Académique Documents

Professionnel Documents

Culture Documents

MST

Transféré par

ParthrajPuranikDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MST

Transféré par

ParthrajPuranikDroits d'auteur :

Formats disponibles

Modern spinning technology

Course Code: 3362901

GUJARAT TECHNOLOGICAL UNIVERSITY, AHMEDABAD, GUJARAT

COURSE CURRICULUM

COURSE TITLE: - MODERN SPINNING TECHNOLOGY

(COURSE CODE: 3362901)

Diploma Programme in which this courses offered

TEXTILE MANUFACTURING TECHNOLOGY

Semester

in

which

offered

SIXTH SEMESTER

1.RATIONALE:

Although ring spinning has the advantage over earlier systems of higher production speeds

and consequently reduced labour costs, the largest size of yarn package that could be built

was limited by the ring size. Further the ring size limited also the traveller speed and thereby

the spindle speed. Modern spinning technology has a number of advantages, over the ring

spinning technology, such as, increased spinning speed, absence of spinning preparatory

machines, like, speed frames, draw frames, etc., as well as, absence of certain, post spinning

operations, like, cheese/ cone winding, etc., which are needed, in case of ring spinning.

Because of the absence of some, preparatory and post spinning operations, as well as high

output per machine, Modern spinning machines give a substantial, saving in labour cost.

This course aims to provide awareness about modern technologies to the students.

2.COMPETENCY

The course content should be taught and implemented with the aim to achieve different types

of skills leading to the achievement of the following competency:

Supervise production process of Modern Spinning Line to achieve targeted production

by maintaining process parameters.

3.Course Outcomes:

i. Use Open end spinning processes.

ii. Utilise open end spinning process and equipment for production of yarn.

iii.Utilise friction spinning process and equipment for production of yarn.

iv.Use modern spinning like- Air jet spinning, Cover spinning, Twistless spinning (Bobtex,

Twillo, Faciated), Siro-spinning, Self twisted, etc for yarn production.

v. Operate and maintain modern blow rooms.

vi. Operate and maintain polyester fibre spinning units.

vii. Use information technology in spinning.

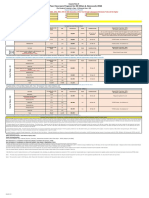

4. TEACHING AND EXAMINATION SCHEME

Teaching Scheme

(In Hours)

L

3

T

0

P

2

GTU/ NITTTR Bhopal/14-15

Total Credits

(L+T+P)

C

5

Examination Scheme

Theory Marks Practical Marks

ESE

70

PA

30

ESE

20

PA

30

Total

Marks

150

Gujarat State

Modern spinning technology

Course Code: 3362901

Legends: L-Lecture; T Tutorial/Teacher Guided Student Activity; P -Practical; C Credit;;

ESE -End Semester Examination; PA - Progressive Assessment.

5. DETAILED COURSE CONTENTS

Unit

Unit I

Introduction

to Open-end

spinning.

Major Learning Outcomes

1.a Explain limitations of

Ring spinning

2.a Describe principle and

advantages of O.E.

spinning

3.a Describe different basic

methods of O.E. spinning

Topics and Sub-topics

1.1 Limitation of ring spinning.

1.2 Principle of open end spinning.

1.3 Advantages of open end spinning

1.4 Basic methods of O.E. spinning

a. Vortex assembly

b. Axial assembly

c. Discontinuous assembly

d. Friction spinning

e. Rotor spinning

Unit II

Rotor

spinning.

2.a Describe Rotor Spinning

principle.

2.b Explain important

functions of Rotor

spinning m/c

2.c Explain operations of

Rotor.

2.d Describe properties,

advantages and

disadvantages of Rotor

spun yarn

2.e Describe General features

of Rotor machine and

calculation

2.1 Introduction to development of Rotor

spinning.

2.2 Principles of operation.

2.3 Sliver preparation for open end spinning.

2.4 Functions of important parts of the Rotor

spinning machine.

2.5 fibre opening, fibre transfer & twistinsertion in rotor spinning.

2.6 Detail study of rotor.

2.7 Properties of Rotor spun yarn.

2.8 Advantages and disadvantages of Rotor

spun yarn.

