Académique Documents

Professionnel Documents

Culture Documents

Jar Test Experiment

Transféré par

wmulvanyCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Jar Test Experiment

Transféré par

wmulvanyDroits d'auteur :

Formats disponibles

DRINKING WATER - LAB EXPERIMENTS

LAB EXPERIMENTS

Coagulation

and flocculation

Jartest

coagulation and flocculation

- jartest

Framework

This module explains the lab experiment on coagulation and flocculation.

Contents

This module has the following contents:

1. Objective

2. Experiment set-up

3. Theory

4. Procedure

4.1 Variation of iron dose at a fixed pH=8

4.2 Variation of FeCl3 dose at final pH=8 at 30 rpm

4.3 Variation of FeCl3 dose at final pH=8 at 60 rpm

5. Elaboration

Data form

lab experiments

coagulation and flocculation

lab experiments

1.

- jartest

Objective

The objective of this experiment is to achieve a

quality improvement of surface water by using

an iron salt as coagulant. Turbidity is the quality

parameter to be improved. When dosing an iron

salt a pH of 8 is expected to be optimal for reducing the turbidity.

Figure 2 - Jar test apparatus in the laboratory

2.

Experiment set-up

A jar test apparatus, used for this experiment, is

schematically drawn in figure 1. It consists of six

identical beakers of 2 liter, each equipped with a

stirrer, two dosing test tubes and a siphon with

Erlenmeyer flask (not drawn). One dosing test tube

is for acid or alkaline dosing, the other for dosing

the coagulant. They can be operated simultaneously. The stirrers are driven by one motor, thus

giving each the same rotation velocity.

rotational speed

control unit

stirrers

dosing

tubes

Figure 1 - The open structure of activated carbon

3.

Theory

Colloidal matter in surface water can not settle by

itself. Dosing of a coagulant is required to achieve

removal by coagulation and subsequent flocculation, followed by sedimentation. The result of this

treatment is depending on many factors, such as

coagulant dose, pH, reaction period and supplied

energy of the stirring device. A jar test is ideal to

asses the influence of these process parameters

within a short time.

Adding ferric chloride causes a number of hydrolysis reactions, where the iron ions react as an acid,

thereby reducing the pH. As a result of these

reactions iron hydroxide already precipitates in an

acidic environment. In a 2.10-4 M solution (about 11

mg Fe/l) the formation of insoluble iron hydroxide

starts at pH=2.7, while at pH=4 even 99.85% of

all available iron will be precipitated.

The hydrolysis products interact with colloidal

matter and finely dispersed particles. They are

destabilized, thereby causing coagulation and flocculation. The application of coagulants can also

be used for reducing the color or the phosphate

concentration.

In order to optimize the flocculation process a

number of process parameters are relevant:

- coagulant dose

- pH

- shear rate during flocculation

- flocculation time

- dosing of a coagulant aid (a polymer)

The shear rate can be calculated with:

G =

P

mV

P = mixing energy, dissipated power

(W)

m = dynamic viscosity

(N.s/m2)

V = volume of mixing tank

(m3)

coagulation and flocculation

4.

- jartest

Procedure

4.1 Variation of iron dose at a fixed

pH=8

In order to maintain pH=8 in each beaker after the

dosing of different quantities of iron (FeCl3.6H2O),

it is necessary to add some NaOH to compensate

the effect of the iron salt on pH. The amount of

NaOH depends on the iron salt dosage and must

be estimated before the jar test is executed.

-

fill a beaker with 1.8 L

Schiewater, put it on a

magnetic stirrer and immerse the pH-electrode;

stir continuously.

-

measure the pH and add with a burette 0.5M

NaOH until the pH=8.

- note the added quantity of NaOH (ml).

- add with a burette five times 2 ml FeCl3-solution

and adjust after each iron addition to pH=8 by

adding NaOH. Note the added quantities.

- calculate the cumulative amount of NaOH that

is needed at iron doses of 0, 2, 4, 6, 8 and 10

mg Fe/l.

4.2 Variation of FeCl3 dose at final pH=8

at 30 rpm

- measure and note the temperature of the

Schiewater and adjust the thermostat on this

temperature to effectuate a constant temperature during the test.

- fill each beaker with 1.8 l Schiewater.

- fill six test tubes with 0, 2, 4, 6, 8, and 10 ml

FeCl3-solution and fix them in the clamps above

the beakers. The zero dosing is the blank determination.

-

fill six other test tubes with NaOH as determined

in the previous paragraph and fix the tubes in

the other clamps.

- add simultaneously the NaOH to the beakers,

while stirring intensively at 200 rpm; rinse the

test tubes with some demineralised water.

