Académique Documents

Professionnel Documents

Culture Documents

Hazards Observation Sheet

Transféré par

ali128Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Hazards Observation Sheet

Transféré par

ali128Droits d'auteur :

Formats disponibles

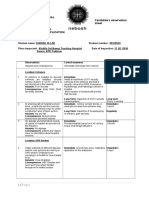

INTERNATIONAL GENERAL

CERTIFICATE

(2011 specification)

Candidates observation

sheet

IGC3 THE HEALTH AND

SAFETY PRACTICAL APPLICATION

Sheet number: 01 of 05

Student number: 00203652

Date of inspection: 12-10-2013

Student name: Syed Abul Hassan Kazmi

Place inspected: Pak Arab Fertilizers Multan

Observation

Hazards and Consequences

Control measures

Immediate and Long term Actions

1. Risk of fire due to the

Removal of fire ignition

availability of chemicals and

substances.

gases at the same time usage

Separate handling of chemicals and

Timescale

Immediately

at a same place.

gases.

2. Chance of ignition of fire Removal of overloading of sockets.

Immediately

Immediately

due to bad maintenance of

the sockets at the storage Installation of circuit breakers on

2 weeks

room.

the sources

3. Threat of fire near the Segregation of chemicals on a side

1 week

sewerage

system

because place and ensuring barriers.

chemical bottles are placed Installation of Fire extinguishers on

2 weeks

there without having any the site.

support to the ground.

4. Threat of explosion due to Making it no smoking zone.

Immediately

smoking of employees near

the chemical trucks for the Proper sign boards and warning.

supply.

5. Fire causality due to the Segregation of cylinders.

Immediately

inappropriate maintenance of Installation of Fire extinguishers on

the gas cylinders.

6.

Panic

2 weeks

the site.

can Proper signs for the evacuation way.

1 week

for Proper

emergency

1 week

evacuation emergency door Providing more than one escape

1 month

increase

causality

2 weeks

the

danger

visibility

of

employees because only one lights.

is there for almost 700 way for the emergency evacuation.

employees

in

the

main

mixture room.

7.

Risk

of

slip

in

the Removal

of

any

hazardous

Immediately

production room because of substances from the ground.

the slippery floor.

Wet floor signs.

1 week

Proving friction to the ground

avoiding slips.

8.

Trip

hazard

in

the Proper maintenance of wires.

1 month

Immediately

computer section because of

the wires spread on the floor Good housekeeping is required.

2 weeks

near tables which are almost

unseen for the new comer.

9. Falling of sacks hazard in

Stacking them in the right manner.

the storage room due to

Housekeeping is required

Immediately

2 weeks

improper heaping system.

10. Almost no local area Ensuring LEV system.

Immediately

ventilation system in the

storage

11. Blockage of ducts in the Maintenance of LEV in control

Immediately

control room affecting the system.

ventilation.

12.

Inadequate

problems

areas.

inside

signage Installation of signboards.

working

2 weeks

13. Almost no usage of

Ensuring the usage of PPE.

personal

Providing employees with the

protective

required PPE.

Immediately

1 month

equipment in

the working

zone.

14. Risk of falling objects

Barriers around the working area.

Immediately

through cranes in the

Use of helmets and hard toe safety

Immediately

construction area within the

shoes.

working area.

Segregation of walkways.

15. No barricades around the Installation of barriers around the

2 weeks

Immediately

usage of mobile elevated MEWP.

working platforms.

Use of PPE.

16. Absence of guardrails on Installation of guardrails around it.

Immediately

Immediately

the working platforms of

cranes.

Use of PPE.

Immediately

17. No usage of Personal

Providing workers with the PPE.

Immediately

protective equipment by the

Supervision for the usage of PPE.

1 week

labours.

18. No facility of gas testing Providing equipment for the gas

in the working areas.

testing.

Ensuring gas testing after regular

intervals

19. Absence of guards in the Installation of guards.

handling

of

Immediately

1 week

Immediately

dangerous

machinery which can cause

1 week

injury.

20.

No

walkways

separation

in

moving zone.

the

of Segregation is required

Immediately

vehicle

Proper signage.

1 week

21.

