Académique Documents

Professionnel Documents

Culture Documents

Experimental Investigation On Hybrid Steel Fiber Reinforced Concrete Beam - Column Joints Under Cyclic Loading

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Experimental Investigation On Hybrid Steel Fiber Reinforced Concrete Beam - Column Joints Under Cyclic Loading

Droits d'auteur :

Formats disponibles

Volume: 1 | Issue: 11 | December 2014 | ISSN: 2349-0845

IJRST

Experimental Investigation on Hybrid Steel Fiber

Reinforced Concrete Beam Column Joints Under

Cyclic Loading

J.Devi Keerthana1, Ch.Surendra Reddy2

1

PG Scholar, Department of Civil Engineering, Jogaiah Institute of Technology & Sciences, Palakollu, Andhra Pradesh,

Assistant Professor, Department of Civil Engineering, Jogaiah Institute of Technology & Sciences, Palakollu, Andhra Pradesh,

Article Info

ABSTRACT

Article history:

An investigation on the performance of reinforced concrete beam column

joints under cyclic loading is reported. Joints have been cast with adequate

and deficient shear capacity and bond of reinforcements at the beam column

joint. Steel Fiber Reinforced like crimped hook end have been applied on

the joints in different volume fraction and aspect ratios. The column subjected

to an axial force while the beams are subjected to cyclic load with controlled

displacement. The displacement is increased monotonically using a hydraulic

push and pull jack. The hysteretic curves of the specimen have been plotted.

The energy dissipation capacity of retrofitted beam column joints with

various hybrid steel fibres configurations has been compared. The results

show that the strengthened beam column joint exhibit increased strength,

stiffness, energy dissipation and composite action until failure.

Received Dec 12th, 2014

Accepted Dec 18th, 2014

Publication Dec 22nd , 2014

Keyword:

Hooked end,

crimpled steel fibers,

Aspect ratio

Copyright 2014 International Journal of Research in Science & Technology

All rights reserved.

Corresponding Author:

J.Devi Keerthana

PG Scholar, Department of Civil Engineering,

Jogaiah Institute of Technology & Sciences,

Palakollu, Andhra Pradesh,

keerthana.devij @gmail.com

I. INTRODUCTION

Recent earthquakes in different parts of the world have

revealed again the importance of design of reinforced

concrete structures with high ductility. Strength and ductility

of structures depend mainly on proper detailing of the

reinforcement in beam-column joints. The flow of forces

within a beam-column joint may be interrupted if the shear

strength of the joint is not adequately provided. Under

seismic excitations, the beam-column joint region is

subjected to horizontal and vertical shear forces whose

magnitudes are many times higher than those within the

adjacent beams and columns. Conventional concrete loses its

6

tensile resistance after the formation of multiple cracks.

However, fiber concrete can sustain a portion of its resistance

following cracking to resist more cycles of loading.

Beam-column joints have a crucial role in the structural

integrity of the buildings. For this reason they must be

provided with adequate stiffness and strength to sustain the

loads transmitted from beam and columns. The formation of

plastic hinges in columns must be prevented since it affects

the entire structure. For adequate ductility of beam-column

joints, use of closely spaced hoops as transverse

reinforcement was recommended in the ACI-ASCE

Committee 352 report (ACI, 2002). Due to the congestion of

reinforcement, casting of beam-column joint will be difficult

International Journal of Research in Science & Technology

Experimental Investigation on Hybrid Steel Fiber Reinforced Concrete Beam Column Joints Under Cyclic Loading

and will lead to honeycombing in concrete (Kumar et al.,

1991).

II. SIGNIFICANCE OF STUDY

Modeling An FRC sub-category named Engineered

Cementitious Composite (ECC) claims 500 times more

resistance to cracking and 40 percent lighter than traditional

concrete.[citation needed] ECC claims it can sustain

strain-hardening up to several percent strain, resulting in a

material ductility of at least two orders of magnitude higher

when compared to normal concrete or standard

fiber-reinforced concrete. ECC also claims a unique cracking

behavior. When loaded to beyond the elastic range, ECC

maintains crack width to below 100 m, even when deformed

to several percent tensile strains. Field results with ECC and

The Michigan Department of Transportation resulted in

early-age cracking.

Recent studies performed on a high-performance

fiber-reinforced concrete in a bridge deck found that adding

fibers provided residual strength and controlled cracking.

There were fewer and narrower cracks in the FRC even

though the FRC had more shrinkage than the control.

Residual strength is directly proportional to the fiber content.

