Académique Documents

Professionnel Documents

Culture Documents

Effects of Increasing Allowable Compressive Stressat Prestress Transfer

Transféré par

Professor Dr. Nabeel Al-Bayati-Consultant EngineerCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Effects of Increasing Allowable Compressive Stressat Prestress Transfer

Transféré par

Professor Dr. Nabeel Al-Bayati-Consultant EngineerDroits d'auteur :

Formats disponibles

ACI STRUCTURAL JOURNAL TECHNICAL PAPER

Title no. 107-S03

Effects of Increasing Allowable Compressive Stress

at Prestress Transfer

by David B. Birrcher, Oguzhan Bayrak, and Michael E. Kreger

The benefits and weaknesses of increasing the allowable compressive

stress at prestress transfer are presented in this paper. A historical

background of the allowable release stress in compression,

including a summary of several research studies that investigated

this stress limit, is provided. A simple design example is used to

quantify potential production and design benefits of increasing the

allowable stress. The applicability of these benefits is also

discussed. Finally, test results of 36 pretensioned beams that were

subjected to maximum compressive stresses at release ranging

from 0.46fci′ to 0.91fci′ are reported and analyzed. The experimental

results suggest that increasing the allowable release stress in

compression at midspan of a member to 0.65fci′ or 0.70fci′ is

possible. Premature flexural cracking was observed for members

subjected to midspan release stresses in excess of 0.70fci′.

Keywords: compressive stress; flexural cracking; prestress transfer.

INTRODUCTION

In ACI-318-08,1 the allowable compressive stress at

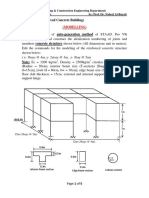

prestress transfer was increased from 0.60fci′ to 0.70fci′ near the Fig. 1—Prestressing strand profiles and potential locations

ends of prestressed concrete members. At other critical locations, of maximum release stress.

such as midspan or the hold-down points, the allowable stress is

still 0.60fci′. In the AASHTO Load and Resistance Factor

Design (LRFD) Bridge Design Specifications,2 the allowable member. Also, little information has been published that

compressive stress at release is 0.60fci′ at all sections. quantifies potential benefits of increasing the compressive

The maximum compressive stress at release can occur in stress at release. The information from this study will aid

the end regions, near midspan, or at any other section of the code developers in appropriately weighing the benefits and

pretensioned beam depending primarily on the profile or the weaknesses of increasing this allowable stress.

debonding of the prestressing strands. If only straight, fully-

bonded strands are used, the maximum compressive stress at HISTORICAL BACKGROUND

release will always be at the transfer section near the ends of The first U.S. code provisions for prestressed concrete

the beam (Fig. 1(a)). If some of the straight strands are members were adopted by the American Association for

debonded, the location of maximum stress can shift to the State Highway and Transportation Officials (AASHTO) in

section where all strands are bonded. If harped strands are 1961 and by the American Concrete Institute (ACI) in

used in combination with straight strands, then the compressive 1963.3,4 The code provisions in each standard were based on

stress at the hold-down point and near the ends of the beam can the following two documents: the “Criteria for Prestressed

be very similar (Fig. 1(b)). For post-tensioning applications Concrete Bridges” published by the Bureau of Public Roads

in which strands are draped, the maximum compressive in 1954 and the “Tentative Recommendations for

stress at release can occur at practically any section along the Prestressed Concrete” published by Joint ACI-ASCE

length of the member (Fig. 1(c)). Committee 323 in 1958 (later, ACI Committee 423).5,6 In

In this paper, benefits of increasing the release stress in both documents, the recommended allowable release stress

compression where the maximum stress occurs anywhere in compression was 0.60f ci′ for pretensioned members and

along the member, are discussed. Afterward, the results of an 0.55f ci′ for post-tensioned members. While the origin of

experimental research study are analyzed, in which a negative these values was not directly stated, two references allude to

outcome of increasing the release stress at midspan was observed. their development. In a paper by E. L. Erickson, in which the

“Criteria for Prestressed Concrete Bridges” specification

was described, the opinions of several “authorities” on the

RESEARCH SIGNIFICANCE

Over the last decade, a substantial amount of research and

discussion have been published related to increasing the ACI Structural Journal, V. 107, No. 1, January-February 2010.

MS No. S-2008-184 received June 6, 2008, and reviewed under Institute publication

allowable release stress in compression. None of the policies. Copyright © 2010, American Concrete Institute. All rights reserved, including the

previous investigations focused on the effect of increasing making of copies unless permission is obtained from the copyright proprietors. Pertinent

discussion including author’s closure, if any, will be published in the November-December

the allowable stress on the flexural performance of the 2010 ACI Structural Journal if the discussion is received by July 1, 2010.

ACI Structural Journal/January-February 2010 21

ACI member David B. Birrcher is a PhD Candidate at the University of Texas at

Table 1—Recommended stress limit in

Austin, Austin, TX. He received his BS in civil engineering from Tulane University, compression at prestress transfer (1957)5

New Orleans, LA, and his MS in structural engineering at the University of Texas at

Austin. His research interests include improving the design and construction of prestressed Suggested by Initial stress Condition

and reinforced concrete structures. Hajnal-Konyi (England) 0.45f ci′ —

ACI member Oguzhan Bayrak is an Associate Professor in the Department of Civil, Dobell (Preload Co.) 0.50f ci′ —

Architectural, and Environmental Engineering and holds the Charles Elmer Rowe

Fellowship in Engineering at the University of Texas at Austin. He serves as the Holley (MIT) 0.60f ci′ – 0.40f ci′ 0.60f ci′ , only if reduced to 0.40f ci′

Director of the Phil M. Ferguson Structural Engineering Laboratory. He is a member of Simpson (MIT) 0.60f ci′ – 0.50f ci′ 0.60f ci′ , only if reduced to 0.50f ci′

ACI Committees 341, Earthquake-Resistant Concrete Bridges; E803, Faculty Network

Coordinating Committee; and Joint ACI-ASCE Committees 441, Reinforced Concrete Siess (U. of Illinois) < 0.60f ci′ —

Columns, and 445, Shear and Torsion.

Bureau of Public 0.60f ci′ pretensioning

Michael E. Kreger, FACI, is a Professor in the School of Civil Engineering and is Roads Criteria 0.55f ci′ post-tensioning

also the Director of the Bowen Laboratory for Large-Scale Civil Engineering

Research at Purdue University, West Lafayette, IN. He is a member of the ACI Technical

Activities Committee; ACI Committees 215, Fatigue of Concrete; 318-C, Safety,

Serviceability, and Analysis (Structural Concrete Building Code); and 374, Performance-

was determined that using a nonlinear analysis resulted in a

Based Seismic Design of Concrete Buildings; and Joint ACI-ASCE Committees 352, lower maximum stress on the section than a linear analysis

Joints and Connections in Monolithic Concrete Structures; and 441, Reinforced when the concrete is stressed into the inelastic range.

Concrete Columns.

In 2001, Noppakunwijai et al.11 introduced a strength-

design approach for member design at prestress transfer. The

appropriate allowable release stress in compression was basis for the design approach was that the allowable release

provided (Table 1).5 It appears that the values listed in Table 1 stress is a strength limit that prevents crushing at transfer, not

were based on research by and experiences of each individual. a serviceability limit. Load factors were applied to the

No references are given by Erickson, but the “Bibliography prestressing force and to the self-weight moment. Resistance

of Prestressed Concrete” prepared by Joint ACI-ASCE factors were applied to the axial and bending moment capacities

Committee 323 lists several papers by the individuals listed of the section. Four equations were developed that relate the

in Table 1.7 Another reference to the origin of the 0.60fci′ appropriate equilibrium, compatibility, and constitutive

limit was given in the closing remarks of a published discussion relationships of a pretensioned member. The strength-

regarding the “Tentative Recommendations for Prestressed design approach permitted compressive stresses at release

Concrete.” The following excerpt is found considerably higher than 0.60f ci′ . The magnitude of the

release stress was based on the section type and the specified

Here, production had preceded design recommendations, values of the load and resistance factors used in the analysis.

and the stress of 0.60fci′ had already been widely established In addition, Noppakunwijai et al.11 designed and fabricated

in the pretensioning industry. No ill effect had been reported two inverted T-specimens using their proposed approach. The

in regard to strength and performance. Only camber maximum compressive stresses at the ends of the two specimens

proved difficult to control for certain building members.8 were 0.79f ci′ and 0.84f ci′ . The corresponding stress at midspan

was approximately 0.70f ci′ . No visual indications of damage

Therefore, the 0.60fci′ limit was likely based on public were detected. For approximately 100 days, the creep,

discussion, experimental research, and empirical practice. It shrinkage, and camber performance of the two members

should be noted that prestressed concrete was being were evaluated and satisfactorily compared with traditional

implemented and researched in Europe for several decades prediction methods. As a result, the authors recommended

prior to the development of U.S. design recommendations. It the adoption of their strength design approach and the subsequent

is highly likely that many of the U.S. specifications are based removal of the current allowable release stress in compression.

