mixtures because their flow would have been drastically

different, which will affect their properties and constitute a hidden parameter in the experimental design. It

was decided to rather adjust the superplasticizer dosage

to obtain a constant flow for all mortar mixtures, keeping in mind the possible effect of varying superplasticizer

dosage in the interpretation of results. It is remarkable

that mortars containing 20%SF combined with 60%FA

or GBFS achieved lower setting time than that of mortars made with either 60%GBFS or 60%FA. Although it

is conceivable that fine silica fume particles constituted

nucleation sites for hydration products, thus enhancing

the hydration process and reducing the setting time, it

would be difficult for this effect alone to compensate for

that of an additional 20% replacement of OPC. The true

mechanisms underlying this behaviour remain to be

explained.

4.3 Drying shrinkage

Drying shrinkage response surfaces at 7, 14, 28 and

112 days for OPC-SF-GBFS and OPC-SF-FA ternary

cement mortars were obtained. For conciseness, only

results at 7 and 112 days are shown in Fig. 4. Results at

14 and 28 days are only transitional stages between these

two extreme states with no noticeable drastic effects. At

7 days, the drying shrinkage of OPC-SF-GBFS slightly

decreased at higher GBFS contents. This behaviour was

partially reversed at 14 days and later stages, as drying

shrinkage seemed to slightly increase when high GBFS

contents are combined with high levels of SF. However,

the major factor that increased the drying shrinkage was

increased dosages of SF. It was observed that the

response surfaces and contour lines for drying shrinkage

had a comparable shape at 14, 28, and 112 days except

that the percentage of shrinkage consistently increased

with time. Nagataki and Wu [8] also observed that a

mortar made of a 60%OPC-10%SF-30%GBFS ternary

blend had increased drying shrinkage compared to a reference OPC mortar. They explained this behaviour by

the fact that the ternary blend had higher surface area

and smaller pore sizes. However, these causes are normally expected to increase autogenous shrinkage but

decrease the drying shrinkage, though these phenomena

interfere and cannot be separated.

For the OPC-SF-FA ternary cement mortars, the

effect of the FA content on drying shrinkage was not

significant at low SF contents, while drying shrinkage

seemed to significantly increase with increased FA contents at high SF levels. Response surfaces and contour

lines for drying shrinkage at 7, 14, 21, 28, and 112 days

had a similar shape but drying shrinkage consistently

increased with time. Again, the most significant parameter in increasing drying shrinkage was the silica fume

dosage and this was more drastic when high SF contents

are combined with high FA contents

in the ternary blend. Generally, the

drying shrinkage strains observed

with the O P C - S F - G B F S mortars

were higher than those measured for

the OPC-SF-FA mortars.

Fig. 3 - Response surfaces of initial setting time for (a) OPC-SF-FA and (b), OPC-SFGBFS ternary cement mortars.

498

Nehdi, Sumner

around 30% for low SF

contents and up to 15%

for high SF contents and

decreased beyond those

levels. The effect of SF on

increasing the strength of

the ternary cement mortars is clearer at this age

but was significant only at

GBFS levels below 30%.

Beyond such dosage, the

effect of SF on the 28-day

compressive strength was

not significant. For OPCSF-FA ternary c e m e n t

mortars, higher levels of

SF also increased the 28day compressive strength

at low FA contents, but

did not have a significant

effect at FA levels beyond

15 to 20%. However, the

28-day strength consistently decreased as the FA

dosage increased regardless of the SF content.

At 56 days, varying the

GBFS content from 0 to

60% did not have a significant

effect on the comFig. 4 - Response surfaces of drying shrinkage for ternary c e m e n t m o r t a r s (a) OPC-SF-FA at 7 days,

pressive strength of the

(b) OPC-SF-GBFS at 7 days, (c) OPC-SF-FA at 112 days, and (d) OPC-SF-GBFS at 112 days.

OPC-SF-GBFS cement

mortars at low SF levels.

4.4 Compressive strength

The higher the SF content in the ternary blend the more

significantly the 56-day compressive strength decreased

Response surfaces for the compressive strength at 1,

with higher GBFS dosage. It should be however under7, 28, and 56 days were obtained for the OPC-SF-GBFS

stood that a 56-day strength that could be achieved with

and OPC-SF-FA ternary cement mortars. For brevity,

95%OPC-5%SF-0%GBFS blend could be achieved

only 1-day and 56-day results are shown in Fig. 5. At one

with 4 0 % O P C - I O % S F - 5 0 % G B F S . Therefore a cost

day the compressive strength of the ternary cement moranalysis is required to determine which ternary blend

tars decreased as the content of GBFS or FA increased. For

would be optimal on a unit cost per MPa basis. For the

both OPC-SF-GBFS and OPC-SF-FA, silica fume did

OPC-SF-FA mortars, the compressive strength response

not seem to drastically enhance the 1-day strength whether

surface at 56 days was similar to the corresponding 28at low or high GBFS/FA contents. This behaviour is in

day response surface, with the strength decreasing with

contrast with some published results. For instance Swamy

increased FA content and increasing with SF only at low

[9] argued that to enhance the early age strength of FA and

FA contents.

