Académique Documents

Professionnel Documents

Culture Documents

43 430 UF Final PDF

Transféré par

Carlos TarquinoDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

43 430 UF Final PDF

Transféré par

Carlos TarquinoDroits d'auteur :

Formats disponibles

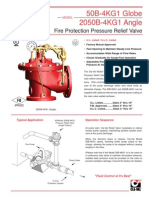

BERMAD Fire Protection

400 Series

Pressure Relief

Valve

1" - 4"

Model: FP 430-UF

6" - 12"

APPROVED

Description

The BERMAD Model FP 430-UF pilot operated valve prevents over pressure, maintaining a constant preset system

pressure regardless of fluctuating demands.

UL-Listed (up to 175 psi) and FM-Approved according to NFPA-20.

The valve offers reliable performance in:

Refineries, petrochemical complexes, tank farms,

high-rise buildings, aviation, marine and on-shore installations.

Typical Applications

Features and Benefits

Pressure relief for individual diesel

fire pump

Advanced Elastomeric Globe type Low pressure loss

One-piece molded elastomeric moving part

No maintenance required

Simple design Cost effective

In-line serviceable Minimal down time

Pump station pressure relief

Optional Features

Centralized thermal pressure relief

Large control filter (code: F)

Seawater service construction

Valve Position Single/Double Limit Switches

Note: Optional features can be mixed and matched.

Foam recirculation; maintains required

foam pressure

Zone safety relief

Consult your local BERMAD representative for full details

BERMAD Fire Protection

400 Series

Model: FP 430-UF

Operation

The BERMAD Model FP 430-UF remains closed as long as the sensed upstream pressure is lower than the adjustable

set point. When the Pressure Relief Pilot [1] senses upstream pressure [2] that is higher than the pilot setting, it acts

upon the control chamber [3] causing the main valve to modulate open, relieving excess pressure to either a reservoir

or sump, thus preventing system over pressure. The Pressure Relief Pilot is equipped with an adjusting screw [4] to

preset the desired upstream pressure, and an integral adjustable needle valve [5] to control the main valve closing

speed. The valves unique design provides quick reaction to system demand and keeps pressure loss at a minimum.

The control system is equipped with a control strainer [6].

[4]

[1]

[6]

[5]

[2]

[3]

Valve Closed

Valve Open (pressure-relief)

Engineer Specifications

The Pressure Relief Valve shall be UL-Listed, FM-Approved, and hydraulic pilot controlled. The main valve shall be an

elastomeric type globe valve with a rolling-diaphragm.

Valve actuation shall be accomplished by a fully peripherally supported, one-piece balanced rolling-diaphragm,

vulcanized with a rugged radial seal disk. The diaphragm assembly shall be the only moving part.

The valve shall have an unobstructed flow path, with no stem guide or supporting ribs.

The valve shall have a removable cover for quick in-line service enabling all necessary inspection and servicing.

The pilot system shall be field adjustable, with adjustable valve closing speed integrated into the main valve,

hydraulically tested and supplied as an assembly consisting of:

Relief pilot valve UL-Listed and FM-Approved as part of the assembly with built-in, internal needle valve

Y strainer

The control trim shall be supplied as an assembly, pre-assembled and hydraulically tested at an

ISO 9000 and 9001 certified factory.

BERMAD Fire Protection

400 Series

Model: FP 430-UF

Typical Installations

System Components

1

2

3

4

BERMAD Model FP 430-UF

Fire Pump

Check Valve

Pressure Gauge

2

4

3

1

Installation Considerations

Valve size should be no less than NFPA-20 requirements.

Provide adequate clearance around valve for maintenance, ensuring that the actuator can be easily removed.

Design installation with the valve cover up for best performance.

Ensure that before the valve is installed, instructions are given to flush the pipeline at full flow.

Approvals

The BERMAD Model FP 430-UF is UL-Listed and FM-Approved when installed as a unit.