on successful European practice and research. In 2004, Castro et al.12 investigated the impact of

The distinction between pretensioned and post-tensioned increasing the allowable release stress in compression on the

members was dropped in the 2007 version of AASHTO short- and long-term camber of 30 pretensioned beams. The

LRFD.2 The 0.60f ci′ limit remains for all pretensioned maximum stress at release based on typical elastic design

members in AASHTO LRFD 2007. calculations ranged from 0.46f ci′ to 0.91f ci′ . Measured

The distinction between pretensioned and post-tensioned camber at 10 and 90 days was compared to several prediction

members was never made in ACI 318. The allowable release methods for all of the specimens. In general, the accuracy of

stress in compression was 0.60f ci′ for all members from 1963 camber prediction was not affected by the increase in the

to 2005. In ACI 318-08, an increase in the allowable release allowable release stress. The magnitude of camber, however,

stress in compression to 0.70f ci′ at the ends of pretensioned increased with increasing compressive stress at release as

members was approved.1 The allowable release stress at expected. The authors concluded that an increase in the

other critical sections remains 0.60f ci′ . Research conducted release stress was acceptable as long as long-term camber

within the last decade provided the basis for the increase in was adequately predicted. At the conclusion of the study, the

the allowable release stress at the member ends and is authors recommended the examination of the live-load

summarized in this section. performance of the highly-stressed girders before an

In 1997, Russell and Pang9 tested several hundred cylinders increase in the release stress was approved. 13 As a result,

in compression that were previously loaded in compression to the project described within this paper was initiated.

various percentages of their 1-day strength.9 The authors In 2006, Hale and Russell14 fabricated four pretensioned

concluded that an increase of the allowable release stress in girders and monitored their prestress loss for 1 year. The

compression to 0.70fci′was a possibility. purpose of the study was to assess “whether the losses indicate

In 1997, Huo and Tadros10 conducted a simple analytical that a damaged condition exists in the concrete due to excessive

study to illustrate the behavior of a concentrically prestessed compressive stresses at release.” The maximum compressive

member subjected to release stresses in excess of 0.60f ci′ . It stresses at release for the four beams were 0.57f ci′ , 0.65f ci′ ,

22 ACI Structural Journal/January-February 2010

0.69f ci′ , and 0.82f ci′ . To account for the inelastic deformations of

the three specimens with a maximum compressive stress in

excess of 0.60f ci′ , an effective concrete modulus was used in

calculating the elastic shortening losses and the transformed

section properties. With this adjustment, the ratio of the

prestress loss to the release stress was approximately the

same for all four girders. As a result, the authors concluded

that the allowable release stress of 0.60f ci′ should be

increased to 0.70f ci′ .

In 2007, Dolan and Krohn15 conducted a survey of the

Prestressed Concrete Institute’s (PCI’s) professional and

producer members. Thirty of 44 respondents reported regularly,

using compressive stresses at release in excess of 0.60f ci′ . The

majority of respondents reported no difficulties with higher

release stresses. Some respondents, however, associated the

following problems with higher release stresses: excessive

camber, concrete splitting around the strand end, excessive

strand slip, minor cracks at the ends, and short horizontal Fig. 2—Design at release of TxDOT Type-C girder with σall

cracks at the top of the web. Also, the results of the survey = 0.60fci′ and 0.70fci′ .

indicated that greater compression transfer stresses were

typically used in building products than in bridge products. length due to their direct correlation. It is important to note

The authors recommended increasing the allowable stress in that the compressive release stresses at the transfer

ACI 318 to 0.70f ci′ . Also, they stated that refined camber and section and at the hold-down point were within 5% of

prestress loss calculation methods may be needed as a result. each other for this section.

In summary, nearly all of the research and discussion over In Fig. 2, increasing the allowable release stress in

the last decade has supported an increase in the allowable compression did not affect the design of the Type C girder

release stress in compression. As a result, the allowable for span lengths less than 65 ft (19.8 m). At 65 ft (19.8 m), a

compressive stress at the ends of prestressed concrete minimum required release strength of 4000 psi (27.6 MPa)

members was increased to 0.70f ci′ in ACI 318-08.1 The governed the design. At 60 ft (18.3 m) and below, the design

allowable compressive release stress everywhere else along of the section was governed by the tensile stress limit,

the member is still 0.60f ci′ . The experimental results 75 f ci′ , at the transfer section.

described in this paper will address the feasibility of increasing Benefits of increasing the allowable release stress to

the allowable release stress at the midspan of the member. 0.70f ci′ did exist for span lengths above 65 ft (19.8 m). For

instance, at a span length of 75 ft (22.9 m), the required

BENEFITS OF INCREASING ALLOWABLE strength at release reduced from approximately 5300 to 4500 psi

RELEASE STRESS (36.5 to 31.0 MPa) with an increase of the allowable release

Several potential benefits of increasing the allowable stress from 0.60fci′ to 0.70f ci′ , respectively. Here, a benefit in

release stress in compression include: production exists in the form of reduced cycle time, curing

• the reduction in cycle time of precast facilities, the costs, or cement content. For these benefits to be realized,

reduction of external curing costs, and the reduction of however, the design of the girder cannot change with the

overall cement content; increase in the allowable release stress. Only the required

• the negation of increased cycle time from using low- compressive strength at release can change.

alkali cement or from replacing cement with other Benefits in design are illustrated in Fig. 2 as well. At a

cementitious materials; required strength at release of 5000 psi (34.5 MPa), the

• the reduction in the number of debonded or harped strands; girder designed with a 0.70f ci′ limit can have six additional

• the increase in span capabilities due to an increase in the 1/2 in. (12.7 mm) diameter strands and an increase in its span

number of prestressing strands in a given section; and length by approximately 10%. Presumably, the maximum

• the increase in efficiency of prestressed concrete girders. achievable span length of a given section can be increased in

It should be noted that increasing the allowable release this manner as well, provided that all long-term stress checks

stress in compression can affect production and design. are permissible. In these cases, the benefit of increasing the

To quantify some of the aforementioned benefits, the allowable release stress is used in design. Production is not

design at release of a Texas Department of Transporation significantly affected because a similar concrete strength at

(TxDOT) Type C girder was performed using an allowable release is required for girders designed under the 0.60f ci′ or

release stress of 0.60f ci′ and 0.70f ci′ . For TxDOT standard 0.70f ci′ limit.

girders, the conditions at release typically provide the upper Another benefit of increasing the allowable release stress

limit of the prestressing force. The flexural capacity and in compression includes the reduction in the number of

service-load stress checks are satisfied through transverse unbonded or harped strands used to limit the high compressive

girder spacing. For this example, the standard Type C girder stresses at the ends of prestressed concrete girders. For this

with an 8 ft (2.4 m) transverse girder spacing was selected.16 benefit to be realized, the increase in the allowable release

The standard design uses harped strands to control stresses at stress must be used to reduce the number of harped or

the ends of the member. The comparison of the two designs unbonded strands—not to increase the span length or reduce

is depicted in Fig. 2. The required compressive strength at section size.

release, f ci′ , was plotted versus the span length. The Some benefits of increasing the allowable release stress in

corresponding number of strands was plotted with the span compression do exist. These benefits, however, are not

ACI Structural Journal/January-February 2010 23

Fig. 3—Cross sections of all test specimens.

always applicable. The release stress in compression must prestress loss procedures present in the literature. The

govern the design of the girder. For a TxDOT Type C girder, comparison of the measured and estimated cracking loads

this requirement was restrictive for short-to-moderate span was used to evaluate the impact of increasing the allowable

lengths when the tensile stress limit at release governed the compressive stress at release near midspan on the live-load

design. Also, it should be emphasized that production benefits performance of pretensioned girders.

and design benefits can contradict one another. Production

benefits of increasing the allowable release stress are maximized Materials

when the section design and the span length are unchanged. It Five concrete mixture designs were used to fabricate the

seems plausible, at least in the long term, that the benefits of specimens in the experimental program. Conventional materials

increasing the allowable release stress will be used in the from Texas were used. Specific details of the concrete mixture

design phase. In making a decision to alter the release stress designs can be found elsewhere.18

in compression, it is essential to weigh these benefits and The prestressing strand used in all of the test specimens

their applicability with any negative implications associated was 1/2 in. (12.7 mm) diameter 270 ksi (1862 MPa) low-

with increasing the allowable stress. relaxation strand. All of the mild steel had a nominal yield

In 2006, Spencer and Chen17 compared the designs of strength of 60 ksi (414 MPa).

several standard Pennsylvania Department of Transportation

(PennDOT) bridge girders using an allowable release stress Test specimens

of 0.60f ci′ and 0.70f ci′ . Potential design benefits of increasing The 24 Series I beams consisted of scaled rectangular, T,

the release stress were focused on in their study. For adjacent and inverted-T sections designed to represent standard

and spread box beams and simply supported AASHTO I- TxDOT I, double-T, and U-girders, respectively.12 The

beams, few design advantages of using 0.70f ci′ were observed. maximum nominal compressive stress at the ends of the

The design of these members was typically governed by Series I beams ranged from 0.46f ci′ to 0.91f ci′ . Dimensions

PennDOT’s strict tensile stress limit at release of 3 f ci ′ along of the scaled section types are illustrated in Fig. 3 and summa-

the member. As such, increasing the allowable release stress in rized in Table 2. All of the beams were 15 ft (4.6 m) in length.

compression did little to improve their design. For Series I beams were fabricated by Castro et al.12 at the

continuous I-beams and simply supported bulb-tees, Ferguson Structural Engineering Laboratory at The University

however, design benefits were noted. Additional strands of Texas at Austin, Austin, TX. Prestressing strands were

were placed in the continuous I-beam, permitting a reduction stressed with a single-strand stressing jack in a straight

of its cross section. Similarly, additional strands were added profile. The stress in the strand was inferred from electrical

to the bulb-tee girders, allowing an increase in their maximum strain gauges attached to the strand and was confirmed with

span length by approximately 5%. The results of this study a pressure reading in the hydraulic ram. Concrete materials

agreed favorably with the previous design example. were batched at the laboratory and placed in the formwork.

