Académique Documents

Professionnel Documents

Culture Documents

Lay A Concrete Driveway at Home

Transféré par

Rm1262Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lay A Concrete Driveway at Home

Transféré par

Rm1262Droits d'auteur :

Formats disponibles

Lay a concrete driveway

at home

A well-laid concrete driveway will give at least 20 to 30

years trouble-free service and can be laid quite easily by

the ordinary homeowner.

The concrete must be of high quality and be at least 75 mm

thick. A width of 2,75 m is adequate. To prevent random,

unsightly cracking, joints should be provided across the

driveway at intervals of 2,5 to 3 m: ie the concrete should be

laid in panels that are square or nearly so.

The surface of the driveway should have a cross-fall of

about 1 in 40 so that water can drain off it. There should not

be any low areas where water can accumulate. The

driveway should slope away from the garage for at least a

metre so that the garage is not flooded when it rains.

Materials for concrete

You will need cement, sand and nominal 19 mm stone.

Store cement in a dry place, on timber or sheets of plastic

or iron to keep it off the floor. If it contains lumps that cannot

be crumbled easily, it is old and should not be used. Protect

the sand and stone from contamination.

Concrete mixes

Each batch of concrete should consist of one bag cement,

80 litres sand, 80 litres stone and enough water to make a

workable mix. Cement should comply with SABS EN 197-1.

For every cubic metre (m3) of concrete, you will require

7,7 bags of cement, 0,62 m3 sand and 0,62 m3 stone. When

ordering materials, allow for some waste.

(Note: 1 000 litres = 1 cubic metre.)

Preparation

The ground below the driveway must be firm and stable to

ensure that it does not settle unevenly at a later stage. The

base must have the same slope(s) as the driveway.

Remove all roots and vegetable matter, and, preferably, the

topsoil. Then trim the base to the required levels and slopes.

Next, check that the surface is uniformly firm. Soft areas and

any fill used to make up the levels should be tamped down

with, for example, the end of a gumpole. If a large area has to

be compacted, consult a plant hire firm about suitable

equipment.

Formwork

Forms should be provided to retain the fresh concrete. Steel

forms or timber, nominally 35 mm by 75 mm, with at least

the top edge planed, are suitable. The forms are held in

place by stakes at about 1 m intervals. They must be set

firmly and accurately because the concrete is finished flush

with the top edges. Forms should be given a coat of form oil

or whitewash before use to prevent the concrete sticking to

them.

Sideforms are placed along the sides of the driveway. They

can be removed, cleaned, re-oiled and re-used the next day.

Crossforms are placed between the sideforms to form the

panels.

Mixing and placing the concrete

Measuring the sand and stone

Wheelbarrows and 10, 20 or 25 litre drums are useful

measures. Make sure they are clean because oil, fertiliser,

sugar, etc will harm the concrete.

A builders wheelbarrow holds 65 litres when filled and struck

off level with the brim. Drums hold approximately 10 per cent

more than their nominal capacity when filled and struck off

level with the brim. The capacity can be checked by filling the

container with water measured from a 1 litre bottle or jug.

Mixing the concrete

Mix the concrete on a clean, smooth, hard surface such as

a steel sheet or a concrete floor. Spread the sand in a layer

about 100 mm thick and pour the cement over it.

Thoroughly mix the two until the colour is uniform.

Add water slowly and continue mixing until the consistence

is rather like a thin porridge. Then add the stone and mix it

in thoroughly. The concrete must be able to stand in a heap,

but must settle quickly if prodded with a spade. Do not make

the concrete too soupy, or too dry.

Placing the concrete

Moisten the ground before placing the concrete. There

should be no free water on the surface when the concrete is

laid. Each panel must be completed in one operation.

Place the concrete in the panel so that it stands about

25 mm above the forms. Make sure there are no gaps along

the forms or in the corners.

thick about 20 mm into the concrete before it has hardened.

Remove the blade and drop a piece of bituminous felt

(Malthoid) cut to size into the groove.

Use a 50 mm thick plank that is long enough to stretch

across the panel to compact the concrete. If a handle is fixed

to each end of the plank, the job will be easier.

Curing

First, use a chopping motion to compact the concrete.

