Académique Documents

Professionnel Documents

Culture Documents

wps63 PDF

Transféré par

Erick HoganDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

wps63 PDF

Transféré par

Erick HoganDroits d'auteur :

Formats disponibles

"

,..

"

rL'::::>.

'::::.IJ

LARSEN & TOUBRO LIMITED

DHDl~ND\~GU,

IOCL PANIPAT

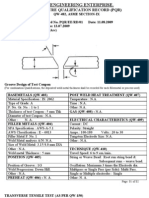

WELDING PROCDURE SPECIFICATION(QW482 ASME SEC IX)

Supporting PQR No: L&T/IOCL/P/DHDT-HGU/PQR/PIPE/04-RO,

DT.:26.03.03

4'

Welding procedure specification No

Welding Process(es) and Type

,,~&:T/IO~/DHDT-HGU/WPS/PIPE

~'~

/22-RO DT: 2603.2003

W,\Manual

Joints(QW 402)

..

10

: Single 'V' Butt

:No

:NA

Joints design

Is Backing used

Backing Material Type

~~-R~"H'5~~

2T5:to'~r'\")"'"

Base MetaIs(QW403)

P No/ Gr.No to P No/ Gr.No

Specification Type and Grade

To Specification Type and Grade

Thickness Range

Pipe Dia Range

: UN ASSIGNED TO UN ASSIGNED

: IS3589 Gr330 to IS3589 Gr330 & IS I239 TO IS 1239

: Grovel.6mm to16.0mm

Fillet - All Thickness

: Grove - All size

Fillet - All size

Filler metals(QW404)

SMAW

GTAW

SF A No

5.1

nn

AWS Class

----

FNo

n_-

2/4

ANo

----

Size of Filler Metals

nn

E60 13/E7018

2.5,3.15 & 4.0mm

DepositedWeld Metals

----

nn

Thickness Range for Groove

_n-

1.6 - 16.0mm

Thickness Range for Fillet

-_u

ALL THK

Positions(QW 405)

Position(s) of Groove: All Positions

Welding Progression:

Up Hill

Position(s) of Fillet : All position

Post Weld Heat Treatment(QW407)

Temperature Range: NA

NA

Time Range

Preheat (QW406)

Gas(QW408)

Gas(es)

Preheat Temp. Min

Interpass Temp Max

Preheat Maintenance:

lOOC

200-250C

NA

Shielding

Trailing

Backing

_u

n-

n-

Mixture

Flow Rate

u-

---

---

-----

- _n

LARSEN& TOUBROLIMITED

'C.lJ

DH~T...AN~HGU,

IOCL PANIPAT

"

WELDING PROCDURE

SPECIFICA TION(QW 482 ASME SEC IX)

Supporting PQR No: L&T/IOCL/PIDHDT-HGU/PQRlPIPE/04-RO,

DT.:26.03.03

'"

Welding procedure specification No

~T/I~/P/DHDT-HGU/WPS/P[PE

/22-RO DT:26.03.2003

Electrical Characteristics(QW 409)

: DC EN & DCEP

: 70- l30A

: 20 - 26V

:NA

:NA

:NA

Current type & Polarity

Ampere Range

, Voltage Range

. Tungsten Electrode Type and Size

,. Mode of Metal Transfer for GMA W

'" Electrode Wire Feed Speed Range

Technique(QW410)

String or Weave Bead

Orifice or Gas Cup Size

Initial and Interpass cleaning

Method of Back Gouging

Oscillation

Contact Tube to Work Distance

Multiple or Single Pass(Per side)

Multiple or Single Electrode

Travel Speed Range

Peening

Weld

: Root String & Subsequent Pass Weave

:NA

: Chipping/Brushing/Grinding

:NA

: 2.5 - 3.0 times the dia. of Filler Metal

: Multiple

: Single

: 50 - l20mm per minute

Filler Metal

Current

Volt

Travel

Range

Speed Range

Layers Process Class

Dia

SMAW E6013

2.5

DCEN

SMAW E7018

3.15

DCEP

90 - 130A 20 - 26V 60 - 120mm/minute

SMAW E7018

3.15

DCEP

90 - 130A 20 - 26V

Type & Polarity Amp Range

70 - 90A 20 - 22V

w..

