Académique Documents

Professionnel Documents

Culture Documents

Ijsrm Template

Transféré par

Prakash Kumar SenCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ijsrm Template

Transféré par

Prakash Kumar SenDroits d'auteur :

Formats disponibles

International Journal of scientific research and management

(IJSRM) ||Volume||||Issue|| ||Pages|| 01-02 ||2013||

Website: www.ijsrm.in ISSN (e): 2321-3418

A Critical review on the concept of effect on

scavenging and fuel injection injection timing on two

stroke engine

Ravikant Sahu1, Eklabya Gupta2, Deepak Kumar Dewangan3

1

Student Bachelor of Engg. (Mechanical Engg.)

Kirodimal Institute Of Technology Raigarh (C.G.) INDIA

ravikantsahu224@gmail.com

2

Student Bachelor Of Engg. (Mechanical Engg.)

Kirodimal Institute Of Technology Raigarh (C.G.) INDIA

eklabyagupta18@gmail.com

3

Student Bachelor Of Engg. (Mechanical Engg.)

Kirodimal Institute Of Technology Raigarh (C.G.) INDIA

deepakkumardewangan311@gmail.com

Abstract:

In present study, A spark ignition and a compression ignition engine with uniflow valve scavenging of the cylinder and a

transfer valve in the piston crown have been described. A great disadvantage of two-stroke engines is ports which are made in the cylinder

bearing surface. Under the heat which is realised during the combustion, the thermal extension of the range in proximity of the ports and

other parts of the cylinder is different and so the distortion of the geometry of the cylinder liner surface force the designer to make the

clearance between the piston and the cylinder liner bigger. This paper presents the critical review to study the effect of fuel injection timing

and scavenging using diesel on the combustion and emission characteristics of a single cylinder, two stroke, air cooled direct injection

diesel engine. It Is well known that injection strategies including the injection timing and pressure play the most important role in

determining engine performance, especially in scavenging emissions. However, the injection timing and pressure quantitatively affect the

performance of diesel engine.

Keywords: scavenging, two stroke engine, valve, injection timing

1. Introduction

In the Internal combustion engine, At the end of the expansion

stroke the combustion of a two-stroke engine is left full of

product of combustion, this is because unlike four-stroke

engine, this is no exhaust stroke available to clear the cylinder

of burnt gases , the process of clearing of cylinder, after the

expansion stroke, is called scavenging process, this must

completed in a very short duration available between the end

of the expansion stroke end start of the charging process.

The efficiency of two stroke engine depend to a

great degree on the effectiveness of the scavenging process,

since bad scavenging gives a low mean indicate pressure and

hence, result in a high weight and high cost per bhp for the

engine. With insufficient scavenging the amount of oxygen

available is low so that the consequent incomplete combustion

results in higher specific fuel consumption. Not only that, the

lubricating oil becomes more contaminated, so that its

lubricating qualities are reduced and results in increased wear

of system and cylinder liners. Poor scavenging also leads to

higher mean temperatures and grater heat stresses on the

cylinder walls.[1]

The reason of the described experiments and

deformations of the liner geometry which were

the disadvantages of the compression ignition

engine in the use of two stroke engines in trucks,

buses, plant machines, fish cutters and so on.

Again the conception leaded two a solution of an

engine without ports in the cylinder liner valves

in the cylinder head to keep the geometry of any

distortion.

To carry out the planned experiments, a

compression ignition engine which was at the

disposal of the authors has been used. This

engine has a direct injection chamber, had a

power output of 7 kW at 3000 rev/min. The

cylinder diameter is of 90 mm and the stroke -90

mm. The swept volume of the cylinder is 573 cm 3.

The engine is air cooled by means of an own

ventilator.

The

reason

of

the described

experiments and deformations of the liner

geometry which were the disadvantages of the

compression ignition engine in the use of two

stroke engines in trucks, buses, plant machines,

fish cutters and so on. Again the conception

leaded two a solution of an engine without ports

in the cylinder liner valves in the cylinder head to

keep the geometry of any distortion.

