Académique Documents

Professionnel Documents

Culture Documents

DC S3-1301 REV.0 Original

Transféré par

Peja JusohDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DC S3-1301 REV.0 Original

Transféré par

Peja JusohDroits d'auteur :

Formats disponibles

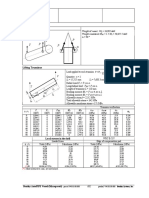

MSET ENGINEERING CORPORATION SDN BHD

DOCUMENT TITLE: DESIGN CALCULATION

DATE: 14.07.2013

DOC. REF. NO.: MSET/M2-231/S3-1301/DC

REVISION: 0

SUBJECT: DESIGN DATA

JOB NO: M2-231

SERIAL NO.: M2-231/001

PAGE: 2

DESIGN DATA

ITEM NO.

S3-1301 MDEA SOLUTION FILTER

DESIGN CODE

ASME SEC.VIII DIV.1, 2010 EDITION & 2011 ADDENDA

CODE STAMPING

YES (U-STAMP)

DESIGN

OPERATING

PRESSURE (kg/cm g)

35

TEMPERATURE (C) (Min/Max)

-10 / 90

PRESSURE (kg/cm g)

24.9

TEMPERATURE (C)

60

HYDROTEST (kg/cm g)

(As Per UG-99c)

TEST PRESSURE

PNEUMATIC

60.5

NO

MAWP (hot & corroded) (kg/cm g)

41.1

MAP (new & cold) (kg/cm g)

46.6

OUTSIDE DIAMETER (mm)

323.9 (NPS 12)

TYPE OF HEAD

CAP NPS 12 x SCH 40

MATERIAL OF CONSTRUCTION (SHELL/HEAD)

SA 106 Gr B / SA 234 WPB

HEAT TREATMENT

NORMALIZED

NO

PWHT

YES

IMPACT TEST

NO

MDMT (C)

-10

RADIOGRAPHY

HEAD: 100% SHELL: 100%

JOINT EFFICIENCY

HEAD:1.0 , SHELL: 1.0

CORROSION ALLOWANCE

(mm)

SHELL & HEAD

NOZZLE

CONTENTS

aMDEA

ERECTION WEIGHT (kg)

367 (w/o Filter)

CAPACITY (m3)

0.12

PRESSURE VESSEL DESIGN CALCULATION

MSET ENGINEERING CORPORATION SDN BHD

DOCUMENT TITLE: DESIGN CALCULATION

DATE: 14.07.2013

DOC. REF. NO.: MSET/M2-231/S3-1301/DC

REVISION: 0

SUBJECT: CHANGE RECORD

JOB NO: M2-231

SERIAL NO.: M2-231/001

PAGE: 3

CHANGE RECORD

Amendment No.

Date

Responsible

Person

Description Of Change

MSET ENGINEERING CORPORATION SDN BHD

DOCUMENT TITLE: DESIGN CALCULATION

DATE: 14.07.2013

DOC. REF. NO.: MSET/M2-231/S3-1301/DC

REVISION: 0

SUBJECT: TABLE OF CONTENT

JOB NO: M2-231

SERIAL NO.: M2-231/001

PAGE: 4

TABLE OF CONTENT

NO

CONTENT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Input Echo

Flange Calculation

Internal Pressure Calculations

Element and Detail Weights

Nozzle Flange MAWP

Wind Load Calculation

Earthquake Load Calculation

Wind/Earthquake Shear, Bending

Wind Deflection

Center of Gravity

Leg Calculation (Operating Case)

Nozzle Calculation

Nozzle Schedule

Nozzle Summary

Vessel Design Summary

Attachment 1: Lifting Lug Calculation

Attachment 2: WRC 297 Calculation

PAGE NO.

5

12

20

23

26

27

30

32

33

34

35

45

78

79

81

-

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 5

Input Echo :

Step:

1

1:42p Jul 14,2013

PV Elite Vessel Analysis Program: Input Data

Design Internal Pressure (for Hydrotest)

Design Internal Temperature

Type of Hydrotest

Hydrotest Position

Projection of Nozzle from Vessel Top

Projection of Nozzle from Vessel Bottom

Minimum Design Metal Temperature

Type of Construction

Special Service

Degree of Radiography

Miscellaneous Weight Percent

Use Higher Longitudinal Stresses (Flag)

Select t for Internal Pressure (Flag)

Select t for External Pressure (Flag)

Select t for Axial Stress (Flag)

Select Location for Stiff. Rings (Flag)

Consider Vortex Shedding

Perform a Corroded Hydrotest

Is this a Heat Exchanger

User Defined Hydro. Press. (Used if > 0)

User defined MAWP

User defined MAPnc

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

Case

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Wind Design Code

Basic Wind Speed

Surface Roughness Category

Importance Factor

Type of Surface

Base Elevation

35.000

90

UG99-c

Horizontal

150.00

150.00

-10

Welded

None

RT-1

5.0

Y

N

N

N

N

N

N

No

0.0000

0.0000

0.0000

kgf/cm

C

mm

mm

C

kgf/cm

kgf/cm

kgf/cm

NP+EW+WI+FW+BW

NP+EW+EE+FS+BS

NP+OW+WI+FW+BW

NP+OW+EQ+FS+BS

NP+HW+HI

NP+HW+HE

IP+OW+WI+FW+BW

IP+OW+EQ+FS+BS

EP+OW+WI+FW+BW

EP+OW+EQ+FS+BS

HP+HW+HI

HP+HW+HE

IP+WE+EW

IP+WF+CW

IP+VO+OW

IP+VE+EW

NP+VO+OW

FS+BS+IP+OW

FS+BS+EP+OW

ASCE-7 98/02/05/IBC-03/STS-1

[V]

33.100

C: Open Terrain

1.0

Moderately Smooth

10000.

m/sec

mm

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 6

Input Echo :

Step:

1

1:42p Jul 14,2013

Percent Wind for Hydrotest

Using User defined Wind Press. Vs Elev.

Height of Hill or Escarpment

H or Hh

Distance Upwind of Crest

Lh

Distance from Crest to the Vessel

x

Type of Terrain ( Hill, Escarpment )

Damping Factor (Beta) for Wind (Ope)

Damping Factor (Beta) for Wind (Empty)

Damping Factor (Beta) for Wind (Filled)

33.0

N

0.0000

0.0000

0.0000

Flat

0.0100

0.0000

0.0000

Seismic Design Code

UBC Seismic Zone (1=1,2=2a,3=2b,4=3,5=4)

UBC Importance Factor

UBC Seismic Coefficient Ca

UBC Seismic Coefficient Cv

UBC Seismic Coefficient Nv

UBC Horizontal Force Factor

Apply Allowables per paragraph 1612.3.2

UBC 1997

1

1.250

0.120

0.180

1.000

2.900

No

Design Nozzle for Des. Press. + St. Head

Consider MAP New and Cold in Noz. Design

Consider External Loads for Nozzle Des.

Use ASME VIII-1 Appendix 1-9

Y

Y

Y

N

Material Database Year

mm

mm

mm

Current w/Addenda or Code Year

Configuration Directives:

Do not use Nozzle MDMT Interpretation VIII-1 01-37

Use Table G instead of exact equation for "A"

Shell Head Joints are Tapered

Compute "K" in corroded condition

Use Code Case 2286

Use the MAWP to compute the MDMT

Using Metric Material Databases, ASME II D

No

Yes

Yes

Yes

No

Yes

No

Complete Listing of Vessel Elements and Details:

Element From Node

Element To Node

Element Type

Description

Distance "FROM" to "TO"

Element Outside Diameter

Element Thickness

Internal Corrosion Allowance

Nominal Thickness

External Corrosion Allowance

Design Internal Pressure

Design Temperature Internal Pressure

Design External Pressure

Design Temperature External Pressure

Effective Diameter Multiplier

10

20

Elliptical

CAP

66.000 mm

323.90 mm

10.310 mm

3.0000 mm

10.310 mm

0.0000 mm

35.000 kgf/cm

90 C

0.0000 kgf/cm

0 C

1.2

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 7

Input Echo :

Step:

1

1:42p Jul 14,2013

Material Name

Allowable Stress, Ambient

Allowable Stress, Operating

Allowable Stress, Hydrotest

Material Density

P Number Thickness

Yield Stress, Operating

UCS-66 Chart Curve Designation

External Pressure Chart Name

UNS Number

Product Form

Efficiency, Longitudinal Seam

Efficiency, Circumferential Seam

Elliptical Head Factor

SA-234 WPB

1202.2

1202.2

2214.7

0.007750

31.750

2263.6

B

CS-2

K03006

Smls. & wld. fittings

1.0

1.0

2.0

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

Height/Length of Liquid

Liquid Density

10

Liquid

FLUID1

-75.820

141.82

1018.0

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

Nozzle Diameter

Nozzle Schedule

Nozzle Class

Layout Angle

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

Grade of Attached Flange

Nozzle Matl

10

Nozzle

N6

0.0000

50.0

160

300

0.0

N

0.0000

GR 1.1

SA-106 B

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

Nozzle Diameter

Nozzle Schedule

Nozzle Class

Layout Angle

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

Grade of Attached Flange

Nozzle Matl

10

Nozzle

N3

100.00

50.0

160

300

0.0

N

0.0000

GR 1.1

SA-106 B

kgf/cm

kgf/cm

kgf/cm

kgm/cm

mm

kgf/cm

mm

mm

kgm/m

mm

mm

kgf

mm

mm

kgf

-------------------------------------------------------------------Element From Node