No

inflammable

segregation

liquids

of Segregation is required

Immediately

and

chemicals.

Proper signage.

22. Absence of sheds in the

Installation of sheds.

1 week

Immediately

open field working areas for

the workers.

23.

Provision of Welfare facilities.

2 weeks

Out of orders water

coolers and washrooms in the Maintenance is required.

Immediately

production area.

24. Lack of supervision in Supervision is required.

Immediately

the major areas of working

which

can

cause

severe Training and information for the

injury.

employees.

25. Low provision of first aid Installation of first aid boxes.

2 weeks

Immediately

equipment in the working

zone.

26.

Presence of medical supervisor

Risk of physical and Ensuring barriers.

2 weeks

Immediately

psychological effects due to Usage of guards.

Immediately

machinery. (Noise, vibration Rotation of job.

2 weeks

etc.)

27. Almost most of the fire Maintenance of extinguisher.

extinguishers were out of

order.

Installation of new extinguisher.

28. Risk of WRULs due to

the repetitive work tasks.

Immediately

1 month

Job rotation.

2 weeks

Rest hours.

Immediately

29. Poor lightning in the

working zones which can

cause severe injury.

Installation of proper and good

lighting system.

Lights sign board should be there.

30. Presence of union system Neglecting negative peer culture.

in the organisation creating

peer pressure on some of the Promoting positive and healthy

workers and affecting them culture.

badly.

Eliminating union system.

Immediately

1 month

Immediately

Immediately

Immediately

31. Good record keeping

process.

Process need to be followed

Continuous monitoring

32. Focus on welfare

facilities.

Process need to be followed

Continuous monitoring

33. Maintenance of vehicles

was outstanding.

Process need to be followed.

Continuous monitoring

34. Standards followed for

the production process were

brilliant.

Process need to be followed.

Continuous monitoring

35. Providing Long terms

medical facilities for the

employees to be fit.

Process need to be followed.

Continuous monitoring

36. Committed leadership

providing guidelines.

Process need to be followed.

Continuous monitoring

Vous aimerez peut-être aussi

- Fire ExtinguisherDocument2 pagesFire ExtinguisherRisali AddiniPas encore d'évaluation

- Weekly excavator checklist template for construction projectsDocument4 pagesWeekly excavator checklist template for construction projectssamiran RouthPas encore d'évaluation

- 11 - Drilling Machine ChecklistDocument1 page11 - Drilling Machine ChecklistAfzal AkhtarPas encore d'évaluation

- EHS Observation Report FormatDocument1 pageEHS Observation Report FormatDore101Pas encore d'évaluation

- Maintenance Manual: Models 8300, 8400, and 8500 Pallet Trucks and Model 8600 Tow TractorDocument291 pagesMaintenance Manual: Models 8300, 8400, and 8500 Pallet Trucks and Model 8600 Tow TractorJosé Luis Ang Soto92% (13)

- Igc 3 Practical NeboshDocument20 pagesIgc 3 Practical NeboshAbdelkader FattouchePas encore d'évaluation

- Safety Observation ReportDocument12 pagesSafety Observation Reportmohammed minhaj0% (1)

- Safety Assessment in HM SymphonyDocument26 pagesSafety Assessment in HM Symphonyvilge rogesonPas encore d'évaluation

- Mock Drill ReportDocument3 pagesMock Drill ReportadyaPas encore d'évaluation

- IEEE C57.12.00 Test Tables 1 & 2Document6 pagesIEEE C57.12.00 Test Tables 1 & 2Galih Trisna NugrahaPas encore d'évaluation

- Safety OfficerDocument16 pagesSafety OfficerAzad pravesh khanPas encore d'évaluation

- Contractor's EHSS Evaluation by PMT EHSS PK CLC Project FMO Jan 2020Document5 pagesContractor's EHSS Evaluation by PMT EHSS PK CLC Project FMO Jan 2020ManPower RecruitingPas encore d'évaluation

- Sor-Landscape-Ppe5 29 Dec. 2020Document1 pageSor-Landscape-Ppe5 29 Dec. 2020haniPas encore d'évaluation

- L&T Chennai Metro Noise Monitoring ReportDocument1 pageL&T Chennai Metro Noise Monitoring Reportsalman farisPas encore d'évaluation