INSPECTIO~

~~t..

MAN AG!.R

",~IN8~S

tN~:"

..

50-90mm / minute

60 - 120mm/min

'CD

LARSEN & TOUBRO LIMITED

DHDT AND HGU

- IOCL

PANIPAT

QW-483 PROCEDURE QUALIFICATION RECORDS(PQR)

(ASME SEC.lX, BOILER & PRESSURE VESSEL CODE)

CONSULTANT

MANUFACTURER'S NAME

PROCEDURE NO

WPS NO

WELDING PROCESS(ES

: ENGINEERS INDIA LIMITED

: LARSEN & TOUBRO LIMITED

: L&T/IOCUP/DHDT -HGU/PQR/PIPE/04-RO, DT.:26.03.03

: L&T/IOCUP/DHDl"!HaU/WIMS/PIPE/22-RO DT:26.03.03

:SMAW

ITYPE

:MANUAL

BASE METALS(QW-403)

POST WELD HEAT TREATMENT(QW-407)

MAREIAL SPEC.

:153589

TIME

:NA

TYPE OR GRADE

:Gr 330

OTHER

:NA

P.NO.TO P.NO.

:UNASSIGNED TO SELF TEMPERATURE

I'"A

THK. OF TEST COUPON

:8.0mm

GAS(QW-408)

PERCENT COMPOSITION

DIA. OF TEST COUPON

:8"

OTHER

:NA

FLOW RATE

GAS(ES)

MIXTURE

SHIELDING

NA

NA

NA

FILLER METAL(QW-404)

SFA SPEC.

:5.1

TRAILING

NA

NA

NA

:E6013/E7018

AWS CLASS.

BACKING

NA

NA

NA

F-NO.

:2&4

ELECTICAL CHARACTERISTICS(QW-409)

:1

A-NO.

CURRENT

:DC

POLARITY :EN/EP

SIZE OF FILLER METAL

:20-130

VOLTS

:20-26

AMPS

:2.5,3.15,4.0mm

TUNGSTEN SIZE

WELD METAL THK.

:NA

:8.0mm

OTHER

OTHER

,~

, :NA

POSITION(QW-405)

TECHNIQUE(QW-410)

TRAVEL SPEED

POSITION OF GROOVE

:6G

:so::i20mm/minu.

STRING OR WEAVE

:BOTH

,WELDING PROGRESSION :UPHILL

OSCILLATION

IOTHER

:NIL

:3d(d-ELECTRODE DIA.)

MULTI OR SINGLE PASS

:MUL TIPASS

PREHEAT(QW-406)

MULTIPLE OR SINGLE ELECTRODE

PREHEAT TEMP.

:10oMIN.

:SINGLE

OTHER

:NA

INTERPASS TEMP.

:200oMAX.

TENSILE TEST(QW-150)

SPECIMEN NO.

WIDTH

THK.

ULTIMATE ULTIMATE

TOTAL

TENSILE

LOAD

STRENGTH

AREA

TYPE OF FAILURE &

LOCATION

T1

T2

TYPE

ROOT BEND(RB1)

ROOT BEND(RB2)

SPECIMEN NO.

19.1mm

19.1mm

FRACTURE IN PM

7.30mm

139.43mm2

58560mm

419.9MPa

FRACTURE IN PM

7.10mm

135.61mm2

56440mm

416.2MPa

GUIDED-BEND TEST(QW-160)

RESULT

TYPE

RESULT'

SATISFACTORY

SATISFACTORY

FACE BEND(FB1)

SATISFACTORY

SATISFACTORY

FACE BEND(FB2)

TOUGHTNESS TEST(QW-170)

NOTCH

DROP WEIGHT

SPECIMEN

TEST TEMP

IMPACT VALUES

LOCATION

.SIZE

.

BREAK(Y/N)

NA

NA

NA

NA

~

NA

NA

NA

NA

NA

I

NA

NA

NA

NA

RESULT-SATISFACTORY

MACRO-RESULTS

FILLET WELD TEST(QW -180)

PENETRATION INTO PARENT METAL

:NA

NA

OTHER TESTS

WELDER'S NAME

:Mr VIJAY SINGH CHAUHAN

IDENTIFICATION NO.