To carry out the planned experiments, a compression ignition

engine which was at the disposal of the authors has been used.

This engine has a direct injection chamber, had a power

output of 7 kW at 3000 rev/min. The cylinder diameter is of

90 mm and the stroke -90 mm. The swept volume of the

cylinder is 573 cm3. The engine is air cooled by means of an

own ventilator.[2]

The NOx is produce data great extent, due to the high local

Author Name, IJSRM volume issue June 2013 [www.ijsrm.in]

Page 1

temperatures found in Diesel engines which are highly

dependent on the initial rise of heat release. In addition, soot

production and oxidation are both dependent on the mixing

rate and local fame temperatures [3]. The injection velocity is

one of the most infuent parameters on the factors (which are

mentioned before), since it controls both the mixing process

and the rate of heat release. This is the reason that injection

system parameters and nozzle geometry have been extensively

studied due to their direct relation with the fuel injection rate

and fuel velocity. To support this, it has been recognized that

the characteristics of the injection system are the most

important fact or sin infuencing emissions and performance

of CI engines.[4,5]

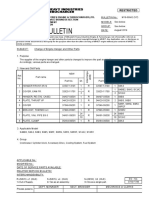

Figure 1: Testing data- load current (amperes)

3.4

Tables

Place table titles above the tables.

2. Page Size and Layout

Set your page as A4, width 210, height 297 and margins as

follows:

Left Margin 17.8 mm (0.67")

Right Margin 14.3 mm (0.56)

Top Margin 17.8 mm (0.7")

Bottom Margin 17.8 mm (0.7")

You should use Times Roman of size 10 for all fonts in the

paper. Format the page as two columns:

Column Width 86.8 mm (3.42")

Column Height 271.4 mm (10.69")

Space/Gap between Columns - 5.0 mm (0.2").

3. Title, Authors, Body Paragraphs, Sections

Headings and References

3.1

Title and authors

The title of the paper is centered 17.8 mm (0.67") below the

top of the page in 24 point font. Right below the title

(separated by single line spacing) are the names of the

authors. The font size for the authors is 11pt. Author

affiliations shall be in 9 pt.

Table 1: Margin specifications

Margin

A4 Paper

US Letter Paper

Left

18.5 mm

14.5 mm (0.58 in)

Right

18mm

13 mm (0.51 in)

3.5

Sections headings

Section headings come in several varieties:

1. first level headings: 1. Heading 1

2. second level: 1.2. Heading 2

3. third level: 1.2.3 Heading 3

4. forth level: (a) Heading 4

5. fifth level: (1) Heading 5

3.6

References

Number citations consecutively in square brackets [1]. The

sentence punctuation follows the brackets [2]. Multiple

references [2], [3] are each numbered with separate brackets

[1][3]. Please note that the references at the end of this

document are in the preferred referencing style. Please ensure

that the provided references are complete with all the details

and also cited inside the manuscript (example: page numbers,

year of publication, publishers name etc.).

4. Equations

3.2

Body paragraphs

The main text for your paragraphs should be 10pt font. All

body paragraphs (except the beginning of a section/subsection) should have the first line indented about 3.6 mm

(0.14").

3.3

Figures and Tables

Place illustrations (figures, tables, drawings, and photographs)

throughout the paper at the places where they are first

discussed in the text, rather than at the end of the paper.

Number illustrations sequentially (but number tables

separately). Place the illustration numbers and caption under

the illustration in 10 pt font. Do not allow illustrations to

extend into the margins or the gap between columns (except 2column illustrations may cross the gap). If your figure has two

parts, include the labels (a) and (b).

If you are using Word, use either the Microsoft Equation

Editor or the MathType add-on (http://www.mathtype.com) for

equations in your paper (Insert | Object | Create New |

Microsoft Equation or MathType Equation). Float over text

should not be selected.

Number equations consecutively with equation numbers in

parentheses flush with the right margin, as in (1). First use the

equation editor to create the equation. Then select the

Equation markup style. Press the tab key and write the

equation number in parentheses.