BERMAD Fire Protection

400 Series

Model: FP 430-UF

Technical Data

Th

Tw

L1, L2

L1 (1)

mm

205

inch

8 1/2

2

mm inch

205

8 1/2

mm

257

inch

10 1/8

mm

320

inch

12 9/16

mm

415

inch

16 5/16

mm

500

inch

19 11/16

L2 (2)

180

7 1/16

210

8 1/4

255

10 1/16

N/A

N/A

N/A

N/A

500

Tw

284

11 /16

284

11 /16

300

11 /16

313

12 /16

341

13 /16

Th

210

8 1/4

210

8 1/4

215

8 7/16

243

9 9/16

315

12 3/8

Dimensions

Size

Notes:

1.L1 is for flanged valves.

2. L2 is for threaded NPT or ISO-7-Rp.

3. Tw & Th are max. for pilot system.

Connection Standard

Flanged: ANSI B16.42 (Ductile Iron),

B16.5 (Steel & Stainless Steel),

B16.24 (Bronze)

ISO PN16

Threaded: NPT or ISO-7-Rp for 2, 2 & 3

Grooved: ANSI/AWWA C606 for 2, 3, 4, 6 & 8

Water Temperature

0.5 50C (33 122F)

10

mm inch

605 23 13/16

12

mm inch

725 28 1/2

19 11/16

N/A

N/A

N/A

N/A

415

16 5/16

443

17 7/16

481

18 15/16

350

13 3/4

382

15

430

6 15/16

4. Data is for envelope dimensions, component positioning may vary.

5. Provide space around valve for maintenance.

Available Sizes

Globe: 2, 2, 3, 4, 6, 8, 10 & 12

UL Listed and FM approved: 2, 2, 3, 4 & 6

UL Listed / FM Pressure Rating

Max. inlet: 175 psi (12 bar)

Set: 30 - 175 psi (2 - 12 bar)

Test: 365 psi (25 bar)

Manufacturers Standard Materials

Optional Materials

Approvals

Main valve body and cover

Ductile Iron ASTM A-536

Main valve internals

Stainless Steel & Elastomer

Control Trim System

Brass control components/accessories

Stainless Steel 316 tubing & fittings

Elastomers

Polyamide fabric reinforced Polyisoprene, NR

Coating

Electrostatic Powder Coating Polyester,

Red (RAL 3002)

Main valve body

Carbon Steel ASTM A-216 WCB

Stainless Steel 316

Ni-Al-Bronze ASTM B-148

Control Trim

Stainless Steel 316

Monel and Al-Bronze

Hastelloy C-276

Elastomers

NBR

EPDM

Coating

High Build Epoxy Fusion-Bonded

with UV Protection, Anti-Corrosion

UL Listed - Fire Pump Relief Valve (QXZQ)

FM Approved - Water Relief Valve and Fire

Pump Relief Valve

ISO 9001 QA certified

ABS approval 2-12

Lloyds Registered 2-12

bermadfir e@bermad.com www .bermad.com

The information herein is subject to change without notice. BERMAD shall not be held

liable for any errors. All rights reserved. Copyright by BERMAD.

PE4PE-3UF 11

Vous aimerez peut-être aussi

- 14 400E 6DC Final Valvula BermadDocument4 pages14 400E 6DC Final Valvula Bermadmax_powerPas encore d'évaluation

- Valvula de Alivio de PresionDocument4 pagesValvula de Alivio de PresioneselcosacPas encore d'évaluation

- FP 400e-3dc PDFDocument4 pagesFP 400e-3dc PDFTessa CHPas encore d'évaluation

- 400e 2MDocument4 pages400e 2MVincent CardenasPas encore d'évaluation

- FP 730-59 Data Sheet PDFDocument4 pagesFP 730-59 Data Sheet PDFCarlos TarquinoPas encore d'évaluation

- Bermad: Fire ProtectionDocument4 pagesBermad: Fire ProtectionTessa CHPas encore d'évaluation

- 730 UlfmDocument4 pages730 UlfmTobias Alberto Gonzalez PeresPas encore d'évaluation

