Académique Documents

Professionnel Documents

Culture Documents

Barrier Wall Systems

Transféré par

onspsnonsCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Barrier Wall Systems

Transféré par

onspsnonsDroits d'auteur :

Formats disponibles

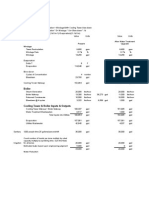

BARRIER WALL SYSTEMS SPECIFICATIONS

1.0 General

Acoustical Barrier Panels shall be insulated double wall construction and shall be provided as indicated on

drawings by a recognized manufacturer with published standards of construction and technical performance.

The manufacturer shall have produced a standard factory fabricated panel system and components for at

least 10 years. Performance of the fabricated and installed system shall conform to all specifications listed

herein.

2.0 Materials

2.1 Acoustical Metal Panels

A. All barrier panels and their components shall be pre-fabricated, sectional, all metal-clad, modular and

designed for easy and accurate field assembly. The panels and components shall not be susceptible to

damage due to extended exposure to vibration, air temperature or humidity with the passage of time.

B. Panel Construction

1.

All panels shall be (2)/(4) inches thick, as noted on drawings, with a solid galvanized steel type G90

exterior shell and a perforated/solid galvanized steel interior shell. The panels shall be connected

together by means of a tongue and groove connection and held together rigidly by the use of selfdrilling sheet metal screws.

2.

The panel shells, framing members, and internal reinforcements shall be welded, screwed and/or

riveted together to form a metal-sheathed panel of sufficient strength for maximum operating loads

specified in the structural performance section of these specifications.

3.

The outer galvanized steel shell thickness shall be 18 ga. minimum and the inner galvanized steel

shell shall be 22-gauge minimum thick.

4.

Where perforated materials are indicated, all perforations shall be 3/32" dia. holes on 3/16"

staggered centers and shall result in an open area of no less than 23 percent.

5.

All panel internal and external reinforcing members shall be minimum 18 ga. galvanized steel.

6.

Each panel shall be filled with sound absorbing materials that are inert, mildew-resistant, vermin

proof, and incombustible.

C. Panel Components

1.

All accessory trim items shall be of 18 ga. minimum galvanized steel and shall be furnished in

factory standard lengths to be field cut to specified dimensions. Location and quantity of sheet

metal screws and trim requirements shall be in accordance with the manufacturers installation

details.

2.

Base channel shall be installed on a level and structurally sound surface.

3.

All external panel connectors, trim items, accessories, base channel/panel interfaces/base

channel/floor interfaces, and other sections as noted on the drawings shall be sealed with an

acoustical sealant that shall not harden and prevent disassembly in the future.

D. Structural Performance

1.

Any special external panel loading conditions including wind, snow, and equipment shall be

provided for as per specifications.

2.

Under the indicated loading conditions, the entire barrier panel system shall be self-supporting

and/or will be supported as per the specifications. The installer shall furnish and assemble all

structural members in strict accordance with drawings and manufacturers installation details.

3.

Under the above loading conditions, the assembled acoustical structure shall not exhibit any panel

joint deflection in excess of L/360, where L is the unsupported span length of any panel section in

the erected structure.

E. Acoustical Performance

1. The

manufacturer shall provide certified independent test data indicating sound absorption and

transmission loss characteristics of the panel assembly.

F. Accessory Items

Doors, windows, electrical systems, ventilating systems, accessory components, etc., shall be provided in

accordance with drawings.

G. Manufacturer

All materials shall be provided by Kinetics Noise Control, Inc.

End of Section

Vous aimerez peut-être aussi

- Basics of Refrigeration CycleDocument2 pagesBasics of Refrigeration CyclePradeep SukumaranPas encore d'évaluation

- Pipe Wall Thickness (ASME B31.3)Document12 pagesPipe Wall Thickness (ASME B31.3)Rachmad HidayatPas encore d'évaluation

- SPEC For Chilled Water Pipework and FittingsDocument4 pagesSPEC For Chilled Water Pipework and FittingsonspsnonsPas encore d'évaluation

- Ashraed2830120060711Document6 pagesAshraed2830120060711kabardeyPas encore d'évaluation