When free mortar appears on the surface, the concrete has

been compacted sufficiently.

Now, resting the plank on top of the formwork and using a

sawing motion, work it gradually from the one end of the

panel to the other to level the surface and remove the

excess concrete. Fill any hollows, if necessary. Woodfloat to

an even surface. The concrete can be lightly brushed with a

soft broom once it has started to harden. Use an edging tool

to round the edges of the panel.

The strength concrete develops will largely depend on how

well it has been cured. When the concrete has set, cover it

with sacking or clean sand and keep it damp for about

seven days.

Opening to traffic

The driveway can be used by pedestrians after one day, by

cars after about five days and by other heavy vehicles after

ten days.

Strip driveways

Joints

If mixing is done by hand, it will be possible to lay one or

maybe two panels 2,75 x 3,0 m in a day. If a concrete mixer

is used, more panels can be laid.

To form joints, it is suggested that alternate panels (ie

numbers 1, 3, 5 etc) be laid on the first day. The crossforms

are removed and the in-fill panels (numbers 2, 4, etc) laid

against the hardened concrete the next day or later.

If large quantities of concrete are ordered from a readymix

supplier, plan the job carefully so that the concrete can be

placed, compacted and finished before it hardens. In this

case joints can be formed by pressing a blade about 3 mm

Strip driveways are much more economical. Each strip

should be 600 mm wide and the centres of the strips should

be 1,5 m apart.

The concrete must be at least 85 mm thick and joints

should be provided every 1,5 to 2 m. The easiest way to

make joints will probably be to cast 50 mm wide strips of

hardboard (3 mm thick) vertically in the concrete so that the

top of the hardboard is flush with the surface of the

concrete.

All other aspects of laying strip driveways are the same as

those for full-width driveways.

Joint

Board for compacting

and levelling concrete

Crossform

Wooden tamper

Sideform

The panel at the back has been completed, that in the middle has been laid and is being levelled and the base and

formwork of the front panel have been prepared.

Cement & Concrete Institute

PO Box 168, Halfway House, 1685

Portland Park, Old Pretoria Road, Halfway House, Midrand

Tel (011) 315-0300 Fax (011) 315-0584

e-mail cnci@cnci.org.za website http://www.cnci.org.za

Published by the Cement & Concrete Institute, Midrand, 1996 reprinted 1997, 1998, 1999, 2003.

Cement & Concrete Institute

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Henderson, Johnson & Wood 2002 Enhancing The Whole Life Structural Performance of Multi-Storey Car ParksDocument50 pagesHenderson, Johnson & Wood 2002 Enhancing The Whole Life Structural Performance of Multi-Storey Car ParksRm1262Pas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- IMIESA April 2021Document60 pagesIMIESA April 2021Rm1262Pas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Reinforcement of Concrete StructuresDocument13 pagesReinforcement of Concrete StructurestevredePas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Russell PHD 2015 Progressive Collapse of Reinforced Concrete Flat Slab StructuresDocument238 pagesRussell PHD 2015 Progressive Collapse of Reinforced Concrete Flat Slab StructuresRm1262Pas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- UJ Postgraduate Engineering ManagementDocument4 pagesUJ Postgraduate Engineering ManagementRm12620% (1)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Retrofitting and Rehabilitation of Fire PDFDocument134 pagesRetrofitting and Rehabilitation of Fire PDFVarun TyagiPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- ADA441347Document17 pagesADA441347habibur Rahman KhanPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Technoslide Elastomeric-Plain-Sliding-Bearings-For-Bridges-Structures-BrochureDocument13 pagesTechnoslide Elastomeric-Plain-Sliding-Bearings-For-Bridges-Structures-BrochureRm1262Pas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Electric Rolling Bridge, Scientific American 24 August 1889 p120Document2 pagesElectric Rolling Bridge, Scientific American 24 August 1889 p120Rm1262Pas encore d'évaluation

- Ijsrp p46106 PDFDocument14 pagesIjsrp p46106 PDFKannan JaganPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- BK Series Kilcher Bearing StripsDocument6 pagesBK Series Kilcher Bearing Stripsforbeska100% (1)

