Académique Documents

Professionnel Documents

Culture Documents

mK5 Jetta Brakes

Transféré par

vixentdDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

mK5 Jetta Brakes

Transféré par

vixentdDroits d'auteur :

Formats disponibles

Front brake caliper, servicing

Volkswagen Golf 5 2004-> VW Rabbit GTI 2006->

(A5)

Front brake caliper, servicing

Brake caliper FN 3, servicing

When carrying out repairs, install all parts supplied in

repair kit.

Only use mineral spirits to clean brake parts.

Apply thin coat of assembly paste G 052 150 A2 to

brake cylinders, pistons and seals.

1 - Dust cap

Install onto bleeder valve

2 - Bleeder valve, 10 Nm

Page 1 / 11

Front brake caliper, servicing

Apply a thin coat of assembly

paste G 052 150 A2 to the threads

before screwing in.

3 - Caps

Insert into bushing

4 - Guide pins, 30 Nm

5 - Bushing

Insert in brake caliper

6 - Brake caliper

7 - Brake carrier

Bolt to brake caliper

8 - Retaining spring

Insert with both ends in holes of

brake caliper

9 - Sealing ring

Removing and installing 47-1,

Brake caliper FN 3 piston,

removing and installing

10 - Piston

Removing and installing 47-1,

Brake caliper FN 3 piston,

removing and installing

Apply thin coat of assembly paste

G 052 150 A2 to piston before

inserting

11 - Protective cap

Removing and installing 47-1,

Brake caliper FN 3 piston,

removing and installing

Do not damage when inserting

piston

Brake caliper FN 3 piston, removing and installing

Special tools, testers and auxiliary items required

Page 2 / 11

Front brake caliper, servicing

Disassembly wedge 3409

Piston resetting tool T 10145

Assembly device for protective cap T 10146/6

Removing

- Force piston from brake caliper using compressed air.

Page 3 / 11

Front brake caliper, servicing

Set a piece of wood into the valley, so that the piston

is not damaged.

- Remove protective cap from brake caliper using Trim

Removal Wedge 3409 .

- Remove seal using Trim Removal Wedge 3409 .

When removing make sure that the surface of the cylinder

is not damaged.

Installing

- The surface of the piston and seal must only be cleaned

with mineral spirits and then dried.

Page 4 / 11

Front brake caliper, servicing

- Thinly coat piston and seal with assembly paste G 052

150 A2 before inserting.

- Install sealing ring in brake caliper.

- Insert protective cap - A - into assembly tool T 10146/6 1- .

- Press protective cap with assembly tool - 1 - and piston

resetting tool - 2 - into brake caliper so that it contacts the

brake caliper all around.

Check seating of protective caps:

- Protective cap must no longer be able to be pulled from

brake caliper by hand.

Page 5 / 11

Front brake caliper, servicing

- Press piston lightly against the protective cap and lock it

into position, e.g. with trim removal wedge - 2 - .

Do not angle piston, to avoid damaging the seal

sleeve.

- Blow protective cap on with pressurized air (max. 3 bar) 1 - . Protective cap springs on to piston.

- Press piston into brake caliper using piston resetting tool

- 1- .

The outer seal lip of the protective cap thereby slips into

the groove on the piston.

Brake caliper FNR-G, servicing

When carrying out repairs, install all parts supplied in

repair kit.

Only use mineral spirits to clean brake parts.

Apply thin coat of assembly paste G 052 150 A2 to

brake cylinders, pistons and seals.

Page 6 / 11

Front brake caliper, servicing

1 - Dust cap

Install onto bleeder valve

2 - Bleeder valve, 12 Nm

Apply a thin coat of assembly

paste G 052 150 A2 to the threads

before screwing in.

3 - Caps

Insert into bushing

4 - Guide pins, 30 Nm

5 - Bushing

Insert in brake caliper

6 - Brake caliper

Must not be bolted apart

Page 7 / 11

Front brake caliper, servicing

7 - Brake carrier

Bolt to brake caliper

8 - Retaining spring

Insert in brake pad retaining spring

and press below brake carrier

9 - Sealing ring

Removing and installing 47-1,

Brake caliper FNR-G piston,

removing and installing

10 - Piston

Removing and installing 47-1,

Brake caliper FNR-G piston,

removing and installing

Apply thin coat of assembly paste

G 052 150 A2 to piston before

inserting

11 - Protective cap

Removing and installing 47-1,

Brake caliper FNR-G piston,

removing and installing

Do not damage when inserting

piston

Brake caliper FNR-G piston, removing and installing

Special tools, testers and auxiliary items required

Disassembly wedge 3409

Page 8 / 11

Front brake caliper, servicing

Piston resetting tool T 10145

Assembly device for protective cap T 10146/6

Removing

- Force piston from brake caliper using compressed air.

Set a piece of wood into the valley, so that the piston

is not damaged.

- Remove protective cap from brake caliper using Trim

Removal Wedge 3409 .

Page 9 / 11

Front brake caliper, servicing

- Remove seal using Trim Removal Wedge 3409 .

When removing, make sure that the surface of cylinder is

not damaged.

Installing

- The surface of the piston and seal must only be cleaned

with mineral spirits and then dried.

- Thinly coat piston and seal with assembly paste G 052

150 A2 before inserting.

- Install sealing ring in brake caliper.

- Insert protective cap - A - into assembly tool T 10146/1 1- .

Page 10 / 11

Front brake caliper, servicing

- Press protective cap using assembly tool - 1 - and piston

resetting tool - 2 - into brake caliper so that it contacts the

brake caliper all around.

Check seating of protective caps:

- Protective cap must no longer be able to be pulled from

brake caliper by hand.