- Ahu 01 (STD)Document5 pagesAhu 01 (STD)onspsnonsPas encore d'évaluation

- 0014-Cpr-001 Concept Phase Report 170409bDocument15 pages0014-Cpr-001 Concept Phase Report 170409bonspsnonsPas encore d'évaluation

- 00 BLANK - Hot and Cold Water LU Calculation SheetDocument17 pages00 BLANK - Hot and Cold Water LU Calculation SheetmaxmorekPas encore d'évaluation

- PDO SMO Buildings - Site Visit ReportDocument9 pagesPDO SMO Buildings - Site Visit ReportonspsnonsPas encore d'évaluation

- Cooling Tower ArticleDocument7 pagesCooling Tower ArticleAudrey Patrick KallaPas encore d'évaluation

- Fire Damper Installation DetailsDocument1 pageFire Damper Installation DetailsonspsnonsPas encore d'évaluation

- Air Distribution Basics and Duct DesignDocument46 pagesAir Distribution Basics and Duct DesignVali GheorghisorPas encore d'évaluation

- CalculationsDocument2 pagesCalculationsAliAliPas encore d'évaluation

- A O Smith Residential Water Heater CatalogDocument24 pagesA O Smith Residential Water Heater CatalogonspsnonsPas encore d'évaluation

- WaStop SS - PVC - PE International Version 2014Document2 pagesWaStop SS - PVC - PE International Version 2014onspsnonsPas encore d'évaluation

- Balancing and Vibration LimitsDocument3 pagesBalancing and Vibration Limitsramamoorthy_sPas encore d'évaluation

- Cib HDocument1 pageCib HonspsnonsPas encore d'évaluation

- Vibration in Pumps PDFDocument5 pagesVibration in Pumps PDFonspsnonsPas encore d'évaluation

- Inline Check Valve SpecificationDocument1 pageInline Check Valve SpecificationonspsnonsPas encore d'évaluation

- Chiller Barrier Wall SpecificationDocument2 pagesChiller Barrier Wall SpecificationonspsnonsPas encore d'évaluation

- ECO V - CatalogueDocument5 pagesECO V - CatalogueonspsnonsPas encore d'évaluation

- Drainge&Waste WaterDocument43 pagesDrainge&Waste WatermohdnazirPas encore d'évaluation

- High TonesDocument2 pagesHigh TonesonspsnonsPas encore d'évaluation

- FLM SpecificationsDocument2 pagesFLM SpecificationsonspsnonsPas encore d'évaluation

- FDS B 4 - CoilDocument1 pageFDS B 4 - CoilonspsnonsPas encore d'évaluation

- Icw SpecDocument3 pagesIcw SpeconspsnonsPas encore d'évaluation

- Icc SpecDocument2 pagesIcc SpeconspsnonsPas encore d'évaluation

- Commercial STL HTL Panels SpecificationDocument4 pagesCommercial STL HTL Panels SpecificationonspsnonsPas encore d'évaluation

- High Impact HardSide Panels Acoustics ControlDocument2 pagesHigh Impact HardSide Panels Acoustics ControlonspsnonsPas encore d'évaluation

- Barrier Wall SystemsDocument2 pagesBarrier Wall SystemsonspsnonsPas encore d'évaluation

- Hard Side Cloud SystemDocument2 pagesHard Side Cloud SystemonspsnonsPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Introduction to Rearrangement Reactions (40Document14 pagesIntroduction to Rearrangement Reactions (40Chandra ReddyPas encore d'évaluation

- Air Freshener Safety Data Sheet RevisionDocument8 pagesAir Freshener Safety Data Sheet RevisionCitra Rizky FernandaPas encore d'évaluation

- MBW Report SF6 Gas Analysis PDFDocument6 pagesMBW Report SF6 Gas Analysis PDFNaveenNavabPas encore d'évaluation

- RC Corbel Design (ACI318-05)Document2 pagesRC Corbel Design (ACI318-05)Mohammed Z. AlSaqqa100% (1)

- SPE 37084 Horizontal Well Length: Drill Short or Long Wells?Document9 pagesSPE 37084 Horizontal Well Length: Drill Short or Long Wells?Waleed Barakat MariaPas encore d'évaluation

- Mass Spectra and IRDocument7 pagesMass Spectra and IRSyed FahimPas encore d'évaluation

- Section 05 Block WorksDocument10 pagesSection 05 Block WorksMarvin MessiPas encore d'évaluation