- Steam Condensate Pot SizingDocument1 pageSteam Condensate Pot SizingSaeid Rahimi MofradPas encore d'évaluation

- Igc3-The Health and Safety Practical ApplicationDocument21 pagesIgc3-The Health and Safety Practical ApplicationSamuel P SPas encore d'évaluation

- Weekly Safety Management Walkthrough Report: Gas Compression Project DepartmentDocument6 pagesWeekly Safety Management Walkthrough Report: Gas Compression Project DepartmentMuhammad TariqPas encore d'évaluation

- ANA Cordon and Search TTP DeliverableDocument33 pagesANA Cordon and Search TTP DeliverablejpgvenancioPas encore d'évaluation

- GC 3 Oberservation SheetDocument4 pagesGC 3 Oberservation SheetIrshad Ali Solangi33% (3)

- Report On Mock DrillDocument6 pagesReport On Mock Drillakshay aryaPas encore d'évaluation

- 129th HSJV Weekly MeetingDocument29 pages129th HSJV Weekly MeetingHumpy DumpyPas encore d'évaluation

- IGC III Obsevation ReportDocument5 pagesIGC III Obsevation ReportAbrahamAbraciaPas encore d'évaluation

- Candidate's observation sheet identifies health and safety risksDocument8 pagesCandidate's observation sheet identifies health and safety risksMarya HasniPas encore d'évaluation

- Nebosh IGC 3 Observation Sheet 00218445 FinalDocument13 pagesNebosh IGC 3 Observation Sheet 00218445 FinalNahaz HydrosePas encore d'évaluation

- Sample Observation - Incident Register - DEC - 2018Document189 pagesSample Observation - Incident Register - DEC - 2018dammy100% (1)

- APPENDIX 4: Candidate’s observation sheet hazards identified and control measures suggestedDocument23 pagesAPPENDIX 4: Candidate’s observation sheet hazards identified and control measures suggestedTom KuriakosePas encore d'évaluation

- LSIS - Molded Case Circuit Breaker (MCCB) - CatalogDocument140 pagesLSIS - Molded Case Circuit Breaker (MCCB) - CatalogNguyen LuongPas encore d'évaluation

- GC3 - The Health and Candidate's Observation Safety Practical Application SheetDocument6 pagesGC3 - The Health and Candidate's Observation Safety Practical Application Sheetmohd zakeerPas encore d'évaluation

- Environmental TrainingDocument45 pagesEnvironmental Trainingali128100% (1)

- Nebosh Safety AssignmentDocument14 pagesNebosh Safety AssignmentMirza Safeer Ahmad100% (3)

- A New GC3Document13 pagesA New GC3Hashim Raza0% (1)

- Introduction To CPHQDocument24 pagesIntroduction To CPHQmonir61Pas encore d'évaluation

- Construction Site Safety ReportDocument35 pagesConstruction Site Safety ReportAkshay Waim100% (1)

- Aksa Lte NW AssessmentDocument43 pagesAksa Lte NW AssessmentSenthilkumar Purushothaman100% (2)

- NEBOSH IGC3 Health and Safety Practical Application GuideDocument18 pagesNEBOSH IGC3 Health and Safety Practical Application GuideAnas Shoaib50% (2)

- GC3 ObservationDocument16 pagesGC3 ObservationjithinPas encore d'évaluation

- Updated New IGC3 - SampleDocument9 pagesUpdated New IGC3 - SampleHossamKandil100% (1)

- 25 Haz Report Nebosh StyleDocument5 pages25 Haz Report Nebosh StyleGothy GamingPas encore d'évaluation

- Farhad Ullah Observation SheetDocument6 pagesFarhad Ullah Observation SheetFarhad UllahPas encore d'évaluation

- Gc3 - The Health and Candidate's Observation Safety Practical Application SheetDocument6 pagesGc3 - The Health and Candidate's Observation Safety Practical Application SheetMidhunRameshThuvasseryPas encore d'évaluation

- Inspection Report From NAIADocument9 pagesInspection Report From NAIARaymondGomezBlancoPas encore d'évaluation