- Lightly press piston against protective cap with an

extension and ratchet adapter - 1 - and hold it there, in

that position.

Do not angle piston, to avoid damaging the seal

sleeve.

- Blow protective cap on with pressurized air (max. 3 bar) 2 - . Protective cap springs on to piston.

- Press piston with hand into brake caliper, possibly push

back slightly with piston resetting tool.

The outer seal lip of protective cap slips into groove on

piston.

Page 11 / 11

Rear brake caliper, servicing

Page 1 / 7

47 - 2

Rear brake caliper, servicing

When carrying out repairs, install all parts supplied in

repair kit.

Only use mineral spirits to clean brake parts.

New brake calipers are filled with brake fluid and

pre-bled.

Apply thin coat of assembly paste G 052 150 A2 to

brake cylinders, pistons and seals.

When carrying out repairs it is essential to

appropriately pre-bleed the brake calipers (without

brake pads) before installing in the vehicle 47-2,

Pre-bleeding brake caliper .

CII 41 brake assembly overview:

15 inch from KW 32/04

Rear brake caliper, servicing

Page 2 / 7

Volkswagen Technical Site: http://volkswagen.msk.ru http://vwts.info http://vwts.ru

Volkswagen, Skoda, Seat, Audi

1 - Brake caliper with parking brake

cable lever

Replace brake caliper if leaking at

parking brake cable lever

Pre-bleed brake caliper after

repairing 47-2, Pre-bleeding

brake caliper

2 - Dust cap

3 - Bleeder valve, 10 Nm

Apply a thin coat of assembly

paste G 052 150 A2 to the threads

before screwing in.

4 - Hex bolt, self-locking, 35 Nm

Replace

When loosening and tightening

Rear brake caliper, servicing

Page 3 / 7

counter hold on guide pin

5 - Guide pin with stepping

Shorter than item 6

Grease before pulling on protective

cap

6 - Guide pins

Longer than item 5

Grease before pulling on protective

cap

7 - Protective cap

Pull onto brake carrier and guide

pin

8 - Brake pad with damper

Supplied as replacement part

assembled with sufficient grease

on guide pins

If protective caps or guide pins are

damaged use repair kit. Use

supplied grease packet to lubricate

guide pins.

9 - Protective cap

Pull outer sealing lip onto piston

Removing and installing

Removing

47-2,

10 - Piston with automatic adjustment

Removing and installing

Removing

47-2,

Apply thin coat of assembly paste

G 052 150 A2 to piston before

inserting

11 - Sealing ring

Removing and installing

Removing

Removing

47-2,

Rear brake caliper, servicing

Special tools, testers and auxiliary items required

Resetting Extracting Tool T10165

Trim Removal Wedge 3409

- Remove piston from brake caliper by turning knurled

wheel toward left.

Insert reset and remove tool so that collar makes contact

on piston.

If the piston is difficult to move, use a 13 mm open

end wrench on the flats - arrow A - provided for this

Page 4 / 7

Rear brake caliper, servicing

purpose.

- Remove seal using Trim Removal Wedge 3409 .

Installing

- The surface of the piston and seal must only be cleaned

with mineral spirits and then dried.

- Thinly coat piston and seal with assembly paste G 052

150 A2 before inserting.

- Place protective seal with outer sealing lip on the piston.

- Insert inner sealing lip in cylinder groove with assembly

wedge 3409.

Page 5 / 7

Rear brake caliper, servicing

Hold piston in front of brake caliper for this procedure.

- Screw piston into housing by turning knurled wheel

clockwise.

- Use special tool 10165/1 for assistance when installing.

Insert reset and screw out tool so that collar makes

contact on brake caliper.

The automatic adjustment in brake caliper is

destroyed when piston is moved with piston resetting

tool (e.g. T 10145) or foot brake is operated.

Pre-bleeding brake caliper

Page 6 / 7

Rear brake caliper, servicing

- Open bleeder valve - arrow A - and fill with brake fluid

using standard bleeder bottle until brake fluid flows out of

threaded hole (end of brake hose) - arrow B - without

bubbles. Close bleeder valve.

Position brake caliper as illustrated to pre-bleed.

Page 7 / 7

Pressure leak test

Page 1 / 1

47 - 3

Pressure leak test

Special tools, testers and auxiliary items required

Brake pressure gauge 0-250 bar V.A.G 1310 A

Adapter M 10 V.A.G 1310/6

Test conditions:

Brake system (hydraulic unit, brake hoses, brake lines and

brake calipers) operating properly and free of leaks.

- Remove bleeder valve at one front brake caliper.

Connect Brake Pressure Gauge 0-250 Bar VAG1310A

and bleed.

- Apply pressure to brake pedal until gauge indicates a

pressure of 50 bar. The pressure must not drop by more

than 4 bar during test period of 45 seconds. Replace

master cylinder if pressure drops greatly.

Bleeding braking system

Page 1 / 4

47 - 4

Bleeding braking system

Description covers bleeding of brake system using the

brake filler and bleeder tool VAS 5234 and V.A.G

1869 .

Note:

Bleeding the braking system on vehicles with ABS is

carried out as for vehicles with conventional braking

systems.

Only use new brake fluid conforming to US standard

FMVSS 116 DOT 4.

Genuine VW/Audi brake fluid conforms to this

specification.

Brake fluid is poisonous. Also due to its corrosive

effect brake fluid must not come into contact with

paintwork.

Brake fluid is hygroscopic, which means it absorbs

moisture from the ambient air and should always be

stored in air tight containers.

Rinse off spillages, by using plenty of water.

There must be a positive pressure of 2 bar to bleed the

hydraulic unit.