P K

E ( opk ) 2

p 1 k 1

(1)

5. Other recommendations

Equalize the length of your columns on the last page. If you

are using Word, proceed as follows: Insert/Break/Continuous.

References

Author Name, IJSRM volume issue June 2013 [www.ijsrm.in]

Page 2

[1] Ganesan v, (2003), Internal Combustion Engines, Tata

McGraw Hill,

[2] Jan A. WAJAND, Adam FIC A Two-Stroke

engine With Uniflow Valve Scavenging of Cylinder

The And A Transfer Valve In The Piston Crown

[3] J.B. Heywood, Internal Combustion Engine

Fundamentals, McGraw-Hill, New York, 1988

[4] P. L. Herzog, L. Burgler E. Winklhofer, P. Zelenka, W.

Cartellieri, NOx reduction strategies for DI diesel

engines, SAE Paper920470,1992.

[5] H. Erlach, F. Chmela, W. Cartellieri, P. Herzog, Pressure

modulated injection and its effect on combustion and

emissions of a HD diesel engine, SAE Paper 952059,

1995.

[6] J. R. Needham, M. P. May, D. M. Doyle, S. A. Faulkner,

Injection timing and rate control a solution for low

emissions, SAE Paper 900854, 1990.

[7]

Author Profile

<Author Photo>

Taro Denshi received the B.S. and M.S. degrees in

Electrical Engineering from Shibaura Institute of Technology

in 1997 and 1999, respectively. During 1997-1999, he stayed

in Communications Research Laboratory (CRL), Ministry of

Posts and Telecommunications of Japan to study digital beam

forming antennas, mobile satellite communication systems,

and wireless access network using stratospheric platforms. He

now with DDI Tokyo Pocket Telephone, Inc.

Author Name, IJSRM volume issue June 2013 [www.ijsrm.in]

Page 3

Vous aimerez peut-être aussi

- A Literature Review On The Performance Analysis of 4 Stroke Diesel Engines With Ceramic Coating Material-36993 PDFDocument7 pagesA Literature Review On The Performance Analysis of 4 Stroke Diesel Engines With Ceramic Coating Material-36993 PDFShiva ShankarPas encore d'évaluation

- Shubham SalunkheDocument14 pagesShubham Salunkheप्रथमेश क्षीरसागरPas encore d'évaluation

- Engine Components and OperationDocument24 pagesEngine Components and OperationAndrew CrawfordPas encore d'évaluation

- Morse Test On Multi Cylinder Petrol EngineDocument4 pagesMorse Test On Multi Cylinder Petrol Engineمصطفى العباديPas encore d'évaluation

- Test On Variable Speed Petrol EngineDocument7 pagesTest On Variable Speed Petrol EngineAbhishek KhatavkarPas encore d'évaluation

- Aero-Engine Speed Reducer Gearbox: Mechanical Design BDocument14 pagesAero-Engine Speed Reducer Gearbox: Mechanical Design BanuPas encore d'évaluation

- ME8595-Thermal Engineering-II Valliammai PDFDocument19 pagesME8595-Thermal Engineering-II Valliammai PDFSiva SubramaniamPas encore d'évaluation

- Week 8Document6 pagesWeek 8shmye100% (1)

- Snowcempaints Colour Chart: European Distributor To Snowcempaints Private LTDDocument1 pageSnowcempaints Colour Chart: European Distributor To Snowcempaints Private LTDAnonymous hQpEadSfPas encore d'évaluation

- Question Bank: UNIT:1 Combustion ThermodynamicsDocument14 pagesQuestion Bank: UNIT:1 Combustion ThermodynamicsVinay KorekarPas encore d'évaluation

- Modeling and Simulation of 1.5MW Wind TurbineDocument3 pagesModeling and Simulation of 1.5MW Wind TurbineInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Electrical Room Heater WiringDocument4 pagesElectrical Room Heater WiringgouravPas encore d'évaluation

- The Second Law of ThermodynamicsDocument12 pagesThe Second Law of ThermodynamicsEdgar PeninsulaPas encore d'évaluation