- 2019-10-15 Daily Observation Report CilamayaDocument1 page2019-10-15 Daily Observation Report CilamayaghifariaghniaPas encore d'évaluation

- Acf-Mra-063 - UaDocument1 pageAcf-Mra-063 - UaFateh AliyaPas encore d'évaluation

- ZFP Sor 2022-11-17Document7 pagesZFP Sor 2022-11-17irfan shafiquePas encore d'évaluation

- Nebosh Igc 3 Observation Sheet 00218445 Ajit Kumar 1 PDFDocument12 pagesNebosh Igc 3 Observation Sheet 00218445 Ajit Kumar 1 PDFAbdelkader Fattouche100% (1)

- Near Miss Investigation ReportDocument1 pageNear Miss Investigation ReportBorislav VulićPas encore d'évaluation

- M013-JAC-HSE-RPT-00146 Close Out 04.10.2018Document10 pagesM013-JAC-HSE-RPT-00146 Close Out 04.10.2018Anonymous 3WKsDwPPas encore d'évaluation

- HSE Site Instruction For Contractor FormDocument2 pagesHSE Site Instruction For Contractor Formابو محمد علي100% (1)

- Daily Observation ReportDocument1 pageDaily Observation ReportAnsar AliPas encore d'évaluation

- 355-Fire Prevention Check List Rev 000Document1 page355-Fire Prevention Check List Rev 000francisPas encore d'évaluation

- Acf-Mra-064 - SCDocument1 pageAcf-Mra-064 - SCFateh AliyaPas encore d'évaluation

- Oman LPG Fire Safety RequirementsDocument47 pagesOman LPG Fire Safety Requirementsadnan amal yusfarPas encore d'évaluation

- Observations Oct 2019Document38 pagesObservations Oct 2019mohammad samirPas encore d'évaluation

- Weekly Report As of September 12Document45 pagesWeekly Report As of September 12Cesar DuriasPas encore d'évaluation

- HSE STATSDocument1 pageHSE STATSPT. ANUGRAH MIRAN MANDIRIPas encore d'évaluation

- Accident Investigation, Reporting and Analysis: Safety Engineering and Management For MEDocument38 pagesAccident Investigation, Reporting and Analysis: Safety Engineering and Management For MEAndre De VillaPas encore d'évaluation

- Workmen Camp Inspection FormDocument3 pagesWorkmen Camp Inspection Formshamshad ahamed100% (1)

- Roofing ActivitiesDocument1 pageRoofing ActivitiesMark BeebakheePas encore d'évaluation

- 10 Site RulesDocument5 pages10 Site Rulesابو محمد علي100% (1)

- Attachment 7 Scaffolding PermitDocument2 pagesAttachment 7 Scaffolding PermitAviects Avie JaroPas encore d'évaluation

- WI-695987 QEF08e Non Conformance ReportDocument3 pagesWI-695987 QEF08e Non Conformance ReportBayu Indra PermanaPas encore d'évaluation

- Electrocuted HelperDocument2 pagesElectrocuted Helperjacc009Pas encore d'évaluation

- HSE Department Graduate Associate Program and IJM Scholar Program Project MonitoringDocument16 pagesHSE Department Graduate Associate Program and IJM Scholar Program Project MonitoringRoza AzaleaPas encore d'évaluation

- Machinery and equipment repair maintenance checklistDocument18 pagesMachinery and equipment repair maintenance checklistpradeepgamage4513Pas encore d'évaluation

- Appendix-AC, Guide For Working at HeightsDocument23 pagesAppendix-AC, Guide For Working at HeightsApm FoumilPas encore d'évaluation

- Proj NebsosDocument12 pagesProj Nebsosnavin0% (1)

- Demolition of Hvac System - Isd Security Building #07Document12 pagesDemolition of Hvac System - Isd Security Building #07Izaaz AhamedPas encore d'évaluation

- Self-Inspection Check List: RecordkeepingDocument11 pagesSelf-Inspection Check List: Recordkeepingernie pPas encore d'évaluation

- Nebosh StatmentDocument1 pageNebosh Statmentali128Pas encore d'évaluation

- Guidelines For Online Submission of ApplicationsDocument11 pagesGuidelines For Online Submission of ApplicationsA Muneeb QPas encore d'évaluation