GBFS concrete, highly reactive pozzolans such as SF could

be added in a ternary blend.

4.5 Cost analysis

At 7 days, the effect of SF on enhancing the compressive strength of the ternary cement mortars became

more significant and was more pronounced in the

Fig. 6 presents a cost analysis for the OPC-SF-GBFS

and OPC-SF-FA ternary cementitious blends on a dolternary blend containing GBFS than in the blend conlar per MPa basis. Cost analysis was based on prices of

taining class F fly ash. Again the 7-day compressive

$130/tonne for cement, $ 8 0 / t o n n e for fly ash,

strength decreased with increased dosage of GBFS and

FA. However, the 7-day strength values generally were

$100/tonne for slag, $3/liter for the superplasticizer and

$600/tonne for silica fume; all figures in Canadian dollar.

in the 28 to 50 MPa range for the OPC-SF-GBFS

No allocation was considered for sand since it is constant

ternary mortars, while they ranged between 11 and 50

MPa for the OPC-SF-FA blend.

in all 26 mortars used.

At one day, the cost per MPa increased at high replaceAt 28 days, the compressive strength of OPC-SFment levels of OPC by either FA or GBFS (Figs. 6(a) and

GBFS increased with increasing GBFS content up to

499

Materials and Structures/Mat6riaux et Constructions, Vol. 3,5, September-October 2002

4.6 Sulphate

expansion

Response surfaces for

the 9 - m o n t h sulphate

expansion of standard bars

made from O P C - S F - F A

and OPC-SF-GBFS ternary

cement mortars are shown

in Fig. 7. Response surfaces

of sulphate expansion of

OPC-SF-FA cement mortars followed linear models.

After one week of exposure

to sulphates, the expansion

decreased with increasing

levels of SF in the ternary

blend, while the FA dosage

had limited effect on sulphate expansion. After

4 weeks of exposure, SF was

still the dominant factor in

controlling expansion, however, FA also started to have

a noticeable effect. After 13

weeks and up to 9 months,

around 27% of fly ash could

reduce expansion by an

equal a m o u n t to that

achieved by around 6% of

SF, and 45%FA could control expansion in a comparaFig. 5 - Response surfaces of compressive strength at I day and 56 days for OPC-SF-FA and OPCble way to about 12%SF.

SF-GBFS ternary cement mortars.

High SF contents combined

with high FA contents were most efficient in controlling

sulphate expansion.

6(b)). This is due to the low reactivity of these mineral

OPC-SF-GBFS ternary cement mortars generally

admixtures and their delay of the early-age gain of

had

higher expansion values due to exposure to sulphates

strength. This effect was however more severe for the

compared

to OPC-SF-FA ternary mortars probably

class F fly ash mortars. The effect of the SF dosage on

because

GBFS

is richer in calcium than class F fly ash.

the 1-day cost per MPa for the various mortars was less

The

reduced

efficiency

of high CaO mineral admixtures

significant when the ternary blend does not contain high

in

controlling

sulphate

expansion was documented by

levels of FA or GBFS. However, at high FA or GBFS

several

researchers

[10-12]

and is recognized by the reccontents, the higher the SF content in the ternary

ommendations

of

ACI

Committee

232 [13], which state

binder, the higher was the cost per MPa.

that

fly

ash

with

a

CaO

level

lower

than 15% will

For OPC-SF-GBFS ternary mortars at 56 days,

improve

sulphate

resistance

while

fly

ash

with higher

higher SF contents in the ternary blend increased the

calcium contents needs to be tested. After one week of

cost per MPa regardless of the GBFS dosage, while the

exposure, sulphate expansion of OPC-SF-GBFS ternary

GBFS content had little effect on the cost per MPa at all

mortars decreased with higher SF dosages and was not

SF contents. For O P C - S F - F A ternary mortars at

significantly affected by the GBFS level in the blend. It

56 days, the FA content did not have a severe effect on

followed a linear model, while quadratic models better

the cost per MPa at low SF dosages, while the cost per

fitted sulphate expansion data at later stages. At 4 weeks

MPa increased with higher FA contents when a high SF

or longer periods of exposure to sulphates, sulphate

dosage is used simultaneously in the blend. Higher SF

expansion was efficiently controlled by either increasing

contents increased the cost per MPa and this was more

levels of SF or GBFS. Combined high levels of SF and

drastic at high FA contents. Again, the OPC-SF-FA

GBFS did not seem to particularly provide an advantage

mortars had higher cost per MPa at 56 days than that of

in terms of controlling expansion. Actually when the

the OPC-SF-GBFS mortars. This behaviour may howternary blend contained 20%SF and 60%GBFS, its

ever change at later stages when the less reactive class F

expansion seemed to slightly increase compared to

fly ash develops its full potential.