A new kind of natural fiber-reinforced concrete (NFRC)

made of cellulose fibers processed from genetically modified

slash pine trees is giving good results [citation needed]. The

cellulose fibers are longer and greater in diameter than other

timber sources. Some studies were performed using waste

carpet fibers in concrete as an environmentally friendly use

of recycled carpet waste. A carpet typically consists of two

layers of backing (usually fabric from polypropylene tape

yarns), joined by CaCO3 filled styrene-butadiene latex

rubber (SBR), and face fibers (majority being nylon 6 and

nylon 66 textured yarns). Such nylon and polypropylene

fibers can be used for concrete reinforcement. Other ideas are

emerging to use recycled materials as fibers: recycled

Polyethylene terephthalate (PET) fiber, for example.

Steel fibre-reinforced shotcrete (SFRS) is a kind of spray

concrete (shotcrete) with steel fibres added.

The scope of the work is to study the behaviour of steel fibre

reinforced concrete beam - column joints under cyclic

loading. The parameters investigated are

a) Beam End Deflection

b) Strain measurement and

c) Location of crack occurrence

IV. METHODS & MATERIALS CEMENT

Ordinary Portland cement of 53 Grade confirming to

IS 12269-1987 was used. The properties of the cement used

were

(a) Fineness of cement by Sieve analysis

fineness Inde

= 3.9 %

(b) Normal consistency

= 32 %

(c) Initial setting time

= 45 Min 30 Secs

(d) Specific gravity

= 3.15

(e) Compressive strength at an

age of 28 days

= 38 N/mm2

A. Aggregates

The properties of coarse aggregates and fine aggregates

are given below

B. Coarse Aggregates

10 mm maximum size broken granite metal of igneous

origin was used. Specific gravity was found to be 2.65.

C.

Fine Aggregates

Fine river sand was used. It was dried, sieved and stored.

The sand which was used falls under zone second of IS383.

The specific gravity was found to be 2.60.

D. Water

Clean water, which was free from all impurities, was used

for the entire work of concrete preparation and curing

Mix Design for M30 Grade Concrete

Mix ratio

= 1: 1.12: 2.52

Cement

= 450

Fine Aggregate

= 502.2

Coarse Aggregate = 1135.49

Water content

= 0 .4

V. METHODS & MATERIALS CEMENT

III. OBJECTIVE

a) To investigate the mechanical properties like split

tensile strength and compressive strength of hybrid

SFRC.

b) To investigate ductility requirement, moment

rotation capacity, energy absorption capacity for

beam column joints under cyclic loading using

hybrid steel fibers of different volume fractions.

a)

b)

c)

d)

e)

Procurement of material

Mix design

Testing( tensile, compression)

Design of beam column joints

Pilot study of beam-column joints under cyclic

loading

f) Casting and testing of SFRC beam column joints

International Journal of Research in Science & Technology

Volume: 1 | Issue: 11 | December 2014 | ISSN: 2349-0845

IJRST

VI. EXPERIMENTAL INVESTIGATION

A. Compressive Strength of Concrete

A total number of 6 cube specimens were casted under

conventional concrete, after curing seventh day testing was

carried out. The following Fig. shows the compressive

strength testing while conducting test in Universal Testing

Machine. Compressive strength of the specimens are

calculated using the following formula:

Compressive strength = Load/Area of cube

B. Spilt Tensile Strength of Concrete

A total number of 6 cylindrical specimens were casted

under conventional concrete, after curing seventh day testing

was carried out. The following Fig. shows the split tensile

strength testing while conducting test in Universal Testing

Machine. Split tensile strength of the specimens are

calculated using the following formula:

Split Tensile strength

= 2P/ DL

P Applied load in Newton

D Diameter in mm

L Length in mm

Table 1 Compressive Strength and split Strength for 28th

days

S. No

Specimen

Compressive

strength

(N/mm2 )

Split tensile

strength

(N/mm2 )

M1

38

3.11

M2

42

5.18

M3

39

3.63

M4

41

4.57

M5

43

5.22

M6

52

8.37

M7

50

7.14

M8

47

6.29

C. Cyclic Loading

Cyclic Load analysis is the application of incremental

Push and Pull Load. The analysis is also known as Push-Pull

loading . The loads are applied incrementally as positive and

negative loads.

D. Test Programme

The project deals with the behaviour of hybrid steel fibre

reinforced concrete beam-column joints subjected to cyclic

loading.

Cyclic Load analysis is the application of

incremental Push and Pull Load. The analysis is also known

as Push-Pull analysis. The loads are applied incrementally as

positive and negative loads.To find out Beam End

Deflection, Strain measurement and Location of crack

occurrence is the prime concern of this study

The beam-column joints were tested under cyclic loading.