Match-curing technology was used to match the temperature of

EXPERIMENTAL INVESTIGATION 4 x 8 in. (102 x 203 mm) concrete cylinders with the temperature

The experimental program consisted of two series of static of the hydrating beams. Thermocouples in beams were

tests. In Series I, 24 scaled rectangular, T, and inverted-T girders positioned near the geometric centroids of beam sections.

15 ft (4.6 m) in length were tested. In Series II, 12 full-scale At release, the strands were flame-cut in a symmetric pattern.

TxDOT Type A girders 40 ft (12.2 m) in length were tested. A more detailed account of the design and fabrication of the

The load due to first flexural cracking was experimentally Series I beams can be found elsewhere.12

evaluated in each test. The measured cracking loads were The 12 Series II beams consisted of full-scale TxDOT

compared to cracking loads estimated with the use of two Type A girders. The same nonstandard strand pattern was

24 ACI Structural Journal/January-February 2010

Table 2—Section and material properties of Series I beams

Section properties Steel properties Concrete properties

Specimen designation Ag, in.2 Ig , in.4 h, in. yb , in. yt , in. Aps , in.2 e, in. fpi, ksi A s, in.2 fci′, psi fc′, psi

R1-52-1-T8 108 2916 18 9 9 0.92 3.25 181 0 5740 9660

R1-52-1-T7 108 2916 18 9 9 0.92 3.25 182 0 5740 9660

R1-50-1-T1 108 2916 18 9 9 0.92 3.25 181 0 6030 9660

R1-49-1-T2 108 2916 18 9 9 0.92 3.25 178 0 6030 9660

R1-46-1-T5 108 2916 18 9 9 0.92 3.25 177 0 6285 9660

R1-48-1-T6 108 2916 18 9 9 0.92 3.25 180 0 6285 9660

T1-68-2-T17 106 2280 15.5 10.3 5.17 0.46 5.53 191 0 4220 10,000

T1-62-2-T18 113 2470 15.5 10.1 5.36 0.46 6.09 185 0 4220 10,000

IT1-68-2-T20 153 4350 18.3 7.69 10.56 1.22 3.19 191 0 3820 10,000

IT1-73-2-T19 152 4320 18.3 7.57 10.68 1.22 3.82 192 0 3820 10,000

R3-75-3-T9 144 3888 18 9 9 1.22 3.5 181 0 4070 10,100

R3-78-3-T3 144 3888 18 9 9 1.22 4 178 0 4070 10,100

T2-79-3-T16 104 2251 15.5 10.27 5.23 0.61 4.52 182 0 3950 10,100

T2-86-3-T15 104 2251 15.5 10.27 5.23 0.61 5.27 181 0 3950 10,100

IT3-79-3-T21 156 4706 19 7.88 11.12 1.53 3.66 189 0.22 4070 10,100

IT2-76-3-T22 156 4706 19 7.88 11.12 1.53 3.66 188 0 4320 10,100

R3-78-4-T11 144 3888 18 9 9 1.22 3.5 180 0 3800 10,000

R3-83-4-T12 144 3888 18 9 9 1.22 4 180 0 3800 10,000

IT3-83-4-T24 156 4706 19 7.88 11.12 1.53 3.66 191 0.22 3800 10,000

R3-75-5-T10 144 3888 18 9 9 1.22 3.48 182 0 4050 7400

R3-80-5-T4 144 3888 18 9 9 1.22 3.97 182 0 4050 7400

T2-91-5-T14 104 2251 15.5 10.27 5.23 0.61 4.6 186 0 3470 7400

IT3-79-5-T23 156 4706 19 7.88 11.12 1.53 3.69 189 0.22 4050 7400

IT2-80-5-T13 156 4706 19 7.88 11.12 1.53 3.67 189 0 4050 7400

2 2

Note: 1 in. = 25.4 mm, 1 ksi = 6.895 MPa; 1 in. = 645.16 mm .

Table 3—Section and material properties of Series II beams

Section properties Steel properties Concrete properties

Specimen Ag, in.2 in.4

Ig, yb, in. yt, in. in.2

Aps, ecl, in. eend , in. fpi, ksi A s, in.2 fci′ , ksi fc′, ksi

designation (mm2) (mm4) (mm) (mm) (mm2) (mm) (mm) (MPa) (mm2) (MPa) (MPa)

A55-T25 5.50 (37.9) 8.3 (57.2)

A60-T26 5.01 (34.5) 7.8 (53.8)

A63-T27 4.79 (33.0) 8.5 (58.6)

A66-T28 4.55 (31.4) 9.6 (66.2)

A67-T29 4.45 (30.7) 7.1 (49.0)

A66-T30 275.4 22,658 12.61 15.39 2.142 8.61 6.32 202.5 0.61 4.50 (31.0) 8.1 (55.8)

A69-T31 (1.78 × 105) (9.43 × 109) (320) (391) (1382) (219) (161) (1396) (394) 4.33 (29.9) 7.7 (53.1)

A68-T32 4.39 (30.3) 7.8 (53.8)

A67-T33 4.48 (30.9) 8.4 (57.9)

A73-T34 4.08 (28.1) 9.1 (62.7)

A71-T35 4.18 (28.8) 9.2 (63.4)

A75-T36 3.96 (27.3) 8.8 (60.7)

Note: 1 in. = 25.4 mm, 1 ksi = 6.895 MPa; 1 in.2 = 645.16 mm2.

used in all 12 specimens. Four of the 14 strands were harped Series II beams were fabricated at a Texas precast

to meet tension stress limits at the ends of the girders. The manufacturing plant in a small stressing bed. One beam

hold-down points were 5 ft (1.5 m) on either side of midspan. was constructed at a time. To achieve a targeted concrete

The only variable controlling the maximum compressive strength at release, approximately twenty-four 4 x 8 in.

stress at transfer was the compressive strength of the concrete at (102 x 203 mm) cylinders were cast with each beam. The

release, fci′ . The targeted concrete strength at transfer ranged cylinders were cured next to the specimen beneath a tarp

from 3900 to 5400 psi (26.9 to 37.2 MPa). The corresponding until they were tested according to ASTM C39-04. After

maximum compressive stress at transfer ranged from 0.75fci′ to initial set, two cylinders were tested every hour to map the

0.55fci′ . Dimensions and section properties of the Series II strength gain. When concrete strength was within 1000 psi

beams are illustrated in Fig. 3 and summarized in Table 3. All (6.9 MPa) of the targeted strength, two cylinders were tested

of the Series II beams were 40 ft (12.2 m) in length. more frequently until the average strength was as close to the

ACI Structural Journal/January-February 2010 25

Fig. 4—Simple beam test setup for Series I beams.

Fig. 5—Simple beam test setup for Series II beams.

targeted value as possible. At this point, the strands were A load cell and a pressure transducer were used to measure

flame-cut in a symmetric pattern. the applied load. Both instruments provided consistent

results. Loads reported in this paper were measured at

Test procedure midspan by the load cell. The midpsan deflection was

The specimens were simply supported (Fig. 4 and 5) and recorded over the course of each test using either a string

were subjected to two concentrated loads using a hydraulic potentiometer or linear potentiometer. For the 24 Series I

specimens, four linear variable displacement transducers

ram at midspan and a stiff spreader beam. The constant

(LVDTs) and an electrical strain gauge attached to each

moment region was approximately 5 ft (1.5 m) in length for

prestressing strand measured applied midspan strains in the

all test specimens. Simple supports were achieved by section. For the 12 Series II specimens, only load and

sandwiching a round steel bar (ϕ = 2 in. [51 mm]) midspan deflection were monitored.

between two steel plates (6 x 8 x 1 in. [152 x 203 x 25 mm]). In each test, the measured cracking load was obtained

The bar at one support was allowed to roll freely. The bar at through visual inspection and examination of load-deflection

the other support was welded to the bottom plate. The load and load-strain plots. The load at which a change in stiffness

was increased incrementally to a level approximately 30% was apparent in these plots was termed the measured

higher than the cracking load, or until failure occurred. At cracking load. In general, cracking loads determined with the

each load step equal to or exceeding the cracking load, the load-deflection or load-strain plots were equal to or slightly

load was maintained, the beam was inspected, and the visible less than those determined through visual inspection. In

cracks were mapped on the beam. The Series I beams were some of the Series I beams, the roughened condition of the

tested at an age of approximately 3 years. The Series II concrete surface hindered the ability to detect first cracking.

beams were tested at an age of approximately 28 days. All The load at first cracking for these beams was obtained with

beams were stored outdoors until they were tested. load-deflection and various load-strain plots. A sample load-

26 ACI Structural Journal/January-February 2010

deflection plot for the Series I beams is provided in Fig. 6. For

the Series II beams, cracking loads determined through visual

inspection and with load-deflection plots were very consistent

due to the smooth finish of the concrete surface. The load-

deflection plot for a Series II test specimen is provided in Fig. 7.