- Valvula Reductora de Presion Bermad Area 675 720-ULDocument4 pagesValvula Reductora de Presion Bermad Area 675 720-ULChristian FherPas encore d'évaluation

- Bermad: Fire ProtectionDocument4 pagesBermad: Fire ProtectionalbertoPas encore d'évaluation

- Fire Protection: ListedDocument4 pagesFire Protection: Listedjohn9999_502754Pas encore d'évaluation

- 12 400E 2MC FinalDocument4 pages12 400E 2MC FinalthadanivishalPas encore d'évaluation

- Burmad 400 Series-Globe Type Deluge ValveDocument8 pagesBurmad 400 Series-Globe Type Deluge Valvenastyn-1Pas encore d'évaluation

- Valvula de DiluvioDocument4 pagesValvula de DiluvioJJ GOLE PRECIOS UNITARIOSPas encore d'évaluation

- Fire Monitor CDocument4 pagesFire Monitor CZack LeePas encore d'évaluation

- Actuator DRD DREDocument35 pagesActuator DRD DRESandi AslanPas encore d'évaluation

- Local Solutions For Individual Customers Worldwide: Accumulators & AccessoriesDocument20 pagesLocal Solutions For Individual Customers Worldwide: Accumulators & Accessoriesamjed_de_enimPas encore d'évaluation

- Crane - Series.rs Center LineDocument23 pagesCrane - Series.rs Center LinenedwestPas encore d'évaluation

- 50B4KGDocument2 pages50B4KGonin007Pas encore d'évaluation

- Pfeiffer Br26d EngDocument4 pagesPfeiffer Br26d EngAleksandr KrigerPas encore d'évaluation

- MS 02 160Document6 pagesMS 02 160salic2013Pas encore d'évaluation

- FP 450-60Document4 pagesFP 450-60Supakanit LimsowanPas encore d'évaluation

- 49 - Model FP 430 UfDocument2 pages49 - Model FP 430 UfAdriano Moyses OutlookPas encore d'évaluation

- Amarex N: Submersible Motor Pumps DN 50 To 100Document44 pagesAmarex N: Submersible Motor Pumps DN 50 To 100Ben RahierPas encore d'évaluation

- 520CJ CK CL - Wob L - 3297 - 11 14Document3 pages520CJ CK CL - Wob L - 3297 - 11 14zayerirezaPas encore d'évaluation

- Pressure and Vacuum Switches - 216Document32 pagesPressure and Vacuum Switches - 216Nirav GandhiPas encore d'évaluation

- WW 770-UDocument4 pagesWW 770-UAhmad NasserPas encore d'évaluation

- Sauter B6R Three-Way Valve With Female Thread, PN 16Document4 pagesSauter B6R Three-Way Valve With Female Thread, PN 16pitanje1991Pas encore d'évaluation

- 730 UfDocument4 pages730 UfDiegoPas encore d'évaluation

- Diapham Valve PDFDocument8 pagesDiapham Valve PDFthouche007Pas encore d'évaluation

- s05nmdl2sm PDFDocument22 pagess05nmdl2sm PDFmn_aminPas encore d'évaluation

- Modelo FP420-00Document4 pagesModelo FP420-00Valdimar CorreiaPas encore d'évaluation

- 400e 1M PDFDocument4 pages400e 1M PDFLuis RolaPas encore d'évaluation

- Aluminum Crust BreakerDocument8 pagesAluminum Crust BreakersenamotoPas encore d'évaluation

- As 1301 en F Series Manifolds and Multi Way CocksDocument20 pagesAs 1301 en F Series Manifolds and Multi Way CocksTache MihaiPas encore d'évaluation

- Mini Hermet Pressure SwitchesDocument24 pagesMini Hermet Pressure SwitchesMilosglPas encore d'évaluation

- Válvula DurcoDocument12 pagesVálvula DurcoJames Henrry López EspejoPas encore d'évaluation