These beam-column joints were divided M1, M6, M7, and

M8. Set M1 contains two beam-column joint with strength of

concrete

Set M6 contains two beams-column joint with Crimped +

H1 (Aspect ratio 50+80 & volume fraction 0.5%+0.5%) and

grade of concrete fixed as M30.

Set M7 contains two beams-column joint with Crimped +

H2 (Aspect ratio 50+65& volume fraction 0.5%+0.5%) and

grade of concrete fixed as M30.

Set M8 contains two beams-column joint with Crimped +

H3 (Aspect ratio 50+45& volume fraction 0.5%+0.5%) and

grade of concrete fixed as M30.The investigated parameters

under this study To Investigate ductility requirement,

moment rotation capacity, energy absorption capacity for

beam column joints under cyclic loading using hybrid steel

fibers of different volume fractions . Further details of

beam-column joint specimens are as follows.

E. Details of Specimens

The details of specimen of different volume fraction and

aspect ratio are given in table 2

Table 2 Details of Specimens

Cubes

Volume

Fraction

(%)

Aspe

ct

Rati

o

(L/D

)

----

----

1%

50

M3

1%

80

M4

1%

65

M5

1%

45

(0.5+0.5)

%

50+8

0

Number of Specimens

Specifi

cations

Beams

-colum

n joint

Cylind

ers

M1

M2

S.No

Fig 1 Compressive Strength and split Strength for 28th days

International Journal of Research in Science & Technology

M6

Experimental Investigation on Hybrid Steel Fiber Reinforced Concrete Beam Column Joints Under Cyclic Loading

M7

M8

48

48

TOTAL

(0.5+0.5)

%

(0.5+0.5)

%

50+6

5

50+4

5

M1-Control beam

M2-Crimped fiber alone (Aspect ratio 50 & volume fraction

1%)

M3-H1 alone (Aspect ratio 80 & volume fraction 1%)

M4-H2 alone (Aspect ratio 65 & volume fraction 1%)

M5-H3 alone (Aspect ratio 45 & volume fraction 1%)

M6-Crimped + H1 (Aspect ratio 50+80 & volume fraction

0.5%+0.5%)

M7-Crimped + H2 (Aspect ratio 50+65 & volume fraction

0.5%+0.5%)

M8-Crimped + H3 (Aspect ratio 50+45 & volume fraction

0.5%+0.5%)

H - HOOKED END STEEL FIBRE.

Fig 3 Experimental setup for Beam Column joint

Description of beam-column joint

1.

No. of Beams

= 8

2. Cross section

= 100 mm x 100 mm

3. Concrete strength

= M30

4. Reinforcement details are shown

Fig 4 Testing of Beam column joint

Fig 2 Reinforcement Details of Beam-column joint

Fig 5 Side view of loading frame with testing specimen

Conduct of Experiment

The experiment was conducted in the following manner.

a) The beam-column joint to be tested was lifted and

kept in the loading platform. Example (Fig. 3 & 4)

a)

b)

International Journal of Research in Science & Technology

The beam column was so adjusted that the centers to

the load cell

The testing was done in a loading frame. Load was

applied by means of a hydraulic jack of capacity 25

Volume: 1 | Issue: 11 | December 2014 | ISSN: 2349-0845

IJRST

c)

d)

e)

tones. The load was measured using a load cell of 5

tones capacity.

Deflection of the joints were measured for every o.2

Ton by using dial gauges which are fixed at both the

sides , with a least count of 0.01mm.

the arrangement has been made ready for

performing the experiment and the dial gauges were

also set for zero reading.

5T capacity load cell was placed above the hydraulic

jack in the center.

Curves of the specimen have been plotted in Fig.s

respectively.

D. Test Results of Beam-Column Joint (M5)

From the experiment it has been found that the first crack

was formed at a load of 1.4 tonne. The ultimate load for

hybrid (CR+HE) can carry was 2.4 tonne. The hysteretic

Curves of the specimen have been plotted in Fig. 8

respectively

VII. RESULTS & DISCUSSION

A. Results of Testing of Beam-Column Joints

The observations from the testing of Beam column joint

are given in Appendix B of this report. The observations were

processed and graph plotted between the load and

deflections.The hysteretic Curves of the specimen have been

plotted.The Energy dissipation capacity of Beam Column

joints with various hybrid steel fibres.

B. Test Results of Beam-Column Joint (M1)

From the experiment it has been found that the first crack

was formed at a load of 0.6 tonne. The ultimate load that for

normal concrete can carry was 1.6 tonne. The hysteretic

Curves of the specimen have been plotted in Fig.6

respectively.