500

Nehdi, Sumner

showed higher sulphate

expansion than a control

mortar. When 3% by mass

of the cementitious material were replaced by silica

fume, the expansion of the

ternary OPC-SF-high calc i u m FA mortars was

decreased significantly.

4.7 Numerical

optimization

Simultaneous optimization of multiple responses

obtained from the factorial

experimental plan can be

performed numerically.

Numerical optimization

could optimize any combination of one or more goals

(experimental factors may

not have a goal of none; the

default goal for a factor is

"keep within the low/high

limits). The first step is to set

goals for the optimization for

each of the measured

Fig. 6 - Response surfaces of cost per MPa for OPC-SF-FA ternary cement mortars at (a) 1 d and

responses. The allowable

(b) 56 d and for OPC-SF-GBFS ternary cement mortars at (c) 1 d and (d) 56 d.

goals are: i) to minimize or

maximize a parameter, ii) to

target a specific level of a

parameter, iii) to keep a

parameter within a specified

range, and iv) none.

Each goal is assigned a

weight (number between 1

and 5 with 5 being most

i m p o r t a n t and I least

important). The goals are

then c o m b i n e d into an

overall desirability function,

which shape is controlled

by the

optimization

weights. T h e numerical

optimization software used

seeks to maximize this

function,

which has a maxiFig. 7 - Response surfaces of 9-month sulphate expansion for (a) OPC-SF-FA and

m u m value of 1 inside the

(b) OPC-SF-GBFS ternary cement mortars.

experimental domain and a

value of zero outside the experimental domain. The goal

ternary blends containing 10%SF and 30% GBFS. This

seeking begins at a random starting point and proceeds

unexpected result remains to be explained. As expected,

up the steepest slope to a maximum. There may be two

for both OPC-SF-FA and OPC-SF-GBFS ternary moror more maximums because of curvature in the response

tars, a pure OPC mortar had the highest value of expansurfaces and their combination into the desirability funcsion at all stages of exposure to sulphates. Results are

somewhat in line with results of Thomas et al. [10] who

tion. Starting from several points in the design space may

observed that mortars made of a combination of 20 to

be necessary to find the "best" local maximum.

To illustrate this concept, goals and weights for mea40% of a high-calcium FA with high C3A cement

501

Materials and Structures/Mat6riaux et Constructions, Vol. 35, September-October2002

high FA contents also tended to decrease the desirability

function but this decrease was drastic at SF levels in excess

of 8 to 10%. Finally, it is recommended that this optimization work be also conducted on concrete mixtures

since results obtained on mortars often cannot be directly

transposed to concrete. In this exercise, the water/binder

ratio should vary between 0.25 to 0.65 to represent the

practical range in the field.

Table 2 - Criteria, goals and weights used in

numerical optimization

Criteria

Goal

Weight

Within range [0,201%

N.A.

Within range [0, 60]%

N.A.

Cost per MPa at 56 days

Minimum

Minimum

5

5

Superplasticizer

Minimum

Setting time

Flow table value

Minimum

Within range [110+51%

3

2

Dryingshrinkage at: 7 days

Minimum

28 days

112 days

Minimum

SF

FA or GBFS

Cost per MPa at I day

5. C O N C L U S I O N S

A rational method based on factorial experimental

design was used in this study to investigate possible synerMinimum

4

gistic effects in ternary OPC-SF-FA and OPC-SF-GBFS

Compressivestrength at:

cementitious blends. Results obtained on mortars indicate

I day

Maximum

5

that the method can be used to design a cementitious

28 days

Maximum

4

blend with a specific superplasticizer demand or a specific

56 days

Maximum

5

setting time. In addition, drying shrinkage contour lines

Sulfate expansionat:

can be obtained at different ages and blends with high

6 months

Minmum

4

shrinkage strains can be avoided. Similarly, contour lines

9 months

Minimum

4

for compressive strength at various ages can be obtained

and the designer can select

cementitious blends with

desired

performance.

Although these results are

obtained at a constant w/b

ratio of 0.40, the effective

method presented can be

easily applied to other materials and experimental conditions. Also, the conclusions drawn here on the

performance of ternary

cements are partial since

transport-related durability

properties and frost durability (of concrete) were not

investigated.