Brake system, bleeding using brake filler and bleeder

tool VAS 5234

Special tools, testers and auxiliary items required

Bleeding braking system

Brake filler/bleeder unit VAS 5234

Brake filler/bleeder unit suction adapter V.A.G

1869/4

Note:

On vehicles with EDL, EDL/ASR or EDL/ASR/ESP,

the brake system must be pre-bled when a chamber

in the brake fluid reservoir is completely empty (e.g.

brake system leaking).

- Remove rear wheels.

Pre-bleed:

- Connect Brake filler/bleeder unit VAS 5234 .

Bleeding sequence:

1 - Bleed left front and right front brake caliper together

simultaneously

2 - Bleed left rear and right rear brake caliper together

simultaneously

- With bleeder bottle hoses attached, leave bleeder valves

open long enough that brake fluid exits without bubbles.

The hydraulic unit must be bled again with tester VAS

5051 via function "Basic settings" .

Initiate basic setting (to bleed brake system):

VAS 5051 , connecting and selecting functions 45-3,

Connecting Vehicle Diagnostic, Testing and Information

System VAS 5051 and selecting functions .

- Then bleed brake system

Page 2 / 4

Bleeding braking system

Bleeding (normal):

Adhere strictly to work sequence when bleeding brake

system.

- Connect Brake filler/bleeder unit VAS 5234 .

- Open bleeder valves in prescribed sequence and bleed

brake caliper.

1 - Left front brake caliper

2 - Right front brake caliper

3 - Left rear brake caliper

4 - Right rear brake caliper

Use suitable bleeder hose. It must fit tightly on bleeder

valve so that no air can enter brake system.

- With bleeder bottle hose attached, leave bleeder valve

open long enough that brake fluid exits without bubbles.

Subsequent bleeding

A second technician is required to assist:

- Depress brake pedal forcefully and hold.

- Open bleeder valve at brake caliper.

- Press brake pedal down onto stop.

- Close bleeder valve with pedal held down.

- Release brake pedal slowly.

This bleeding procedure must be performed 5 times

per brake caliper.

Bleeding sequence:

1 - Left front brake caliper

2 - Right front brake caliper

3 - Left rear brake caliper

4 - Right rear brake caliper

A road test must be performed after bleeding. During

this, at least one ABS regulation must be performed!

- Install rear wheels.

Torque specification for wheel bolts

Page 3 / 4

Bleeding braking system

Repair Manual, Suspension, Wheels, Steering, Repair

Group 44, Torque specifications for wheel bolts

.

Changing brake fluid (every 2 years)

Changing brake fluid

Repair Manual, Maintenance

Page 4 / 4

Brake booster/brake master cylinder, assembly overview

Page 1 / 7

47 - 5

Brake booster/brake master cylinder, assembly

overview

Note:

Use only new brake fluid. Observe information on

brake fluid reservoir!

Pedal assembly

Hex nut, self-locking, 25 Nm

Replace each time

Gasket

For brake booster

Brake booster/brake master cylinder, assembly overview

Brake booster

On gasoline engines the

vacuum required is taken

from the intake manifold.

Some vehicles with gasoline

engine and automatic

transmission are equipped

with a Brake System

Vacuum Pump V192

475, Brake system vacuum

pump V192 .

On vehicles with HBV, a

vacuum sensor is installed

45-8, Brake Booster

Vacuum Sensor G483 ,

removing and installing

Functional check:

- With engine switched off,

depress brake pedal firmly

several times (to exhaust

the vacuum in the unit).

- Depress brake pedal with

average foot pressure, hold

and start engine. If booster

unit is working properly, the

pedal will be felt to give

slightly under foot (booster

assist becomes effective).

If faulty, replace completely.

Removing and installing

47-7, Brake booster,

removing and installing

Sealing ring

Brake Booster Vacuum Sensor

G483

Only on vehicles with HBV

Removing and installing

45-8, Brake Booster Vacuum

Sensor G483 , removing and

installing

Page 2 / 7

Brake booster/brake master cylinder, assembly overview

Brake master cylinder without

brake light switch

Application Electronic

Parts Catalog (ETKA)

Cannot be repaired. If faulty,

replace completely.

Removing and installing

47-6, Brake master cylinder,

removing and installing

Brake master cylinder with brake

light switch

Application Electronic

Parts Catalog (ETKA)

Cannot be repaired. If faulty,

replace completely.

Removing and installing

47-6, Brake master cylinder,

removing and installing

Brake light switch F

Includes Brake Pedal Switch

F47

On vehicles before KW

45/05, Brake Light Switch F

is located on brake pedal

46-4, Brake pedal, assembly

overview

Removing and installing

46-4, Brake pedal, assembly

overview

Inner Torx bolt, 5 Nm

Heat shield

Hex nut, self-locking, 25 Nm

Replace each time it is

removed

Brake line, 14 Nm

Page 3 / 7

Brake booster/brake master cylinder, assembly overview

Brake line, 14 Nm

Brake master

cylinder/secondary piston

circuit to hydraulic unit

Brake master

cylinder/primary piston circuit

to hydraulic unit

Sealing plug

Moisten with brake fluid and

press into brake fluid

reservoir

Brake fluid reservoir

Cap

Sealing plug

Connection for vacuum hose

Vacuum hose

Insert into brake booster

Check-valve, checking

The check valve - A - must allow air through in

direction of - arrow - .

Check-valve must remain closed for opposite

direction.

Page 4 / 7

Brake booster/brake master cylinder, assembly overview

Observe correct installation position!

Brake system vacuum pump V192

Component location of Brake System Vacuum Pump V192

is located on automatic transmission at front in direction of

travel.