2.9 General features of modern rotor spinning

machine.

2.10 Calculation for production, draft & twist

Unit III

Friction

spinning.

3.a Describe principle and

different types of friction

spg. Machines.

3.b Describe properties of

friction spun yarn

3.1 Principle of operation.

3.2 Different types of friction spinning

machines : (Dref-I, Dref -II, Dref-III,

P.S.L.)

3.3 Properties of friction spun yarn.

Unit IV

Other

Modern

Spinning

System

4.a Describe various modern

spinning systems and

properties of yarn

4.1 Outline of various spinning systems and

properties of yarn.

a. Air jet spinning

b. Cover spinning

c. Twistless spinning (Bobtex,

Twillo, Faciated)

d. Siro-spinning

e. Self twisted

Unit V

Modern

development

s in Blow

5.a Describe Chute feed

systems

5.b Describe Auto leveller in

Card and Draw frame

GTU/ NITTTR Bhopal/14-15

5.1 Chute feed systems.

5.2 Auto leveller in Card & Draw frame.

5.3 Developments in B.R., card, draw frame,

comber, speed frame & ring frame -Ring

Gujarat State

Modern spinning technology

Unit

room to

Ring frame.

Major Learning Outcomes

5.c Describe modern

developments in B.R. to

Ring frame

Unit VI

Processing

of Polyester

on

conventional

spinning

6.a Describe Machine

sequences and process

parameters of polyester

fibre spinning.

Unit VII

Use of

Information

Technology

in Spinning

7.a Explain application of

Information technology In

Spinning Technology

Course Code: 3362901

Topics and Sub-topics

can system.

6.1 Introduction for polyester fibre spinning

6.2 Brief study of basic requirement of polyester

fibre spinning.

6.3 Machine sequences and process parameter

used for polyester fibre spinning.

7.1 Micro processors controls used for modern

spinning.

6. SUGGESTED SPECIFICATION TABLE WITH HOURS & MARKS (THEORY):

Unit

No.

Unit Title

1

2

3

4

5

Introduction to Open-end spinning.

Rotor spinning.

Friction spinning.

Other Modern Spinning System

Modern developments in Blow room

to Ring frame.

Processing of Polyester on

conventional spinning

Use of Information Technology in

Spinning

6

7

Total

Teach

ing

Hours

08

12

04

04

08

Distribution of Theory Marks

(Duration 2.5 Hours)

R

U

A

Total

Level

Level Level

02

10

02

14

04

18

02

24

01

05

01

07

02

10

02

14

04

02

03

01

07

02

01

02

01

04

42

12

40

13

70

Legends:

R = Remembrance; U= Understanding; A= Application and above levels (Revised Blooms

taxonomy)

7. SUGGESTED LIST OF EXERCISES / PRACTICALS:

The practical/exercises should be properly designed and implemented with an attempt to

develop different types of cognitive and practical skills (Outcomes in cognitive,

psychomotor and affective domain) so that students are able to acquire the competencies.

Following is the list of practical exercises for guidance.

Note: Here only outcomes in psychomotor domain are listed as practical/exercises. However,

if these practical/exercises are completed appropriately, they would also lead to development

GTU/ NITTTR Bhopal/14-15

Gujarat State

Modern spinning technology

Course Code: 3362901

of Programme Outcomes/Course Outcomes in affective domain as given in a common list at

the beginning of curriculum document for this programme. Faculty should refer to that

common list and should ensure that students also acquire those Programme

Outcomes/Course Outcomes related to affective domain

S. No. Unit

No.

1

2

3

4

5

6

I

II

II

II

II

II

III

9

10

11

IV

IV

IV

12

13

14

Experiment/Tutorial

Find out important features of Open End

Spinning assembly.

Draw sketches of different open end Systems.

Draw passage of material in Rotor spinning.

Set the yarn production on Rotor spinning

Set the various devices in Rotor spinning.

Set the draft, twist and speed in Rotor spinning.

Calculate Production, TPI, & back doubling&

Draft of rotor spinning machine

Draw passage of material of Friction spinning.

DREF-I, DREF-II, DREF-III, P.S.L.

Draw sketch of Air jet spinning..