This paper provides a

Fig. 8 - Response surfaces of desirability function based on multi-parametric numerical optimizasimple and cost-effective

tion for (a) OPC-SF'GBFS, and (b) OPC-SF-FA ternary mortar mixtures.

approach for conducting

multi-parametric optimization of ternary cementitious blends. The factorial expersured responses in this study were selected and are sumimental design used provides response surfaces for the

marized in Table 2. Fig. 8 shows the response surfaces of

various parameters investigated based only on 13 mortar

the desirability functions for OPC-SF-FA and OPC-SFmixtures. Such response surfaces offer a simple visual

GBFS ternary blends to achieve the goals set in Table 2. It

tool to compare the performance of ternary cementishould be remembered that these response surfaces of the

tious blends. Multi-parametric optimization can be cardesirability functions will change if the operator selects

ried out using a simple software program, with the user

different goals or different weights for the optimization

controlling the goal of the optimization and the signifiprocess or when other data, such as chloride ion penetracance of each experimental parameter. This provides

tion, is also included. It can be observed that the desirabilflexibility to optimize cementitious blends with tailority function increased with increased GBFS in the OPCmade properties that suit each particular job requireSF-GBFS ternary blend up to around 30%, then tended

ments. It also allows obtaining response surfaces for cost

to decrease at higher dosages. Generally, the &sirability

analysis in order to select cost-effective solutions.

function decreased beyond 3%SF in the ternary blend,

Results of this optimization reveal that when rheowhile SF levels beyond 5% could not be justified based on

logical, mechanical, durability and cost requirements are

this optimization. In the case of OPC-SF-FA ternary

combined; the use of costly mineral admixtures such as

blends, the desirability function also decreased beyond

silica fume is not economic in ternary OPC-SF-FA or

30% fly ash. High SF contents either at very low or very

502

Nehdi, Sumner

OPC-SF-GBFS blends beyond levels of about 3 to 5%.

These results also show that the major hurdle for highvolume replacements of OPC with class F fly ash is

compromising the early age performance. Hence, there

is a fundamental need for developing cost-effective techniques to enhance the early-age reactivity of class F fly

ash. Results also show that a good quality high-fineness

GBFS can be used at replacement levels of OPC up to

60% without major disadvantages.

The proposed approach is especially useful because

there is growing interest in developing environmentally

efficient cement-based products based on multi-component cementitious blends incorporating high-volume

replacements of ordinary portland cement with recycled

by-products. Components in such blends can be optimized with synergistic effects so that they can compensate for any mutual shortcomings. Such optimization

will be multi-parametric accounting for various performance criteria and conflicting requirements. Thus, in

order to reach reliable results, the number of mixtures

that needs to be investigated can be very large and the

procedure can by costly and time consuming. Factorial

experimental plans can provide fairly reliable results

based on a limited number of experimental data points.

More research is needed in this area to assist the industry

in developing the next generation of high-performance

environmentally-effective cement-based materials.

ACKNOWLEDGEMENT

The support of the Natural Science and Engineering

Research Council of Canada (NSERC) to M. Nehdi

was instrumental for this research. M. Nehdi also

acknowledges funding of the Ontario Innovation Trust

and the Canada Foundation for Innovation that allowed

creating a state-of-the-art lab in which this research was

conducted.

REFERENCES

[1] Clough, G. W., 'Civil engineering in the next millennium',

Presented at the MIT CEE New Millennium Colloquium

(March 2000) 13 p.

[2] Mehta, P. K., 'Concrete technology for sustainable development',

Concrete International 21 (11) (1999) 47-53.

[3] Nehdi, M., 'Ternary and quaternary cements for sustainable

development', ConcreteInternational 24 (4) (2001) 35-42.

[4] Nehdi, M., Mindess, S. and Mtcin, P.-C., 'Statistical modeling of

the microfiller effect on the rheology of composite cement

pastes', Advances in Cement Research 9 (33) (1997) 37-46.

[5] Douglas, E. and Pouskouleli, G., 'Prediction of compressive

strengths of mortars made with portland cement-blast furnace

slag-fly ash blends', Cement and Concrete Research 21 (4) (1991)

523-534.

[6] Wang, D. and Chen, Z., 'On predicting compressive strengths of

mortars with ternary blends of cement, GGBFS and fly ash',

Cement and ConcreteResearch 27 (4) (1997) 487-493.

[7] Design Expert, Version 5.0.3, STAT-EASE-Inc., 2021 East

Hennepin Ave., Suite 191, Minneapolis, MN 55413.

[8] Nagataki, S. and Wu, C., 'A study of portland cement incorporating silica fume and blast furnace slag', in CANMET-ACI SP153. Malhotra, V. M., editor. II (1995) 1051-1068.

[9] Swamy, R. N., 'Design for durability and strength through the

use of fly ash and slag in concrete', in 3 rd CANMET-ACI

International Conference on Advances in Concrete Technology,

SP-171, Malhotra, V.M., editor. (1997) 1-72.

[10] Thomas, M. D. A., Shehata, M. H., Shashiprakash, S. G.,

Hopkins, D. S. and Call, K., 'Use of ternary cementitious systems containing silica fume and fly ash in concrete', Cement and

Concrete Research 29 (1999) 1207-1214.