Additional information regarding the experimental program can

be found elsewhere.18

ANALYTICAL INVESTIGATION

The loads required for first flexural cracking were

estimated using typical design methods. First, prestress

losses up to the time of the test were approximated with two

different prestress loss procedures. The two procedures

included the National Cooperative Highway Research

Program (NCHRP) Report 496 Detailed Prestress Loss

Method (2003) and the AASHTO LRFD Refined Loss of

Prestress Estimate (2005).19,20 AASHTO LRFD adopted the Fig. 6—Sample load-deflection plot for T2-91-5-T14.

recommendations of the NCHRP Report 496 in the 2005

specifications. As such, the two prestress loss procedures are

very similar. The main differences included the suggested

use of transformed section properties instead of gross section

properties and a different equation for the modulus of elasticity

of concrete in the NCHRP procedure. These procedures

were selected because they provide a loss estimate at any

time in the life of the girder, not just the total losses that

lump-sum methods provide. Because the Series II beams

were only 28 days old at the time of the test, this time-dependent

feature was required.

With the prestress loss estimates of each procedure, an

estimated cracking moment was calculated. To remain

consistent with each procedure, the same geometric properties

(gross or transformed) used in the loss calculations were also

used in the cracking moment calculations.

The estimated cracking moment, according to the

Fig. 7—Sample load-deflection plot for A73-T34.

AASHTO prestress loss procedure, is provided as Eq. (1).

The effective prestressing force is calculated as the initial

prestressing force minus losses due to elastic shortening,

Examples of the prestress loss calculations for each procedure

concrete creep, concrete shrinkage, and steel relaxation.

and the subsequent cracking moment estimate can be

Gross section properties are used throughout as is typically

found elsewhere.18

done by design engineers.

COMPARISON OF PREDICTIONS AND

I g ⎞ ⎛ P eff P eff e p y bg M g y bg

M cr - -------- + ----------------------- – --------------- + f r⎞

= ⎛ ------- (1) EXPERIMENTAL RESULTS

⎝ y bg ⎠ ⎝ A g Ig Ig ⎠ With the cracking moments from Eq. (1) and (2), the

corresponding midpsan load was calculated with statics.

The variables in Eq. (1) are defined in the Notation section This predicted cracking load was then compared to the

of this paper. measured cracking loads obtained from each beam test. To

The estimated cracking moment, according to the NCHRP facilitate the comparison, a percent difference formula was

prestress loss procedure, is provided as Eq. (2). Elastic shortening used to compare the two values (Eq. (3)). The estimated and

losses were automatically accounted for with the use of the measured cracking loads for all of the test specimens are

initial prestressing force and transformed section properties listed in Tables 4 and 5.

at release.19 Long-term losses due to creep, shrinkage, and

relaxation were accounted for with the net section properties, P measured – P predicted⎞

as per NCHRP Report 496. Accuracy CL = ⎛ -------------------------------------------------- × 100 (3)

⎝ P measured ⎠

I tt ⎛ P i ΔP LT P i e pti y bti ΔP LT e pnt y bnt where Pmeasured is the cracking load measured during static

M cr = ------- ------ – ------------ + ------------------------ – ------------------------------- –

y btt ⎝ A ti A nt I ti I nt test (kips or kN); and Ppredicted is the cracking load estimated

(2) analytically (kips or kN).

M g y bti

- + fr⎞

-------------- For each procedure, the value from Eq. (3) for all of the

I ti ⎠

test specimens was plotted versus the compressive stress at

release at the critical section (σb in Tables 4 and 5). The critical

The variables in Eq. (2) are defined in the Notation section section was defined as the location along the beam with the

of this paper. highest applied moment that was previously subjected to the

ACI Structural Journal/January-February 2010 27

Table 4—Measured and estimated cracking loads for Series I beams

Estimated cracking loads and accuracy

Measured cracking load, NCHRP Report 496 2003 AASHTO LRFD 2005

Specimen designation σb (x f ci′ )* kips (kN) kips (kN) % kips (kN) %

R1-52-1-T8 0.50 35 (156) 35.8 (159) –2.3 35.1 (156) –0.3

R1-52-1-T7 0.50 35 (156) 36.0 (160) –2.9 35.3 (157) –0.9

R1-50-1-T1 0.48 35 (156) 35.6 (158) –1.7 34.8 (155) 0.6

R1-49-1-T2 0.47 35 (156) 35.1 (156) –0.3 34.4 (153) 1.7

R1-46-1-T5 0.45 35 (156) 35.8 (159) –2.3 35.0 (156) 0.0

R1-48-1-T6 0.46 35 (156) 36.3 (161) –3.7 35.5 (158) –1.4

T1-68-2-T17 0.64 21 (93) 22.0 (98) –4.8 21.5 (96) –2.4

T1-62-2-T18 0.58 23 (102) 23.3 (104) –1.3 22.7 (101) 1.3

IT1-68-2-T20 0.66 55 (245) 53.8 (239) 2.2 53.0 (236) 3.6

IT1-73-2-T19 0.71 55 (245) 57.5 (256) –4.5 56.1 (250) –2.0

R3-75-3-T9 0.72 42 (187) 46.0 (205) –9.5 45.5 (202) –8.3

R3-78-3-T3 0.75 42 (187) 46.9 (209) –11.7 46.0 (205) –9.5

T2-79-3-T16 0.75 20 (89) 22.9 (102) –14.5 22.6 (101) –13.0

T2-86-3-T15 0.82 22 (98) 24.2 (108) –10.0 23.7 (105) –7.7

IT3-79-3-T21 0.77 63 (280) 67.4 (300) –7.0 65.5 (291) –4.0

IT2-76-3-T22 0.74 64 (285) 67.7 (301) –5.8 66.3 (295) –3.6

R3-78-4-T11 0.75 40 (178) 43.3 (193) –8.2 42.5 (189) –6.3

R3-83-4-T12 0.80 42 (187) 45.2 (201) –7.6 44.0 (196) –4.8

IT3-83-4-T24 0.81 58 (258) 63.9 (284) –10.2 61.3 (273) –5.7

R3-75-5-T10 0.72 40 (178) 44.9 (200) –12.3 43.7 (194) –9.3

R3-80-5-T4 0.77 42 (187) 46.4 (206) –10.5 44.9 (200) –6.9

T2-91-5-T14 0.87 20 (89) 22.0 (98) –10.0 21.4 (95) –7.0

IT3-79-5-T23 0.78 57 (254) 65.9 (293) –15.6 62.9 (280) –10.4

IT2-80-5-T13 0.77 58 (258) 65.3 (290) –12.6 62.9 (280) –8.4

*Linear-elastic stress calculation at prestress transfer at critical section.

Table 5—Measured and estimated cracking loads for Series II beams

Estimated cracking loads and accuracy

Measured cracking load, NCHRP Report 496 2003 AASHTO LRFD 2005

Specimen designation σb (x f ci′ )* kips (kN) kips (kN) % kips (kN) %

A55-T25 0.55 62 (276) 64.3 (286) –3.7 60.6 (270) 2.3

A60-T26 0.60 63 (280) 63.5 (282) –0.8 59.7 (266) 5.2

A63-T27 0.63 63 (280) 63.6 (283) –1.0 60.0 (267) 4.8

A66-T28 0.66 63 (280) 63.8 (284) –1.3 60.5 (269) 4.0

A67-T29 0.67 60 (267) 62.5 (278) –4.2 58.6 (261) 2.3

A66-T30 0.66 59 (262) 63.1 (281) –6.9 59.4 (264) –0.7

A69-T31 0.69 60 (267) 62.6 (278) –4.3 58.9 (262) 1.8

A68-T32 0.68 58 (258) 62.8 (279) –8.3 59.0 (262) –1.7

A67-T33 0.67 63 (280) 63.0 (280) 0.0 59.5 (265) 5.6

A73-T34 0.73 57 (254) 62.8 (279) –10.2 59.5 (265) –4.4

A71-T35 0.71 63 (280) 63.1 (281) –0.2 59.8 (266) 5.1

A75-T36 0.75 60 (267) 62.6 (278) –4.3 59.2 (263) 1.3

*

Linear-elastic stress calculation at prestress transfer at critical section.

highest compressive stress at prestress transfer. For all of the the beams cracked at lower loads than predicted. The major

test specimens, the critical section was located directly difference between the two plots is the upward shift of the

beneath either of the two symmetric load points. Here, the data in the AASHTO plot with respect to the NCHRP plot.

compressive stress at release was slightly higher than at This shift is primarily due to the use of gross section properties

midspan of each specimen due to the effects of dead load. in the cracking moment equation of the former.