Servicing work on brake system vacuum pump V192 is not

possible. If there is a malfunction, replace Brake System

Vacuum Pump V192 .

Can be checked in "Guided Fault Finding" using VAS

5051

Removing

- Disconnect vacuum hose - 1 - from Brake System

Vacuum Pump V192 .

- Disconnect harness connector - 2 - for Brake System

Vacuum Pump V192 .

- Remove remaining harness connectors and wires from

bracket - 3 - .

- Remove - arrows - bracket - 3 - with Brake System

Vacuum Pump V192 .

Page 5 / 7

Brake booster/brake master cylinder, assembly overview

Page 6 / 7

- Remove - arrows - Brake System Vacuum Pump V192

- 1 - from bracket - 2 - .

Installing

Installation is in reverse order of removal.

Torque specifications:

Brake System Vacuum Pump V192 to bracket

Bracket to automatic transmission

Brake Light Switch F from KW 45/05, removing and

installing

On vehicles before KW 45/05, brake light switch was

located on brake pedal.

Removing

- Remove engine cover.

- On some vehicles, intake hose must be removed.

- Disconnect connector - 1 - from Brake Light Switch F .

- Remove bolt - 2 - from brake master cylinder.

- Pull Brake Light Switch F - 3 - downward and off from

8 Nm

25 Nm

Brake booster/brake master cylinder, assembly overview

Page 7 / 7

the brake master cylinder and remove it from the retaining

tab at the top - 4 - .

Installing

- Installation is in reverse order of removal.

Tightening torque:

Torx bolt to brake master cylinder

5 Nm

Brake master cylinder, removing and installing

Page 1 / 3

47 - 6

Brake master cylinder, removing and installing

Special tools, testers and auxiliary items

required

Hose clamps up to 25 mm dia.

3094

Torque wrench V.A.G 1331

Brake filler/bleeder unit V.A.G

1869

Brake filler/bleeder unit suction

adapter V.A.G 1869/4

Brake master cylinder, removing and installing

Brake filler/bleeder unit VAS

5234

Removing

- Note or request radio code on vehicles with coded radio if

necessary.

- Disconnect battery.

Repair Manual, Electrical Equipment, Repair Group 27,

Batteries, disconnecting and connecting

- Battery, removing and installing.

Repair Manual, Electrical Equipment, Repair Group 27,

Batteries, removing and installing

.

- Remove battery carrier.

- Place sufficient lint-free cloths in area of engine and

transmission.

- Extract as much brake fluid as possible from brake fluid

reservoir using Brake filler/bleeder unit VAS 5234 or

extraction device V.A.G 1869/4 .

For vehicles with manual transmission:

- Disconnect clutch master cylinder supply hose - B using Hose Clamps Up to 25 mm dia. 3094 .

- Pull off supply hose - B - for clutch master cylinder.

Page 2 / 3

Brake master cylinder, removing and installing

Page 3 / 3

Continued for all vehicles:

- Disconnect connector - A - from floating warning

indicator sensor.

- Disconnect connector from Brake Light Switch F (only on

vehicles from KW 45/05).

- Remove brake fluid reservoir. To do this press locking

tabs on the reservoir outward and simultaneously pull

brake fluid reservoir out of sealing plugs.

- Unfasten brake lines - 1 - at brake master cylinder and

plug brake lines with sealing plugs from repair kit Part No.

1H0 698 311 A.

- Remove nuts - 2 - from main brake cylinder.

- If present, remove heat shield.

- Carefully take brake master cylinder out of brake

booster.

Installing

- Installation is in reverse order of removal.

Observe the following points when installing:

- When installing together the brake master cylinder and

brake booster, make sure that the push rod is correctly

located in the brake master cylinder.

- Bleed braking system

47-4, Bleeding braking system

Torque specifications:

Master brake cylinder at brake booster

25 Nm

Use new nuts!

Brake lines to main brake cylinder

14 Nm

Brake booster, removing and installing

Page 1 / 5

47 - 7

Brake booster, removing and installing

Special tools, testers and auxiliary items

required

Hose clamps up to 25 mm dia.

3094

Torque wrench V.A.G 1331

Brake filler/bleeder unit V.A.G

1869

Brake filler/bleeder unit suction

adapter V.A.G 1869/4

Brake booster, removing and installing

Brake filler/bleeder unit VAS

5234

Removing

- Note or request radio code on vehicles with coded radio if

necessary.

- Disconnect battery.

Repair Manual, Electrical Equipment, Repair Group 27,

Batteries, disconnecting and connecting

- Battery, removing and installing.

Repair Manual, Electrical Equipment, Repair Group 27,

Batteries, removing and installing

.

- Remove battery carrier.

- Place sufficient lint-free cloths in area of the engine and

transmission.

- Extract as much brake fluid as possible from brake fluid

reservoir using Brake filler/bleeder unit VAS 5234 or

extraction device V.A.G 1869/4 .

For vehicles with manual transmission:

- Disconnect clutch master cylinder supply hose - B using Hose Clamps Up to 25 mm dia. 3094 .

- Pull off supply hose - B - for clutch master cylinder.

Page 2 / 5

Brake booster, removing and installing

Continued for all vehicles:

- Disconnect connector - A - from floating warning

indicator sensor.

- Disconnect connector from Brake Light Switch F (only on

vehicles from KW 45/05).

- Remove brake fluid reservoir. To do this press locking

tabs on reservoir outward and simultaneously pull brake

fluid reservoir out of sealing plugs.

- Unfasten brake lines - 1 - at brake master cylinder and

plug brake lines with sealing plugs from repair kit Part No.

1H0 698 311 A.

- Remove nuts - 2 - from brake master cylinder.

- If present, remove heat shield.