- Exhibit 5f - Concept - Design - Submission 100-119Document20 pagesExhibit 5f - Concept - Design - Submission 100-119NasserZakiPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Extend Abstract - 67792 - Joao GeadaDocument10 pagesExtend Abstract - 67792 - Joao GeadaRm1262Pas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Concrete Society - Fire DamageDocument6 pagesThe Concrete Society - Fire DamageRm1262Pas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Mera DilDocument12 pagesMera DilIqbal AhmadPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Annerel & Taerwe 2008 Diagnosis of The State of Concrete Structures After FireDocument6 pagesAnnerel & Taerwe 2008 Diagnosis of The State of Concrete Structures After FireRm1262Pas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Swing Jib CranesDocument2 pagesSwing Jib CranesRm1262Pas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- Annerel & Taerwe 2008 Diagnosis of The State of Concrete Structures After FireDocument6 pagesAnnerel & Taerwe 2008 Diagnosis of The State of Concrete Structures After FireRm1262Pas encore d'évaluation

- Guide To Lifting Equipment Testing Inspections 2015Document8 pagesGuide To Lifting Equipment Testing Inspections 2015Rm1262Pas encore d'évaluation

- Cranerunwaybeams 4ed bk180 PDFDocument13 pagesCranerunwaybeams 4ed bk180 PDFMacPas encore d'évaluation

- Structural Scheme Design Guide by ArupDocument129 pagesStructural Scheme Design Guide by ArupNatalie Sullivan100% (15)

- Arup DesignYearbook 2010Document39 pagesArup DesignYearbook 2010Si MonaPas encore d'évaluation

- Arup Scheme Design Guide 2006Document139 pagesArup Scheme Design Guide 2006Boris Escubio100% (1)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- STEEL CONFERENCE EXPANSION JOINTSDocument4 pagesSTEEL CONFERENCE EXPANSION JOINTSCharles Orebola OresanwoPas encore d'évaluation

- Flange BendingDocument2 pagesFlange BendingMotoro AkinwolePas encore d'évaluation

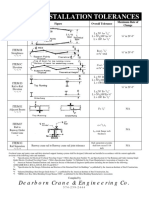

- Crane Runway Installation Tolerances-BechtelDocument1 pageCrane Runway Installation Tolerances-BechtelRm1262Pas encore d'évaluation

- BinsDocument17 pagesBinsRm1262Pas encore d'évaluation

- How Silos FailDocument14 pagesHow Silos FailMedhat Hasanain100% (2)

- A Challenge For Designers of Steel Silos PDFDocument6 pagesA Challenge For Designers of Steel Silos PDFRm1262Pas encore d'évaluation

- Narayangharh-Mugling HighwayDocument85 pagesNarayangharh-Mugling HighwayRm1262Pas encore d'évaluation

- En 14651 PDFDocument17 pagesEn 14651 PDFDaniel De Andrade Souza83% (6)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Eduardo Souto Moura - Estadio Do BragaDocument4 pagesEduardo Souto Moura - Estadio Do BragaarkitektusPas encore d'évaluation

- BLDG STD Spec 2004Document703 pagesBLDG STD Spec 2004PcEngPas encore d'évaluation

- Price Data - DPWHDocument11 pagesPrice Data - DPWHChristian LuaresPas encore d'évaluation

- DOWSIL™ 813C Construction and Concrete Silicone Sealant: Features & BenefitsDocument6 pagesDOWSIL™ 813C Construction and Concrete Silicone Sealant: Features & BenefitsMurali KrishnaPas encore d'évaluation

- High Stiffness Flexural Frame, 350 KN Cap., SimplexDocument4 pagesHigh Stiffness Flexural Frame, 350 KN Cap., SimplexHaikalPas encore d'évaluation

- NYC DOB 8 Hour Site Safety - Lesson #1 of 15 - Intro - VLDocument38 pagesNYC DOB 8 Hour Site Safety - Lesson #1 of 15 - Intro - VLCONE LANDSCAPE SERVICESPas encore d'évaluation

- Comparison of Seismic Performance of Sol PDFDocument5 pagesComparison of Seismic Performance of Sol PDFIsmailPas encore d'évaluation

- IJRPR2138Document8 pagesIJRPR2138Hamunyela LikiusPas encore d'évaluation

- Highway Research RecDocument132 pagesHighway Research RecGaneshalingam Ramprasanna2Pas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