Draw sketch of Cover spinning process

Draw sketch of Twistless spinning.

Discover important features of Modern Blow

room machine and chute feeding.

Discover important features of Modern Carding,

Combing, Draw frame, Fly frame and Ring frame

process.

Draw sketch of type of auto levelers & Describe

the important features of Auto levelers in card &

draw frame.

No of Hours

02

02

02

02

02

02

02

02

02

02

02

02

02

02

8. SUGGESTED LIST OF STUDENT ACTIVITIES

Following is the list of proposed student activities like: course/topic based seminars, internet

based assignments, teacher, guided self learning activities, course/library/internet/lab based

mini-projects---etc.

1. Prepare journals based on practical performed in laboratory

2. Literature survey of Modern spinning Technology.

3. Collection of Sample of Technical Textiles.

4. Visit to Modern spinning textile industry & preparing report with sketches.

9. SPECIAL INSTRUCTIONAL STRATEGIES (if any)

Educational video & CDs

Prepare Sample Charts

GTU/ NITTTR Bhopal/14-15

Gujarat State

Modern spinning technology

Course Code: 3362901

10.SUGGESTED LEARNING RESOURCES

A. List of Books

S.No.

Author

Title of Books

Publication

Oxtoby

Spun Yarn Technology

Nield

Open-End Sinning

C.A. Lawrence and

K.Z. Chen

Rotor Spinning

W.Klein

Short Staple Spinning - vol. I-VI

Butterworths

Publication

The Textile Institute

(August 1975)

The Textile Institute,

Textile Progress

Vol.13,

The Textile Institute

R. V. MAHENDRA

GOWDA

W.Klein

New Spinning System

NCUTE

Open-End Spinning

The Textile Institute

B. List of Major Equipment/ Instrument

S.No.

1

Machine Name

Rotor Spinning

Machine

DREF Spinning

GTU/ NITTTR Bhopal/14-15

Specification

Number of Spinning position up to : 220

Range of yarn linear density: 12 125 tex, 8-80 Nm,

5-50 Ne

Draft: 25 to 400

Opening roller Speed: 6000 to 11000 rpm

Rotor speed: up to 150000 rpm

Rotor Diameter: 32 65 mm

Delivery speed: up to 200 mpm

Winding angle: 29 to 45

Package (Mass): up to 5 kg

DREF-2

Number of Spinning position : 6 to 48

Count Range : 120 3300 tex, 0.18 -5 Ne

Raw Material: Wool / bast Fiber / Synthetic fiber

Delivery speed: 280 mpm

Feed stock : Card Sliver

Yarn type : Normal OE yarn

DREF-3

Number of Spinning position : 12 to 96

Count Range : 33 165 tex, 3.5 -18 Ne

Raw Material: Cotton / Synthetic fiber

Delivery speed: 300 mpm

Feed stock : Draw Fame Sliver

Yarn type : Bundle Yarn

Gujarat State

Modern spinning technology

Course Code: 3362901

C. LIST OF SOFTWARE /LEARNING WEBSITESSearching engine could be used to locate textile related sites

A. http://www.rieter.com/cz/rikipedia/articles/rotor-spinning/the-importance-of-rotorspinning/the-principle-of-rotor-spinning/

B. http://nptel.ac.in/courses/116102038/new%20spinning%20systems/rotor%20spinning1.htm

C. http://textilelearner.blogspot.in/2013/02/an-overview-of-developments-in-yarn.html

D. http://www.indiantextilejournal.com/articles/FAdetails.asp?id=2010

E. http://textiletodaybd.com/magazine/printable.php?id=371

F. http://www.rieter.com/cz/rikipedia/articles/fibre-preparation/the-blowroom/summary-ofthe-process/the-blowroom-installation-as-asequence-of-machines/

G. http://www.slideshare.net/nayen/blowroom

H. http://www.rieter.com/cz/rikipedia/articles/alternative-spinning-systems/the-variousspinning-methods/open-end-spinning-processes/friction-spinning/operating-principle/