- Carefully take brake master cylinder out of brake

booster.

- Pull vacuum hose out of brake booster.

For vehicles with manual transmission:

- Remove cable - 1 - , unscrew mounting bracket - 2 and lay it aside.

Page 3 / 5

Brake booster, removing and installing

Page 4 / 5

Repair Manual, Manual Transmission, Repair Group 34,

Selector mechanism, servicing

Continued for all vehicles:

- Remove trim on drivers side.

Repair Manual, Body Interior, Repair Group 70,

Instrument panel

Brake light switch is no longer present on mounting bracket

from KW 45/05.

- Disconnect connector - 1 - from brake light switch.

- Remove Brake Light Switch - 2 - by rotating 45

left.

toward

- Remove air channel - 3 - .

- Remove cover - 4 - .

- Disconnect brake pedal from brake booster

Separating brake pedal from brake booster .

46-4,

Brake booster, removing and installing

Page 5 / 5

- Remove nuts - 1 - from brake booster.

- Loosen both upper nuts - 2 - from mounting bracket.

- Carefully remove brake booster from vehicle.

Installing

- Installation is in reverse order of removal.

Observe the following when installing:

- Clip brake pedal together with brake booster

4

- After installing, bleed brakes

system and clutch.

Topic 46-

47-4, Bleeding braking

Only on vehicles up to KW 45/05:

- Adjust brake light switch 46-4, Brake light switch F up

to KW 45/05, removing, installing and adjusting .

Torque specifications:

Brake booster to foot pedal assembly/cross panel

Use new nuts!

Master brake cylinder at brake booster

25 Nm

25 Nm

Use new nuts!

Brake lines to main brake cylinder

14 Nm

Brake line repairs

Page 1 / 7

47 - 8

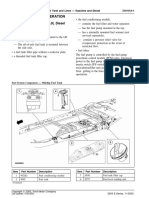

Brake line repairs

Flare brake lines with 5 mm outer diameter using brake line

flaring appliance VAS 6056 without damaging coating. In

this way, brake lines can be inexpensively partially

replaced in certain cases.

Work with brake line kit V.A.B. 1356 is not permitted

because of the coating and diameter of black brake lines.

Note:

Brake lines must not be bent more than 90 ,

otherwise they kink or deform causes unacceptable

constriction in the line.

Disconnect brake lines preferably at vehicle floor.

Position of intermediate pieces should be selected

so that they cannot rub against moving parts.

Do not lubricate spindle, clean only with mineral

spirits.

Special tools, testers and auxiliary items required

Brake line flaring appliance VAS 6056

Brake filler/bleeder unit VAS 5234

Brake line repairs

Listing of individual tools:

Flaring appliance VAS 6056/1

flaring jaws VAS 6056/6 are

contained in the flaring

appliance VAS 6056/1

Tube cutter VAS 6056/2

Brake line shearing tool VAS

6056/3

The threaded pins (in shaft

and at sides) are set and

must not be adjusted!

Self-grip pliers with plastic

clamping jaws VAS 6056/4

Page 2 / 7

Brake line repairs

Line bending tool VAS 6056/5

SW6 angle screwdriver

Flaring jaws VAS 6056/7

Flaring tool, assembly overview

Upper part of flaring tool

Hand grip mount

Remove to change flaring

jaws

Must be removed to reach

retaining screw for upper

part

Retaining screw

Page 3 / 7

Brake line repairs

For upper part of flaring tool

Flaring jaws threaded pins

Center and hold flaring jaws

2 mm hex socket head

Flaring jaws

Various

Assembly instructions 478, Flaring jaws assembly

instructions:

Flaring jaws assembly instructions:

VAS 6056/6 (dark) for black brake lines

VAS 6056/7 (light) for green brake lines

Note:

The arrow on the rounded side of the flaring jaws

must face toward edge of housing and the straight

side of the flaring jaws must be installed toward

spindle, otherwise flared head will not be formed

correctly.

Instructions

Page 4 / 7

Brake line repairs

- Remove affected brake line at brake caliper or wheel

brake cylinder and collect escaping brake fluid and dispose

of it correctly.

- Disconnect brake line at appropriate location (straight,

accessible part) with line cutter - 2 - .

- Remove piece to be exchanged.

- Lubricate brake line surface.

- Clamp brake line in self-grip pliers - 4 - so that 50 mm of

the plastic clamping jaws show.

- Clamp shearing tool - 3 - in a drill and place it on brake

line.

- Shear coating from brake line at a slow drill RPM and

with light pressure against the line.

The length of the sheared-off portion is determined by the

stop in the shearing tool.

- Remove shearing tool from brake line and remove

shearing remains.

Page 5 / 7

Brake line repairs

- Remove self-grip pliers and tube fitting - D - from brake

line.

- Slide brake line - B - against stop - A - in flaring tool.

Note:

Brake line must contact stop when hex socket heat

screws are tightened, otherwise flared head will not

be formed correctly.

- Clamp brake line in flaring tool until it cannot be moved

any more. Fold stop - A - up and tighten hex socket head

screws diagonally with angle screw driver - C - .

Page 6 / 7

Brake line repairs

Page 7 / 7

- Turn spindle to stop in flaring tool.

- Turn spindle back.

- Loosen hex socket head screws diagonally.

- Remove brake line from flaring tool, clean and check

brake line and flared head.

Briefly rinse part of brake line remaining in vehicle.

- Connect brake filler/bleeder unit VAS 5234 , place

bleeder container hose on flanged head of brake line and

run brake filler/bleeder unit VAS 5234 briefly until some

brake fluid runs through.

- Blow out brake line to be inserted with compressed air.