- MSc Surveying and Water Resources TopicsDocument3 pagesMSc Surveying and Water Resources TopicsNirjhor KabirPas encore d'évaluation

- Calibration Sheet Ultrasonic Test EquipmentDocument1 pageCalibration Sheet Ultrasonic Test EquipmentjohnPas encore d'évaluation

- How To Process and Print Black-and-White FilmDocument6 pagesHow To Process and Print Black-and-White FilmPepParamosPas encore d'évaluation

- Quantitative Mueller Matrix Polarimetry With Diverse ApplicationsDocument63 pagesQuantitative Mueller Matrix Polarimetry With Diverse ApplicationsHarsh Purwar100% (1)

- Tablas de Perfiles Estructurales. Beer & Johnston & DeWolf & Mazurek. 6th Edition. 2012 PDFDocument17 pagesTablas de Perfiles Estructurales. Beer & Johnston & DeWolf & Mazurek. 6th Edition. 2012 PDFJGibson FiestasPas encore d'évaluation

- Report Text About RainbowDocument2 pagesReport Text About RainbowCornelia Ayu Trisna67% (3)

- ZirconiaDocument12 pagesZirconiaAna Massiel NarváezPas encore d'évaluation

- NPTELDocument2 pagesNPTELMayur ArodaPas encore d'évaluation

- Centrifugal Pump TheoryDocument5 pagesCentrifugal Pump TheoryFungsam LimPas encore d'évaluation

- Hydrogen-Enriched Compressed Natural Gas As A Fuel For EnginesDocument26 pagesHydrogen-Enriched Compressed Natural Gas As A Fuel For EnginesRahul AroraPas encore d'évaluation

- Microdroplet Technology - Principles and Emerging Applications in Biology and Chemistry - Philip Day Et Al. (Springer, 2012)Document249 pagesMicrodroplet Technology - Principles and Emerging Applications in Biology and Chemistry - Philip Day Et Al. (Springer, 2012)CA Uttam Prakash Agarwal100% (1)

- Everything StarsDocument166 pagesEverything StarsBilly The KidPas encore d'évaluation

- Aalborg Solutions: Keep Your Feedwater Steaming HotDocument2 pagesAalborg Solutions: Keep Your Feedwater Steaming HotRavikumar GangadharanPas encore d'évaluation

- Hendricks, David W-Fundamentals of Water Treatment Unit Processes - Physical, Chemical, and biological-CRC Press (2011) PDFDocument930 pagesHendricks, David W-Fundamentals of Water Treatment Unit Processes - Physical, Chemical, and biological-CRC Press (2011) PDFÂn HồngPas encore d'évaluation

- Freeze-Drying of Acerola (Malpighia Glabra L.)Document7 pagesFreeze-Drying of Acerola (Malpighia Glabra L.)mPas encore d'évaluation

- Media File Sheehan Perf of HDG in Coastal Envs PDFDocument18 pagesMedia File Sheehan Perf of HDG in Coastal Envs PDFFrankie ChanPas encore d'évaluation

- How to read a pump curve and understand key parameters like best efficiency point, NPSH, friction losses and moreDocument2 pagesHow to read a pump curve and understand key parameters like best efficiency point, NPSH, friction losses and moreNo PersonPas encore d'évaluation

- Design For Environment PDFDocument20 pagesDesign For Environment PDFAnonymous 7bsvkAEloPas encore d'évaluation

- HW2 SolutionDocument4 pagesHW2 SolutiontsengullerPas encore d'évaluation

- 03.ASTM A572-15 - Eqv. A709Gr50Document4 pages03.ASTM A572-15 - Eqv. A709Gr50Mauricio_Vera_525950% (2)

- Chemistry Assessment - Task 2 Report (Update 3)Document15 pagesChemistry Assessment - Task 2 Report (Update 3)kaylasadgrove4Pas encore d'évaluation

- Dissolution Improvement of Telmisartan by Surface Solid Dispersion MethodDocument5 pagesDissolution Improvement of Telmisartan by Surface Solid Dispersion MethodHafidz PrasetyaPas encore d'évaluation

- Activity No. 2 The Microscope: Term FunctionDocument5 pagesActivity No. 2 The Microscope: Term FunctionUNSA MANEPas encore d'évaluation