-

add simultaneously, at the same stirring intensity of 200 rpm, the coagulant and rinse the test

tubes with some demineralised water. Stir for

10 to 15 seconds.

- reduce the stirring intensity to 30 rpm and stir

gently for a period of 20 minutes. Examine the

lab experiments

flocculation phenomena that occur in the beakers. Note the appearance of the first visible

flocs, floc shape and size.

- after 20 minutes of slow stirring turn off the stirrer and let the solution stand for 20 minutes to

enable settling of flocs.

- take carefully with a siphon a sample of about

500 ml from each beaker and collect it in a flask

of 1000 ml.

- determine of each sample the turbidity and

pH.

4.3 Variation

of FeCl3

dose at final pH=8

at 60 rpm

- measure and note the temperature of the

Schiewater and adjust the thermostat on this

temperature to effectuate a constant temperature during the test.

- fill each beaker with 1.8 l Schiewater.

- fill six test tubes with 0, 2, 4, 6, 8, and 10 ml

FeCl3-solution and fix them in the clamps above

the beakers. The zero dosing is the blank determination.

- fill six other test tubes with NaOH as determined

in the previous paragraph and fix the tubes in

the other clamps.

- add simultaneously the NaOH to the beakers,

while stirring intensively at 200 rpm; rinse the

test tubes with some demineralised water.

- add simultaneously, at the same stirring intensity of 200 rpm, the coagulant and rinse the test

tubes with some demineralised water. Stir for

10 to 15 seconds.

- reduce the stirring intensity to 60 rpm and stir

gently for a period of 20 minutes. Examine the

flocculation phenomena that occur in the beakers. Note the appearance of the first visible

flocs, floc shape and size.

- after 20 minutes of slow stirring turn off the stirrer and let the solution stand for 20 minutes to

enable settling of flocs.

- take carefully with a siphon a sample of about

500 ml from each beaker and collect it in a flask

of 1000 ml.

- determine of each sample the turbidity and

pH.

lab experiments

5.

coagulation and flocculation

- jartest

Elaboration

Execute the following steps:

- present the results in tables.

- what water quality parameter has an influence

on the buffer capacity of water? Can you calculate the amount of that buffer in the Schiewater?

You can either calculate it with the formulas in

the lecture notes (softening) or use Stimela.

- explain why the extra NaOH-dose is necessary

after dosing ironchloride. Is the extra amount

in the range of what you expect?

- Plot in a graph the iron dose against the turbidity and residual iron concentration for the two

experiments.

- give your comment on all results.

- calculate the optimal stirring rate at a water

temperature of 2 degrees.

- at low temperatures the coagulation is often

less efficient also at an optimal shear rate.

What process parameters can be adapted in

order to enhance the coagulation/sedimentation process at low temperatures?

coagulation and flocculation

- jartest

lab experiments

Data form

Group number:

Date:

Variable dosing FeCl3 at constant end pH = 8

Temperature Schiewater : C

Iron analysis extinction blank: 1/m

Beaker

FeCl3 sol.

1,8 g Fe/l

ml

NaOH

0,5 M

ml

Extinction

Fe-meting

1/m

End quality water

(pH)

Turbidity

(NTU)

Fe

(mg/l)

1

2

3

4

5

6

Constant dosing at variable end pH

Iron dosing (constant) : mg Fe/l

Temperature Schiewater : C

Iron analysis extinction blank: 1/m

Beaker

FeCl3 sol.

1,8 g Fe/l

ml

Required

end-pH

Dosage

NaOH

(ml)

1

2

3

4

5

6

Extinction

Fe-meting

1/m

HCl

(ml)

End quality water

pH

(-)

Turbidity.

(NTU)

Fe

(mg/l)

Vous aimerez peut-être aussi

- Ethical PyramidDocument1 pageEthical PyramidwmulvanyPas encore d'évaluation

- I RobotDocument1 pageI RobotwmulvanyPas encore d'évaluation

- The Biology of ReligionDocument5 pagesThe Biology of ReligionwmulvanyPas encore d'évaluation

- Idges 1973Document506 pagesIdges 1973hcabanillaspPas encore d'évaluation

- Autocad Resume: Startup : StartupDocument22 pagesAutocad Resume: Startup : StartupwmulvanyPas encore d'évaluation

- 14 Tips To Speed Up Your MetabolismDocument29 pages14 Tips To Speed Up Your MetabolismwmulvanyPas encore d'évaluation

- 14 Tips To Speed Up Your MetabolismDocument29 pages14 Tips To Speed Up Your MetabolismwmulvanyPas encore d'évaluation

- Steel Design Notes PDFDocument50 pagesSteel Design Notes PDFwmulvanyPas encore d'évaluation