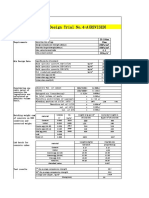

- Piling: Amount (QR) Item Description Quantity Unit Rate (QR)Document1 pagePiling: Amount (QR) Item Description Quantity Unit Rate (QR)Ahmed Raza100% (2)

- TM - MasterSuna - SBS - 8000 ENDocument3 pagesTM - MasterSuna - SBS - 8000 ENVyankat ChatePas encore d'évaluation

- Construction of Pump Driver Quarter Pump House WorksDocument58 pagesConstruction of Pump Driver Quarter Pump House WorksTahia CorporationPas encore d'évaluation

- Paver Block Using Single-Use Face Masks As A Sub-Base For GravelDocument23 pagesPaver Block Using Single-Use Face Masks As A Sub-Base For Gravelalegarbes PatPas encore d'évaluation

- Long-Term Structural Performance of Modular High-Rise Concrete Building (CEB-FIB International Conference Oslo June 2022)Document10 pagesLong-Term Structural Performance of Modular High-Rise Concrete Building (CEB-FIB International Conference Oslo June 2022)Goh Kay YunPas encore d'évaluation

- Lab Concrete Mix Design C15-C40Document19 pagesLab Concrete Mix Design C15-C40Soundar Pachiappan100% (1)

- Build Up Rate Format - PavingDocument4 pagesBuild Up Rate Format - PavingFaiz Ahmad75% (4)

- CVX7640 28Document18 pagesCVX7640 28malingauomPas encore d'évaluation

- BIS - CementDocument12 pagesBIS - CementSuvendu DeyPas encore d'évaluation

- Constructions Material - AmetheusDocument34 pagesConstructions Material - AmetheusAmetheus // GKSahaPas encore d'évaluation

- Areca Reinforced ConcreteDocument54 pagesAreca Reinforced ConcreteAjayakumara K100% (1)

- DuraBarrier - General Brochure (Rev2)Document6 pagesDuraBarrier - General Brochure (Rev2)JRAINMANPas encore d'évaluation

- New Procedures For Materials 2020Document700 pagesNew Procedures For Materials 2020Mengalvio GraçaPas encore d'évaluation

- Review of Related LiteratureDocument12 pagesReview of Related LiteratureangelofsteelPas encore d'évaluation

- NDT - RHDocument2 pagesNDT - RHRajesh KumarPas encore d'évaluation

- FMDS0122Document11 pagesFMDS0122Soumyadip RoyPas encore d'évaluation

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Ceilcote - 6640 - Ceilcrete - Eng - A4 - 20150818 PDFDocument4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Ceilcote - 6640 - Ceilcrete - Eng - A4 - 20150818 PDFCuong Nguyen Manh100% (1)

- 19.building Movement Control During Construction - Rev.01-17august 2009Document49 pages19.building Movement Control During Construction - Rev.01-17august 2009Syerifaizal Hj. Mustapha100% (1)

- Quality Certificate PCC June 2017Document1 pageQuality Certificate PCC June 2017Tri NardiPas encore d'évaluation

- DAR14 Vol2Document712 pagesDAR14 Vol2tanzu4uPas encore d'évaluation

- Advanced Modelling Techniques in Structural DesignD'EverandAdvanced Modelling Techniques in Structural DesignÉvaluation : 5 sur 5 étoiles5/5 (3)

- Guidelines for the Management of Change for Process SafetyD'EverandGuidelines for the Management of Change for Process SafetyPas encore d'évaluation

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsD'EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsPas encore d'évaluation

- Marine Structural Design CalculationsD'EverandMarine Structural Design CalculationsÉvaluation : 4.5 sur 5 étoiles4.5/5 (13)

- Chemical Process Safety: Learning from Case HistoriesD'EverandChemical Process Safety: Learning from Case HistoriesÉvaluation : 4 sur 5 étoiles4/5 (14)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationD'EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationPas encore d'évaluation

- To Engineer Is Human: The Role of Failure in Successful DesignD'EverandTo Engineer Is Human: The Role of Failure in Successful DesignÉvaluation : 4 sur 5 étoiles4/5 (137)