- BFV TechDocument120 pagesBFV TechSatyamEngPas encore d'évaluation

- InlineSamplingValves SIVDocument6 pagesInlineSamplingValves SIVmorizonePas encore d'évaluation

- GF System Specification PVC-U BS InchDocument14 pagesGF System Specification PVC-U BS InchDale CokleyPas encore d'évaluation

- Cla-Val, Relief VanaDocument2 pagesCla-Val, Relief Vanadeyson galeanoPas encore d'évaluation

- Enquiry - FFTG - Sprinkle - ValvesDocument8 pagesEnquiry - FFTG - Sprinkle - Valvesrkpatel40Pas encore d'évaluation

- Monoflanges VariAS BlocksDocument20 pagesMonoflanges VariAS BlocksamuihPas encore d'évaluation

- Bermad: Fire ProtectionDocument4 pagesBermad: Fire ProtectionalbertoPas encore d'évaluation

- Fainger Leser Catalogue' 11Document68 pagesFainger Leser Catalogue' 11rudrakrPas encore d'évaluation

- Halton Single-Blade Damper Technical DocumentDocument12 pagesHalton Single-Blade Damper Technical Documentalecs008Pas encore d'évaluation

- Alco Hi Tek Mono FlangeDocument7 pagesAlco Hi Tek Mono FlangelimresPas encore d'évaluation

- Technical YCSA 120-150Document22 pagesTechnical YCSA 120-150nairam2003Pas encore d'évaluation

- Valvula WW-820Document4 pagesValvula WW-820Anonymous Iic1fi49uEPas encore d'évaluation

- Valves BarendsenDocument63 pagesValves BarendsenidontlikeebooksPas encore d'évaluation

- Schmidt Armaturen FlowPak Class 150, 1/2” - 4” Technical DocumentDocument12 pagesSchmidt Armaturen FlowPak Class 150, 1/2” - 4” Technical DocumentMisael Castillo CamachoPas encore d'évaluation

- AP Technical Data Sheet CatalogDocument16 pagesAP Technical Data Sheet CatalogsajuherePas encore d'évaluation

- Ycjd18 Thru 60Document20 pagesYcjd18 Thru 60Alberto NavarroPas encore d'évaluation

- Series 825Y Specification SheetDocument2 pagesSeries 825Y Specification SheetFEBCOPas encore d'évaluation

- E 50B 4KG1 - Fire PDFDocument2 pagesE 50B 4KG1 - Fire PDFdocrafiPas encore d'évaluation

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsD'EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsPas encore d'évaluation

- Swagelok-Thread and End Connection Identification Guide-MS-13-77 PDFDocument56 pagesSwagelok-Thread and End Connection Identification Guide-MS-13-77 PDFmac9papPas encore d'évaluation

- ChemRestChart PDFDocument12 pagesChemRestChart PDFCarlos TarquinoPas encore d'évaluation

- +pipe Fittings PDFDocument12 pages+pipe Fittings PDFCarlos TarquinoPas encore d'évaluation

- Sil Quick Guide 1528 PDFDocument4 pagesSil Quick Guide 1528 PDFCarlos TarquinoPas encore d'évaluation

- PDFDocument2 pagesPDFCarlos TarquinoPas encore d'évaluation

- Asme B40Document2 pagesAsme B40Durgarao Vasa100% (1)

- Bostik NeverseezDocument8 pagesBostik NeverseezginuxPas encore d'évaluation

- SIL Explained: Fluid Power Actuators and Control SystemsDocument8 pagesSIL Explained: Fluid Power Actuators and Control Systemsprihartono_diasPas encore d'évaluation

- Measuring Petroleum StandardsDocument101 pagesMeasuring Petroleum StandardsJonathan Narh-DometeyPas encore d'évaluation

- IATD April 2015 Packaging - Solutions - LoRes PDFDocument48 pagesIATD April 2015 Packaging - Solutions - LoRes PDFCarlos TarquinoPas encore d'évaluation