I. http://www.indiantextilejournal.com/articles/FAdetails.asp?id=4636

J. http://www.slideshare.net/aybalaozcan/aybala-te-550friction-spinning

K. http://textilelearner.blogspot.in/2011/08/high-speed-spun-yarn-productionrotor_5195.html

L. http://nptel.ac.in/courses/116102038/32

M. http://www.rieter.com/en/rikipedia/articles/technology-ofshort-staple-spinning/yarnformation/assembly-of-fibers-to-make-up-a-yarn/the-positions-of-the-fibers-in-the-yarnstructure/open-end-spun-yarns/

N. http://www.rieter.com/en/rikipedia/articles/ring-spinning/the-ring-spinningmachine/introduction/

11.COURSE CURRICULUM DEVELOPMENT COMMITTEE

Faculty Members from Polytechnics

Prof.Y.M.Gandhi , HOD Textile Manufacturing , Shri B.P.T.I, Bhavanagar

Prof.V.N. Soni , HOD Textile Manufacturing , R.C Technical Institute, Ahmedabad

Shri R T Patel, Lecturer in Textile Manufacturing, R.C Technical Institute, Ahmedabad

Shri S.P.Patel ,Lecturer in Textile Manufacturing, R C technical Institute Ahmedabad

Co-ordinator and Faculty Member from NITTTR Bhopal

Dr.C.K.Chugh, NITTTR, Bhopal, Professor and head Dept, of Electronic Media,

NITTTR, Bhopal

Prof.S.K.Gupta, NITTTR Extension Centre, Ahmedabad,

GTU/ NITTTR Bhopal/14-15

Gujarat State

Vous aimerez peut-être aussi

- User Acceptance Testing: A step-by-step guideD'EverandUser Acceptance Testing: A step-by-step guideÉvaluation : 3 sur 5 étoiles3/5 (2)

- Gujarat Technological University Textile Technology (29) : Yarn Manufacturing-I B.E. Semester IiiDocument3 pagesGujarat Technological University Textile Technology (29) : Yarn Manufacturing-I B.E. Semester IiiKagi mecPas encore d'évaluation

- M Tech (Part Time) SyllabusDocument21 pagesM Tech (Part Time) SyllabusKrishna PrasadPas encore d'évaluation

- Gujarat Technological University: W.E.F. AY 2018-19Document2 pagesGujarat Technological University: W.E.F. AY 2018-19Rushi TannaPas encore d'évaluation

- Sem 6Document51 pagesSem 6IndraniPas encore d'évaluation

- Manufacturing Practices FinalDocument65 pagesManufacturing Practices FinalRoman ReignPas encore d'évaluation

- Gujarat Technological University, Ahmedabad, Gujarat Course Curriculum Course Title: CourseDocument6 pagesGujarat Technological University, Ahmedabad, Gujarat Course Curriculum Course Title: CourseSher Hai HamPas encore d'évaluation

- Fabrication TechnologyDocument11 pagesFabrication Technologyhiren mandaliaPas encore d'évaluation

- Adobe Scan Jul 29, 2022Document6 pagesAdobe Scan Jul 29, 2022AMAR KHARATPas encore d'évaluation

- Cotton Ginning Plant OperatorDocument18 pagesCotton Ginning Plant Operatorsapphire207100% (1)

- Stenter Machine Operator CurriculumDocument5 pagesStenter Machine Operator CurriculumMohon KhanPas encore d'évaluation

- B Tech Syllabus (3-8 Semester)Document55 pagesB Tech Syllabus (3-8 Semester)ramanarya76Pas encore d'évaluation

- V de 1 Mec 314 SMF Course HandoutDocument12 pagesV de 1 Mec 314 SMF Course Handoutambika1969inPas encore d'évaluation

- Gujarat Technological University, Ahmedabad, Gujarat Course Curriculum CourseDocument5 pagesGujarat Technological University, Ahmedabad, Gujarat Course Curriculum CourseParthrajPuranikPas encore d'évaluation

- Automatic Tshirt Folding Machine Project ReportDocument65 pagesAutomatic Tshirt Folding Machine Project Reportsamadhan khaire100% (1)

- Suggested Readingsfor TextilestudentsDocument7 pagesSuggested Readingsfor TextilestudentsGurumurthy BRPas encore d'évaluation