Element To Node

Element Type

20

30

Cylinder

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 8

Input Echo :

Step:

1

1:42p Jul 14,2013

Description

Distance "FROM" to "TO"

Element Outside Diameter

Element Thickness

Internal Corrosion Allowance

Nominal Thickness

External Corrosion Allowance

Design Internal Pressure

Design Temperature Internal Pressure

Design External Pressure

Design Temperature External Pressure

Effective Diameter Multiplier

Material Name

Allowable Stress, Ambient

Allowable Stress, Operating

Allowable Stress, Hydrotest

Material Density

P Number Thickness

Yield Stress, Operating

UCS-66 Chart Curve Designation

External Pressure Chart Name

UNS Number

Product Form

Efficiency, Longitudinal Seam

Efficiency, Circumferential Seam

SHELL

1600.0

323.90

10.310

3.0000

10.310

0.0000

35.000

90

0.0000

0

1.2

SA-106 B

1202.2

1202.2

2214.7

0.007750

31.750

2263.6

B

CS-2

K03006

Smls. pipe

1.0

1.0

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

Height/Length of Liquid

Liquid Density

20

Liquid

FLUID2

0.0000

1600.0

1018.0

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

Nozzle Diameter

Nozzle Schedule

Nozzle Class

Layout Angle

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

Grade of Attached Flange

Nozzle Matl

20

Nozzle

N1

1390.0

50.0

160

300

90.0

N

0.0000

GR 1.1

SA-106 B

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

Nozzle Diameter

Nozzle Schedule

Nozzle Class

20

Nozzle

N2

135.00

50.0

160

300

mm

mm

mm

mm

mm

mm

kgf/cm

C

kgf/cm

C

kgf/cm

kgf/cm

kgf/cm

kgm/cm

mm

kgf/cm

mm

mm

kgm/m

mm

mm

kgf

mm

mm

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 9

Input Echo :

Step:

1

1:42p Jul 14,2013

Layout Angle

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

Grade of Attached Flange

Nozzle Matl

270.0

N

0.0000

GR 1.1

SA-106 B

kgf

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

Diameter at Leg Centerline

Leg Orientation

Number of Legs

Section Identifier

Length of Legs

20

Leg

LEGS

200.00

376.64

3

4

L2X2X0.2500

1000.0

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

Miscellaneous Weight

Offset from Element Centerline

20

Weight

SUPPORT

200.00

14.000

0.0000

mm

kgf

mm

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

Miscellaneous Weight

Offset from Element Centerline

20

Weight

FILTER

733.00

300.00

0.0000

mm

kgf

mm

mm

mm

mm

-------------------------------------------------------------------Element From Node

Element To Node

Element Type

Description

Distance "FROM" to "TO"

Flange Inside Diameter

Element Thickness

Internal Corrosion Allowance

Nominal Thickness

External Corrosion Allowance

Design Internal Pressure

Design Temperature Internal Pressure

Design External Pressure

Design Temperature External Pressure

Effective Diameter Multiplier

Material Name

[Normalized]

Allowable Stress, Ambient

Allowable Stress, Operating

Allowable Stress, Hydrotest

Material Density

P Number Thickness

30

40

Flange

BODY FLANGE

73.000

327.00

49.300

3.0000

49.300

0.0000

35.000

90

0.0000

0

1.2

SA-105

1406.1

1406.1

2277.9

0.007750

31.750

mm

mm

mm

mm

mm

mm

kgf/cm

C

kgf/cm

C

kgf/cm

kgf/cm

kgf/cm

kgm/cm

mm

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 10

Input Echo :

Step:

1

1:42p Jul 14,2013

Yield Stress, Operating

UCS-66 Chart Curve Designation

External Pressure Chart Name

UNS Number

Product Form

Perform Flange Stress Calculation (Y/N)

Weight of ANSI B16.5/B16.47 Flange

Class of ANSI B16.5/B16.47 Flange

Grade of ANSI B16.5/B16.47 Flange

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

Height/Length of Liquid

Liquid Density

2326.9

C

CS-2

K03504

Forgings

Y

0.0000

30

Liquid

FLUID3

0.0000

73.000

1018.0

kgf/cm

kgf

mm

mm

kgm/m

-------------------------------------------------------------------Element From Node

Element To Node

Element Type

Description

Distance "FROM" to "TO"

Flange Inside Diameter

Element Thickness

Internal Corrosion Allowance

Nominal Thickness

External Corrosion Allowance

Design Internal Pressure

Design Temperature Internal Pressure

Design External Pressure

Design Temperature External Pressure

Effective Diameter Multiplier

Material Name

[Normalized]

Perform Flange Stress Calculation (Y/N)

Weight of ANSI B16.5/B16.47 Flange

Class of ANSI B16.5/B16.47 Flange

Grade of ANSI B16.5/B16.47 Flange

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

Nozzle Diameter

Nozzle Schedule

Nozzle Class

Layout Angle

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

Grade of Attached Flange

Nozzle Matl

40

50

Flange

BLIND

51.300

520.00

49.300

3.0000

49.300

0.0000

35.000

90

0.0000

0

1.2

SA-105

Y

0.0000

40

Nozzle

N5

100.00

50.0

160

300

0.0

N

0.0000

GR 1.1

SA-106 B

mm

mm

mm

mm

mm

mm

kgf/cm

C

kgf/cm

C

kgf

mm

mm

kgf

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 11

Input Echo :

Step:

1

1:42p Jul 14,2013

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2012

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 12

Flg Calc [Int P] : FLANGE

Flng:

8

1:42p Jul 14,2013

Flange Input Data Values

Description: FLANGE

BODY FLANGE

Description of Flange Geometry (Type)

Design Pressure

P

Design Temperature

Internal Corrosion Allowance

ci

External Corrosion Allowance

ce

Use Corrosion Allowance in Thickness Calcs.

Flange Inside Diameter

Flange Outside Diameter

Flange Thickness

Thickness of Hub at Small End

Thickness of Hub at Large End

Length of Hub

Integral Slip On

35.00 kgf/cm

90 C

3.0000 mm

0.0000 mm

No

B

A

t

go

g1

h

303.280

520.000

49.3000

28.8900

35.8600

21.7000

mm

mm

mm

mm

mm

mm

Sfo

Sfa

SA-105

K03504

1406.14

1406.14

kgf/cm

kgf/cm

Bolt Material

Bolt Allowable Stress At Temperature

Bolt Allowable Stress At Ambient

Sb

Sa

SA-193 B7

1757.68

1757.68

kgf/cm

kgf/cm

Diameter of Bolt Circle

Nominal Bolt Diameter

Type of Threads

Number of Bolts

C

450.800

dB

28.5750

UNC Thread Series

16

mm

mm

Fod

381.000

Fid

327.000

1, Code Sketch 1a

mm

mm

Flange

Flange

Flange

Flange

Material

Material UNS number

Allowable Stress At Temperature

Allowable Stress At Ambient

Flange Face Outside Diameter

Flange Face Inside Diameter

Flange Facing Sketch

Gasket

Gasket

Gasket

Gasket

Outside Diameter

Inside Diameter

Factor

Design Seating Stress

Go

Gi

m

y

Column for Gasket Seating

Gasket Thickness

374.700

339.900

2.5000

703.07

2, Code Column II

tg

4.5000

mm

mm

kgf/cm

mm

ASME Code, Section VIII, Division 1, 2010, 2011a

Corroded Flange ID,

Corroded Large Hub,

Corroded Small Hub,

Code R Dimension,

Gasket Contact Width,

Bcor

g1Cor

g0Cor

R

=

=

=

=

B+2*Fcor

g1-ci

go-ci

((C-Bcor)/2)-g1cor

N = (Go - Gi) / 2

309.280

32.860

25.890

37.900

mm

mm

mm

mm

17.400

mm

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 13

Flg Calc [Int P] : FLANGE

Flng:

8

1:42p Jul 14,2013

Basic Gasket Width,

Effective Gasket Width,

Gasket Reaction Diameter,

bo = N / 2

b = Cb sqrt(bo)

G = Go - 2 * b

8.700

7.433

359.835

mm

mm

mm

Basic Flange and Bolt Loads:

Hydrostatic End Load due to Pressure [H]:

= 0.785 * G * Peq

= 0.785 * 359.8346 * 35.000

= 35592.887 kgf

Contact Load on Gasket Surfaces [Hp]:

= 2 * b * Pi * G * m * P

= 2 * 7.4327 * 3.1416 * 359.8346 * 2.5000 * 35.00

= 14704.051 kgf

Hydrostatic End Load at Flange ID [Hd]:

= Pi * Bcor * P / 4

= 3.1416 * 309.2800 *35.0000/4

= 26294.264 kgf

Pressure Force on Flange Face [Ht]:

= H - Hd

= 35592 - 26294

= 9298.622 kgf

Operating Bolt Load [Wm1]:

= max( H + Hp + H'p, 0 )

= max( 35592 + 14704 + 0 , 0 )

= 50296.934 kgf

Gasket Seating Bolt Load [Wm2]:

= y * b * Pi * G + yPart * bPart * lp

= 703.07*7.4327*3.141*359.835+0.00*0.0000*0.00

= 59074.152 kgf

Required Bolt Area [Am]:

= Maximum of Wm1/Sb, Wm2/Sa

= Maximum of 50296/1757 , 59074/1757

= 33.609 cm

ASME Maximum Circumferential Spacing between Bolts per App. 2 eq. (3) [Bsmax]:

= 2a + 6t/(m + 0.5)

= 2 * 28.575 + 6 * 49.300/(2.50 + 0.5)

= 155.750 mm

Actual Circumferential Bolt Spacing [Bs]:

= C * sin( pi / n ) )

= 450.800 * sin( 3.142/16 )

= 87.947 mm

ASME Moment Multiplier for Bolt Spacing per App. 2 eq. (7) [Bsc]:

= max( sqrt( Bs/( 2a + t )), 1 )

= max( sqrt( 87.947/( 2 * 28.575 + 49.300 )), 1 )

= 1.0000

Bolting Information for UNC Thread Series (Non Mandatory):

----------------------------------------------------------------------------Minimum

Actual

Maximum

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 14

Flg Calc [Int P] : FLANGE

Flng:

8

1:42p Jul 14,2013

----------------------------------------------------------------------------Bolt Area, cm

33.609

71.535

Radial distance bet. hub and bolts

38.100

37.900

Radial distance bet. bolts and the edge

28.575

34.600

Circumferential spacing between bolts

63.500

87.947

155.750

----------------------------------------------------------------------------Min. Gasket Contact Width (Brownell Young) [Not an ASME Calc] [Nmin]:

= Ab * Sa/( y * Pi * (Go + Gi) )

= 71.535 * 1757.68/(703.07 * 3.14 * (374.700 + 339.90 ) )

= 7.966 mm

Flange Design Bolt Load, Gasket Seating [W]:

= Sa * ( Am + Ab ) / 2

= 1757.68 * ( 33.6093 + 71.5353 )/2

= 92404.93 kgf

Gasket Load for the Operating Condition [HG]:

= Wm1 - H

= 50296 - 35592

= 14704.05 kgf

Moment Arm Calculations:

Distance to Gasket Load Reaction [hg]:

= (C - G ) / 2

= ( 450.8000 - 359.8346 )/2

= 45.4827 mm

Distance to Face Pressure Reaction [ht]:

= ( R + g1 + hg ) / 2

= ( 37.9000 + 32.8600 + 45.4827 )/2

= 58.1213 mm

Distance to End Pressure Reaction [hd]:

= R + ( g1 / 2 )

= 37.9000 + ( 32.8600/2.0 )

= 54.3300 mm

Summary of Moments for Internal Pressure:

Loading

Force

Distance Bolt Corr

End Pressure,

Md

26294.

54.3300

1.0000

Face Pressure, Mt

9299.

58.1213

1.0000

Gasket Load,

Mg

14704.

45.4827

1.0000

Gasket Seating, Matm

92405.

45.4827

1.0000

Total Moment for Operation,

Mop

Total Moment for Gasket seating, Matm

Effective Hub Length, ho = sqrt(Bcor*goCor)

Hub Ratio,

h/h0 = HL / H0

Thickness Ratio,

g1/g0 = (g1Cor/goCor)

Flange

Factor

Factor

Factor

Factors for Integral Flange:

F per 2-7.2

V per 2-7.3

f per 2-7.6

Moment

1429.

540.

669.

4203.

kgf-m.

kgf-m.

kgf-m.

kgf-m.

2638. kgf-m.

4203. kgf-m.

89.483

0.243

1.269

0.894

0.445

1.000

mm

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 15

Flg Calc [Int P] : FLANGE

Flng:

8

1:42p Jul 14,2013

Factors from Figure 2-7.1

T =

1.633

Y =

3.911

d = .57944E+06 mm

Stress Factors

BETA =

1.657

DELTA =

0.207

K

U

Z

e

ALPHA

GAMMA

Lamda

Longitudinal Hub Stress, Operating [SHo]:

= ( f * Mop / Bcor ) / ( L * g1 )

= (1.0000*2637/309.2800)/(1.1208*32.8600)

= 704.72 kgf/cm

Longitudinal Hub Stress, Seating [SHa]:

= ( f * Matm / Bcor ) / ( L * g1 )

= (1.0000*4202/309.2800)/(1.1208*32.8600)

= 1122.84 kgf/cm

Radial Flange Stress, Operating [SRo]:

= ( Beta * Mop / Bcor ) / ( L * t )

= (1.6570*2637/309.2800)/(1.1208*49.3000)

= 518.76 kgf/cm

Radial Flange Stress, Seating [SRa]:

= ( Beta * Matm/Bcor ) / ( L * t )

= (1.6570*4202/309.2800)/(1.1208*49.3000)

= 826.55 kgf/cm

Tangential Flange Stress, Operating [STo]:

= ( Y * Mo / (t * Bcor) ) - Z * SRo

= (3.9109*2637/(49.3000*309.2800))-2.0948*518

= 285.70 kgf/cm

Tangential Flange Stress, Seating [STa]:

= ( y * Matm / (t * Bcor) ) - Z * SRa

= (3.9109*4202/(49.3000*309.2800))-2.0948*826

= 455.20 kgf/cm

Average Flange Stress, Operating [SAo]:

= ( SHo + max( SRo, STo ) ) / 2

= (704+max(518,285))/2

= 611.74 kgf/cm

Average Flange Stress, Seating [SAa]:

= ( SHa + max( SRa, STa ) ) / 2

= (1122+max(826,455))/2

= 974.70 kgf/cm

Bolt Stress, Operating [BSo]:

= ( Wm1 / Ab )

= (50296/71.5353)

= 703.11 kgf/cm

Bolt Stress, Seating [BSa]:

= ( Wm2 / Ab )

= (59074/71.5353)

= 825.80 kgf/cm

=

=

=

=

=

=

=

1.681

4.298

2.095

0.0100 mm ^-1

1.493

0.914

1.121

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 16

Flg Calc [Int P] : FLANGE

Flng:

8

1:42p Jul 14,2013

Stress Computation Results:

Operating

Actual

Allowed

Longitudinal Hub

705.

1803.

Radial Flange

519.

1406.

Tangential Flange

286.

1406.

Maximum Average

612.

1406.

Bolting

703.

1758.

Gasket Seating

Actual

Allowed

1123.

1803.

827.

1406.

455.

1406.

975.

1406.

826.

1758.

Minimum Required Flange Thickness

Estimated M.A.W.P. ( Operating )

Estimated Finished Weight of Flange at given Thk.

Estimated Unfinished Weight of Forging at given Thk

39.243

80.5

59.3

77.1

kgf/cm

kgf/cm

kgf/cm

kgf/cm

kgf/cm

mm

kgf/cm

kgm

kgm

Flange Rigidity Based on Required Thickness [ASME]:

Flange Rigidity Index, Seating (rotation check) per APP. 2 [Js]:

= 52.14 * Ma / Bsc * Cnv_fac * V / ( Lambda * Eamb * go^(2) * ho * Ki )

= 52.14 * 4202.8/1.0000 * 100000.023 * 0.445/( 0.957 * 2067025 *

25.890^(2) * 89.483 * 0.300 )

= 0.274 (should be <= 1)

Flange Rigidity Index Operating (rotation check) per APP. 2 [J]:

= 52.14 * Mo / Bsc * Cnv_fac * V / ( Lambda * Eop * goc^(2) * ho * Ki )

= 52.14 * 2637.8/1.0000 * 100000.023 * 0.445/( 0.957 * 2026793

* 25.890^(2) * 89.483 * 0.300 )

= 0.175 (should be <= 1)

Flange Rigidity Based on Given Thickness [ASME]:

Flange Rigidity Index, Seating (rotation check) per APP. 2 [Js]:

= 52.14 * Ma / Bsc * Cnv_fac * V / ( Lambda * Eamb * go^(2) * ho * Ki )

= 52.14 * 4202.8/1.0000 * 100000.023 * 0.445/( 1.121 * 2067025 *

25.890^(2) * 89.483 * 0.300 )

= 0.234 (should be <= 1)

Flange Rigidity Index Operating (rotation check) per APP. 2 [J]:

= 52.14 * Mo / Bsc * Cnv_fac * V / ( Lambda * Eop * goc^(2) * ho * Ki )

= 52.14 * 2637.8/1.0000 * 100000.023 * 0.445/( 1.121 * 2026793

* 25.890^(2) * 89.483 * 0.300 )

= 0.150 (should be <= 1)

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2012

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 17

Flg Calc [Int P] : FLANGE

Flng:

9

1:42p Jul 14,2013

Flange Input Data Values

Description: FLANGE

BLIND

Description of Flange Geometry (Type)

Design Pressure

P

Design Temperature

Internal Corrosion Allowance

ci

External Corrosion Allowance

ce

Use Corrosion Allowance in Thickness Calcs.