- Join brake lines with connecting piece - E - .

- Assemble brake line.

- Bleed braking system

47-4, Bleeding braking system

Vous aimerez peut-être aussi

- Body MK5 Jetta GolfDocument549 pagesBody MK5 Jetta Golfvixentd100% (3)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualD'EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualPas encore d'évaluation

- 2008 VW JettaDocument14 pages2008 VW Jettawhynot0567% (3)

- OBDelevenDocument20 pagesOBDelevenprogamer0125631Pas encore d'évaluation

- Air Bag System VWDocument13 pagesAir Bag System VWPablo SilvaPas encore d'évaluation

- Inmobilizer Guia VW PDFDocument55 pagesInmobilizer Guia VW PDFCarlos Garcia Godoy100% (2)

- Jetta A5 January 2010Document10 pagesJetta A5 January 2010billydump100% (1)

- 9 Electrical SystemsDocument182 pages9 Electrical Systemsminihasz100% (2)

- VW Golf 3 Door TrimDocument19 pagesVW Golf 3 Door Trimyt7rjb100% (2)

- Front Crankshaft Seal Replacement Mk4 VW ALH and BEW TDI Engine - VW TDI Forum, Audi, Porsche, and Chevy Cruze Diesel ForumDocument10 pagesFront Crankshaft Seal Replacement Mk4 VW ALH and BEW TDI Engine - VW TDI Forum, Audi, Porsche, and Chevy Cruze Diesel ForumAladin MujakićPas encore d'évaluation

- Edc15Vm: Re: Difference - +, EDC15V, EDC15PDocument4 pagesEdc15Vm: Re: Difference - +, EDC15V, EDC15PNicuCatalinPas encore d'évaluation

- Passat Estate b5 BrochureDocument31 pagesPassat Estate b5 BrochureWytalik100% (1)

- VW Golf Gti 2005Document8 pagesVW Golf Gti 2005alePas encore d'évaluation

- Vagtacho Usb: See The List of Supported Cars For The Delco Hsfi, and Delco "F" UpdateDocument9 pagesVagtacho Usb: See The List of Supported Cars For The Delco Hsfi, and Delco "F" UpdateViorel GutanuPas encore d'évaluation

- Installing A Golf Mark VI Rear View Camera (RVC) Into A Golf Mark VI - My-GtiDocument9 pagesInstalling A Golf Mark VI Rear View Camera (RVC) Into A Golf Mark VI - My-GtiPoopinClumpinPas encore d'évaluation

- Volkswagen MKVI Jetta W/keyless Start Traction Control Button Retrofit Kit Installation InstructionsDocument28 pagesVolkswagen MKVI Jetta W/keyless Start Traction Control Button Retrofit Kit Installation InstructionstomoPas encore d'évaluation

- Golf 5Document93 pagesGolf 5Asvedin SalihovicPas encore d'évaluation

- Bi Xenon UpgradeDocument8 pagesBi Xenon UpgradeRafael StriederPas encore d'évaluation

- SSP 191 - VW Passat B5 '97 - Construction & OperationDocument47 pagesSSP 191 - VW Passat B5 '97 - Construction & OperationaleuzevaxPas encore d'évaluation

- Manual de Instrucciones Del SEAT Ibiza (Febrero 1988) : La Página de La Historia de SeatDocument39 pagesManual de Instrucciones Del SEAT Ibiza (Febrero 1988) : La Página de La Historia de SeatMiguel TorresPas encore d'évaluation

- Audi Symphony To Rns-E Install Guide: Contributing Editor: TeddybgameDocument61 pagesAudi Symphony To Rns-E Install Guide: Contributing Editor: TeddybgameVily MarianPas encore d'évaluation

- Corrado vr6Document19 pagesCorrado vr6danieluki100% (4)

- Timitng Belt Replacement Procedure For A VW Passat b5Document18 pagesTimitng Belt Replacement Procedure For A VW Passat b5forray_catalin2000100% (1)

- Ext PDF Volkswagen Golf 5Document1 pageExt PDF Volkswagen Golf 5StaceyPas encore d'évaluation

- Electro-Mechanical Parking Brake, ComponentDocument7 pagesElectro-Mechanical Parking Brake, ComponentPopa MihaiPas encore d'évaluation

- mk5 Front Seat Covers and Padding Cover and Upholstery For Rear Seats.Document20 pagesmk5 Front Seat Covers and Padding Cover and Upholstery For Rear Seats.mihai mihalcescu100% (1)

- Drtool - Indice Información de Motor Seat 1987-2016: Modelo Submarca Motor C.C. ComputadoraDocument33 pagesDrtool - Indice Información de Motor Seat 1987-2016: Modelo Submarca Motor C.C. ComputadoraAlex PorfirioPas encore d'évaluation

- Golf Manual: From: Bard Livings Date: Wed, 15 Jul 2009 02:37:58 0700 (PDT)Document15 pagesGolf Manual: From: Bard Livings Date: Wed, 15 Jul 2009 02:37:58 0700 (PDT)natec1230% (3)

- FullDocument2 pagesFullGabi UngureanuPas encore d'évaluation

- VW Golf 4 Secondary Air System, Engine AfpDocument24 pagesVW Golf 4 Secondary Air System, Engine AfpNPPas encore d'évaluation

- 2006VolkswagenJettaTDI 1 PDFDocument5 pages2006VolkswagenJettaTDI 1 PDFArmando Carrasco100% (1)

- Manual Trans Overhaul - Type 02A Article TextDocument20 pagesManual Trans Overhaul - Type 02A Article TextHakim Ben Abdeljelil100% (1)