- M - SC Garment Manufacturing Technology (GMT) (Scheme & Syllabus 1st To 4th Sem)Document105 pagesM - SC Garment Manufacturing Technology (GMT) (Scheme & Syllabus 1st To 4th Sem)Mohammad Zahirul IslamPas encore d'évaluation

- New Rich Text DocumentDocument49 pagesNew Rich Text DocumentMardiyya SuleimanPas encore d'évaluation

- TOM Manual 2022Document51 pagesTOM Manual 2022badalmewada2002Pas encore d'évaluation

- Trainee Operator Progress ChartDocument1 pageTrainee Operator Progress Chartrajurana25Pas encore d'évaluation

- Textile Technology SyllabusDocument97 pagesTextile Technology SyllabusaneeshajaiswalPas encore d'évaluation

- FF III SyllabusDocument3 pagesFF III SyllabusBinal TivarPas encore d'évaluation

- Tool and Die MakerDocument24 pagesTool and Die MakerArun ManoharPas encore d'évaluation

- 4th Semester: Ptx4I102 Yarn Manufacture - IiDocument2 pages4th Semester: Ptx4I102 Yarn Manufacture - Iilalit kashyapPas encore d'évaluation

- Plant Maintenance and Safety Course Code: 3341906Document8 pagesPlant Maintenance and Safety Course Code: 3341906Dhaval UpadhyayPas encore d'évaluation

- Elements of Textile and Garment TechnologyDocument7 pagesElements of Textile and Garment Technologypavan panwalaPas encore d'évaluation

- (2015) Einforcement Learning Approach To Learning Human Experience in Tuning Cavity FiltersDocument6 pages(2015) Einforcement Learning Approach To Learning Human Experience in Tuning Cavity FiltersAMINA AGHANIMPas encore d'évaluation

- Course File 2016-2017Document16 pagesCourse File 2016-2017sirajudeen IPas encore d'évaluation

- Digital Design Lab ManualDocument39 pagesDigital Design Lab ManualDhananjayaPas encore d'évaluation

- Manual 12Document83 pagesManual 12JAINTONYPas encore d'évaluation

- MODULE J3103: Malaysia PolytechnicsDocument17 pagesMODULE J3103: Malaysia PolytechnicsPok KuPas encore d'évaluation

- 7.project work-II On Design of Mechatronics System and Industrial VisitsDocument7 pages7.project work-II On Design of Mechatronics System and Industrial VisitsNIKHIL ASPas encore d'évaluation

- Me R13 Iv-IDocument26 pagesMe R13 Iv-IRajeshPas encore d'évaluation

- Cs6303 Lesson PlanDocument6 pagesCs6303 Lesson PlanVENKATRAMANPas encore d'évaluation

- Workshop 4Document2 pagesWorkshop 4ANKESH SHRIVASTAVAPas encore d'évaluation

- Curriculum For Certificate in Textile Machinery Repair & Maintenance (Weaving) (PDFDrive)Document41 pagesCurriculum For Certificate in Textile Machinery Repair & Maintenance (Weaving) (PDFDrive)sulzer texPas encore d'évaluation

- 63H10B02 RCDocument15 pages63H10B02 RCLo Shun FatPas encore d'évaluation

- Suryamitra Curriculum GuideDocument19 pagesSuryamitra Curriculum GuideKetan WarikooPas encore d'évaluation

- U.P Technical University, LucknowDocument9 pagesU.P Technical University, LucknowgunaPas encore d'évaluation

- Per ManualDocument144 pagesPer ManualMovith CrastoPas encore d'évaluation

- PDFDocument11 pagesPDFjaniirPas encore d'évaluation

- Machining Operations-: Cycle TimeDocument25 pagesMachining Operations-: Cycle Timenurul_mohamed_10Pas encore d'évaluation

- Industrial Engineering: End Term Jury DocumentDocument29 pagesIndustrial Engineering: End Term Jury DocumentSWAPNIL KRISHNAPas encore d'évaluation

- CPP Reportv 2024Document41 pagesCPP Reportv 202435Manish SuryawanshiPas encore d'évaluation

- Idoko Samuel Audu 2Document20 pagesIdoko Samuel Audu 2ekojamichaelPas encore d'évaluation