Flange Outside Diameter

Flange Thickness

Flange

Flange

Flange

Flange

Material

Material UNS number

Allowable Stress At Temperature

Allowable Stress At Ambient

520.000

49.3000

mm

mm

Sfo

Sfa

SA-105

K03504

1406.14

1406.14

kgf/cm

kgf/cm

Sb

Sa

SA-193 B7

1757.68

1757.68

kgf/cm

kgf/cm

D

d

L

0.000

0.000

1416.230

mm

mm

mm

C

450.800

dB

28.5750

UNC Thread Series

16

mm

mm

Fod

381.000

Fid

327.000

1, Code Sketch 1a

mm

mm

Diameter of the Load Reaction, Long Span

Diameter of the Load Reaction, Short Span

Perimeter along the Center of the Bolts

Flange Face Outside Diameter

Flange Face Inside Diameter

Flange Facing Sketch

Gasket

Gasket

Gasket

Gasket

Outside Diameter

Inside Diameter

Factor

Design Seating Stress

Go

Gi

m

y

Column for Gasket Seating

Gasket Thickness

Blind

kgf/cm

C

mm

mm

A

t

Bolt Material

Bolt Allowable Stress At Temperature

Bolt Allowable Stress At Ambient

Diameter of Bolt Circle

Nominal Bolt Diameter

Type of Threads

Number of Bolts

35.00

90

3.0000

0.0000

Yes

374.700

339.900

2.5000

703.07

2, Code Column II

tg

4.5000

mm

mm

kgf/cm

mm

ASME Code, Section VIII, Division 1, 2010, 2011a

Gasket Contact Width,

Basic Gasket Width,

Effective Gasket Width,

Gasket Reaction Diameter,

N

bo

b

G

=

=

=

=

(Go - Gi) / 2

N / 2

Cb sqrt(bo)

Go - 2 * b

17.400

8.700

7.433

359.835

mm

mm

mm

mm

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 18

Flg Calc [Int P] : FLANGE

Flng:

9

1:42p Jul 14,2013

Basic Flange and Bolt Loads:

Hydrostatic End Load due to Pressure [H]:

= 0.785 * G * Peq

= 0.785 * 359.8346 * 35.000

= 35592.887 kgf

Contact Load on Gasket Surfaces [Hp]:

= 2 * b * Pi * G * m * P

= 2 * 7.4327 * 3.1416 * 359.8346 * 2.5000 * 35.00

= 14704.051 kgf

Operating Bolt Load [Wm1]:

= max( H + Hp + H'p, 0 )

= max( 35592 + 14704 + 0 , 0 )

= 50296.934 kgf

Gasket Seating Bolt Load [Wm2]:

= y * b * Pi * G + yPart * bPart * lp

= 703.07*7.4327*3.141*359.835+0.00*0.0000*0.00

= 59074.152 kgf

Required Bolt Area [Am]:

= Maximum of Wm1/Sb, Wm2/Sa

= Maximum of 50296/1757 , 59074/1757

= 33.609 cm

ASME Maximum Circumferential Spacing between Bolts per App. 2 eq. (3) [Bsmax]:

= 2a + 6t/(m + 0.5)

= 2 * 28.575 + 6 * 46.300/(2.50 + 0.5)

= 149.750 mm

Actual Circumferential Bolt Spacing [Bs]:

= C * sin( pi / n ) )

= 450.800 * sin( 3.142/16 )

= 87.947 mm

ASME Moment Multiplier for Bolt Spacing per App. 2 eq. (7) [Bsc]:

= max( sqrt( Bs/( 2a + t )), 1 )

= max( sqrt( 87.947/( 2 * 28.575 + 46.300 )), 1 )

= 1.0000

Bolting Information for UNC Thread Series (Non Mandatory):

----------------------------------------------------------------------------Minimum

Actual

Maximum

----------------------------------------------------------------------------Bolt Area, cm

33.609

71.535

Radial distance bet. bolts and the edge

28.575

34.600

Circumferential spacing between bolts

63.500

87.947

149.750

----------------------------------------------------------------------------Min. Gasket Contact Width (Brownell Young) [Not an ASME Calc] [Nmin]:

= Ab * Sa/( y * Pi * (Go + Gi) )

= 71.535 * 1757.68/(703.07 * 3.14 * (374.700 + 339.90 ) )

= 7.966 mm

Flange Design Bolt Load, Gasket Seating [W]:

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 19

Flg Calc [Int P] : FLANGE

Flng:

9

1:42p Jul 14,2013

= Sa * ( Am + Ab ) / 2

= 1757.68 * ( 33.6093 + 71.5353 )/2

= 92404.93 kgf

Gasket Load for the Operating Condition [HG]:

= Wm1

= 50296.93 kgf

Moment Arm Calculations:

Distance to Gasket Load Reaction [hg]:

= (C - G ) / 2

= ( 450.8000 - 359.8346 )/2

= 45.4827 mm

Tangential Flange Stress, Flat Head (UG-34), Operating [STo]:

= 1.9 * Wm1 * hG * Bcor/(t * G) + C * Z * Peq * G/t

= 1.9*50296*45.4827*1.0000/(46.3000*359.8346)+

0.30*1.0000*35.00*359.8346/46.3000

= 1197.69 kgf/cm

Tangential Flange Stress, Flat Head (UG-34), Seating [STa]:

= 1.9 * W * hG * Bcor / (t * G)

= 1.9*92404*45.4827*1.000/(46.3000*359.8346)

= 1035.21 kgf/cm

Bolt Stress, Operating [BSo]:

= ( Wm1 / Ab )

= (50296/71.5353)

= 703.11 kgf/cm

Bolt Stress, Seating [BSa]:

= ( Wm2 / Ab )

= (59074/71.5353)

= 825.80 kgf/cm

Stress Computation Results:

Operating

Actual

Allowed

Tangential Flange

1198.

1406.

Bolting

703.

1758.

Gasket Seating

Actual

Allowed

1035.

1406. kgf/cm

826.

1758. kgf/cm

Reqd. Blind Flange Thickness at Center

Reqd. Blind Flange Thickness at Gasket

Estimated M.A.W.P. ( Operating )

Estimated Finished Weight of Flange at given Thk.

Estimated Unfinished Weight of Forging at given Thk

45.731

42.727

41.1

81.1

81.1

mm

mm

kgf/cm

kgm

kgm

Minimum Design Metal Temperature Results:

Stress Ratio = 1.000 , Temperature Reduction per Fig. UCS 66.1 = 0 C

Min Metal Temp. w/o impact per UCS-66

Min Metal Temp per UCS-66 and UCS-68(c),PWHT credit

-39 C

-55 C

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2012

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 20

Internal Pressure Calculations :

Step:

5

1:42p Jul 14,2013

Element Thickness, Pressure, Diameter and Allowable Stress :

|

| Int. Press |

Nominal | Total Corr|

Element | Allowable |

From| To | + Liq. Hd | Thickness | Allowance |

Diameter | Stress(SE)|

|

| kgf/cm

|

mm

|

mm

|

mm

| kgf/cm

|

--------------------------------------------------------------------------CAP|

35.177 |

10.310 |

3.0000 |

323.90 |

1202.2 |

SHELL|

35.163 |

10.310 |

3.0000 |

323.90 |

1202.2 |

BODY FLANG|

35.000 |

49.300 |

3.0000 |

327.00 |

1406.1 |

BLIND|

35.000 |

49.300 |

3.0000 |

520.00 |

1406.1 |

Element Required Thickness and MAWP :

|

|

Design |

M.A.W.P. |

M.A.P. |

Minimum |

Required |

From| To |

Pressure | Corroded | New & Cold | Thickness | Thickness |

|

| kgf/cm

| kgf/cm

| kgf/cm

|

mm

|

mm

|

---------------------------------------------------------------------------CAP|

35.0000 |

55.0946 |

81.1889 |

10.3100 |

7.50420 |

SHELL|

35.0000 |

55.1013 |

78.5371 |

10.3100 |

7.68187 |

BODY FLANG|

35.0000 |

80.4502 |

82.4378 |

49.3000 |

39.2430 |

BLIND|

35.0000 |

41.0909 |

46.5889 |

49.3000 |

45.7306 |

Minimum

41.091

46.589

MAWP: 41.091 kgf/cm, limited by: BLIND.