:PW03

TEST CONDUCTED BY

:V.K.RAI

LAB TEST NO.

:SPECTRO R.NO:04/12/606/1658

WE CERTIFY THAT THE STATEMENTS IN THIS RECORD ARE CORRECT AND THAT THE TEST WELDS

WERE PREPERED,WELDED,AND TESTED IN ACCORDANCE WITH THE REQUIREMENT OF SECTION IX

OF THE ASME CODE

~.

APPROVED

sf, P. et:reJGAb

DATE :l.'1-. ~1A~GER

INGINIPS

INDIA I T'

MAN

~)

/I

-@

===-=======-==-=

-- ~=.;::=

= -=-==== -

;NALYr/~~L

~iB-;(;)-LTD.

C-55, Okhla Industrial Area

Phase-I, New Delhi-1! 0020

Ph. : 2681-7949/50/51/52

51611000 (5 Lines)

Fax: 91-11-2681-7954

MECHANICALTEST REPORT Web E-mail:

spectrolabs@vsnl.com

site: www.spectrolablndia.com

10-]658

Transverse

Tensile Test

S.No. Dimension

(mm)

Area

(mm2)

Ultimate Load

(Newton)

Ultimate Tensile Strength

(MPa)

T-l *

I9.1X7.30

139.43

58560

419.9

T-2*

19.1X7.I 0

135.61

56440

416.2

* Location of Fracture

Bend Test:

Parent Metal

Root Bend Test-RBI (4tXI80o)

Satisfactory

Root Bend Test-RB2 (4tXI80o)

Satisfactory

Face Bend Test-FBI (4tXI80o)

Satisfactory

Face Bend Test-FB2 (4tXI80o)

Satisfactory

~Protocol-ASME-IX

,\~~

(\~.

~,

.)

(\I

,~.Ie'Qy

\..".

NABL ACCREDITED LAB

L "'- \

c-

COD-ED

~ G

y\~tl

,,'?< ~

~~G'iY,,'"

~~

,\)\t-

~

..i

".'

,.- '~,

'../ ..~natQry

A

",.'

uthorisere-$

. .;

~""'>~s \t'

-#6\ .

(APPROVED BY VARIOUS GOVT. & OTHERINSPECTIONAGENCIES)

Note:

1. Total liability of our laboratory is limited to the invoiced amount. No liability will be accepted after the sample is taken back.

2. The result listed refer only to the tested samples and applicable Parameters. Endorsement of product is neither inferred nor implied.

3. The sample description is not verified in all cases and is given as described by customers. Sample not drawn by us and Analysis conducted on

'As received basis'. unless specified otherwise.

4. Sample will be destroyed after one month unless instructed otherwise.

5. Any complaints aboutthis report should be communicated

in writing within 7 days of issue of this report.

6. This

is not

be reproduced

wholly or in parts and cannot be used as an evidence in a court 01 Law and shall not be used in advertising

mediareport

without

ourtopermission

in writing.

PAGER

NOS

FOR

SAMPLE

COLLECTION

- 9632171-242INOIDAI.

243IFBD.\.24M~('

,.nl

n"lhi\

Vous aimerez peut-être aussi

- WPS002 312Document2 pagesWPS002 312proxywarPas encore d'évaluation

- Concast WPS - REV-01Document28 pagesConcast WPS - REV-01meena34Pas encore d'évaluation

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyPas encore d'évaluation

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaPas encore d'évaluation

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidPas encore d'évaluation

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejPas encore d'évaluation

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadPas encore d'évaluation

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadPas encore d'évaluation

- PQR REV. 2010a Interactive FormDocument2 pagesPQR REV. 2010a Interactive FormcosmicbunnyPas encore d'évaluation

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoPas encore d'évaluation

- WPS FormatDocument2 pagesWPS FormatAmit SarkarPas encore d'évaluation

- Table of Content: SR. TitleDocument2 pagesTable of Content: SR. TitlePratik KarekarPas encore d'évaluation

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasPas encore d'évaluation

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 pagesProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXPas encore d'évaluation

- WPQ Is 2062 Haresh Shah W1Document1 pageWPQ Is 2062 Haresh Shah W1Anand KesarkarPas encore d'évaluation