Fig 7 Cyclic Load - Deflection Curve for beam-column joint (M2)

The energy dissipation are calculated from the load deflection curve is found to be 73.97kN/m.

Fig 8 Cyclic Load - Deflection Curve for beam-column joint (M5)

Fig 6 Cyclic Load - Deflection Curve for beam-column joint (M1)

The energy dissipation are calculated from the load deflection curve is found to be 41.837kN/m.

The energy dissipation are calculated from the load deflection curve is found to be 116.97 kN/m.

E. Test Results of Beam-Column Joint (M8)

C. Test Results of Beam-Column Joint (M2)

From the experiment it has been found that the first crack

was formed at a load of 0.8 tonne. The ultimate load for

ductile detailing can carry was 1.9 tonne. The hysteretic

10

From the experiment it has been found that the first crack

was formed at a load of 0.9 tonne. The ultimate load for

hybrid (HE+HE) can carry was 2 tonne. The hysteretic

International Journal of Research in Science & Technology

Experimental Investigation on Hybrid Steel Fiber Reinforced Concrete Beam Column Joints Under Cyclic Loading

Curves of the specimen have been plotted in Fig.s 5.4

respectively.

Fig 9 Cyclic Load - Deflection Curve for beam-column joint (M8)

b) The interaction between ultimate loads and degree of

confinement are not linear. This has to be further

investigated.

c) The Hybrid Steel fibers can be efficiently used for

seismic reinforced beam column joint.

d) The deficiency in cumulative energy dissipation in the

case of non ductile reinforced beam column joint can be

made good by Hybrid Steel fibers strengthening.

e) The increase in cumulative energy dissipation is 28.3

percent for non ductile and 31.6 percent for ductile

reinforced concrete beam column joint strengthened by

Hybrid Steel fibers.

f) Much of experimental investigation is needed in the

direction of establishing a relationship between

confinement reinforcements volume and the region of

extent to which this provided on the stiffness and

ultimate load characteristics of joints.

g) Joints with high strength may be investigated

The energy dissipation are calculated from the load deflection curve is found to be 92.711kN/m.

REFERENCES

[1]

DISCUSSIONS

From the experiments carried out, it is observed that the

use of Hybrid Steel Fibers increases the Strength energy

dissipation, The increases cumulative energy dissipation is

28.3 % for non-ductile and 31.6 % for ductile reinforced

concrete beam column joint strengthen by Hybrid Steel

Fibers Fig. 5.5 shows the Comparison of Cyclic Load Deflection Curve for beam-column joint

[2]

[3]

[4]

[5]

[6]

[7]

Ehsani and J.K.Wight (1985), Exterior Reinforced Concrete

Beam-column Connection Subjected to Earthquake-type Loading, ACI

Structural Journal, No.7, july. pp .492-499.

Filip.C, Popov.F and Bertero.F (1986)., Analytical Studies Of

Hysteretic Behaviour Of R/C Joints , ASCE journal of Structural

Engineering ,V.112,No 7 , july , pp . 1065-1622.

Galeota.D,Giammatteo M.M and Marino.R (1994)., High Strength RC

Beam-column Joints Under Large Reversal Loads , proceedings of the

ACI international conference held in Singapore 1994,ACI

SP-149,American Concrete Institute , pp. 195-208.

Joaquim A O BARROS, Jos M S CRUZ , Raimundo M DELGADO

And Anbal G COSTA, (2007) Reinforced Concrete Under Cyclic

Loading.

M.Lakshmipathy (1983), Ductility Of Reinforced Concrete Structural

Members , thesis submitted to the Anna University for the Degree of

Philosophy in Civil Engineering.

Ganesan, P.V. Indira and Ruby Abraham , (2007),Steel Fibre

Reinforced High Performance Concrete Beam-column Joints Subjected

To Cyclic Loading, ISET Journal of Earthquake Technology, Technical

Note, vol. 44, no. 3-4, sept.-dec. 2007, pp. 445456.

Perumal.P,Thanukumari.B,(2010). Seismic Performance of Hybrid

Fiber Reinforced Beam-Column Joint, International Journal of Civil and

Structural Engineering, Vol 1, No 3.