Internal Pressure Calculation Results :

ASME Code, Section VIII, Division 1, 2010, 2011a

Elliptical Head From 10 To 20 SA-234 WPB , UCS-66 Crv. B at 90 C

CAP

Longitudinal

Joint:

Circumferential Joint:

Material UNS Number:

Seamless

Full Radiography per UW-11(a) Type 1

K03006

Required Thickness due to Internal Pressure [tr]:

= (P*Do*Kcor)/(2*S*E+2*P*(Kcor-0.1)) per Appendix 1-4 (c)

= (35.177*323.9000*0.975)/(2*1202.25*1.00+2*35.177*(0.97-0.1))

= 4.5042 + 3.0000 = 7.5042 mm

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Less Operating Hydrostatic Head Pressure of 0.177 kgf/cm

= (2*S*E*t)/(Kcor*Do-2*t*(Kcor-0.1)) per Appendix 1-4 (c)

= (2*1202.25*1.00*7.3100)/(0.975*323.9000-2*7.3100*(0.97-0.1))

= 58.015 - 0.177 = 57.838 kgf/cm

Maximum Allowable Pressure, New and Cold [MAPNC]:

= (2*S*E*t)/(K*Do-2*t*(K-0.1)) per Appendix 1-4 (c)

= (2*1202.25*1.00*10.3100)/(1.000*323.9000-2*10.3100*(1.000-0.1))

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 21

Internal Pressure Calculations :

Step:

5

1:42p Jul 14,2013

= 81.189 kgf/cm

Actual stress at given pressure and thickness, corroded [Sact]:

= (P*(Kcor*Do-2*t*(Kcor-0.1)))/(2*E*t)

= (35.177*(0.975*323.9000-2*7.3100*(0.975-0.1)))/(2*1.00*7.3100)

= 728.977 kgf/cm

Straight Flange Required Thickness:

= (P*Ro)/(S*E+0.4*P) + c

per Appendix 1-1 (a)(1)

= (35.177*161.9500)/(1202.25*1.00+0.4*35.177)+3.000

= 7.684 mm

Straight Flange Maximum Allowable Working Pressure:

Less Operating Hydrostatic Head Pressure of 0.170 kgf/cm

= (S*E*t)/(Ro-0.4*t) per Appendix 1-1 (a)(1)

= (1202.25 * 1.00 * 7.3100 )/(161.9500 - 0.4 * 7.3100 )

= 55.264 - 0.170 = 55.095 kgf/cm

Factor K, corroded condition [Kcor]:

= ( 2 + ( Inside Diameter/( 2 * Inside Head Depth ))^(2))/6

= ( 2 + ( 309.280/( 2 * 78.820 ))^(2))/6

= 0.974867

MDMT Calculations in the Knuckle Portion:

Govrn. thk, tg = 10.310 , tr = 5.261 , c = 3.0000 mm , E* = 1.00

Stress Ratio = tr * (E*)/(tg - c) = 0.720 , Temp. Reduction = 16 C

Min Metal Temp. w/o impact per UCS-66

Min Metal Temp per UCS-66 and UCS-68(c),PWHT credit

Min Metal Temp. at Required thickness (UCS 66.1)

-28 C

-45 C

-60 C

MDMT Calculations in the Head Straight Flange:

Govrn. thk, tg = 10.310 , tr = 5.484 , c = 3.0000 mm , E* = 1.00

Stress Ratio = tr * (E*)/(tg - c) = 0.750 , Temp. Reduction = 14 C

Min Metal Temp. w/o impact per UCS-66

Min Metal Temp per UCS-66 and UCS-68(c),PWHT credit

Min Metal Temp. at Required thickness (UCS 66.1)

-28 C

-45 C

-58 C

Cylindrical Shell From 20 To 30 SA-106 B , UCS-66 Crv. B at 90 C

SHELL

Longitudinal

Joint:

Circumferential Joint:

Material UNS Number:

Seamless

Full Radiography per UW-11(a) Type 1

K03006

Required Thickness due to Internal Pressure [tr]:

= (P*Ro) / (S*E+0.4*P) per Appendix 1-1 (a)(1)

= (35.163*161.9500)/(1202.25*1.00+0.4*35.163)

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 22

Internal Pressure Calculations :

Step:

5

1:42p Jul 14,2013

= 4.6819 + 3.0000 = 7.6819 mm

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Less Operating Hydrostatic Head Pressure of 0.163 kgf/cm

= (S*E*t)/(Ro-0.4*t) per Appendix 1-1 (a)(1)

= (1202.25*1.00*7.3100)/(161.9500-0.4*7.3100)

= 55.264 - 0.163 = 55.101 kgf/cm

Maximum Allowable Pressure, New and Cold [MAPNC]:

= (S*E*t)/(Ro-0.4*t) per Appendix 1-1 (a)(1)

= (1202.25*1.00*10.3100)/(161.9500-0.4*10.3100)

= 78.537 kgf/cm

Actual stress at given pressure and thickness, corroded [Sact]:

= (P*(Ro-0.4*t))/(E*t)

= (35.163*((161.9500-0.4*7.3100))/(1.00*7.3100)

= 764.954 kgf/cm

Minimum Design Metal Temperature Results:

Govrn. thk, tg = 10.310 , tr = 5.482 , c = 3.0000 mm , E* = 1.00

Stress Ratio = tr * (E*)/(tg - c) = 0.750 , Temp. Reduction = 14 C

Min Metal Temp. w/o impact per UCS-66

Min Metal Temp per UCS-66 and UCS-68(c),PWHT credit

Min Metal Temp. at Required thickness (UCS 66.1)

-28 C

-45 C

-58 C

Note: Heads and Shells Exempted to -20F (-29C) by paragraph UG-20F

Hydrostatic Test Pressure Results:

Pressure

Pressure

Pressure

Pressure

Pressure

per

per

per

per

per

UG99b

UG99b[34]

UG99c

UG100

PED

=

=

=

=

=

1.3 * M.A.W.P. * Sa/S

1.3 * Design Pres * Sa/S

1.3 * M.A.P. - Head(Hyd)

1.1 * M.A.W.P. * Sa/S

1.43 * MAWP

53.418

45.500

60.484

45.200

58.760

kgf/cm

kgf/cm

kgf/cm

kgf/cm

kgf/cm

Horizontal Test performed per: UG-99c

Please note that Nozzle, Shell, Head, Flange, etc MAWPs are all considered

when determining the hydrotest pressure for those test types that are based

on the MAWP of the vessel.

Stresses on Elements due to Hydrostatic Test Pressure:

From To

CAP

SHELL

Stress

896.1

926.4

Allowable

2214.7

2214.7

Ratio

0.405

0.418

Pressure

60.52

60.52

Elements Suitable for Internal Pressure.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2012

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 23

Element and Detail Weights :

Step:

7

1:42p Jul 14,2013

Element and Detail Weights

|

|

Element |

Element | Corroded |

Corroded | Extra due |

From| To | Metal Wgt. | ID Volume |Metal Wgt. | ID Volume | Misc %

|

|

|

kgm

|

m

|

kgm

|

m

|

kgm

|

--------------------------------------------------------------------------10| 20|

14.6003 | 0.0082205 |

10.3519 | 0.0086223 |

0.73002 |

20| 30|

125.954 |

0.11285 |

90.1586 |

0.11736 |

6.29772 |

30| 40|

59.2850 |

... |

59.2850 |

... |

2.96425 |

40| 50|

81.1458 |

... |

81.1458 |

... |

4.05729 |

--------------------------------------------------------------------------Total

280

0.12

240

0.13

14

Weight of Details

|

| Weight of | X Offset, | Y Offset, |

From|Type|

Detail | Dtl. Cent. |Dtl. Cent. | Description

|

|

kgm

|

mm

|

mm

|

------------------------------------------------10|Liqd|

8.57087 |

... | -37.9100 |

FLUID1

10|Nozl|

9.27871 |

... | -75.8200 |

N6

10|Nozl|

7.58853 |

100.000 | -56.9971 |

N3

20|Liqd|

117.664 |

... |

800.000 |

FLUID2

20|Nozl|

5.39509 |

181.802 |

1390.00 |

N1

20|Nozl|

5.39509 |

181.802 |

135.000 |

N2

20|Legs|

24.5040 |

... | -300.000 |

LEGS

20|Wght|

14.0000 |

... |

200.000 |

SUPPORT

20|Wght|

300.000 |

... |

733.000 |

FILTER

30|Liqd|

... |

... |

36.5000 |

FLUID3

40|Nozl|

5.36055 |

... |

1200.00 |

N5

Total Weight of Each Detail Type

Total Weight of Liquid

126.2

Total Weight of Nozzles

33.0

Total Weight of Legs

24.5

Total Weight of Weights

314.0

--------------------------------------------------------------Sum of the Detail Weights

497.8 kgm

Weight Summation

Fabricated

Shop Test

Shipping

Erected

Empty

Operating

-----------------------------------------------------------------------------295.0

366.6

295.0

366.6

295.0

366.6

...

123.9

...

...

...

126.2

33.0

...

33.0

...

...

...

24.5

...

24.5

...

...

...

...

...

...

...

...

300.0

...

...

...

...

...

...

...

...

...

...

33.0

...

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 24

Element and Detail Weights :

Step:

7

1:42p Jul 14,2013

14.0

...

14.0

...

24.5

...

...

...

...

...

14.0

...