- Chem ResistanceDocument18 pagesChem Resistancepeng88apPas encore d'évaluation

- Systems Handbook M&R Station InstrometDocument31 pagesSystems Handbook M&R Station Instrometandy131078Pas encore d'évaluation

- Fundamental Principles of Gas Turbine Meters Robert Bennett American Meter CompanyDocument6 pagesFundamental Principles of Gas Turbine Meters Robert Bennett American Meter CompanyCarlos TarquinoPas encore d'évaluation

- GPC 2100 PDFDocument24 pagesGPC 2100 PDFCarlos TarquinoPas encore d'évaluation

- 23 11 13 - Gas Meter StationDocument8 pages23 11 13 - Gas Meter StationCarlos TarquinoPas encore d'évaluation

- Introduccion A La AutomatizacionDocument23 pagesIntroduccion A La AutomatizacionCarlos TarquinoPas encore d'évaluation

- CONFPAPERS ALTOSONICV12 Installation Effects en 120524 PDFDocument20 pagesCONFPAPERS ALTOSONICV12 Installation Effects en 120524 PDFCarlos TarquinoPas encore d'évaluation

- EFM Family Brochure PDFDocument4 pagesEFM Family Brochure PDFCarlos TarquinoPas encore d'évaluation

- Eam BR2100 4 PDFDocument24 pagesEam BR2100 4 PDFCarlos TarquinoPas encore d'évaluation

- Normas de RefDocument4 pagesNormas de Refrolulbadel16Pas encore d'évaluation

- Fundamental Principles of Gas Turbine Meters Robert Bennett American Meter CompanyDocument6 pagesFundamental Principles of Gas Turbine Meters Robert Bennett American Meter CompanyCarlos TarquinoPas encore d'évaluation

- Catalogo Medidor Gt3Document12 pagesCatalogo Medidor Gt3luis_d_mPas encore d'évaluation

- Optimum Pipe Diameter Calculation SheetDocument81 pagesOptimum Pipe Diameter Calculation Sheetpandu_prabowo_jati100% (2)

- Ben Gliwa - Network Pressure Regulation in Natural Gas Distribution PDFDocument22 pagesBen Gliwa - Network Pressure Regulation in Natural Gas Distribution PDFCarlos TarquinoPas encore d'évaluation

- Masoneilan Control Valve Sizing PDFDocument32 pagesMasoneilan Control Valve Sizing PDFOwen Hennessy100% (1)

- Valve Sizing Application NotesDocument12 pagesValve Sizing Application Notestxagus100% (1)

- Control Valve SizingDocument36 pagesControl Valve SizingOmar Samir100% (2)

- Gas Flow Calculation Using Cv ValuesDocument1 pageGas Flow Calculation Using Cv ValuesCarlos TarquinoPas encore d'évaluation

- Emerson-Valve Sizing Calculations (Traditional Method)Document21 pagesEmerson-Valve Sizing Calculations (Traditional Method)iqtorresPas encore d'évaluation

- Spare Parts List RieterDocument1 pageSpare Parts List RieterMd. Bulbul AhmedPas encore d'évaluation

- PS 7 - Material Balance With Chemical Reactions For Multiple UnitsDocument1 pagePS 7 - Material Balance With Chemical Reactions For Multiple UnitsBernie SuarezPas encore d'évaluation

- My ScramjetDocument13 pagesMy ScramjetHimanshu GuptaPas encore d'évaluation

- PHWRDocument2 pagesPHWRNoraishah Syahirah AzharPas encore d'évaluation

- Canal of Nuck Hernia in An Elderly Patient A Case ReportDocument8 pagesCanal of Nuck Hernia in An Elderly Patient A Case ReportAthenaeum Scientific PublishersPas encore d'évaluation

- Arjen Kleinherenbrink - Against Continuity - Gilles Deleuze's Speculative Realism (2019, Edinburgh University Press) PDFDocument328 pagesArjen Kleinherenbrink - Against Continuity - Gilles Deleuze's Speculative Realism (2019, Edinburgh University Press) PDFRondnelly Nunes100% (1)