Comparison plots with predicted data, according to the

NCHRP prestress loss method and AASHTO prestress loss DISCUSSION

method, are given in Fig. 8 and 9, respectively. Data presented in Fig. 8 and 9 were analyzed, assuming

The same general trend exists in Fig. 8 and 9. As the that a cracking load prediction accuracy of ±5% was acceptable.

compressive stress at release increased above a certain limit, This level of accuracy seemed consistent with the techniques

28 ACI Structural Journal/January-February 2010

Fig. 8—Comparison of measured and estimated cracking Fig. 9—Comparison of measured and estimated cracking

loads using NCHRP 496 losses. loads using AASHTO losses.

used to measure first cracking loads and the assumptions

built into the prestress loss procedures. The lower bound of

the data intersects the –5% accuracy line at approximately

0.65f ci′ and 0.70f ci′ in Fig. 8 and 9, respectively. As such, for

the beams in this study, an increase in the allowable

compressive midspan stress at release to either 0.65f ci′ or

0.70f ci′ may be justified. Data in Fig. 8 and 9 do not support

an increase of the allowable limit in excess of 0.70fci′ . Above

this level, premature flexural cracking of the prestressed

girders was more prevalent.

Premature cracking of the beams subjected to release

stresses in excess of 0.70fci′ is linked to the nonlinear

behavior of the concrete in compression at prestress transfer.

As shown in Fig. 10, at prestress transfer of slender beams, a

linear strain profile is imposed onto the girder section. If the

material is elastic, as is assumed throughout conventional

prestress loss calculations, a linear stress profile also exists.

If the material is inelastic, as is the case for highly stressed Fig. 10—Section analysis at prestress transfer of midspan

concrete, a nonlinear stress profile exists. For the highly- cross section.

stressed girders in this study, the extreme bottom-fiber stress

was overestimated by the linear-elastic prestress loss calculations.

In the calculation of the cracking moment, this stress must be these tensile strength reductions only contribute a few

overcome—after losses are subtracted—to produce flexural percentage points to the cracking moment calculations, they

cracking. Therefore, through the use of conventional methods, quantify internal damage that can result from loading

first cracking of the highly-stressed girders was overestimated. concrete to high levels of compressive stress.

It is possible to account for the nonlinear deformation of Nonlinear creep deformation could have contributed to

the highly-stressed girders through the use of an effective premature cracking of the beams subjected to release stresses

concrete modulus or an inelastic stress-strain curve for well in excess of 0.70fci′ . Material research studies have

concrete in compression as others have suggested.10,11,14 investigated the creep proportionality limit, or the stress

This alteration, however, adds additional complication to limit of elastic creep deformation, for both normal- and high-

already-complicated prestress loss calculations. Furthermore, strength concrete (>9000 psi [62 MPa]). Because the equations

accounting for inelastic deformation does not mitigate the for prestress loss due to creep are based on elastic assumptions,

presence of internal damage that is concurrent with the exceeding the creep proportionality limit could result in

departure of the stress-strain curve from the elastic region, additional creep losses not accounted for in loss calculations.

that is, the initial tangent. Ngab et al. 24,25 and Smadi et al. 26,27 determined the

As early as 1929, Richart et al.21 discovered that the creep proportionality limit for high-strength concrete to

departure of the stress-strain curve of concrete loaded in be 0.70fc′ and 0.65fc′, respectively. For normal-strength

compression from the initial, elastic region was the result of concrete, a creep proportionality limit ranging from 0.30fc′ to

internal microcracking. More recently, this internal micro- 0.50fc′ exists.25 While the results of these studies are not directly

cracking was quantified in two material research studies. In applicable to prestressed concrete, they do provide guidance

both studies, the tensile strength of concrete previously because the specimens were loaded with sustained stress after

loaded to high levels of compressive stress was the concrete was at least 28 days old. Additionally, it

measured. Gettu et al.22 found that concrete cubes loaded to should be noted that prestress loss due to creep is a function

80% of their strength and maintained at this level for 15 minutes of the compressive stress at the location of the prestressing

exhibited tensile strength reductions of approximately 12%. For strands. Depending on the stress gradient, these stresses may

a similar stress level and load duration, Delibes Liniers23 be considerably less than those in the bottom fibers. With

reported a tensile strength loss of approximately 17%. While these considerations, it is likely that nonlinear creep deformation

ACI Structural Journal/January-February 2010 29

only contributed to the premature flexural cracking of the most ACKNOWLEDGMENTS

highly-stressed members at release. The authors would like to express their sincere appreciation to the Texas

Department of Transportation for the support of this research project. The tireless

The allowable compressive midspan stress at release is a involvement of J. Cotham in this research study was truly valued. The suggestions

serviceability limit. It should ensure satisfactory performance of of ACI Subcommittee 318-G were also greatly appreciated. Completion of this

the precompressed tensile zone of a prestressed concrete project would not have been possible without the help of A. Castro, R.

member. For this reason, exposing this zone to inelastic Tuchscherer, and numerous helping hands at the Ferguson Structural

Engineering Laboratory.

deformation (due to initial stresses or nonlinear creep) or

potential internal damage is not recommended. Therefore, an

NOTATION

increase in the allowable compressive midspan stress at Ag = area of gross section, in.2

release in excess of 0.70fci′ is not justified. The results of this Ant , Int , ybnt,

study indicate, however, that an increase in this allowable stress and epnt = net section properties at time of test

to a level between 0.60fci′ and 0.70fci′ is possible. In doing so, Ati, Iti , ybti,

it is essential that the potential benefits and weaknesses of and epti = transformed section properties at the time of release

increasing the allowable release stress in compression are ep = eccentricity of prestressing strands, in.

appropriately weighed with the intended use of the fc′ = compressive strength of concrete, psi

pretensioned member. fr = tensile strength of concrete taken as 7.5/1000 f c ′ , ksi

For members that are not intended to crack in service (such Ig = moment of inertia of gross section, in.4

as Class U beams in ACI 318 Chapter 18 or bridge girders Itt and ybtt = transformed section properties at time of test

Mg = moment due to dead load, in.-kips

designed per AASHTO LRFD), increasing the allowable Peff = prestressing force after all losses, kips

release stress should be done prudently.1,2 Premature flexural Pi = initial prestressing force just prior to release, kips

cracking can accelerate fatigue-related problems and can create ybg = distance from geometric centroid to extreme bottom

future durability concerns. Based on the results of this study, fiber, in.

ΔPLT = the long-term prestress losses, kips

an increase in the allowable stress at midspan to 0.65fci′ is

justified. The performance of the test specimens subjected to

this level of stress at release was comparable to those subjected REFERENCES

1. ACI Committee 318, “Building Code Requirements for Structural

to the current allowable midspan stress of 0.60fci′ (Fig. 8 and 9). Concrete (ACI 318-08) and Commentary,” American Concrete Institute,

In addition, a modest increase to 0.65fci′ will provide some Farmington Hills, MI, 2008, 465 pp.

insurance to the condition of the precompressed tensile zone in 2. AASHTO, “LRFD Bridge Design Specifications,” American Association

of State Highway and Transportation Officials, Washington, DC, 2007.

case the member is unintentionally overstressed at transfer. 3. AASHTO, “Standard Specifications for Highway Bridges,” eighth

For members that are allowed to crack in service (such as edition, American Association of State Highway and Transportation Officials,

Class C and T beams in ACI 318 Chapter 18), a higher allowable Washington, DC, 1961, 345 pp.

stress at midspan of 0.70fci′ is justified.1 For these members, 4. ACI Committee 318, “Building Code Requirements for Reinforced

Concrete (ACI 318-63),” American Concrete Institute, Farmington

premature flexural cracking is not as critical. In addition, the Hills, MI, 1963, 144 pp.

minor design or production benefits illustrated previously 5. Erickson, E. L., “The Bureau of Public Roads ‘Criteria for Prestressed

could offset negative implications to increasing the allowable Concrete Bridges’,” Proceedings, World Conference on Prestressed

release stress. Concrete, San Francisco, CA, July 1957, pp. A9-1 to A9-8.

6. Joint ACI-ASCE Committee 323, “Tentative Recommendations for

Due to concerns regarding the limited number of full-scale Prestressed Concrete,” ACI J OURNAL, Proceedings V. 54, Jan. 1958,

specimens in the study and the extreme variation in concrete pp. 545-578.

properties, additional full-scale specimens need to be tested 7. Joint ACI-ASCE Committee 323, “Bibliography on Prestressed

Concrete,” first edition, American Concrete Institute, Farmington Hills, MI,

to further evaluate the findings of this study. At that time, Aug. 1954, 83 pp.

national code provisions can be modified accordingly. 8. Joint ACI-ASCE Committee 323, “Tentative Recommendations for

Prestressed Concrete—Committee Closure,” ACI JOURNAL, Proceedings V. 54,

Part 2, Dec. 1958, pp. 1291-1299.