-----------------------------------------------------------------------------366.6

490.5

366.6

366.6

366.6

792.8 kgm

Miscellaneous Weight Percent: 5.0 %

Note that the above value for the miscellaneous weight percent has

been applied to the shells/heads/flange/tubesheets/tubes etc. in the

weight calculations for metallic components.

Note: The shipping total has been modified because some items have

been specified as being installed in the shop.

Weight Summary

Fabricated Wt. Shop Test Wt.

Shipping Wt.

Erected Wt.

Ope. Wt. no Liq Operating Wt.

Field Test Wt. Mass of the Upper

Bare Weight W/O Removable Internals

Fabricated Weight + Water ( Full )

Fab. Wt + Rem. Intls.+ Shipping App.

Fab. Wt + Rem. Intls.+ Insul. (etc)

Fab. Wt + Intls. + Details + Wghts.

Empty Wt + Operating Liq. Uncorroded

Empty Weight + Water (Full)

1/3 of the Vertical Vessel

366.6

490.5

366.6

366.6

366.6

792.8

490.5

235.0

kgm

kgm

kgm

kgm

kgm

kgm

kgm

kgm

Outside Surface Areas of Elements

|

|

Surface

|

From| To |

Area

|

|

|

cm

|

---------------------------10| 20|

1808.81 |

20| 30|

16281.0 |

30| 40|

2462.34 |

40| 50|

2929.10 |

--------------------------Total

23481.244 cm

Element and Detail Weights

| To | Total Ele.| Total. Ele.|Total. Ele.| Total Dtl.| Oper. Wgt. |

From| To | Empty Wgt.| Oper. Wgt.|Hydro. Wgt.| Offset Mom.| No Liquid |

|

|

kgm

|

kgm

|

kgm

|

kgf-m.

|

kgm

|

--------------------------------------------------------------------------10| 20|

32.1976 |

40.7685 |

40.6131 |

0.75885 |

32.1976 |

20|Legs|

19.6303 |

71.8383 |

34.0718 |

0.24521 |

57.1303 |

Legs| 30|

137.412 |

502.868 |

238.503 |

1.71647 |

399.912 |

30| 40|

62.2492 |

62.2492 |

62.2492 |

... |

62.2492 |

40| 50|

90.5636 |

90.5636 |

90.5636 |

... |

90.5636 |

Cumulative Vessel Weight

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 25

Element and Detail Weights :

Step:

7

1:42p Jul 14,2013

|

| Cumulative Ope | Cumulative | Cumulative |

From| To | Wgt. No Liquid | Oper. Wgt. | Hydro. Wgt. |

|

|

kgm

|

kgm

|

kgm

|

------------------------------------------------------10| 20|

... |

... |

... |

20|Legs|

-32.1976 |

-40.7685 |

-40.6131 |

Legs| 30|

552.725 |

655.681 |

391.315 |

30| 40|

152.813 |

152.813 |

152.813 |

40| 50|

90.5636 |

90.5636 |

90.5636 |

Note: The cumulative operating weights no liquid in the column above

are the cumulative operating weights minus the operating liquid

weight minus any weights absent in the empty condition.

Cumulative Vessel Moment

|

| Cumulative | Cumulative |Cumulative |

From| To | Empty Mom. | Oper. Mom. |Hydro. Mom.|

|

|

kgf-m.

|

kgf-m.

| kgf-m.

|

------------------------------------------------10| 20|

0.75885 |

0.75885 |

0.75885 |

20|Legs|

1.00406 |

1.00406 |

1.00406 |

Legs| 30|

1.71647 |

1.71647 |

1.71647 |

30| 40|

... |

... |

... |

40| 50|

... |

... |

... |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2012

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 26

Nozzle Flange MAWP :

Step:

8

1:42p Jul 14,2013

Nozzle Flange MAWP Results :

Nozzle

Description

----- Flange Rating

Operating

Ambient

Temperature

Class

Grade|Group

kgf/cm

kgf/cm

C

---------------------------------------------------------------------------N6

48.2

52.1

90

300

GR 1.1

N3

48.2

52.1

90

300

GR 1.1

N1

48.2

52.1

90

300

GR 1.1

N2

48.2

52.1

90

300

GR 1.1

N5

48.2

52.1

90

300

GR 1.1

---------------------------------------------------------------------------Minimum Rating

48.2

52.1 kgf/cm

Note: ANSI Ratings are per ANSI/ASME B16.5 2009 Metric Edition

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2012

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 27

Wind Load Calculation :

Step:

10

1:42p Jul 14,2013

Input Values:

Wind Design Code

ASCE-7 98/02/05/IBC-03/STS-1

Basic Wind Speed

[V]

33.100

Surface Roughness Category

C: Open Terrain

Importance Factor

1.0

Type of Surface

Moderately Smooth

Base Elevation

10000.

Percent Wind for Hydrotest

33.0

Using User defined Wind Press. Vs Elev.

N

Height of Hill or Escarpment

H or Hh

0.0000

Distance Upwind of Crest

Lh

0.0000

Distance from Crest to the Vessel

x

0.0000

Type of Terrain ( Hill, Escarpment )

Flat

Damping Factor (Beta) for Wind (Ope)

0.0100

Damping Factor (Beta) for Wind (Empty)

0.0000

Damping Factor (Beta) for Wind (Filled)

0.0000

m/sec

mm

mm

mm

mm

Wind Analysis Results

Static Gust-Effect Factor, Operating Case [G]:

= min(0.85, 0.925((1 + 1.7 * gQ * Izbar * Q )/( 1 + 1.7 * gV * Izbar)))

= min(0.85,0.925((1+1.7*3.400*0.228*0.978)/(1+1.7*3.400*0.228)))

= min(0.85, 0.913 )

= 0.850

Natural Frequency of Vessel (Operating)

Natural Frequency of Vessel (Empty)

Natural Frequency of Vessel (Test)

10.877 Hz

11.647 Hz

13.467 Hz

Note: Per Section 1609 of IBC 2003/06/09 these results are also applicable

for the determination of Wind Loads on structures (1609.1.1).

User Entered Importance Factor is

Force Coefficient

Structure Height to Diameter ratio

Height to top of Structure

1.000

[Cf] 0.568

5.108

1717.300 mm

This is classified as a rigid structure. Static analysis performed.

Sample Calculation for the First Element

The ASCE code performs all calculations in Imperial Units

only. The wind pressure is therefore computed in these units.

Value of [Alpha] and [Zg]:

Exposure Category: C from Table C6-2

Alpha = 9.500 : Zg = 274320.000 mm

Effective Height [z]:

= Centroid Height + Vessel Base Elevation

= 83.924 + 10000.000 = 10083.924 mm

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 28

Wind Load Calculation :

Step:

10

1:42p Jul 14,2013

= 33.084 ft. Imperial Units

Velocity Pressure coefficient evaluated at height z [Kz]:

Because z (33.084 ft.) > 15 ft.

= 2.01 * ( z / Zg ) ^(2 / Alpha)

= 2.01 * ( 33.084/900.000 )^(2/9.500 )

= 1.003

Type of Hill: No Hill

Wind Directionality Factor [Kd]:

= 0.95 per [6-6 ASCE-7 98][6-4 ASCE-7 02/05]

As there is No Hill Present: [Kzt]:

K1 = 0, K2 = 0, K3 = 0

Topographical Factor [Kzt]:

= ( 1 + K1 * K2 * K3 )

= ( 1 + 0.000 * 0.000 * 0.000 )

= 1.0000

Velocity Pressure evaluated at height z, Imperial Units [qz]:

= 0.00256 * Kz * Kzt * Kd * I * Vr(mph)

= 0.00256 * 1.003 * 1.000 * 0.950 * 1.000 * 74.044

= 13.4 psf [65.276 ] kgf/m

Force on the first element [F]:

= qz * G * Cf * WindArea

= 13.370 * 0.850 * 0.568 * 0.559

= 3.6 lbs. [1.6 ] kgf

Element

Hgt (z)

K1

K2

K3

Kz

Kzt

qz

mm

kgf/m

--------------------------------------------------------------------------CAP

10083.9

0.000

0.000

0.000

1.003

1.000

65.276

SHELL

10941.8

0.000

0.000

0.000

1.020

1.000

66.407

BODY FLANGE

11705.3

0.000

0.000

0.000

1.035

1.000

67.357

BLIND

11767.5

0.000

0.000

0.000

1.036

1.000

67.432

Wind Vibration Calculations

This evaluation is based on work by Kanti Mahajan and Ed Zorilla

Nomenclature

Cf

D

Df

Dr

f

f1

L

Correction factor for natural frequency

Average internal diameter of vessel mm

Damping Factor < 0.75 Unstable, > 0.95 Stable

Average internal diameter of top half of vessel mm

Natural frequency of vibration (Hertz)

Natural frequency of bare vessel based on a unit value of (D/L)(10^(4))

Total height of structure mm

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 29

Wind Load Calculation :

Step:

10

1:42p Jul 14,2013

Lc

tb

V30

Vc

Vw

W

Ws

Z

Dl

Vp

P30

Total length of conical section(s) of vessel mm

Uncorroded plate thickness at bottom of vessel mm

Design Wind Speed provided by user m/sec

Critical wind velocity m/sec

Maximum wind speed at top of structure m/sec

Total corroded weight of structure kgf

Cor. vessel weight excl. weight of parts which do not effect stiff. kgf

Maximum amplitude of vibration at top of vessel mm

Logarithmic decrement ( taken as 0.03 for Welded Structures )

Vib. Chance, <= 0.320E-06 (High); 0.320E-06 < 0.400E-06 (Probable)

wind pressure 30 feet above the base

Check other Conditions and Basic Assumptions:

#1 - Total Cone Length / Total Length < 0.5

0.000/1717.300 = 0.000

#2 - ( D / L ) * 10^(4) < 8.0 (English Units)

- ( 1.10/5.63 ) * 10^(4) = 347.448 [Geometry Violation]

Compute the vibration possibility. If Vp > 0.400E-06 no chance. [Vp]:

= W / ( L * Dr)

= 750/( 1717.30 * 309.280 )

= 0.45703E-05

Since Vp is > 0.400E-06 no further vibration analysis is required !