- AMP MicroprojectDocument20 pagesAMP Microproject130 Vipul ZopePas encore d'évaluation

- Wa0024.Document40 pagesWa0024.nnabuchichideraPas encore d'évaluation

- 10 - FCFS and SJF AlgorithmDocument28 pages10 - FCFS and SJF AlgorithmMukul GajarePas encore d'évaluation

- Manufacturing Practice - IIDocument4 pagesManufacturing Practice - IIPradip PatelPas encore d'évaluation

- Muhammad Ahad Munawar, 092, ITES - Student Workbook - Spring 2020Document208 pagesMuhammad Ahad Munawar, 092, ITES - Student Workbook - Spring 2020Durraiz ShuaibPas encore d'évaluation

- ATS-Shirt-Trouser Maker-NSQF-4Document33 pagesATS-Shirt-Trouser Maker-NSQF-4bltailors4Pas encore d'évaluation

- Production EngineeringDocument39 pagesProduction EngineeringkeepingbusyPas encore d'évaluation

- DFTDocument338 pagesDFTPriyanshu UniyalPas encore d'évaluation

- Manufacturing TechnologyDocument34 pagesManufacturing TechnologyGeorge OliverPas encore d'évaluation

- Department of Textile Technology Second Year: Proposed Scheme ForDocument13 pagesDepartment of Textile Technology Second Year: Proposed Scheme For007_tajasPas encore d'évaluation

- Final Report - Wan Ibrahim Bin Wan Mamat Me 11526 - Petronas Gas Berhad - TerengganuDocument51 pagesFinal Report - Wan Ibrahim Bin Wan Mamat Me 11526 - Petronas Gas Berhad - TerengganuWan Ibrahim Al-KutaniPas encore d'évaluation

- Syllabus 3-8th SemesterDocument56 pagesSyllabus 3-8th Semesterapi-287058159Pas encore d'évaluation

- Communication Lab ManualDocument63 pagesCommunication Lab ManualSathiya NathanPas encore d'évaluation

- Pec IvDocument6 pagesPec Iv3111hruthvikPas encore d'évaluation

- A Beginner's Guide To The Capital Market: July 12-17, 2010 An Initiative Under The Year Long Investor Awareness ProgrammeDocument30 pagesA Beginner's Guide To The Capital Market: July 12-17, 2010 An Initiative Under The Year Long Investor Awareness ProgrammemayanksaksPas encore d'évaluation

- First Steps To Investing A Beginners Guide Prithvi Haldea PDFDocument21 pagesFirst Steps To Investing A Beginners Guide Prithvi Haldea PDFnagaravikrishnadiviPas encore d'évaluation

- Gujarat Technological University, Ahmedabad, Gujarat Course Curriculum CourseDocument5 pagesGujarat Technological University, Ahmedabad, Gujarat Course Curriculum CourseParthrajPuranikPas encore d'évaluation

- Gujarat Technological University, Ahmedabad, Gujarat Course Curriculum CourseDocument5 pagesGujarat Technological University, Ahmedabad, Gujarat Course Curriculum CourseParthrajPuranikPas encore d'évaluation

- Clinical Map of Family Therapy ModelsDocument3 pagesClinical Map of Family Therapy ModelsTe-Erika87% (15)

- Sample Lesson Plan Based On 5e's For TMMAT23 2020.2021Document5 pagesSample Lesson Plan Based On 5e's For TMMAT23 2020.2021SINDAMBIWE SylverePas encore d'évaluation

- The Promise of Open EducationDocument37 pagesThe Promise of Open Educationjeremy_rielPas encore d'évaluation

- (2019) Piecewise Reproducing Kernel Method For Linear Impulsive Delay Differential Equations With Piecewise Constant ArgumentsDocument10 pages(2019) Piecewise Reproducing Kernel Method For Linear Impulsive Delay Differential Equations With Piecewise Constant ArgumentsAlejandro ChiuPas encore d'évaluation

- Activity 4 Written Assessment - BambaDocument3 pagesActivity 4 Written Assessment - BambaMatsuoka LykaPas encore d'évaluation