CONCLUSIONS 9. Russell, B. W., and Pang, J. P., “Investigation of Allowable Compressive

Based on the results of this analytical and experimental Stresses for High Strength, Prestressed Concrete,” Proceedings of the

research study, the following conclusions are drawn: PCI/FHWA International Symposium on High Performance Concrete,

New Orleans, LA, Oct. 1997, pp. 554-565.

1. The compressive stress limit at prestress transfer must 10. Huo, X., and Tadros, M., “Allowable Compressive Strength of

govern the design of the pretensioned member to achieve Concrete at Prestress Release—Open Forum Problems and Solutions,” PCI

significant production or design benefits from increasing the Journal, V. 42, No. 1, Jan.-Feb. 1997, pp. 95-99.

allowable stress. 11. Noppakunwijai, P.; Tadros, M. K.; Ma, Z.; and Mast, R. F., “Strength

Design of Pretensioned Flexural Concrete Members at Prestress Transfer,”

2. Production and design benefits of increasing the allow- PCI Journal, V. 46, No. 1, Jan.-Feb. 2001, pp. 34-52.

able compressive stress at release cannot be maximized 12. Castro, A.; Kreger, M. E.; Bayrak, O.; Breen, J. E.; and Wood, S. L.,

simultaneously. “Allowable Design Release Stresses for Pretensioned Concrete Beams,”

Research Report 0-4086-2, Center for Transportation Research, The

3. Increasing the allowable compressive midspan stress at University of Texas at Austin, Austin, TX, Aug. 2004, 142 pp.

release in excess of 0.70fci′ is not recommended. 13. Kreger, M. E., and Bayrak, O., “Project 0-4086: Allowable Design

4. An increase in the allowable compressive midspan Release Stresses for Pretensioned Concrete Beams,” Project Summary

Report 0-4086-S, Center for Transportation Research, The University of

stress at release to 0.65fci′ is justified for members designed Texas at Austin, Austin, TX, July 2005, 4 pp.

to be uncracked in service. For members allowed to crack in 14. Hale, W. M., and Russell, B. W., “Effect of Allowable Compressive

service, an increase in the allowable stress to 0.70fci′ is justified. Stress at Release on Prestress Losses and on the Performance of Precast,

Additional testing on commercially fabricated full-scale Prestressed Concrete Girders,” PCI Journal, V. 51, No. 2, Mar.-Apr. 2006,

pp. 14-25.

specimens is recommended prior to making changes to 15. Dolan, C. W., and Krohn, J. J., “A Case for Increasing the Allowable

design codes. In this way, additional concrete mixture Compressive Release Stress for Prestressed Concrete,” PCI Journal, V. 52,

designs and different fabrication practices can be considered. No. 1, Jan.-Feb. 2007, pp. 102-105.

30 ACI Structural Journal/January-February 2010

16. Texas Department of Transportation, Bridge Division Standard 22. Gettu, R.; Aguado, A.; and Oliveira, O. F., “Damage in High-

Drawings, 2005. (www.dot.state.tx.us.) Strength Concrete Due to Monotonic and Cyclic Compression—A Study

17. Spencer, J. W., and Chen, Y., “Effects of Compressive Stress Limits Based on Splitting Tensile Strength,” ACI Materials Journal, V. 93, No. 6,

on Prestressed Concrete Girder Design,” Proceedings of PCI National Nov.-Dec. 1996, pp. 519-523.

Bridge Conference, Grapevine, TX, Oct. 2006, 20 pp. 23. Delibes Liniers, A., “Microcracking of Concrete under Compression

18. Birrcher, D., and Bayrak, O., “Effects of Increasing the Allowable and its Influence on Tensile Strength,” Materials and Structures, V. 20, No. 116,

Compresssive Stress at Release of Prestressed Concrete Girders,” Research pp. 111-116.

Report 0-5197-1, Center for Transportation Research, The University of 24. Ngab, A. S.; Nilson, A. H.; and Slate, F. O., “Shrinkage and Creep of

Texas at Austin, Austin, TX, Jan. 2007, 226 pp. High Strength Concrete,” ACI JOURNAL, Proceedings V. 78, No. 4, July-

19. Tadros, M. K.; Al-Omaishi, N.; Seguirant, S. J.; and Gallt, J. G., Aug. 1981, pp. 255-261.

“Prestress Losses in Pretensioned High-Strength Concrete Bridge Girders,” 25. Ngab, A. S.; Slate, F. O.; and Nilson, A. H., “Microcracking and

NCHRP Report 496, Transportation Research Board, Washington, DC, Time-Dependent Strains in High Strength Concrete,” ACI JOURNAL,

2003, 73 pp. Proceedings V. 78, No. 4, July-Aug. 1981, pp. 262-268.

20. AASHTO, “LRFD Bridge Design Specifications,” Interim 2005 26. Smadi, M. M.; Slate, F. O.; and Nilson, A. H., “High-, Medium-, and

Edition, American Association of State Highway and Transportation Officials, Low-Strength Concretes Subject to Sustained Overloads—Strains,

Washington, DC, 2005. 1334 pp. Strengths, and Failure Mechanisms,” ACI JOURNAL, Proceedings V. 82, No. 5,

21. Richart, F. E.; Brandtzaeg, A.; and Brown, R. L., “The Failure of Sept.-Oct. 1985, pp. 657-664.

Plain and Spirally Reinforced Concrete in Compression,” Bulletin No. 190, 27. Smadi, M. M.; Slate, F. O.; and Nilson, A. H., “Shrinkage and Creep

University of Illinois Engineering Experiment Station, Urbana, IL, of High-, Medium-, and Low-Strength Concretes, Including Overloads,”

Apr. 1929, pp. 1-74. ACI Materials Journal, V. 84, No. 3, May-June 1987, pp. 224-234.

ACI Structural Journal/January-February 2010 31

Vous aimerez peut-être aussi

- ACI 108 s34 PDFDocument11 pagesACI 108 s34 PDFSoveasna ChanPas encore d'évaluation

- 102 s45 PDFDocument10 pages102 s45 PDFCesarRicaldiMirandaPas encore d'évaluation

- Seismic Behavior and Design of Gusset PlatesDocument41 pagesSeismic Behavior and Design of Gusset PlatesRigobertoGuerraPas encore d'évaluation

- 1963 - Bresler Scordelis - Shear Strength of RC Beams PDFDocument24 pages1963 - Bresler Scordelis - Shear Strength of RC Beams PDFKaio César Arnaud DeonPas encore d'évaluation

- Effects of Transverse Reinforcement On Seismic Performance of ColumnsDocument9 pagesEffects of Transverse Reinforcement On Seismic Performance of ColumnsAhmad YaniPas encore d'évaluation

- Rectangular Stress Block For High-Strength Concrete: Aci Structural Journal July 2004Document10 pagesRectangular Stress Block For High-Strength Concrete: Aci Structural Journal July 2004nikola1popovi1Pas encore d'évaluation

- J. Aci PDFDocument54 pagesJ. Aci PDFSamir Vara Medina100% (2)

- An Adequate Theory For The Shear Strength of ReinfDocument21 pagesAn Adequate Theory For The Shear Strength of ReinfTriet TruongPas encore d'évaluation

- Seismic Behavior & Design of Gusset PlatesDocument41 pagesSeismic Behavior & Design of Gusset PlateswilfredPas encore d'évaluation

- Columns Biaxial Bending PDFDocument11 pagesColumns Biaxial Bending PDFDiegoPas encore d'évaluation

- Design Provisions For Shear WallsDocument13 pagesDesign Provisions For Shear WallsRm1262Pas encore d'évaluation

- Behavior and Testing of Anchors in Simulated Seismic Cracks: Aci Structural Journal May 2008Document11 pagesBehavior and Testing of Anchors in Simulated Seismic Cracks: Aci Structural Journal May 2008coolkaisyPas encore d'évaluation

- Shear Strength of Steel Fiber-Reinforced ConcreteDocument10 pagesShear Strength of Steel Fiber-Reinforced ConcreteSiva GuruPas encore d'évaluation

- Effect of Size ConcreteDocument8 pagesEffect of Size ConcreteekaciptaPas encore d'évaluation

- Effective Flexural Rigidities For Ordinary ReinforDocument21 pagesEffective Flexural Rigidities For Ordinary ReinforabdiseptiaputraPas encore d'évaluation

- Allowable Tensile Stress For Webs of Prestressed Segmental Concrete BridgesDocument8 pagesAllowable Tensile Stress For Webs of Prestressed Segmental Concrete BridgesShikhar SinghPas encore d'évaluation

- Effective Stiffness of Reinforced Concrete ColumnsDocument9 pagesEffective Stiffness of Reinforced Concrete ColumnsrjtcostaPas encore d'évaluation

- 2010 Confinement of Deep Beam Nodal RegionsDocument9 pages2010 Confinement of Deep Beam Nodal RegionsKhPas encore d'évaluation