Wind Loads on Masses/Equipment/Piping

ID

Wind Area

Elevation

Pressure

Force

cm

mm

kgf/m

kgf

------------------------------------------------------------------------SUPPORT

0.00

10266.00

65.52

0.00

FILTER

0.00

10799.00

66.22

0.00

The Natural Frequency for the Vessel (Ope...) is 10.8771 Hz.

Wind Load Calculation

|

|

Wind |

Wind |

Wind |

Wind |

Element |

From| To |

Height |

Diameter |

Area | Pressure | Wind Load |

|

|

mm

|

mm

|

cm

|

kgf/m

|

kgf

|

--------------------------------------------------------------------------10| 20|

10083.9 |

388.680 |

519.457 |

65.2756 |

1.63843 |

20| 30|

10941.8 |

388.680 |

6218.88 |

66.4074 |

19.9552 |

30| 40|

11705.3 |

363.936 |

265.673 |

67.3571 |

0.86469 |

40| 50|

11767.5 |

363.936 |

186.699 |

67.4323 |

0.60833 |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2012

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 30

Earthquake Load Calculation :

Step:

11

1:42p Jul 14,2013

Note: Loads multiplied by the Scalar multiplier value of 0.7143

Earthquake Analysis Results

The

The

The

The

The

The

The

The

per UBC 1997

UBC Zone Factor for the Vessel is .............

Importance Factor as Specified by the User is .

UBC Force Factor as Specified by the User is ..

UBC Total Weight (W) for the Vessel is ........

UBC Total Shear (V) for the Vessel is .........

UBC Top Shear (Ft) for the Vessel is ..........

UBC Seismic Coefficient Value Ca is ...........

UBC Seismic Coefficient Value Cv is ...........

0.0750

1.250

2.900

768.3

71.0

0.0

0.120

0.180

kgf

kgf

kgf

Note: The base shear and top load printed above have been modified

by the user defined Earthquake scalar.

Calculation Steps for Computing the design Base Shear (V) per UBC 1997

Computation of V per equation (30-4):

V = Cv * I * W / ( R * T )

V = 0.180 * 1.250 * 768/( 2.900 * 0.0919 )

V = 648.4 kgf

Computation of V per equation (30-5):

V = 2.5 * Ca * I * W / R

V = 2.5 * 0.120 * 1.25 * 768/2.900

V = 99.3 kgf

The computed base shear is the minimum of V from 30-4 and 30-5.

Computation of V per equation (34-2), minimum V.

this value !

V = 0.56 * Ca * I * W

V = 0.56 * 0.120 * 1.250 * 768

V = 64.5 kgf

V cannot be less than

Total Adjusted Base Shear V:

= V * Scalar Multiplier = 99.3 * 0.7143 = 71.0 kgf

Next compute the top load per equation 30-14. The top load is

zero if the period of vibration (T) is less than 0.7 seconds.

Note:

Ft =

Ft =

Ft =

This value does not need to exceed 0.25V.

Min( 0.07 * T * V, 0.25 * V )

Min( 0.07 * 0.092 * 99 , 0.25 * 99 )

0.0 kgf

Next Sum the earthquake weights times their heights (wi*hi):

Current Sum = Prev. Sum + Wght 41. * Hght 33.000 = 1.

Current Sum = Prev. Sum + Wght 72. * Hght 266.000 = 20.

Current Sum = Prev. Sum + Wght 503. * Hght 966.000 = 506.

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 31

Earthquake Load Calculation :

Step:

11

1:42p Jul 14,2013

Current Sum = Prev. Sum + Wght 62. * Hght 1702.500 = 612.

Current Sum = Prev. Sum + Wght 91. * Hght 1691.650 = 765.

Compute the load at each level based on equation 30-15 and multiply

by the load case scalar. The sum will be the total adjusted shear.

Fx

Fx

Fx

Fx

Fx

Fx

=

=

=

=

=

=

(( V [(99.)

[(99.)

[(99.)

[(99.)

[(99.)

Ft ) * wx * hx / ( sum of ( wi * hi ))) * EqFact

* 41. * 33.000/765.]*0.7143 = 0.

* 72. * 266.000/765.]*0.7143 = 2.

* 503. * 966.000/765.]*0.7143 = 45.

* 62. * 1702.500/765.]*0.7143 = 10.

* 91. * 1691.650/765.]*0.7143 = 14.

The Natural Frequency for the Vessel (Ope...) is 10.8771 Hz.

Earthquake Load Calculation

|

| Earthquake | Earthquake |

Element |

Element |

From| To |

Height |

Weight | Ope Load |

Emp Load |

|

|

mm

|

kgf

|

kgf

|

kgf

|

-------------------------------------------------------------10| 20|

33.0000 |

40.7685 |

0.12473 |

0.084302 |

20|Legs|

266.000 |

71.8383 |

1.77167 |

0.41429 |

Legs| 30|

966.000 |

502.868 |

45.0378 |

10.5318 |

30| 40|

1702.50 |

62.2492 |

9.82578 |

8.40855 |

40| 50|

1691.65 |

90.5636 |

14.2040 |

12.1553 |

Top Load

2378.30

0

0

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2012

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 32

Wind/Earthquake Shear, Bending :

Step:

12

1:42p Jul 14,2013

The following table is for the Operating Case.

Wind/Earthquake Shear, Bending

|

| Distance to| Cumulative |Earthquake |

Wind | Earthquake |

From| To |

Support| Wind Shear |

Shear |

Bending |

Bending |

|

|

mm

|

kgf

|

kgf

|

kgf-m.

|

kgf-m.

|

--------------------------------------------------------------------------10| 20|

268.206 |

... |

... |

... |

... |

20|Legs|

100.000 |

1.63843 |

0.12473 | 0.0036140 | 0.00027513 |

Legs| 30|

700.000 |

20.5723 |

69.1923 |

13.6881 |

64.9715 |

30| 40|

1363.50 |

1.47302 |

24.0298 |

0.091573 |

1.75987 |

40| 50|

1425.65 |

0.60833 |

14.2040 |

0.015604 |

0.36433 |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2012

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 33

Wind Deflection :

Step:

13

1:42p Jul 14,2013

Wind Deflection Calculations:

The following table is for the Operating Case.

Wind Deflection

|

| Cumulative |

Centroid | Elem. End | Elem. Ang. |

From| To | Wind Shear | Deflection |Deflection | Rotation |

|

|

kgf

|

mm

|

mm

|

|

-------------------------------------------------------------10| 20|

... |

0.57048 |

0.57048 | 0.00085436 |

20|Legs|

1.63843 |

0.57052 |

0.57065 | 0.00085597 |

Legs| 30|

20.5723 |

0.57325 |

0.57717 | 0.00086013 |

30| 40|

1.47302 |

0.57695 |

0.57674 | 0.00086013 |

40| 50|

0.60833 |

0.57689 |

0.57704 | 0.00086013 |

Critical Wind Velocity for Tower Vibration

|

| 1st Crit. | 2nd Crit. |

From| To | Wind Speed | Wind Speed |

|

|

m/sec

|

m/sec

|

------------------------------------10| 20|

21.0817 |

131.761 |

20| 30|

21.0817 |

131.761 |

30| 40|

19.7396 |

123.373 |

40| 50|

19.7396 |

123.373 |

Allowable deflection at the Tower Top (Ope)( 6.000"/100ft. Criteria)

Allowable deflection : 8.587

Actual Deflection : 0.577 mm

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2012

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 34

Center of Gravity Calculation :

Step:

18

1:42p Jul 14,2013

Shop/Field Installation Options :

Note : The CG is computed from the first Element From Node

Center

Center

Center

Center

Center

of

of

of

of

of

Gravity

Gravity

Gravity

Gravity

Gravity

of

of

of

of

of

Liquid

Nozzles

Legs

Added Weights (Operating)

Added Weights (Empty)

804.628

701.647

-234.000

775.236

266.000

mm

mm

mm

mm

mm

Center of Gravity of Bare Shell New and Cold

Center of Gravity of Bare Shell Corroded

1220.357 mm

1294.580 mm

Vessel CG in the Operating Condition

Vessel CG in the Fabricated (Shop/Empty) Condition

907.056 mm

1039.961 mm

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2012

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 35

Leg Check, (Operating Case) :