- EEE3091F Test 1 Questions - 2022Document3 pagesEEE3091F Test 1 Questions - 2022Student 80Pas encore d'évaluation

- 3.2 Design Parameters and CalculationsDocument9 pages3.2 Design Parameters and CalculationsMasAmirahPas encore d'évaluation

- Design and Analysis of Brake and Gas PedalDocument5 pagesDesign and Analysis of Brake and Gas PedalIJAERS JOURNAL100% (1)

- Design and Fabrication of Air Intake For FSAE Race CarDocument5 pagesDesign and Fabrication of Air Intake For FSAE Race Carabhinav abburiPas encore d'évaluation

- PSE Certification Mark GuidelineDocument2 pagesPSE Certification Mark Guidelineอาทิตย์ เพ็ชรคงPas encore d'évaluation

- Abstract: Robowars: Hell in A CellDocument8 pagesAbstract: Robowars: Hell in A CellYashwin IddyaPas encore d'évaluation

- Assignment No 1 (ME 461)Document6 pagesAssignment No 1 (ME 461)Jayant Raj SauravPas encore d'évaluation

- FLENDER Standard Couplings: Torsionally Rigid All-Steel Couplings - ARPEX ARP-6 SeriesDocument18 pagesFLENDER Standard Couplings: Torsionally Rigid All-Steel Couplings - ARPEX ARP-6 SeriesNickPas encore d'évaluation

- Final Edr ReportDocument10 pagesFinal Edr ReportNitin KharetaPas encore d'évaluation

- NFL BathindaDocument26 pagesNFL BathindaSukhman ChahalPas encore d'évaluation

- Flujo de Aire PDFDocument10 pagesFlujo de Aire PDFJoffre Lautaro Benavides Seminario100% (1)

- Internship Report On Online Training at Sandvik Asia PVT - LTDDocument10 pagesInternship Report On Online Training at Sandvik Asia PVT - LTDShravani GogawalePas encore d'évaluation

- GVM Motor SolutionsDocument56 pagesGVM Motor Solutions1907nirmalPas encore d'évaluation

- Comparative Study of Performance of LPG Fuelled Si Engine at Different Compression Ratio and Ignition TimingDocument7 pagesComparative Study of Performance of LPG Fuelled Si Engine at Different Compression Ratio and Ignition TimingIAEME PublicationPas encore d'évaluation

- Bearing Pad - Regular Test 1 PDFDocument1 pageBearing Pad - Regular Test 1 PDFShoyeeb AhmedPas encore d'évaluation

- Classification of Heat EnginesDocument20 pagesClassification of Heat EnginesParva ShrivastavaPas encore d'évaluation

- Surface EngineeringDocument43 pagesSurface Engineering10rajPas encore d'évaluation

- Energies 12 03010Document16 pagesEnergies 12 03010prathamesh naikPas encore d'évaluation

- SAMDocument38 pagesSAMCHELVASERPas encore d'évaluation

- Mechanical Recruitment Questions November 2019Document5 pagesMechanical Recruitment Questions November 2019Devashish Verma 16BME0446Pas encore d'évaluation

- 2K17-ICE Lecture-1Document50 pages2K17-ICE Lecture-1AbdullahJavedPas encore d'évaluation

- MaterialUniverse Metals and Alloys Ferrous Cast Iron Alloy White High ChromiumDocument3 pagesMaterialUniverse Metals and Alloys Ferrous Cast Iron Alloy White High ChromiumKarl Her ArtyomPas encore d'évaluation

- Review of Design and Analysis of PistonDocument4 pagesReview of Design and Analysis of PistonEditor IJTSRDPas encore d'évaluation

- Gas Dynamics LAB 02 PDFDocument16 pagesGas Dynamics LAB 02 PDFmuhammad zia ur rehmanPas encore d'évaluation

- Ime ProjectDocument11 pagesIme Projectrashmi patilPas encore d'évaluation

- 20ME901 Automobile Engineering Unit 2Document82 pages20ME901 Automobile Engineering Unit 26044 sriramPas encore d'évaluation