[11] Dunstan, E. R., 'Possible methods of identifying fly ashes that

will improve sulphate resistance', Cement, Concrete and Aggregates

2 (1) (1980) 20-30.

[12] Tikalsky, P. J. and Carrasquillo, R. L., 'Influence of fly ash on

the sulphate resistance of concrete', ACI MaterialsJournal 89 (1)

(1992) 69-75.

[13] ACI Committee 232, 'Use of Fly Ash in Concrete', (American

Concrete Institute, Farmington Hills, Michigan, 1996).

503

Vous aimerez peut-être aussi

- Advances in Materials Science for Environmental and Energy Technologies VID'EverandAdvances in Materials Science for Environmental and Energy Technologies VITatsuki OhjiPas encore d'évaluation

- Cement and Concrete Research: A. Morandeau, M. Thiéry, P. DanglaDocument11 pagesCement and Concrete Research: A. Morandeau, M. Thiéry, P. DanglaTarek ChikerPas encore d'évaluation

- Statistical Modeling of Mechanical and Transport Properties of Concrete Incorporating Glass PowderDocument19 pagesStatistical Modeling of Mechanical and Transport Properties of Concrete Incorporating Glass PowderAly Hussein AbdallaPas encore d'évaluation

- Effect of Saw Dust Ash and Eggshell Powder On The Properties of Cement BlendsDocument12 pagesEffect of Saw Dust Ash and Eggshell Powder On The Properties of Cement BlendsSamsouma BkPas encore d'évaluation

- The Engineering Properties and Microstructure Development of Cementmortar Containing High Volume of Inter-Grinded GGBS and PFA Cured Atambient TemperatureDocument11 pagesThe Engineering Properties and Microstructure Development of Cementmortar Containing High Volume of Inter-Grinded GGBS and PFA Cured Atambient TemperatureLingLing TiongPas encore d'évaluation

- Construction and Building Materials: Telma Ramos, Ana Mafalda Matos, Bruno Schmidt, João Rio, Joana Sousa-CoutinhoDocument9 pagesConstruction and Building Materials: Telma Ramos, Ana Mafalda Matos, Bruno Schmidt, João Rio, Joana Sousa-CoutinhoTarek ChikerPas encore d'évaluation

- Tittle: Pozzolana As Non OPC Binder MaterialsDocument8 pagesTittle: Pozzolana As Non OPC Binder MaterialsVIMAL MAURYAPas encore d'évaluation

- Strength Development of Ternary Blended Cement With Limestone Filler and Blast-Furnace SlagDocument7 pagesStrength Development of Ternary Blended Cement With Limestone Filler and Blast-Furnace Slagdevildriver_990Pas encore d'évaluation

- Cement & Concrete Composites: Dale P. Bentz, Andrew S. Hansen, John M. GuynnDocument8 pagesCement & Concrete Composites: Dale P. Bentz, Andrew S. Hansen, John M. GuynnChin KamRongPas encore d'évaluation

- Materials and Design: Alaa M. RashadDocument21 pagesMaterials and Design: Alaa M. RashadLenia LuciaPas encore d'évaluation

- Opc As FillerDocument16 pagesOpc As Fillerkiwaallan3Pas encore d'évaluation

- High-Performance, High-Volume Fly Ash Concrete For Sustainable DevelopmentDocument12 pagesHigh-Performance, High-Volume Fly Ash Concrete For Sustainable DevelopmentDeep SidPas encore d'évaluation

- Construction and Building Materials: Yeonho Park, Ali Abolmaali, Young Hoon Kim, Masoud GhahremannejadDocument9 pagesConstruction and Building Materials: Yeonho Park, Ali Abolmaali, Young Hoon Kim, Masoud GhahremannejadaminPas encore d'évaluation

- Evaluation of The Impact of Short-Term Aging On Volumetric and Marshall Properties of Palm Oil Clinker Fine Modified Asphalt Concrete (Pocf-Mac)Document12 pagesEvaluation of The Impact of Short-Term Aging On Volumetric and Marshall Properties of Palm Oil Clinker Fine Modified Asphalt Concrete (Pocf-Mac)Cesar Idrogo MontalvoPas encore d'évaluation

- Al-Kutti - Hybrid Binders Containing Date Palm AshDocument11 pagesAl-Kutti - Hybrid Binders Containing Date Palm AshFerisma RatugiriPas encore d'évaluation

- Utilising Unprocessed Low-Lime Coal Fly Ash in Foamed ConcreteDocument12 pagesUtilising Unprocessed Low-Lime Coal Fly Ash in Foamed ConcreteAlberto Tupa OrtizPas encore d'évaluation

- Numerical Model For Quantifying Degree of Hydration in Concrete Mixes With Reduced CO2 FootprintDocument11 pagesNumerical Model For Quantifying Degree of Hydration in Concrete Mixes With Reduced CO2 Footprintbikramjit debPas encore d'évaluation