Step:

19

1:42p Jul 14,2013

RESULTS FOR LEGS :

Operating Case

Description:

LEGS

Legs attached to: SHELL

Section Properties :

Single Angle L2X2X0.2500

USA AISC 1989 Steel Table

Overall Leg Length

Effective Leg Length

Distance Leg Up Side

Number of Legs

Cross Sectional Area

Section Inertia

(

Section Inertia

(

Section Modulus

(

Section Modulus

(

Radius of Gyration (

Radius of Gyration (

Leglen

of Vessel

Nleg

Aleg

for L2X2X0.2500

strong axis )

weak

axis )

strong axis )

weak

axis )

strong axis )

weak

axis )

1000.000

870.000

200.000

4

6.052

14.485

14.485

4047.604

4047.604

15.469

15.469

mm

mm

mm

cm

cm**4

cm**4

mm

mm

mm

mm

Leg Orientation - Diagonal

Overturning Moment at top of Legs

Total Weight Load at top of Legs

Total Shear force at top of Legs

Additional force in Leg due to Bracing

Occasional Load Factor

Effective Leg End Condition Factor

W

Fadd

Occfac

k

65.0

769.5

71.0

0.0

1.333

1.000

kgf-m.

kgf

kgf

kgf

Note: The Legs are Not Cross Braced

The Leg Shear Force includes Wind and Seismic Effects

Pad Width along Circumference

Pad Length along Vessel Axis

Pad Thickness

C11P

C22P

Tpad

Maximum Shear at top of one Leg [Vleg]:

= ( Max(Wind, Seismic) + Fadd ) * ( Imax / Itot )

= ( 71.0 + 0.0 ) * ( 23.0/57.87 )

= 28.16 kgf

Axial Compression, Leg futhest from N.A. [Sma]

= ((W/Nleg)+(Mleg/(Nlegm*Rn)))/Aleg)

= ((769 / 4 ) + (64 /( 2 * 188.32 )))/ 6.052 )

= 60.29 kgf/cm

Axial Compression, Leg closest to

= ( W / Nleg ) / Aleg

= ( 769 / 4 ) / 6.052

= 31.79 kgf/cm

N.A. [Sva]

Computing Principal Axis and Inertias for Angle.

100.000

150.000

10.310

mm

mm

mm

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 36

Leg Check, (Operating Case) :

Step:

19

1:42p Jul 14,2013

Leg lengths and thickness:

Distance to geometric centroid:

Arm about YY:

Arm about ZZ:

Leg areas:

Geometric inertia components YY:

Geometric inertia components ZZ:

Geometric inertias Iy & Iz:

Product of inertia:

Mohrs Radius:

Average Inertia:

50.800

15.037

11.862

10.363

3.2258

4.6472

10.402

14.468

84981.

5.1858

14.468

QFACT =

1.0000

FBZ

=

Principal Axis Inertias (Z&W)

=

Angle to Principal Axis

=

Distances to extreme fibers CW & CZ =

FOB from Eq 5-5

=

Bending allowables Fby & Fbz

=

50.800

15.037

13.538

11.862

2.8226

9.8207

4.0663

14.468

1.5358

5.9698

45.000

35.921

14.497

1.5358

6.3500

22.966

14.656

1.5358

Shear Center Coordinates Wo & Zo:

16.187

0.0000

Values for Elastic Flexural-Torsional Buckling Stress:

E,

G,

J,

R0:

29500.

11346.

0.19542E-01

AREA, LENGTH, Kw, Kz:

0.93800

34.252

1.0000

H,

Few,

Fez, Fej:

0.64600

145.98

37.947

Fe computed from C4-1:

106.10

Initial (Kl/r)max, & (Kl/r)equiv

Final (Kl/r)max, & Cc

Fa based on Eq 4-1

Weak Axis Bending

Strong Axis Bending

Axial Compression

:

:

:

UNITY CHECKS ARE: H1-1

H1-2

H1-3

AISC Unity Check :

=

=

=

Actual

425.32

270.97

60.29

87.594

87.594

0.96871

Allowable

2047.16

2047.16

1291.29

1.1473

1.0000

206.04

52.384

132.64

kgf/cm

kgf/cm

kgf/cm

0.000

0.000

0.387

0.387 Should be <= to 1

WRC 107 Stress Analysis for Leg to Shell Junction, Ope Condition

Rectangular Attachment Parameter

Rectangular Attachment Parameter

Input Echo, WRC107 Item

1,

Diameter Basis for Vessel

Cylindrical or Spherical Vessel

Internal Corrosion Allowance

Vessel Diameter

Vessel Thickness

C11

C22

71.842

130.950

mm

mm

Description: LEGS

Vbasis

Cylsph

Cas

Dv

Tv

ID

Cylindrical

3.0000 mm

303.280 mm

10.310 mm

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 37

Leg Check, (Operating Case) :

Step:

19

1:42p Jul 14,2013

Design Temperature

90.00

Attachment Type

Parameter C11

Parameter C22

Type

C11

C22

Thickness of Reinforcing Pad

Pad Parameter C11P

Pad Parameter C22P

Tpad

C11p

C22p

10.310

100.000

150.000

Dp

35.000

No

Vx

Vy

Vz

Nx

Ny

Nz

0.000

1.000

0.000

1.000

0.000

0.000

Fx

Fy

Fz

Mx

My

Mz

0.0

192.4

0.0

0.0

0.0

5.1

kgf

kgf

kgf

kgf-m.

kgf-m.

kgf-m.

35.00

No

kgf/cm

Fx

Fy

Fz

Mx

My

Mz

28.2

172.5

0.0

0.0

0.0

16.8

kgf

kgf

kgf

kgf-m.

kgf-m.

kgf-m.

Pvar

0.00

Design Internal Pressure

Include Pressure Thrust

Vessel

Vessel

Vessel

Nozzle

Nozzle

Nozzle

Centerline

Centerline

Centerline

Centerline

Centerline

Centerline

Global

Global

Global

Global

Global

Global

Force

Force

Force

Moment

Moment

Moment

Direction

Direction

Direction

Direction

Direction

Direction

Cosine

Cosine

Cosine

Cosine

Cosine

Cosine

(SUS)

(SUS)

(SUS)

(SUS)

(SUS)

(SUS)

Internal Pressure (SUS)

Include Pressure Thrust

Global

Global

Global

Global

Global

Global

Force

Force

Force

Moment

Moment

Moment

(OCC)

(OCC)

(OCC)

(OCC)

(OCC)

(OCC)

Occasional Internal Pressure (OCC)

Use Interactive Control

WRC107 Version

Version

Include Pressure Stress Indices per Div. 2

Compute Pressure Stress per WRC-368

WRC 107 Stress Calculation for SUStained loads:

Radial Load

P

Circumferential Shear

VC

Longitudinal Shear

VL

Circumferential Moment

MC

Rectangular

71.84 mm

130.95 mm

No

March

mm

mm

mm

kgf/cm

kgf/cm

1979

No

No

0.0

0.0

192.4

0.0

kgf

kgf

kgf

kgf-m.

PV Elite 2012 Licensee: MSET ENGINEERING SDN BHD

FileName : S3-1301

--------------------------------------- Page 38

Leg Check, (Operating Case) :

Step:

19

1:42p Jul 14,2013

Longitudinal Moment

Torsional Moment

ML

MT

Dimensionless Parameters used :

Gamma =

-5.1

0.0

kgf-m.

kgf-m.

9.28

Dimensionless Loads for Cylindrical Shells at Attachment Junction:

------------------------------------------------------------------Curves read for 1979

Beta Figure

Value

Location

------------------------------------------------------------------N(PHI) / ( P/Rm )

0.382

4C

1.335

(A,B)

N(PHI) / ( P/Rm )

0.382

3C

0.942

(C,D)

M(PHI) / ( P )

0.275

2C1

0.061

(A,B)

M(PHI) / ( P )

0.275

1C

0.085

(C,D)

N(PHI) / ( MC/(Rm**2 * Beta) )

0.268

3A !

0.322

(A,B,C,D)

M(PHI) / ( MC/(Rm

* Beta) )

0.294

1A

0.090

(A,B,C,D)

N(PHI) / ( ML/(Rm**2 * Beta) )

0.328

3B !

1.132

(A,B,C,D)

M(PHI) / ( ML/(Rm

* Beta) )

0.314

1B

0.033

(A,B,C,D)

N(x)

N(x)

M(x)

M(x)

N(x)

M(x)

N(x)

M(x)

/

/

/

/

/

/

/

/

(

(

(

(

(

(

(

(

P/Rm )

P/Rm )

P )

P )

MC/(Rm**2

MC/(Rm

ML/(Rm**2

ML/(Rm

*

*

*

*

Beta)

Beta)

Beta)

Beta)

)

)

)

)

0.332

0.332

0.341

0.341

0.268

0.362

0.328

0.364

3C

4C

1C1

2C

4A !