- Mech 2412 Embodiment Design Report 1Document25 pagesMech 2412 Embodiment Design Report 1api-510467572Pas encore d'évaluation

- PB-632 How To Replace TS1 With TS2 V1aDocument3 pagesPB-632 How To Replace TS1 With TS2 V1avikram banthiaPas encore d'évaluation

- Me8593 Design of Machine Elements: M.A.M. College of Engineering and TechnologyDocument66 pagesMe8593 Design of Machine Elements: M.A.M. College of Engineering and TechnologymanikandanPas encore d'évaluation

- Genset Control and Protection: Figure 1: Typical Genset Block DiagramDocument53 pagesGenset Control and Protection: Figure 1: Typical Genset Block DiagramTonyPas encore d'évaluation

- English GPW Catalog 2016Document8 pagesEnglish GPW Catalog 2016YioYin100% (1)

- Ass 1 Mech 6511 Mechanical Shaping of Metals and PlasticsDocument2 pagesAss 1 Mech 6511 Mechanical Shaping of Metals and PlasticsVarinder ThandiPas encore d'évaluation

- 156 - Engineering - Drawing - EE-155 - Lab - Manual Final-2Document24 pages156 - Engineering - Drawing - EE-155 - Lab - Manual Final-2Hamza AkhtarPas encore d'évaluation

- Applied Thermodynamics AssignmentDocument4 pagesApplied Thermodynamics AssignmentGurpreet BhanguPas encore d'évaluation

- Combustion Research Unit CRU ToolDocument5 pagesCombustion Research Unit CRU ToolMachineryengPas encore d'évaluation

- Is 866 1957Document7 pagesIs 866 1957sarath6725Pas encore d'évaluation

- Service Letter SL2021-715/PRP: Starting Air SystemDocument7 pagesService Letter SL2021-715/PRP: Starting Air Systemmichall123100% (1)

- 1-17 - Kale and Khandare Engine Data BookDocument17 pages1-17 - Kale and Khandare Engine Data BookTEJ SAKPALPas encore d'évaluation

- Young's Modulus by Bending of BeamsDocument3 pagesYoung's Modulus by Bending of BeamsAwny Habib100% (1)

- APPLICATION FORM GOVERNMENT PUJAB 2022-2023 Final 12-7-2022Document2 pagesAPPLICATION FORM GOVERNMENT PUJAB 2022-2023 Final 12-7-2022Blaq DaggyPas encore d'évaluation

- Scavenging Detanation IgnitionDocument18 pagesScavenging Detanation IgnitionSajjad Hossain ShuvoPas encore d'évaluation

- Pipe Burner FaqDocument6 pagesPipe Burner FaqdyravanzellaPas encore d'évaluation

- CaecdDocument43 pagesCaecdManikandaKumarPas encore d'évaluation

- Project Details 6511Document4 pagesProject Details 6511Kaushik SamineniPas encore d'évaluation

- CFD Analysis & Optimization of Fuel Injector by Changing Its GeometryDocument5 pagesCFD Analysis & Optimization of Fuel Injector by Changing Its GeometryIJIRSTPas encore d'évaluation

- Gas Turbine Engine ThesisDocument4 pagesGas Turbine Engine ThesisCustomPapersOnlineSingapore100% (2)

- Experimental Investigation of Laser Surface Texturing On Piston Rings For Reduction of Friction PowerDocument7 pagesExperimental Investigation of Laser Surface Texturing On Piston Rings For Reduction of Friction PowerfuturemukundPas encore d'évaluation

- Spoken EnglishDocument225 pagesSpoken EnglishKumuda Srinath100% (2)

- Simulation Driven Design With Inspire Ebook PDFDocument423 pagesSimulation Driven Design With Inspire Ebook PDFk krishna chaitanyaPas encore d'évaluation

- 18 Means of TransportDocument11 pages18 Means of TransportPrakash Kumar SenPas encore d'évaluation

- Head Hardened Rails - Weldfab Tech TimesDocument13 pagesHead Hardened Rails - Weldfab Tech TimesPrakash Kumar SenPas encore d'évaluation