- Twelve Rules for Writing a Publishable ArticleDocument4 pagesTwelve Rules for Writing a Publishable ArticleAliya NaseemPas encore d'évaluation

- Academic Open Internet JournalDocument58 pagesAcademic Open Internet Journalali128Pas encore d'évaluation

- Coca Cola Internship Report Executive SummaryDocument85 pagesCoca Cola Internship Report Executive Summaryali128Pas encore d'évaluation

- Coca ColaDocument111 pagesCoca Colakoti_verissimoPas encore d'évaluation

- Sme BankDocument5 pagesSme Bankali128Pas encore d'évaluation

- Job AnalysisDocument15 pagesJob Analysisali128Pas encore d'évaluation

- Designing A Job Evaluation Scheme + Market SurveysDocument13 pagesDesigning A Job Evaluation Scheme + Market Surveysali128Pas encore d'évaluation

- Chapter 5: Solid Waste ManagementDocument40 pagesChapter 5: Solid Waste ManagementRehan IbrahimPas encore d'évaluation

- 20 Questions On Aircraft Asked in Indian Air Force InterviewDocument9 pages20 Questions On Aircraft Asked in Indian Air Force InterviewPreran PrasadPas encore d'évaluation

- Mechanical Advantage and EfficiencyDocument16 pagesMechanical Advantage and EfficiencyYadana1Pas encore d'évaluation

- KomatsuHydraulicBreaker8 29Document22 pagesKomatsuHydraulicBreaker8 29Ke HalimunPas encore d'évaluation

- Alloy Steel Welding Precautions in Power PlantsDocument41 pagesAlloy Steel Welding Precautions in Power PlantsVijayakumar TPas encore d'évaluation

- BW17V1D24Document5 pagesBW17V1D24Lye YpPas encore d'évaluation

- 1.1.3.4 Lab - Visualizing The Black HatsDocument3 pages1.1.3.4 Lab - Visualizing The Black HatsCordis CordisPas encore d'évaluation

- Forbes Investor Jan2014 Master Buy List PDFDocument1 pageForbes Investor Jan2014 Master Buy List PDFForbesPas encore d'évaluation

- EE331 Lab 1 v2Document13 pagesEE331 Lab 1 v2Áo ĐenPas encore d'évaluation

- Glossary of Heat Exchanger TerminologyDocument2 pagesGlossary of Heat Exchanger Terminologypvwander100% (1)

- MMP - Intro To ElectronicDocument12 pagesMMP - Intro To ElectronicAye Chan OoPas encore d'évaluation

- Compiler Design (2170701) : Epartment of Omputer NgineeringDocument3 pagesCompiler Design (2170701) : Epartment of Omputer NgineeringRancho ChauhanPas encore d'évaluation

- Biodegradabilty Prediction Using Deep LearningDocument9 pagesBiodegradabilty Prediction Using Deep LearningMadhuri DPas encore d'évaluation

- ResumeDocument3 pagesResumeAadil AhmadPas encore d'évaluation

- Limestone Problems & Redrilling A WellDocument4 pagesLimestone Problems & Redrilling A WellGerald SimPas encore d'évaluation

- Analyzing Kernel Crash On Red HatDocument9 pagesAnalyzing Kernel Crash On Red Hatalexms10Pas encore d'évaluation

- Advertisement No. 2/2020: Csir-Central Scientific Instruments Organisation (Council of Scientific & Industrial Research)Document3 pagesAdvertisement No. 2/2020: Csir-Central Scientific Instruments Organisation (Council of Scientific & Industrial Research)Saharsh PatelPas encore d'évaluation

- Rate CardDocument1 pageRate CardSalvato HendraPas encore d'évaluation

- Army C-sUAS Systems AssessmentDocument4 pagesArmy C-sUAS Systems AssessmentArthur WongPas encore d'évaluation

- Section 3.: Battery ChargingDocument9 pagesSection 3.: Battery Chargingborle_vilasPas encore d'évaluation

- Refrigeration Cycles and Systems: A Review: ArticleDocument18 pagesRefrigeration Cycles and Systems: A Review: ArticleSuneel KallaPas encore d'évaluation