- Probabilistic Joint Shear Strength Models For Design of RC Beam-Column ConnectionsDocument11 pagesProbabilistic Joint Shear Strength Models For Design of RC Beam-Column ConnectionsangthiankongPas encore d'évaluation

- Design of Shear Tab Connections For GravDocument66 pagesDesign of Shear Tab Connections For GravRonald SiraitPas encore d'évaluation

- Behavior and Efficiency of Bottle-Shaped Struts: Aci Structural Journal Technical PaperDocument8 pagesBehavior and Efficiency of Bottle-Shaped Struts: Aci Structural Journal Technical PaperMishraq ul quraishPas encore d'évaluation

- Restrepo RodriguezDocument19 pagesRestrepo RodriguezREYNA ALVAREZPas encore d'évaluation

- 2013 ACI New ModelDocument1 page2013 ACI New ModelErrPas encore d'évaluation

- NSEL Report 014 Part IIDocument44 pagesNSEL Report 014 Part IIAllison KeyPas encore d'évaluation

- 212Document12 pages212cu1988Pas encore d'évaluation

- The History of The Development of The Single Angle Design Provisions in The Aisc SpecificationDocument15 pagesThe History of The Development of The Single Angle Design Provisions in The Aisc SpecificationrubensPas encore d'évaluation

- Behavior of Interior Beam-to-Column Connections UnderDocument7 pagesBehavior of Interior Beam-to-Column Connections UnderMarimuthu KaliyamoorthyPas encore d'évaluation

- The Evolution of Stability Provisions in The AISC SpecificationDocument30 pagesThe Evolution of Stability Provisions in The AISC SpecificationapirakqPas encore d'évaluation

- Allowable Tensile Stress Limit at Prestress Transfer: April 2009Document36 pagesAllowable Tensile Stress Limit at Prestress Transfer: April 2009Michael AbeledaPas encore d'évaluation

- ACI STRUCTURAL JOURNAL-Shear Strength of Steel Fiber ReinforcedDocument9 pagesACI STRUCTURAL JOURNAL-Shear Strength of Steel Fiber ReinforcedMuchtar SufaatPas encore d'évaluation

- An Experimental Study On Steel Encased Buckling Restrained Brace Hysteretic Dampers PDFDocument21 pagesAn Experimental Study On Steel Encased Buckling Restrained Brace Hysteretic Dampers PDFM. Murat ErginPas encore d'évaluation

- J. Aci PDFDocument54 pagesJ. Aci PDFJunior Garcia100% (1)

- Justification of ACI 446 Proposal For Updating ACI CodeDocument10 pagesJustification of ACI 446 Proposal For Updating ACI Codemcivil 9Pas encore d'évaluation

- Ultimate Load Capacities of Mooring Bollards and Hull Foundation StructuresDocument8 pagesUltimate Load Capacities of Mooring Bollards and Hull Foundation StructuresKhalilPas encore d'évaluation

- Deformation of Progressively Cracking Reinforced Concrete BeamsDocument11 pagesDeformation of Progressively Cracking Reinforced Concrete BeamsCE19D506 Shaik Farooq AhamedPas encore d'évaluation

- Bond Between Normal Strength and High-Strength Concrete (HSC) and Reinforcing Bars in Splices in BeamsDocument8 pagesBond Between Normal Strength and High-Strength Concrete (HSC) and Reinforcing Bars in Splices in BeamsAhmad YaniPas encore d'évaluation

- Compatibility Torsion in Spandrel Beams Using Modified Compression Field TheoryDocument11 pagesCompatibility Torsion in Spandrel Beams Using Modified Compression Field TheoryMishraq ul quraishPas encore d'évaluation

- Strength of Welded Joints Under Combined Shear and Out-Of-Plane BendingDocument12 pagesStrength of Welded Joints Under Combined Shear and Out-Of-Plane BendingPatrick PolujanPas encore d'évaluation

- Experimental Studies On High-Strength Concrete Deep Beams: Aci Structural Journal Technical PaperDocument9 pagesExperimental Studies On High-Strength Concrete Deep Beams: Aci Structural Journal Technical PaperMsheer Hasan AliPas encore d'évaluation

- Seismic Behavior and Design of Composite Steel Plate Shear Walls PDFDocument73 pagesSeismic Behavior and Design of Composite Steel Plate Shear Walls PDFmanpreetkhanujaPas encore d'évaluation

- One-Way Shear Strength of Thick Slabs and Wide BeamsDocument9 pagesOne-Way Shear Strength of Thick Slabs and Wide BeamsWasin WaiyasusriPas encore d'évaluation

- A Brief History of Beam-Column DesignDocument11 pagesA Brief History of Beam-Column DesigntaosyePas encore d'évaluation

- AISC K FactorDocument30 pagesAISC K FactorEric NolascoPas encore d'évaluation

- Shear Strength Concrete StructuresDocument18 pagesShear Strength Concrete Structuresmmendez113Pas encore d'évaluation

- Fatigue Evaluation For Reinforced Concrete Box CulvertsDocument8 pagesFatigue Evaluation For Reinforced Concrete Box CulvertsProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (2)

- Recent Developments in Steel Building Design: Lynns - Beedle, Le-Wu Lu, and Erkan OzerDocument14 pagesRecent Developments in Steel Building Design: Lynns - Beedle, Le-Wu Lu, and Erkan OzerNIBEDITA DEYPas encore d'évaluation

- Use of Steel Fiber Reinforced Concrete For Enhanced Performance of Deep Beams With Large OpeningsDocument10 pagesUse of Steel Fiber Reinforced Concrete For Enhanced Performance of Deep Beams With Large OpeningssuhagPas encore d'évaluation

- Effective Stiffness of Reinforced Concrete ColumnsDocument9 pagesEffective Stiffness of Reinforced Concrete ColumnsAlberto Ezequiel León TamayoPas encore d'évaluation

- 2018 Hanssan Moehle Shear Strength of Exterior Beam Column Joint WO Transverse ReinforcementDocument10 pages2018 Hanssan Moehle Shear Strength of Exterior Beam Column Joint WO Transverse ReinforcementFernando TorresPas encore d'évaluation

- 100-S09influence of Tension Strain On Buckling of Reinforcement in Concrete ColumnsDocument11 pages100-S09influence of Tension Strain On Buckling of Reinforcement in Concrete ColumnsshuangyaksaPas encore d'évaluation

- High-Strength Concrete Columns: State of The Art: Repor Ted by Joint ACI-ASCE Committee 441Document13 pagesHigh-Strength Concrete Columns: State of The Art: Repor Ted by Joint ACI-ASCE Committee 441DIDIER ANGEL LOPEZ RINCONPas encore d'évaluation

- Behaviour of Building Structures Subjected to Progressive CollapseD'EverandBehaviour of Building Structures Subjected to Progressive CollapsePas encore d'évaluation

- Fatigue Analysis of Welded Components: Designer’s Guide to the Structural Hot-Spot Stress ApproachD'EverandFatigue Analysis of Welded Components: Designer’s Guide to the Structural Hot-Spot Stress ApproachÉvaluation : 5 sur 5 étoiles5/5 (1)

- Structural Elements for Architects and Builders: Design of Columns, Beams, and Tension Elements in Wood, Steel, and Reinforced ConcreteD'EverandStructural Elements for Architects and Builders: Design of Columns, Beams, and Tension Elements in Wood, Steel, and Reinforced ConcretePas encore d'évaluation

- Buckling and Ultimate Strength of Ship and Ship-like Floating StructuresD'EverandBuckling and Ultimate Strength of Ship and Ship-like Floating StructuresÉvaluation : 4 sur 5 étoiles4/5 (4)

- Introduction to Design of Building StructuresD'EverandIntroduction to Design of Building StructuresÉvaluation : 4 sur 5 étoiles4/5 (22)

- Mechanics of Rubber Bearings for Seismic and Vibration IsolationD'EverandMechanics of Rubber Bearings for Seismic and Vibration IsolationPas encore d'évaluation

- Reinforced Concrete Buildings: Behavior and DesignD'EverandReinforced Concrete Buildings: Behavior and DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- Composite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)D'EverandComposite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Évaluation : 4 sur 5 étoiles4/5 (10)

- New Approach Prediction of Compression Strength of Normal and Porcelanite Aggregate Lightweight Concrete by Non-Destructive TestDocument8 pagesNew Approach Prediction of Compression Strength of Normal and Porcelanite Aggregate Lightweight Concrete by Non-Destructive TestProfessor Dr. Nabeel Al-Bayati-Consultant EngineerPas encore d'évaluation

- Steel Frame Structure Analysis and Design by Staad-Pro (Example - 4) by Prof. Dr. Nabeel Al-BayatiDocument3 pagesSteel Frame Structure Analysis and Design by Staad-Pro (Example - 4) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (2)