- Problem 1Document2 pagesProblem 1wmulvanyPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- GeomembranesinDams (INACOLD)Document38 pagesGeomembranesinDams (INACOLD)Robbi Shobri Rakhman100% (1)

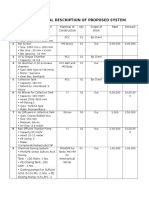

- Boq of Technical Description of Proposed System.Document5 pagesBoq of Technical Description of Proposed System.M.A. MonimPas encore d'évaluation

- Scope of Work Commercial BuildingDocument2 pagesScope of Work Commercial BuildingShahdan AzmanPas encore d'évaluation

- Open Ended Lab: Environmental Engineering-I LabDocument9 pagesOpen Ended Lab: Environmental Engineering-I LabSaroosh ul Musatafa CheemaPas encore d'évaluation

- Maharashtra Regional and Town Planning Act, 1966Document8 pagesMaharashtra Regional and Town Planning Act, 1966Pradnya Inamdar100% (1)

- Ultrafiltration Explained: Ultrafilter vs. Conventional FilterDocument5 pagesUltrafiltration Explained: Ultrafilter vs. Conventional Filteran_iboreg8720Pas encore d'évaluation

- Assessment of Water Quality in Isaka, Okrika NigeriaDocument7 pagesAssessment of Water Quality in Isaka, Okrika NigeriaInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Pinedale Roundup Headlines, Aug. 31, 2018Document24 pagesPinedale Roundup Headlines, Aug. 31, 2018Anonymous IX15EDMnwPas encore d'évaluation

- Boquillas para Torre de EnfriamientoDocument3 pagesBoquillas para Torre de EnfriamientoAnonymous Lb4hrlAf7VPas encore d'évaluation

- Causes and Effects of Seepage Force 1Document14 pagesCauses and Effects of Seepage Force 1femccetaiwoPas encore d'évaluation

- Water DistributionDocument17 pagesWater DistributionkarunyaPas encore d'évaluation

- Ess801x My1 enDocument28 pagesEss801x My1 enrolandbcaspePas encore d'évaluation

- F27980036 - 181108SV Revised 30042019Document21 pagesF27980036 - 181108SV Revised 30042019hhPas encore d'évaluation

- Pipe Size CalculationDocument6 pagesPipe Size CalculationBao Duy Nguyen0% (1)

- Rain Water HarvestingDocument31 pagesRain Water HarvestingDharani Kumar G RPas encore d'évaluation

- Report On DCS (District Cooling System) GIFT CITY, GANDHINAGAR Industrial VisitDocument6 pagesReport On DCS (District Cooling System) GIFT CITY, GANDHINAGAR Industrial VisitAnandPas encore d'évaluation

- Rain Catch: Presented by Adrika Sivadas Adrija SivadasDocument11 pagesRain Catch: Presented by Adrika Sivadas Adrija SivadasPriyanka ChaudharyPas encore d'évaluation

- Khalid CemDocument19 pagesKhalid CemMohd SaadPas encore d'évaluation

- Assignment - SDGDocument2 pagesAssignment - SDGNur Fatihah ZulkifliPas encore d'évaluation

- The Drainage System of A HouseDocument42 pagesThe Drainage System of A HouseJez CayetanoPas encore d'évaluation

- Breaches of Embankment and DamDocument17 pagesBreaches of Embankment and Damyk410Pas encore d'évaluation

- Ceramic Membrane Technical DirectionsDocument7 pagesCeramic Membrane Technical DirectionsSterlitech100% (1)

- Is 458-1988Document46 pagesIs 458-1988Rajashekhar Katta100% (2)

- ALDEC 400 Series: High Performance DecanterDocument2 pagesALDEC 400 Series: High Performance DecanterCaio NunesPas encore d'évaluation

- Production of Chlorine Dioxide: Using Diluted Naclo and HCL SolutionsDocument2 pagesProduction of Chlorine Dioxide: Using Diluted Naclo and HCL SolutionsJuan Carlos GonzalezPas encore d'évaluation

- Civil Engineering R16 4-1 Syllabus JntukDocument34 pagesCivil Engineering R16 4-1 Syllabus JntukB mehaboobPas encore d'évaluation

- Energy ConversionDocument47 pagesEnergy Conversionkass00488_18085260988% (8)

- WaterDocument24 pagesWaterAiron Kaye Samelo100% (1)

- BSR307 WSA PresentationDocument12 pagesBSR307 WSA PresentationSafa HaziqPas encore d'évaluation

- Pipe Wall Thickness PDFDocument1 pagePipe Wall Thickness PDFjig812Pas encore d'évaluation