- b6 42 EngDocument159 pagesb6 42 EngepicenterrulezPas encore d'évaluation

- VW Golf MKV (5) - LED Tail Light (Install Manual) (ENGLISH+multi)Document6 pagesVW Golf MKV (5) - LED Tail Light (Install Manual) (ENGLISH+multi)DuplexDrivePas encore d'évaluation

- Turn Signals Mirrors Passat b6Document6 pagesTurn Signals Mirrors Passat b6mc_keith23Pas encore d'évaluation

- Audi TT MKI 1.8T & VW Mkiv 1.8T: Timing Belt InstallationDocument20 pagesAudi TT MKI 1.8T & VW Mkiv 1.8T: Timing Belt InstallationBoth JánosPas encore d'évaluation

- VW-Audi Remote Key AdaptationDocument16 pagesVW-Audi Remote Key AdaptationBrian_denhaagPas encore d'évaluation

- VW Golf mk5 - Fuse Box Fuse Box in Passenger CompartmentDocument4 pagesVW Golf mk5 - Fuse Box Fuse Box in Passenger CompartmentKãdíPas encore d'évaluation

- GOLF IV AdaptionsDocument5 pagesGOLF IV AdaptionsCristian SindiePas encore d'évaluation

- Revoflash 3 r19 Vag Ecu List v08 05Document6 pagesRevoflash 3 r19 Vag Ecu List v08 05Gasper Ceballos100% (1)

- D4B802CE070-ODIS Workbook PDFDocument21 pagesD4B802CE070-ODIS Workbook PDFandrew smith100% (1)

- Jetta SE 2.5 2010Document123 pagesJetta SE 2.5 2010Xexux Salvador Mercado100% (2)

- B8 TFSI Catch Can Kit Installation 034-101-1000Document7 pagesB8 TFSI Catch Can Kit Installation 034-101-1000DedelPas encore d'évaluation

- Volkswagen Passat B6 - Windshield Wipe SystemDocument60 pagesVolkswagen Passat B6 - Windshield Wipe SystemiTiSWRiTTENPas encore d'évaluation

- Vagcom Info For MKVDocument22 pagesVagcom Info For MKVIker AlonsoPas encore d'évaluation

- MK4 B5 ColorMFA Install GuideDocument17 pagesMK4 B5 ColorMFA Install GuideAbdelouahab TOUATIPas encore d'évaluation

- Despiece Interior Jetta A4Document52 pagesDespiece Interior Jetta A4Leo Palacios100% (4)

- VW Scheduled MaintenanceDocument8 pagesVW Scheduled MaintenancerobertoPas encore d'évaluation

- b5 45-06Document15 pagesb5 45-06Tanee BoonmalertPas encore d'évaluation

- BMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesD'EverandBMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesPas encore d'évaluation

- Brake Caliper Servicing g5 - 47 - EngDocument45 pagesBrake Caliper Servicing g5 - 47 - EngIulian BurtumacPas encore d'évaluation

- VW Eos Front Brake CaliperDocument16 pagesVW Eos Front Brake CaliperNick PPas encore d'évaluation

- VW Eos Rear Brake CaliperDocument8 pagesVW Eos Rear Brake CaliperNick PPas encore d'évaluation

- Volkswagen Jetta, Golf, GTI 1999, 2000 Brake System: 47 Brakes - Hydraulic Components (Page GR-47)Document41 pagesVolkswagen Jetta, Golf, GTI 1999, 2000 Brake System: 47 Brakes - Hydraulic Components (Page GR-47)SandorPas encore d'évaluation

- 02 - Manual Do Safe Set - ST-B 90 - TGM - #11519778-11519784Document11 pages02 - Manual Do Safe Set - ST-B 90 - TGM - #11519778-11519784rodrigoq1Pas encore d'évaluation

- CK30 WM 03 ClutchDocument16 pagesCK30 WM 03 ClutchvixentdPas encore d'évaluation

- CK30 WM 00 GeneralDocument54 pagesCK30 WM 00 GeneralvixentdPas encore d'évaluation

- 1955 56 57 SpecsDocument9 pages1955 56 57 SpecsvixentdPas encore d'évaluation

- B44, B25, C25 Series 1967 Workshop Manual 00-4136 X PDFDocument158 pagesB44, B25, C25 Series 1967 Workshop Manual 00-4136 X PDFvixentdPas encore d'évaluation

- BSA InstructionDocument55 pagesBSA InstructionvixentdPas encore d'évaluation

- 78 Olds CSMCHPT 07Document325 pages78 Olds CSMCHPT 07vixentdPas encore d'évaluation

- 1982 All Others Multiplex TypeDocument2 pages1982 All Others Multiplex TypevixentdPas encore d'évaluation

- 78 Olds CSMCHPT 09Document64 pages78 Olds CSMCHPT 09vixentdPas encore d'évaluation

- 78 Olds CSMCHPT 08Document94 pages78 Olds CSMCHPT 08vixentdPas encore d'évaluation

- 78 Olds CSMCHPT 07Document325 pages78 Olds CSMCHPT 07vixentdPas encore d'évaluation

- Superduty 6.0L Powerstroke Engine: Removal/Installation Service TipsDocument21 pagesSuperduty 6.0L Powerstroke Engine: Removal/Installation Service Tipsvixentd100% (1)

- Vehicle Name Component Global Tool Number NA Number DescriptionDocument1 pageVehicle Name Component Global Tool Number NA Number DescriptionvixentdPas encore d'évaluation

- W123 716 Manual Transmission ManualDocument163 pagesW123 716 Manual Transmission ManualvixentdPas encore d'évaluation