- Reinforced Concrete Building Modeling by Staad-Pro (Example-1) by Prof. Dr. Nabeel Al-BayatiDocument6 pagesReinforced Concrete Building Modeling by Staad-Pro (Example-1) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- Steel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiDocument6 pagesSteel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- Structural Concrete Details by AutoCAD-Example 2-Prof. Dr. Nabeel Al-Bayati PDFDocument7 pagesStructural Concrete Details by AutoCAD-Example 2-Prof. Dr. Nabeel Al-Bayati PDFProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- Reinforced Concrete Building, Modelling, Analysis and Design by Staad-Pro (Example 3) by Prof. Dr. Nabeel Al-BayatiDocument5 pagesReinforced Concrete Building, Modelling, Analysis and Design by Staad-Pro (Example 3) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer50% (2)

- Bending Stiffness and Neutral Axis Depth Variation of High Strength Concrete Beams in Seismic Hazardous Areas Experimental InvestigationDocument13 pagesBending Stiffness and Neutral Axis Depth Variation of High Strength Concrete Beams in Seismic Hazardous Areas Experimental InvestigationArjun MulluPas encore d'évaluation

- Experimental Behavior of Composite Deep Beams, AUB Conference, 2015 PDFDocument8 pagesExperimental Behavior of Composite Deep Beams, AUB Conference, 2015 PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerPas encore d'évaluation

- Experimental Behavior of Composite Deep Beams, AUB Conference, 2015 PDFDocument8 pagesExperimental Behavior of Composite Deep Beams, AUB Conference, 2015 PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerPas encore d'évaluation

- Repair of Reinforced Concrete Deep Beams Using Post-Tensioned CFRP Rods PDFDocument39 pagesRepair of Reinforced Concrete Deep Beams Using Post-Tensioned CFRP Rods PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerPas encore d'évaluation

- Strength and Behavior in Shear of Reinforced Concrete Deep Beams Under Dynamic Loading Conditions PDFDocument15 pagesStrength and Behavior in Shear of Reinforced Concrete Deep Beams Under Dynamic Loading Conditions PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerPas encore d'évaluation

- Aci Structural Journal Jan.-Feb. 2015 v. 112 No. 01Document122 pagesAci Structural Journal Jan.-Feb. 2015 v. 112 No. 01Professor Dr. Nabeel Al-Bayati-Consultant Engineer100% (3)

- New Approach Prediction of Compression Strength of Normal and Porcelanite Aggregate Lightweight Concrete by Non-Destructive TestDocument8 pagesNew Approach Prediction of Compression Strength of Normal and Porcelanite Aggregate Lightweight Concrete by Non-Destructive TestProfessor Dr. Nabeel Al-Bayati-Consultant EngineerPas encore d'évaluation

- Shear StrengtheningDocument8 pagesShear StrengtheningMohamed MoatazPas encore d'évaluation

- EIA Practice in India and Its EvaluationDocument19 pagesEIA Practice in India and Its EvaluationDharmesh100% (1)

- Astm C-42Document6 pagesAstm C-42Víctor M Fernández JiménezPas encore d'évaluation

- Strength Assessment of Concrete Structures PDFDocument58 pagesStrength Assessment of Concrete Structures PDFProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- StaircaseDocument14 pagesStaircaserameshbabu_1979Pas encore d'évaluation

- Computer Application in Water Works EngineeringDocument12 pagesComputer Application in Water Works EngineeringProfessor Dr. Nabeel Al-Bayati-Consultant EngineerPas encore d'évaluation

- MAMansur 2006 Design of Reinforced Concrete Beams With Web Openings PDFDocument17 pagesMAMansur 2006 Design of Reinforced Concrete Beams With Web Openings PDFvinthfPas encore d'évaluation

- A Design For Circular Concrete Tank Pca Design MethodDocument15 pagesA Design For Circular Concrete Tank Pca Design MethodajebPas encore d'évaluation

- Oil StorFage Tank Foundations BobergDocument3 pagesOil StorFage Tank Foundations BobergNabil Al-KhirdajiPas encore d'évaluation

- Aci Structural Journal Mar.-Apr. 2015 v. 112 No. 02Document146 pagesAci Structural Journal Mar.-Apr. 2015 v. 112 No. 02Professor Dr. Nabeel Al-Bayati-Consultant Engineer100% (5)

- Deep BeamDocument8 pagesDeep BeamShashikant Gaur0% (1)

- Ansi - Eia 748 BDocument34 pagesAnsi - Eia 748 BProfessor Dr. Nabeel Al-Bayati-Consultant EngineerPas encore d'évaluation

- IBM SPSS Statistics PDFDocument8 pagesIBM SPSS Statistics PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerPas encore d'évaluation

- MS Project 2002 Getting Started PDFDocument20 pagesMS Project 2002 Getting Started PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerPas encore d'évaluation

- Bulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForDocument4 pagesBulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForIbeth S OTPas encore d'évaluation

- Beam Design Formulas With Shear and MomentDocument20 pagesBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- IBM SPSS Statistics PDFDocument8 pagesIBM SPSS Statistics PDFProfessor Dr. Nabeel Al-Bayati-Consultant EngineerPas encore d'évaluation

- 5R55W-S Repair DiagnosisDocument70 pages5R55W-S Repair Diagnosisaxallindo100% (2)

- Hitachi HDDs Repair Scheme Based On MRT ProDocument21 pagesHitachi HDDs Repair Scheme Based On MRT ProvicvpPas encore d'évaluation

- Book Review: Laser Fundamentals, 2nd Edition by William T. SilfvastDocument2 pagesBook Review: Laser Fundamentals, 2nd Edition by William T. SilfvastAbhishekPas encore d'évaluation

- Che 410 ................... Transition Metal ChemistryDocument13 pagesChe 410 ................... Transition Metal ChemistryElizabeth AnyangoPas encore d'évaluation

- ATR4518R2Document2 pagesATR4518R2estebanarca50% (4)

- EConsole1 Quick Start Guide ENGDocument21 pagesEConsole1 Quick Start Guide ENGManuel Casais TajesPas encore d'évaluation

- Chapter 3Document23 pagesChapter 3pganoelPas encore d'évaluation

- 3 DB RDMDocument49 pages3 DB RDMfaisal shahzadPas encore d'évaluation

- F3 Chapter 1 (SOALAN) - RespirationDocument2 pagesF3 Chapter 1 (SOALAN) - Respirationleong cheng liyPas encore d'évaluation

- 16620YDocument17 pages16620YbalajivangaruPas encore d'évaluation

- EC 201 Network TheoryDocument2 pagesEC 201 Network TheoryJoseph JohnPas encore d'évaluation

- Plagiarism - ReportDocument6 pagesPlagiarism - ReportDipesh NagpalPas encore d'évaluation

- T 096Document3 pagesT 096abelPas encore d'évaluation

- 02 Survey Calculations - PpsDocument96 pages02 Survey Calculations - PpsLeo Ivan Aviles RicaldiPas encore d'évaluation

- API2000 Tank Venting CalcsDocument5 pagesAPI2000 Tank Venting Calcsruhul01Pas encore d'évaluation

- Articles On SidisDocument146 pagesArticles On SidisMircea492003100% (1)

- Limitations of Learning by Discovery - Ausubel PDFDocument14 pagesLimitations of Learning by Discovery - Ausubel PDFOpazo SebastianPas encore d'évaluation

- US2726694 - Single Screw Actuated Pivoted Clamp (Saxton Clamp - Kant-Twist)Document2 pagesUS2726694 - Single Screw Actuated Pivoted Clamp (Saxton Clamp - Kant-Twist)devheadbot100% (1)

- GMS60CSDocument6 pagesGMS60CSAustinPas encore d'évaluation

- Effect of Petrol Fumes On An Anthropometry and Ventilatory Function Among Petrol Pump Workers of Puducherry, IndiaDocument13 pagesEffect of Petrol Fumes On An Anthropometry and Ventilatory Function Among Petrol Pump Workers of Puducherry, IndiaABHINABA GUPTAPas encore d'évaluation

- 21 API Functions PDFDocument14 pages21 API Functions PDFjet_mediaPas encore d'évaluation

- Abr Sinai Onshore Gas Pipeline PDFDocument42 pagesAbr Sinai Onshore Gas Pipeline PDFhamza2085100% (1)

- STD XTH Geometry Maharashtra BoardDocument35 pagesSTD XTH Geometry Maharashtra Boardphanikumar50% (2)

- Science BDocument2 pagesScience BIyer JuniorPas encore d'évaluation

- Exploring Music ContentsDocument370 pagesExploring Music ContentsRoby SamboraPas encore d'évaluation

- X-Plane Mobile ManualDocument66 pagesX-Plane Mobile ManualRafael MunizPas encore d'évaluation

- Fongs ProgrammerDocument5 pagesFongs ProgrammerPankaj PolaraPas encore d'évaluation

- Orthographic Views in Multiview Drawings: Autocad 2015 Tutorial: 2D Fundamentals 5-1Document30 pagesOrthographic Views in Multiview Drawings: Autocad 2015 Tutorial: 2D Fundamentals 5-1Uma MageshwariPas encore d'évaluation

- Ampla's Technology ArchitectureDocument4 pagesAmpla's Technology ArchitecturesyeadtalhaaliPas encore d'évaluation

- Types of Solids 1Document16 pagesTypes of Solids 1Fern BaldonazaPas encore d'évaluation