Fig 10 Comparison of Cyclic Load - Deflection Curve for beam-column joint

I. CONCLUSION

The behavior of beam column joints were studied in the

present work and it has been concluded that

a) Based on the behavior of joints under the loads, it is

concluded that the use of hybrid steel fibers gives us

optimum value for exterior joints

11

International Journal of Research in Science & Technology

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- 25 All Ceramic RestorationsDocument31 pages25 All Ceramic RestorationsJúliaJulie100% (2)

- Assignment 2Document9 pagesAssignment 2zumaiPas encore d'évaluation

- Physics 481: Condensed Matter Physics - Homework 10Document2 pagesPhysics 481: Condensed Matter Physics - Homework 10Mike GarciaPas encore d'évaluation

- Penetration Into Ductile Metal Targets With Rigid Spherical-Nose RodsDocument12 pagesPenetration Into Ductile Metal Targets With Rigid Spherical-Nose Rodsamar100% (1)

- RCD RulDocument54 pagesRCD RulCj GuerreroPas encore d'évaluation

- Flocculation PDFDocument5 pagesFlocculation PDFSunilPas encore d'évaluation

- 10.1007@978 3 030 36540 0 PDFDocument1 008 pages10.1007@978 3 030 36540 0 PDFdavibraga8041100% (1)

- Gas Phase Embrittlement and Time Dependent Cracking of Nickel Based Super AlloysDocument48 pagesGas Phase Embrittlement and Time Dependent Cracking of Nickel Based Super AlloysgtrdcPas encore d'évaluation

- 243-wikarta-KULIAH V VII BEAM Gaya Internal Diagram Gaya Geser Dan MomenDocument22 pages243-wikarta-KULIAH V VII BEAM Gaya Internal Diagram Gaya Geser Dan Momenikhsan nurfauziPas encore d'évaluation

- Flashing LiquidsDocument31 pagesFlashing LiquidsAmerPas encore d'évaluation

- ThermodynamicsDocument7 pagesThermodynamicsCitra Adelina SitorusPas encore d'évaluation

- Assignment - Flexibility Method PDFDocument3 pagesAssignment - Flexibility Method PDFZazliana IzattiPas encore d'évaluation

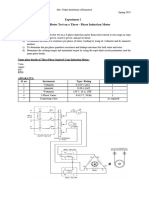

- Exp-2 - Blocked-Rotor Test On A Three-Phase IMDocument3 pagesExp-2 - Blocked-Rotor Test On A Three-Phase IMMudit BhatiaPas encore d'évaluation

- Som Strength of Material Question BankDocument16 pagesSom Strength of Material Question BankarindamckbtPas encore d'évaluation

- Internal Flows (Laminar Flow) : Lecture - 04Document25 pagesInternal Flows (Laminar Flow) : Lecture - 04غيث منعمPas encore d'évaluation

- 324 00582 01 Aculyn 88 Rheology ModifierDocument3 pages324 00582 01 Aculyn 88 Rheology ModifierAbdulrahman HamdanPas encore d'évaluation

- Rubber PDFDocument22 pagesRubber PDFkiranPas encore d'évaluation

- Lec# 09 Paschen's LawDocument15 pagesLec# 09 Paschen's LawshafquatPas encore d'évaluation

- Circular Column Design Based On ACI 318-19: Input Data & Design SummaryDocument5 pagesCircular Column Design Based On ACI 318-19: Input Data & Design SummaryJEEVENDRANPas encore d'évaluation

- Air Standard CycleDocument93 pagesAir Standard CycleJonathan CerdanPas encore d'évaluation

- ProQuestDocuments 2024 04 04Document2 pagesProQuestDocuments 2024 04 04Theodøros D' SpectrøømPas encore d'évaluation

- ChE Objective Type Questions Compilation-Dean MedinaDocument165 pagesChE Objective Type Questions Compilation-Dean MedinaSasi Kumar100% (10)

- Chem Academy: Assignment Home Work DPPDocument6 pagesChem Academy: Assignment Home Work DPPHamit RanaPas encore d'évaluation

- SS400 Structural Steel - An OverviewDocument2 pagesSS400 Structural Steel - An OverviewrsbguesthousePas encore d'évaluation

- NEET Test SeriesDocument4 pagesNEET Test SeriesAbir Dn100% (1)

- Poisson's Ratio Values For Different MaterialsDocument2 pagesPoisson's Ratio Values For Different Materialsricardogv2010Pas encore d'évaluation

- Hdpe 3255uDocument1 pageHdpe 3255udiana sarmientoPas encore d'évaluation

- Cement Chemistry - H.W. TaylorDocument12 pagesCement Chemistry - H.W. TaylorVaishnav Kumar100% (1)

- FM Lab ManualDocument70 pagesFM Lab ManualRishi PatilPas encore d'évaluation

- Mecánica de SuelosDocument6 pagesMecánica de SuelosDjRacksPas encore d'évaluation