Académique Documents

Professionnel Documents

Culture Documents

Tube Still Heater

Transféré par

StalinNarayanasamyTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tube Still Heater

Transféré par

StalinNarayanasamyDroits d'auteur :

Formats disponibles

1|P a g e

Module 3: Liquid Fossil Fuel (Petroleum)

Lecture 25: Refinery Equipments

IITKharagpurNPTELPhaseIIWebCourses

2|P a g e

Keywords: Pipe still heater, heat exchangers, distillation tower, pumps

Refinery equipments

Introduction

In refinery, there are different types of equipments used for different purposes. It is difficult

to include the description of all the equipments. Here, some of the important equipments are

briefly discussed.

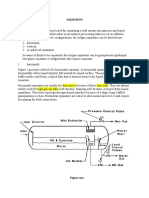

Pipe still heater

Crude oils are heated in pipe still heater before entering into the atmospheric distillation

column. This heater is a special type of furnace which heats crude oil upto about 3500C

depending on the type of feed. A large number of tubes connected through bends are housed

within the furnace in multiple rows. The still is built with two distinct heating sections, a

radiant section, which can receive heat directly from the flame and a convection section,

which takes heat from the hot gases travelling to the stack. The hot flue gases arising in the

radiation section flow into the convection section where they circulate at high speed through

a tube bundle before leaving the furnace through the stack. Shield or shock section separates

the two major heating sections. The tubes in this section are close to the radiation section that

protects the convection section tubes from direct radiation. The shield section normally

consists of two to three rows of bare tubes that are directly exposed to the hot gases and

radiation flame. Fig 1. depicts a pipe still heater.

There are two major types of fired heaters, such as vertical cylindrical or box-type heaters

depending on the geometrical configuration of the radiant section. In box-type heaters, the

radiation section usually is of a square or a rectangular cross section. The tubes in the

radiation section may be arranged horizontally or vertically along the heater walls and the

burners are located on the floor or on the lower part of the longest side wall where there are

IITKharagpurNPTELPhaseIIWebCourses

3|P a g e

no tubes. Box-type furnaces are mainly used where large capacities and large heat duties are

required.

Fig. 1. Pipe still heater

In the cylindrical-type furnace, the radiation section is of the shape of a cylinder having a

vertical axis and the burners are situated on the floor at the base of the cylinder. The vertical

walls of the furnace are the heat transfer area and therefore exhibit circular symmetry with

respect to the tube bundles. In the radiation section, the tubes may be arranged in a circular

pattern around the walls of the furnace or they may have a cross or octagonal design which

will expose them to firing from both sides.

Crude oil is pumped into the furnace through the tubes at the convection section. At this

section the crude is preheated and then goes to the radiation section to be heated upto 3500C.

Heat transfer at a high rate is obtained by passing the crude with a high flow rate.

IITKharagpurNPTELPhaseIIWebCourses

4|P a g e

The fired heaters have corrosion and material problems due to the elevated temperatures experienced both on the process side and in the fire-box. The Atmospheric Heater receives

flashed crude at about 260C and sends it to the atmospheric column at about 350C. For

sweet crude, the radiant tubes and lower rows of convection tubes are typically 5% chrome

with carbon steel in the up section.

Heat exchangers

Different types of heat exchangers are used in refinery. If the hot stream is a vapour and is

cooled without much condensation, the heat exchanger is called a vapour heat exchanger. If

the vapour is condensed in the exchanger, then it is called a vapour denser exchanger. The

vapour condensed in this way is then subsequently cooled in a exchanger which is called

cooler or after-cooler. The heating equipment used to heat the bottoms of a fractionator is

called a reboiler. Double pipe heat exchangers are common in refinery. Fins, either in spiral

form or as longitudinal plates on the inside pipe in the double pipe

Viscous or low-heat transfer rate fluids can be passed through the finned tube to get higher

heat transfer area. Jet type condenser has application in refinery. Barometric jet type

condenser is used in vacuum distillation to condense steam as well as create some vacuum.

The working principle of this type of condenser is to mix the vapour and the cooling medium

intimately by high pressure jets and heat exchange is done by mixing of the two streams or

conduction heat transfer.

In heat exchangers, the decision of which material (fluid/slurry) is to be passed through tube

is dependent on different factors. Usually dirty streams are passed through tubes as the tubes

in tube bundles can be cleaned, but sometimes, if the stream contains lots of coke or debris,

then that should be passed through shell and shell may be disposed after certain time. High

pressure fluids are passed through tubes as they can withstand high pressure but shell does

IITKharagpurNPTELPhaseIIWebCourses

5|P a g e

not. Corrosive fluids and water are usually sent through tubes, as corrosion resistant tubes are

cheap and the cleaning of deposition or water scale is easier in tubes than shell. Normally

large volume liquids are passed through shell.

The metallurgy of heat exchanger varies with temperature and the composition of stream. The

material of construction for majority of the exchangers is 100% carbon steel. Admiralty brass

tubes have been used in fresh water cooled exchangers to prevent water-side fouling and

corrosion. Due to the high cost of the brass bundles and improvements in cooling water

treatment, many brass tube bundles are replaced with carbon steel. In hot hydrocarbon

service, 5% chrome materials in heat exchangers are mostly used. As the sulphur content in

the crude increases, the use of high chrome tubes and 12% chrome shell and channel linings

are required.

Fractionating tower

Fractionating towers are the equipments which separate the components from a mixture.