- F3 - Day 20Document6 pagesF3 - Day 20Duy LêPas encore d'évaluation

- Converting Metric Mass UnitsDocument9 pagesConverting Metric Mass UnitsAnonymous EvbW4o1U7Pas encore d'évaluation

- Chapter-3-Control Strategies For Environmental RisksDocument30 pagesChapter-3-Control Strategies For Environmental Riskswaleedsalama1Pas encore d'évaluation

- 1.03 Graphs and Shapes of Distributions: 1 Exploring DataDocument2 pages1.03 Graphs and Shapes of Distributions: 1 Exploring DataThiziri AMEZZA100% (1)

- (WHO - PQS - E004 - VC01-VP2) - Vaccine Carrier PQS Independent-Type Testing ProtocolDocument13 pages(WHO - PQS - E004 - VC01-VP2) - Vaccine Carrier PQS Independent-Type Testing ProtocolartnaboyjogjaPas encore d'évaluation

- D345 PDFDocument3 pagesD345 PDFHusseinawyPas encore d'évaluation

- Miconium Ctac29: Quaternary Ammonium SaltDocument1 pageMiconium Ctac29: Quaternary Ammonium Saltanon_993394650Pas encore d'évaluation

- Eating When Sick:: Should You Feed A Cold? Starve A Fever?Document5 pagesEating When Sick:: Should You Feed A Cold? Starve A Fever?Clau DinuPas encore d'évaluation

- Design & Optimization of Bed Material Screening Machine For AFBC BoilerDocument11 pagesDesign & Optimization of Bed Material Screening Machine For AFBC BoilermansukhPas encore d'évaluation

- Hillsong United Lyrics - Still Hillsong United Lyrics - StillDocument2 pagesHillsong United Lyrics - Still Hillsong United Lyrics - StillJohn Jufel ValdezPas encore d'évaluation

- Bally Total Health ReceipesDocument30 pagesBally Total Health Receipesmalmane100% (9)

- Sentinel EventsDocument14 pagesSentinel EventsNatasha BhasinPas encore d'évaluation

- Writing Chemical EquationsDocument4 pagesWriting Chemical EquationsGlenda Cate CanaPas encore d'évaluation

- Fs Technical StudyDocument8 pagesFs Technical StudyRenz Ian DeePas encore d'évaluation

- Tecnis Eyhance SpecSheetDocument2 pagesTecnis Eyhance SpecSheetkesavan91Pas encore d'évaluation

- Iso 1182 2020Document12 pagesIso 1182 2020Alessandro MendonçaPas encore d'évaluation

- Instant Download Test Bank For Positive Psychology 4th by Lopez PDF FullDocument32 pagesInstant Download Test Bank For Positive Psychology 4th by Lopez PDF FullAlejandraPruittarqbp100% (8)

- Paper IndustryDocument10 pagesPaper IndustryKushal SisodiyaPas encore d'évaluation

- Biologia BeetrootDocument20 pagesBiologia BeetrootKatarzyna KasPas encore d'évaluation

- Lecture Notes on Non-Conventional Energy Sources (18ME651Document29 pagesLecture Notes on Non-Conventional Energy Sources (18ME651Puneeth hr2Pas encore d'évaluation

- TDS EU G-Energy X Hydro Bio EngDocument2 pagesTDS EU G-Energy X Hydro Bio EngАлексей ДэконPas encore d'évaluation

- Operating Instructions G: Downloaded From Manuals Search EngineDocument179 pagesOperating Instructions G: Downloaded From Manuals Search Enginea safaie100% (1)

- Policy Brief: India and Sustainable Development Goals (SDGS)Document12 pagesPolicy Brief: India and Sustainable Development Goals (SDGS)Nishat SinghPas encore d'évaluation

- Comparison of DC and AC Container Crane Drive SystemsDocument6 pagesComparison of DC and AC Container Crane Drive Systemsbstack10Pas encore d'évaluation