- Electrical Wiring Power Take-Off Circuit Installation: Return To Body Builders Layout Book INDEXDocument1 pageElectrical Wiring Power Take-Off Circuit Installation: Return To Body Builders Layout Book INDEXvixentdPas encore d'évaluation

- 6.0 E-Van Fuel Pump and LinesDocument2 pages6.0 E-Van Fuel Pump and LinesvixentdPas encore d'évaluation

- 6.0 Late 2004 Hardstart - Nostart - DiagnosticsDocument1 page6.0 Late 2004 Hardstart - Nostart - DiagnosticsvixentdPas encore d'évaluation

- 6.0 PSD E-Van Fuel PumpDocument3 pages6.0 PSD E-Van Fuel PumpvixentdPas encore d'évaluation

- F-Super Duty/Excursion 2004 - Early Build 6.0L Power Stroke Diesel Engine Performance Diagnostic GuideDocument1 pageF-Super Duty/Excursion 2004 - Early Build 6.0L Power Stroke Diesel Engine Performance Diagnostic GuidevixentdPas encore d'évaluation

- 337 and 341 EXCAVATOR Wiring Schematic: Left Hand Console Harness - 6806191Document6 pages337 and 341 EXCAVATOR Wiring Schematic: Left Hand Console Harness - 6806191vixentd100% (1)

- PD3 - Strategic Supply Chain Management: Exam Exemplar QuestionsDocument20 pagesPD3 - Strategic Supply Chain Management: Exam Exemplar QuestionsHazel Jael HernandezPas encore d'évaluation

- Optimized Maximum Power Point Tracker For Fast Changing Environmental ConditionsDocument7 pagesOptimized Maximum Power Point Tracker For Fast Changing Environmental ConditionsSheri ShahiPas encore d'évaluation

- 11.3.1 Some Special CasesDocument10 pages11.3.1 Some Special CasesSiddharth KishanPas encore d'évaluation

- SEILDocument4 pagesSEILGopal RamalingamPas encore d'évaluation

- 2500 Valve BrochureDocument12 pages2500 Valve BrochureJurie_sk3608Pas encore d'évaluation

- LP32HS User Manual v1Document52 pagesLP32HS User Manual v1tonizx7rrPas encore d'évaluation

- Analysis of Rates (Nh-15 Barmer - Sanchor)Document118 pagesAnalysis of Rates (Nh-15 Barmer - Sanchor)rahulchauhan7869Pas encore d'évaluation

- Math F112Document3 pagesMath F112ritik12041998Pas encore d'évaluation

- UNIT 5-8 PrintingDocument17 pagesUNIT 5-8 PrintingNOODPas encore d'évaluation

- Img 20201010 0005Document1 pageImg 20201010 0005Tarek SalehPas encore d'évaluation

- FHWA Guidance For Load Rating Evaluation of Gusset Plates in Truss BridgesDocument6 pagesFHWA Guidance For Load Rating Evaluation of Gusset Plates in Truss BridgesPatrick Saint-LouisPas encore d'évaluation

- 02 Object Modeling TechniqueDocument50 pages02 Object Modeling TechniqueMuhammad Romadhon Batukarang EsdPas encore d'évaluation

- CH-5 Further Percentages AnswersDocument5 pagesCH-5 Further Percentages AnswersMaram MohanPas encore d'évaluation

- Simran's ResumeDocument1 pageSimran's ResumesimranPas encore d'évaluation

- SW OSDocument11 pagesSW OSErnest OfosuPas encore d'évaluation

- Culture 2007 2013 Projects Overview 2018-03-18Document133 pagesCulture 2007 2013 Projects Overview 2018-03-18PontesDeboraPas encore d'évaluation

- Engleza Referat-Pantilimonescu IonutDocument13 pagesEngleza Referat-Pantilimonescu IonutAilenei RazvanPas encore d'évaluation

- 9400 Series - Catalogue - AccessoriesDocument86 pages9400 Series - Catalogue - AccessoriesSaulo Leonardo Fabelo FontesPas encore d'évaluation

- Grade 7 Nap MayDocument6 pagesGrade 7 Nap Mayesivaks2000Pas encore d'évaluation

- Sample CVFormat 1Document2 pagesSample CVFormat 1subham.sharmaPas encore d'évaluation

- Borges, The SouthDocument4 pagesBorges, The Southdanielg233100% (1)

- Instant Download Business in Action 7Th Edition Bovee Solutions Manual PDF ScribdDocument17 pagesInstant Download Business in Action 7Th Edition Bovee Solutions Manual PDF ScribdLance CorreaPas encore d'évaluation

- Ch-10 Human Eye Notes FinalDocument27 pagesCh-10 Human Eye Notes Finalkilemas494Pas encore d'évaluation

- RARE Manual For Training Local Nature GuidesDocument91 pagesRARE Manual For Training Local Nature GuidesenoshaugustinePas encore d'évaluation

- KDE11SSDocument2 pagesKDE11SSluisgomezpasion1Pas encore d'évaluation

- Simon Ardhi Yudanto UpdateDocument3 pagesSimon Ardhi Yudanto UpdateojksunarmanPas encore d'évaluation

- Sundar Pichai PDFDocument6 pagesSundar Pichai PDFHimanshi Patle100% (1)

- 2nd Term Project 4º Eso Beauty Canons 2015-16 DefinitivoDocument2 pages2nd Term Project 4º Eso Beauty Canons 2015-16 DefinitivopasferacosPas encore d'évaluation

- Test 2-Module 1 12-10-2017: VocabularyDocument2 pagesTest 2-Module 1 12-10-2017: VocabularySzabolcs Kelemen100% (1)

- AE Notification 2015 NPDCLDocument24 pagesAE Notification 2015 NPDCLSuresh DoosaPas encore d'évaluation