- 11-Foundations of GMAT VerbalDocument35 pages11-Foundations of GMAT VerbalDroea Intimates100% (1)

- Grade 7 Term 3 Learner - S WorkbookDocument21 pagesGrade 7 Term 3 Learner - S WorkbookBotle MakotanyanePas encore d'évaluation

- Mind Maps in SurgeryDocument31 pagesMind Maps in Surgerygus_lions50% (2)

- Bonafide Certificate: Head of Department SupervisorDocument10 pagesBonafide Certificate: Head of Department SupervisorSaumya mPas encore d'évaluation

- DePumpo Calling The Shots - BWS March 19, 2015Document1 pageDePumpo Calling The Shots - BWS March 19, 2015Heidi Kerr-SchlaeferPas encore d'évaluation

- FIITJEE1Document5 pagesFIITJEE1Raunak RoyPas encore d'évaluation

- Rubric For Creating Positive Learning Environment in ClassroomsDocument6 pagesRubric For Creating Positive Learning Environment in ClassroomsABD RAHMAN MAT ALIPas encore d'évaluation

- Fate MapDocument5 pagesFate MapRitesh Singh Kharwar100% (1)

- Belfiore, 2008 Rethinking The Social Impact of The Arts: A Critical-Historical ReviewDocument248 pagesBelfiore, 2008 Rethinking The Social Impact of The Arts: A Critical-Historical ReviewViviana Carolina Jaramillo Alemán100% (1)

- Implementation of Intrusion Detection Using Backpropagation AlgorithmDocument5 pagesImplementation of Intrusion Detection Using Backpropagation Algorithmpurushothaman sinivasanPas encore d'évaluation

- Architecture - Hybris Lifecycle FrameworkDocument214 pagesArchitecture - Hybris Lifecycle Frameworkrindang cahyaningPas encore d'évaluation

- T04S - Lesson Plan Unit 7 (Day 3)Document4 pagesT04S - Lesson Plan Unit 7 (Day 3)9csnfkw6wwPas encore d'évaluation

- Planning Training Sessions: Written Exam)Document13 pagesPlanning Training Sessions: Written Exam)Valerie Joy GomezPas encore d'évaluation

- Sandy Shores: Sink or FloatDocument5 pagesSandy Shores: Sink or FloatElla Mae PabitonPas encore d'évaluation

- Adaptation CardsDocument17 pagesAdaptation CardsNubar MammadovaPas encore d'évaluation

- Reading Writing Speaking Listening: in A Classroom, I Prefer ToDocument10 pagesReading Writing Speaking Listening: in A Classroom, I Prefer ToAnaJGPas encore d'évaluation

- Free PDF of Computer HardwareDocument2 pagesFree PDF of Computer HardwareKatiePas encore d'évaluation

- Tle Housekeeping 1st Module 5-Prepare Rooms For Guests (RG) Make Up Beds (For Teacher)Document21 pagesTle Housekeeping 1st Module 5-Prepare Rooms For Guests (RG) Make Up Beds (For Teacher)Kate Cornelio100% (1)

- INDOOR SPORTS CENTRES - RESEARCH v3Document66 pagesINDOOR SPORTS CENTRES - RESEARCH v3thomas.miller43995Pas encore d'évaluation

- Curriculum Vitae: Anghel-Alexandru GheneaDocument5 pagesCurriculum Vitae: Anghel-Alexandru GheneaAnghel-Alexandru GheneaPas encore d'évaluation

- Phonics Sentences Blends and Digraphs From A Teachable TeacherDocument37 pagesPhonics Sentences Blends and Digraphs From A Teachable TeacherDeepti Darak100% (4)

- 098 Southern Thailand Insurgency Not JihadDocument53 pages098 Southern Thailand Insurgency Not JihadGohar HaaziqPas encore d'évaluation

- Jamieson Knowledge and Animal Minds 1998Document25 pagesJamieson Knowledge and Animal Minds 1998Maldoror666Pas encore d'évaluation

- Insurance List Panipat 4 OCTDocument21 pagesInsurance List Panipat 4 OCTpark hospitalPas encore d'évaluation

- CSCM BrochureDocument8 pagesCSCM BrochureMd Shah AlamPas encore d'évaluation