- Gauge Conundrum by Rajiv Kumar TyagiDocument5 pagesGauge Conundrum by Rajiv Kumar TyagiPrakash Kumar SenPas encore d'évaluation

- Usually Track Fractures Occur Because of Temperature FluctuationsDocument4 pagesUsually Track Fractures Occur Because of Temperature FluctuationsPrakash Kumar SenPas encore d'évaluation

- SimplexManual PDFDocument391 pagesSimplexManual PDFPrakash Kumar SenPas encore d'évaluation

- Project Proposal On Developing Suitable Pedagogical Methods For Various Classes, Intellectual Calibers and Research in E-LearningDocument14 pagesProject Proposal On Developing Suitable Pedagogical Methods For Various Classes, Intellectual Calibers and Research in E-LearningGuttula EswaraRaoPas encore d'évaluation

- Updated Lesson Plan Blank FormatDocument2 pagesUpdated Lesson Plan Blank FormatPrakash Kumar SenPas encore d'évaluation

- Report FormatDocument3 pagesReport FormatPrakash Kumar SenPas encore d'évaluation

- GATE Mechanical SyllabusDocument2 pagesGATE Mechanical Syllabussgupta_192494Pas encore d'évaluation

- Bachelor of Engineering:: Courses OfferedDocument2 pagesBachelor of Engineering:: Courses OfferedPrakash Kumar SenPas encore d'évaluation

- MM ZG523Document13 pagesMM ZG523Prakash Kumar SenPas encore d'évaluation

- M. Tech Syllabus (Iem) Csit DurgDocument23 pagesM. Tech Syllabus (Iem) Csit DurgPrakash Kumar SenPas encore d'évaluation

- Notification KV Chakeri PGT TGT PRT Other PostsDocument2 pagesNotification KV Chakeri PGT TGT PRT Other PostsPrakash Kumar SenPas encore d'évaluation

- Broshure Department of Mechanical EngineeringDocument1 pageBroshure Department of Mechanical EngineeringPrakash Kumar SenPas encore d'évaluation

- Quantitative Ability SyllabusDocument3 pagesQuantitative Ability SyllabusSakshi KhuranaPas encore d'évaluation

- ASTM International Graduate Scholarship: ObjectiveDocument12 pagesASTM International Graduate Scholarship: ObjectivePrakash Kumar SenPas encore d'évaluation

- IJSRD Copyright FormDocument1 pageIJSRD Copyright FormPrakash Kumar SenPas encore d'évaluation

- Gopal 3 of 4Document27 pagesGopal 3 of 4Prakash Kumar SenPas encore d'évaluation

- Assignment: Constructing Peer-Instruction QuestionsDocument10 pagesAssignment: Constructing Peer-Instruction QuestionsNileshSolankiPas encore d'évaluation

- Deepak Resume WordDocument3 pagesDeepak Resume WordPrakash Kumar SenPas encore d'évaluation

- Lession Plan Blank FormatDocument2 pagesLession Plan Blank FormatPrakash Kumar SenPas encore d'évaluation

- Gopal 2 of 4Document8 pagesGopal 2 of 4Prakash Kumar SenPas encore d'évaluation

- Gopal 1 of 4Document1 pageGopal 1 of 4Prakash Kumar SenPas encore d'évaluation

- 422 EWEC2010presentationDocument54 pages422 EWEC2010presentationPrakash Kumar SenPas encore d'évaluation

- Career Form FormatDocument4 pagesCareer Form FormatPartha Sarathi JenaPas encore d'évaluation

- 115Document15 pages115Prakash Kumar SenPas encore d'évaluation

- Gopal 3 of 4Document27 pagesGopal 3 of 4Prakash Kumar SenPas encore d'évaluation

- VTPDocument1 pageVTPPrakash Kumar SenPas encore d'évaluation

- 2011.06.28 SN4X Construction Report-AnteriorDocument245 pages2011.06.28 SN4X Construction Report-AnteriorDennis Manuel Gutierrez Avila100% (4)