- Studies On Relationship Between Water/Binder Ratio and Compressive Strength of High Volume Fly Ash ConcreteDocument8 pagesStudies On Relationship Between Water/Binder Ratio and Compressive Strength of High Volume Fly Ash ConcreteAJER JOURNALPas encore d'évaluation

- DX 24785787Document3 pagesDX 24785787Jithesh.k.sPas encore d'évaluation

- Materials 16 07009Document15 pagesMaterials 16 07009Christian RAMADJIPas encore d'évaluation

- Particle Packing TheoryDocument15 pagesParticle Packing Theorysrujan varma kaithojuPas encore d'évaluation

- Properties of Green Concrete Mix by Concurrent Use of Fly Ash and Quarry DustDocument7 pagesProperties of Green Concrete Mix by Concurrent Use of Fly Ash and Quarry DustIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalPas encore d'évaluation

- FA GGBS Long Curing 90 180Document14 pagesFA GGBS Long Curing 90 180Yaswanth SinhaPas encore d'évaluation

- Replacement of Cement Using Fly AshDocument22 pagesReplacement of Cement Using Fly Ashkaushal yadavPas encore d'évaluation

- Final Project Report 2Document8 pagesFinal Project Report 2Mallesh MaranurPas encore d'évaluation

- ReferencesDocument36 pagesReferencesAsad QaziPas encore d'évaluation

- Meddah Et Al., Potential Use of BinaryDocument13 pagesMeddah Et Al., Potential Use of BinaryÁlvaro MendozaPas encore d'évaluation

- Construction and Building Materials: Cheah Chee Ban, Lim Jay Sern, Mahyuddin B. RamliDocument16 pagesConstruction and Building Materials: Cheah Chee Ban, Lim Jay Sern, Mahyuddin B. Ramlijaysern7Pas encore d'évaluation

- LJMU Research Online: Intend To Cite From This Work)Document11 pagesLJMU Research Online: Intend To Cite From This Work)zainabPas encore d'évaluation

- 1 s2.0 S0950061823037674 MainDocument11 pages1 s2.0 S0950061823037674 Mainguirv03Pas encore d'évaluation

- Rubberized Concrete (Rubcrete) : Critic ReportsDocument4 pagesRubberized Concrete (Rubcrete) : Critic ReportsTheBeast NaralPas encore d'évaluation

- The Use of Blast Furnace Slag As A Supplementary CDocument13 pagesThe Use of Blast Furnace Slag As A Supplementary CCivil manPas encore d'évaluation

- Use of Water Reducers To Impove Grindability and Performance of PC Clinker PDFDocument10 pagesUse of Water Reducers To Impove Grindability and Performance of PC Clinker PDFTran Huynh NamPas encore d'évaluation

- Al-Fahdawi 2020 IOP Conf. Ser. Mater. Sci. Eng. 881 012179Document10 pagesAl-Fahdawi 2020 IOP Conf. Ser. Mater. Sci. Eng. 881 012179Saif LlPas encore d'évaluation

- Thesis On Rice Husk Ash ConcreteDocument5 pagesThesis On Rice Husk Ash Concretefjf8xxz4100% (2)

- 1 PB PDFDocument6 pages1 PB PDFRIZALPas encore d'évaluation

- Proportioning of Fly Ash Concrete MixesDocument6 pagesProportioning of Fly Ash Concrete Mixesjignesh shahPas encore d'évaluation

- 2014-09-01 - Microstructure and Properties of Concrete Using Bottom Ash and Waste - Construction and Building MaterialsDocument14 pages2014-09-01 - Microstructure and Properties of Concrete Using Bottom Ash and Waste - Construction and Building MaterialsRoxy MansPas encore d'évaluation

- Evaluation of Sustainable Green Concrete With Partial Replacement of Cement by Banana Leaf Powder and Cattle Bone PowderDocument4 pagesEvaluation of Sustainable Green Concrete With Partial Replacement of Cement by Banana Leaf Powder and Cattle Bone PowderJeriel PacerPas encore d'évaluation

- Construction and Building Materials: A. Ruiz-Sánchez, M. Sánchez-Polo, M. RozalenDocument10 pagesConstruction and Building Materials: A. Ruiz-Sánchez, M. Sánchez-Polo, M. RozalenAya QatawnaPas encore d'évaluation

- 2018 Fillers in Cementitious Materials - Experience, Recent Advances and Future PotentialDocument14 pages2018 Fillers in Cementitious Materials - Experience, Recent Advances and Future PotentialTiago BragaPas encore d'évaluation

- Geosciences 10 00241Document18 pagesGeosciences 10 00241Karely González GálvezPas encore d'évaluation

- Construction and Building Materials: Ana Mafalda Matos, Joana Sousa-CoutinhoDocument11 pagesConstruction and Building Materials: Ana Mafalda Matos, Joana Sousa-CoutinhoTarek ChikerPas encore d'évaluation