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- Name:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDocument2 pagesName:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiPas encore d'évaluation

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraPas encore d'évaluation

- Gtaw 106Document2 pagesGtaw 106ganeshkumarg_1Pas encore d'évaluation

- PQR WPQ Witness Report LatestDocument1 pagePQR WPQ Witness Report LatestSatish KeskarPas encore d'évaluation

- 1035 03Document2 pages1035 03Anuj ShahiPas encore d'évaluation

- Wps For Smaw06-001 (Pipe 6g CS)Document10 pagesWps For Smaw06-001 (Pipe 6g CS)walitedisonPas encore d'évaluation

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONPas encore d'évaluation

- Suggested Wps Forms ASME - IX 2010Document5 pagesSuggested Wps Forms ASME - IX 2010Ajay ChodankarPas encore d'évaluation

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191Pas encore d'évaluation

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluPas encore d'évaluation

- WPS PQR FormatsDocument22 pagesWPS PQR Formatsmdharmaraj28Pas encore d'évaluation

- Weld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020Document3 pagesWeld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020bishalPas encore d'évaluation

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- TopCoreBelco 101 FCDocument9 pagesTopCoreBelco 101 FCCesar ArellanoPas encore d'évaluation

- PQR TipsDocument2 pagesPQR TipsWaqas WaqasPas encore d'évaluation

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraPas encore d'évaluation

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Dokumen - Tips Wqt-FormatDocument2 pagesDokumen - Tips Wqt-FormatMr Pie100% (1)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387Pas encore d'évaluation

- Clad PQRDocument5 pagesClad PQRRinshadPas encore d'évaluation

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1Pas encore d'évaluation

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Ut Format Report For Ut Libra (Naidu)Document4 pagesUt Format Report For Ut Libra (Naidu)vsnaiduqcPas encore d'évaluation

- Welder ID Card BRE KarahaDocument5 pagesWelder ID Card BRE KarahaHerruSetiawan100% (1)

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielPas encore d'évaluation

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanPas encore d'évaluation

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanPas encore d'évaluation

- T.C.L. Co. - Test & Control LaboratoriesDocument2 pagesT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταPas encore d'évaluation

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinPas encore d'évaluation

- Welder Job Clearance Card: Nesma/TanmiaDocument8 pagesWelder Job Clearance Card: Nesma/TanmiaMohamed Reda Hussein SengarPas encore d'évaluation

- 16 MM Grade 60-70 p1g1 To p2g2Document8 pages16 MM Grade 60-70 p1g1 To p2g2John EvansPas encore d'évaluation

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- WPS & PQRDocument46 pagesWPS & PQRJohn Candidate CIns88% (8)

- Ce Const2 220kv CB Siemens 2012Document18 pagesCe Const2 220kv CB Siemens 2012erkamlakar223450% (2)

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- EN6114Document17 pagesEN6114Andrei Cozma67% (3)

- Qualification Soudeur PDFDocument3 pagesQualification Soudeur PDFr_racPas encore d'évaluation

- Manual Structural WeldingDocument12 pagesManual Structural WeldingwalitedisonPas encore d'évaluation

- WPSDocument2 pagesWPSJuli Agus50% (2)

- Cambridge English Vocabulary PDFDocument269 pagesCambridge English Vocabulary PDFErick HoganPas encore d'évaluation

- Week13 Iron Carbon Phase DiagramDocument49 pagesWeek13 Iron Carbon Phase DiagramvishalPas encore d'évaluation

- Iron Carbon Part1 PDFDocument33 pagesIron Carbon Part1 PDFErick HoganPas encore d'évaluation

- English DialogueDocument5 pagesEnglish DialogueErick HoganPas encore d'évaluation

- Quality Related QuestionsDocument22 pagesQuality Related QuestionsHotPriyu OnlyforgalsPas encore d'évaluation

- Electrical Load For Indoor UnitsDocument2 pagesElectrical Load For Indoor UnitsMD BILAL ASLAMPas encore d'évaluation

- Lordk Edid 6507-Case Study Assignment 1 2 3Document34 pagesLordk Edid 6507-Case Study Assignment 1 2 3api-310042469Pas encore d'évaluation