- 02 Alfred Leodolter OMVPetromDocument15 pages02 Alfred Leodolter OMVPetromscottigPas encore d'évaluation

- Service BulletinDocument7 pagesService BulletinFalgon IslamPas encore d'évaluation

- Subaru Boxer DieselDocument15 pagesSubaru Boxer DieselAlberto Torres LeonPas encore d'évaluation

- Ezekiel John Roque 2015707041Document3 pagesEzekiel John Roque 2015707041Keizer DelacruzPas encore d'évaluation

- Ohio Special Operating and Maintenance Guide PDFDocument200 pagesOhio Special Operating and Maintenance Guide PDFfauzi endraPas encore d'évaluation

- A. Genset.2Document2 pagesA. Genset.2menggandakanPas encore d'évaluation

- Serp4562 01 01 All PDFDocument982 pagesSerp4562 01 01 All PDFjose floresPas encore d'évaluation

- Ums OperationDocument27 pagesUms OperationSwarg Vibha0% (1)

- W Q D M: HEN Uality and Elivery AtterDocument24 pagesW Q D M: HEN Uality and Elivery AtterRashidul Islam MasumPas encore d'évaluation

- Gas Cut MudDocument53 pagesGas Cut Mudabnou_223943920Pas encore d'évaluation

- Engine 114 - 2 Series KomatsuDocument444 pagesEngine 114 - 2 Series KomatsuLuis Mendez100% (5)

- NTPC DLN Systems VamsiDocument13 pagesNTPC DLN Systems VamsiAbhishek Prakash SrivastavaPas encore d'évaluation

- EnviroGear PDFDocument4 pagesEnviroGear PDFrasottoPas encore d'évaluation

- Washing Machine: Owner'S ManualDocument80 pagesWashing Machine: Owner'S ManualravasamaPas encore d'évaluation

- 1) - Small-Town Taxi Operates One Vehicle During The 9:00 A.M. To 5:00 P.M. PeriodDocument2 pages1) - Small-Town Taxi Operates One Vehicle During The 9:00 A.M. To 5:00 P.M. PeriodWaqas50% (2)

- 330 CDocument2 pages330 CMarco Olivetto0% (1)

- Mobile Telescopic Cylinders: Selection GuideDocument4 pagesMobile Telescopic Cylinders: Selection Guidehanamant1991100% (1)

- Lecture (1) Properties of Fluids: LecturerDocument28 pagesLecture (1) Properties of Fluids: LecturerILAYAPERUMAL KPas encore d'évaluation

- SourcesDocument23 pagesSourcesmmkattaPas encore d'évaluation

- OCIMF PublicationsDocument2 pagesOCIMF PublicationsAnonymous qKz3IEa6d780% (5)

- TelusDocument3 pagesTelusGembonz Crew Gon'z SpeedPas encore d'évaluation

- Technical Bulletin: RT-82 Wärtsilä 2-StrokeDocument23 pagesTechnical Bulletin: RT-82 Wärtsilä 2-StrokeRaul DiazPas encore d'évaluation

- Exchange Summary Volume and Open Interest Energy Futures: FinalDocument9 pagesExchange Summary Volume and Open Interest Energy Futures: FinalavadcsPas encore d'évaluation

- Cat c6.6 Fuel SystemDocument14 pagesCat c6.6 Fuel SystemaliPas encore d'évaluation

- Forklift - Policy From DowjonesDocument11 pagesForklift - Policy From DowjonesAs ElmoPas encore d'évaluation

- PHQ250Jackleg BrochureDocument2 pagesPHQ250Jackleg BrochurePieroGamarraGarciaPas encore d'évaluation

- 500 Technical Questions Safety&Fire-1Document26 pages500 Technical Questions Safety&Fire-1Saad GhouriPas encore d'évaluation

- Resume 1558528606250Document3 pagesResume 1558528606250Rajkishan GuptaPas encore d'évaluation

- Omara SamiDocument3 pagesOmara SamiSami M. OmaraPas encore d'évaluation