- Developing A Sustainable Concrete Using Sugarcane Bagasse Ash (SBA) With Partial Replacement of Fine Aggregate and CementDocument12 pagesDeveloping A Sustainable Concrete Using Sugarcane Bagasse Ash (SBA) With Partial Replacement of Fine Aggregate and CementIJRASETPublicationsPas encore d'évaluation

- BuildingsDocument22 pagesBuildingsSai PavanPas encore d'évaluation

- Applied SciencesDocument17 pagesApplied SciencesDanielPas encore d'évaluation

- Article 2024Document43 pagesArticle 2024Ali SherPas encore d'évaluation

- A Study On Effect of Fly Ash and Glass Powder On The Compressive Strength and Permeability of ConcreteDocument23 pagesA Study On Effect of Fly Ash and Glass Powder On The Compressive Strength and Permeability of ConcreteArul RajPas encore d'évaluation

- Thermogravimetric Analysis (TGA) Methodology of Calculating TheDocument15 pagesThermogravimetric Analysis (TGA) Methodology of Calculating TheHamed HamidpourPas encore d'évaluation

- Fly Ash Amended Soils As Highway Base MaterialsDocument10 pagesFly Ash Amended Soils As Highway Base MaterialsSalman HaiderPas encore d'évaluation

- Optimizationandperformanceofcost Effectiveultra HighperformanceconcreteDocument17 pagesOptimizationandperformanceofcost Effectiveultra Highperformanceconcretestephan simaPas encore d'évaluation

- A Step by Step Methodology For Building SustainablDocument25 pagesA Step by Step Methodology For Building SustainablOrhan YanyatmazPas encore d'évaluation

- 06 - Chao Yao and All 2021Document12 pages06 - Chao Yao and All 2021Sahnoune Ben sahnounePas encore d'évaluation

- Rice Husk Ash Concrete Literature ReviewDocument6 pagesRice Husk Ash Concrete Literature Reviewaiqbzprif100% (1)

- Use of Incineration Solid Waste Bottom Ash As CemeDocument7 pagesUse of Incineration Solid Waste Bottom Ash As CemeARIANA EMMA IRENE BENAVIDES GAMARRAPas encore d'évaluation

- Materials 16 04778Document28 pagesMaterials 16 04778Yasir ComposingPas encore d'évaluation

- 287 303Document17 pages287 303Ehsan GhaffariPas encore d'évaluation

- Use of Biomass Ash From Different Sources and Processes in CementDocument22 pagesUse of Biomass Ash From Different Sources and Processes in CementEng mohammadPas encore d'évaluation

- Properties of Self Leveling Mortars Incorporating A High - 2020 - Journal of BuDocument9 pagesProperties of Self Leveling Mortars Incorporating A High - 2020 - Journal of BuVincent PilienPas encore d'évaluation

- 1 s2.0 S0008884600003860 Main PDFDocument8 pages1 s2.0 S0008884600003860 Main PDFTarek ChikerPas encore d'évaluation

- What Causes Differences of C-S-H Gel Grey Levels in Backscattered Electron Images?Document7 pagesWhat Causes Differences of C-S-H Gel Grey Levels in Backscattered Electron Images?Tarek ChikerPas encore d'évaluation

- Research in Economics: Lonnie K. StevansDocument12 pagesResearch in Economics: Lonnie K. StevansTarek ChikerPas encore d'évaluation

- Pr7.Irassar Disc. 2000Document2 pagesPr7.Irassar Disc. 2000Tarek ChikerPas encore d'évaluation

- Pr125. Harrison.c. 03Document2 pagesPr125. Harrison.c. 03Tarek ChikerPas encore d'évaluation

- Technical Committees: Chloride Ions Can Penetrate Into The Concrete and CauseDocument4 pagesTechnical Committees: Chloride Ions Can Penetrate Into The Concrete and CauseTarek ChikerPas encore d'évaluation

- Construction and Building Materials: Md. Safiuddin, J.S. West, K.A. SoudkiDocument6 pagesConstruction and Building Materials: Md. Safiuddin, J.S. West, K.A. SoudkiTarek ChikerPas encore d'évaluation

- The Influence of Different Curing Conditions On The Pore Structure and Related Properties of Fly-Ash Cement Pastes and MortarsDocument11 pagesThe Influence of Different Curing Conditions On The Pore Structure and Related Properties of Fly-Ash Cement Pastes and MortarsTarek ChikerPas encore d'évaluation

- MS-A.4 Determination of The Durability of Hardened MortarDocument5 pagesMS-A.4 Determination of The Durability of Hardened MortarTarek ChikerPas encore d'évaluation

- Qualitrol 900 910Document6 pagesQualitrol 900 910chennupati999Pas encore d'évaluation

- JCIPDocument5 pagesJCIPdinesh.nayak.bbsrPas encore d'évaluation

- Ransomware: Prevention and Response ChecklistDocument5 pagesRansomware: Prevention and Response Checklistcapodelcapo100% (1)