- A Car Parking Guard Circuit Using Infrared SensorDocument9 pagesA Car Parking Guard Circuit Using Infrared Sensorhamed razaPas encore d'évaluation

- Email Id of Controllers PDFDocument10 pagesEmail Id of Controllers PDFAbhishek KumarPas encore d'évaluation

- Current Volt Meter Ina219Document40 pagesCurrent Volt Meter Ina219sas999333Pas encore d'évaluation

- V8 Pro BRDocument20 pagesV8 Pro BRwtn2013Pas encore d'évaluation

- Adirondack Life Media KitDocument8 pagesAdirondack Life Media KitJohnny LibitzPas encore d'évaluation

- Xid-2025857 1Document6 pagesXid-2025857 1Thanh NguyenPas encore d'évaluation

- MclogitDocument19 pagesMclogitkyotopinheiroPas encore d'évaluation

- Product Presentation PPT NeerajDocument8 pagesProduct Presentation PPT NeerajNeeraj UdiniyaPas encore d'évaluation

- How To Configure A Wi-Fi Network How To Configure A RADIUS/EAP ServerDocument7 pagesHow To Configure A Wi-Fi Network How To Configure A RADIUS/EAP ServerSeluuunnnPas encore d'évaluation

- MD RAKIBUL ISLAM Update CVDocument2 pagesMD RAKIBUL ISLAM Update CVনীল বেদনাPas encore d'évaluation

- The Healthy PC. Preventive Care and Home Remedies For Your Computer - Carey Holzman PDFDocument257 pagesThe Healthy PC. Preventive Care and Home Remedies For Your Computer - Carey Holzman PDFLeonardoMartinPas encore d'évaluation

- MSS - Manual Bernoulli FilterDocument3 pagesMSS - Manual Bernoulli FilterFLTR PURPLE E.Pas encore d'évaluation

- 00 Datasheet of STS-6000K-H1 For 185KTL 20200706Document2 pages00 Datasheet of STS-6000K-H1 For 185KTL 20200706Lindy PortsuPas encore d'évaluation

- Online Bank SynopsisDocument7 pagesOnline Bank SynopsisPrashant VermaPas encore d'évaluation

- Ht-Discharge Pipes and Fittings (PPS) : KunststoffeDocument35 pagesHt-Discharge Pipes and Fittings (PPS) : Kunststoffeluis eduardo ramos rebataPas encore d'évaluation

- Sapthagiri College of Engineering: Tracing Manufacturing Processes Using Blockchain Based Token CompositionsDocument19 pagesSapthagiri College of Engineering: Tracing Manufacturing Processes Using Blockchain Based Token CompositionsYashi FakePas encore d'évaluation

- BUT11F/11AF: NPN Silicon TransistorDocument4 pagesBUT11F/11AF: NPN Silicon TransistorfabioboogPas encore d'évaluation

- Ellis Patents Cable Cleats Complete CatalogueDocument28 pagesEllis Patents Cable Cleats Complete CataloguefndprojectPas encore d'évaluation

- Waste Management in Selected Hotels in GoaDocument11 pagesWaste Management in Selected Hotels in GoaSyna SoaresPas encore d'évaluation

- Answers of Chapter (8) : Course: Operating SystemDocument7 pagesAnswers of Chapter (8) : Course: Operating SystemasdPas encore d'évaluation

- Report For Neha Lem ArchitectureDocument17 pagesReport For Neha Lem ArchitecturewafasaPas encore d'évaluation

- CVDocument2 pagesCVAkash JainPas encore d'évaluation

- Confined Spaces: Avoiding Common Mistakes in Gas DetectionDocument1 pageConfined Spaces: Avoiding Common Mistakes in Gas Detectiontrravi1983Pas encore d'évaluation

- Screenshots Itil Process Map VisioDocument16 pagesScreenshots Itil Process Map VisiomabesninaPas encore d'évaluation

- Logic GatesDocument19 pagesLogic GatesblazespiritPas encore d'évaluation

- Sand Reclamation - Standard Devices: Shake Out MachinesDocument2 pagesSand Reclamation - Standard Devices: Shake Out MachinesKaarthicNatarajanPas encore d'évaluation

- Informatics and Patient SafetyDocument5 pagesInformatics and Patient SafetyCuriePas encore d'évaluation