- 1st Problem Solving Assignment - Barrels of Apples - M383 Sp22.docx-2Document4 pages1st Problem Solving Assignment - Barrels of Apples - M383 Sp22.docx-2Kor16Pas encore d'évaluation

- Module 2Document7 pagesModule 2karthik karti100% (1)

- Statistical Techniques EE 532Document1 pageStatistical Techniques EE 532AdnanPas encore d'évaluation

- MSC ACFN2 RD4 ClassDocument25 pagesMSC ACFN2 RD4 Classmengistu jiloPas encore d'évaluation

- Ose Sample QuotationDocument37 pagesOse Sample Quotationrj medelPas encore d'évaluation

- Allegro Delivery Shipping Company Employment Application FormDocument3 pagesAllegro Delivery Shipping Company Employment Application FormshiveshPas encore d'évaluation

- Strategic Capital Management: Group - 4 Jahnvi Jethanandini Shreyasi Halder Siddhartha Bayye Sweta SarojDocument5 pagesStrategic Capital Management: Group - 4 Jahnvi Jethanandini Shreyasi Halder Siddhartha Bayye Sweta SarojSwetaSarojPas encore d'évaluation

- Shaqlawa Technical College: IT DepartmentDocument20 pagesShaqlawa Technical College: IT Departmentbilind_mustafaPas encore d'évaluation

- RevlonDocument13 pagesRevlonSarosh AtaPas encore d'évaluation

- Property House Invests $1b in UAE Realty - TBW May 25 - Corporate FocusDocument1 pageProperty House Invests $1b in UAE Realty - TBW May 25 - Corporate FocusjiminabottlePas encore d'évaluation

- Assessing The Marks and Spencers Retail ChainDocument10 pagesAssessing The Marks and Spencers Retail ChainHND Assignment Help100% (1)

- KiSoft Sort & Pack Work Station (User Manual)Document41 pagesKiSoft Sort & Pack Work Station (User Manual)Matthew RookePas encore d'évaluation

- 2001 Ford F150 ManualDocument296 pages2001 Ford F150 Manualerjenkins1100% (2)

- Induction Motor Steady-State Model (Squirrel Cage) : MEP 1422 Electric DrivesDocument21 pagesInduction Motor Steady-State Model (Squirrel Cage) : MEP 1422 Electric DrivesSpoiala DragosPas encore d'évaluation

- Participatory EvaluationDocument4 pagesParticipatory EvaluationEvaluación Participativa100% (1)

- Compact 1.8" Height Standardized Installation 9 Months To Flight Powerful and LightweightDocument2 pagesCompact 1.8" Height Standardized Installation 9 Months To Flight Powerful and LightweightStanley Ochieng' OumaPas encore d'évaluation

- PR Earth Users Guide EMILY1Document2 pagesPR Earth Users Guide EMILY1Azim AbdoolPas encore d'évaluation

- Dept & Sem: Subject Name: Course Code: Unit: Prepared byDocument75 pagesDept & Sem: Subject Name: Course Code: Unit: Prepared by474 likithkumarreddy1Pas encore d'évaluation

- Marieb ch3dDocument20 pagesMarieb ch3dapi-229554503Pas encore d'évaluation

- Dash 3000/4000 Patient Monitor: Service ManualDocument292 pagesDash 3000/4000 Patient Monitor: Service ManualYair CarreraPas encore d'évaluation

- Lakh Only) Being The Amount Covered Under The Aforesaid Dishonoured Cheque, and So AlsoDocument2 pagesLakh Only) Being The Amount Covered Under The Aforesaid Dishonoured Cheque, and So AlsoShivam MishraPas encore d'évaluation

- Process Industry Practices Insulation: PIP INEG2000 Guidelines For Use of Insulation PracticesDocument15 pagesProcess Industry Practices Insulation: PIP INEG2000 Guidelines For Use of Insulation PracticesZubair RaoofPas encore d'évaluation

- Empanelled Hospitals List Updated - 06-12-2022 - 1670482933145Document19 pagesEmpanelled Hospitals List Updated - 06-12-2022 - 1670482933145mechmaster4uPas encore d'évaluation

- STARCHETYPE REPORT ReLOADED AUGURDocument5 pagesSTARCHETYPE REPORT ReLOADED AUGURBrittany-faye OyewumiPas encore d'évaluation

- Helipal Tbs Powercube ManualDocument29 pagesHelipal Tbs Powercube Manualoualid zouggarPas encore d'évaluation

- Rubber Band Arrangements - Concert BandDocument25 pagesRubber Band Arrangements - Concert BandJonatas Souza100% (1)

- Contigency Plan On Class SuspensionDocument4 pagesContigency Plan On Class SuspensionAnjaneth Balingit-PerezPas encore d'évaluation