Crude oil atmospheric distillation tower is the most important fractionating unit in refinery.

Distillation tower with bubble-cap trays is the most conventional and familiar design. The

other types of trays used are sieve tray, perforated tray etc. Small bubble caps are best for

large liquid loads and large caps are for large vapour load. Some designers use small cap for

small tower and large cap for towers of 10 to 20 ft in diameter. Cast ion is largely used for

bubble cap as it is more corrosion resistant than steel. In vacuum towers, pressed alloy steel

caps are becoming important. Many caps are of removable types, i.e, the vapour uptake and

cap are properly assembled on the plate, but sometimes this arrangement is not satisfactory as

bolts rusts and cast iron caps may break.

The atmospheric column is commonly lined more extensively than the preflash column

because the feed, which is at about 3500C, is not only hotter but also contains larger amounts

IITKharagpurNPTELPhaseIIWebCourses

6|P a g e

of HCl and H2S. The top of the column is often lined with Monel 400 (about 67% Ni 23%

Cu) to protect against condensing HCl. Normally, the lower 2/3 or of the column will be

lined with 12% chrome cladding to protect against high temperature sulfur corrosion. In the

area of the feed inlet, or flash zone, 316 stainless steel may be required in those plants

processing crudes high in naphthenic acid content.

Pumps

Different types of pumps are used in the refinery as per requirements. Asphalts or semi-solid

materials are handled with reciprocating steam pumps. For handling large amounts of

medium viscosity oil, centrifugal pumps may be used. Centrifugal pumps are largely used for

pumping non-viscous fluids because of their high capacity low head characteristics. But more

viscous materials are handled by rotary pumps.

IITKharagpurNPTELPhaseIIWebCourses

7|P a g e

Reference

1. Petroleum refinery engineering, W. L. Nelson, 4th edition, McGraw-Hill Book Company,

1987.

2. Fired Process Heaters, Matlab - Modelling, Programming and Simulations, Hassan Al-Haj

Ibrahim, Emilson Pereira Leite (Ed.), 327-364, Sciyo, 2010 ISBN: 978-953-307-125-1.

3. Fuels and combustion, S. Sarkar, 2nd edition, Orient Longman Ltd., 1990.

IITKharagpurNPTELPhaseIIWebCourses

Vous aimerez peut-être aussi

- Equipments Regarding AbsorptionDocument7 pagesEquipments Regarding AbsorptionGerry Lou QuilesPas encore d'évaluation

- Boiler NotesDocument6 pagesBoiler NotesRadhika Arora100% (1)

- Shell and Tube Heat ExchangersDocument69 pagesShell and Tube Heat ExchangersVenkitaraj K PPas encore d'évaluation

- Air-Cooled Heat Exchangers: LectureDocument39 pagesAir-Cooled Heat Exchangers: LectureBaraa Shurbaji No 111Pas encore d'évaluation

- 6.equipments For Gas Liquid Operations PDFDocument27 pages6.equipments For Gas Liquid Operations PDFMohit SathwaraPas encore d'évaluation

- Fired Heater Components-1Document8 pagesFired Heater Components-1ahmed atwaPas encore d'évaluation

- Boiler PerformanceDocument30 pagesBoiler PerformanceJoeb DsouzaPas encore d'évaluation

- Separators: Figure OneDocument8 pagesSeparators: Figure OneMohamed Moder100% (1)

- Steam Genrators Lecture-2Document19 pagesSteam Genrators Lecture-2Gurpreet MeeluPas encore d'évaluation

- FALLSEM2021-22 CHE4001 ETH VL2021220100382 Reference Material I 17-Aug-2021 Lecture-1 (Tray Vs Packed Column)Document62 pagesFALLSEM2021-22 CHE4001 ETH VL2021220100382 Reference Material I 17-Aug-2021 Lecture-1 (Tray Vs Packed Column)sanyukta sinhaPas encore d'évaluation

- Presentation On Fccu Operation: Bhupesh MishraDocument44 pagesPresentation On Fccu Operation: Bhupesh MishraHarish GojiyaPas encore d'évaluation

- Tray TowerDocument21 pagesTray TowerMiraj savaniPas encore d'évaluation

- Packed TowersDocument44 pagesPacked Towersnawazkhan98482Pas encore d'évaluation

- Lect FractionizationDocument57 pagesLect Fractionizationraja.mtPas encore d'évaluation

- Eletrochemicaldesalter 191231094907Document6 pagesEletrochemicaldesalter 191231094907ShakerMahmoodPas encore d'évaluation

- Thermal CrackingDocument40 pagesThermal CrackingSatyaPas encore d'évaluation

- Flow and Heat Transfer in A Mixing ElbowDocument5 pagesFlow and Heat Transfer in A Mixing Elbowjose antonioPas encore d'évaluation

- Crude Oil DesaltingDocument5 pagesCrude Oil DesaltingAhmed Mohamed Khalil0% (1)

- Industrial Process FurnacesDocument11 pagesIndustrial Process FurnacesMohammed AlkhafajiPas encore d'évaluation

- Vacuum DistillationDocument6 pagesVacuum DistillationKhaqan AminPas encore d'évaluation

- Cooling Tower Basics Calculation Formulas - Cooling Tower EfficiencyDocument9 pagesCooling Tower Basics Calculation Formulas - Cooling Tower EfficiencySantosh JayasavalPas encore d'évaluation

- Boiler Blow Down: Workshop On Efficient Operation & Maintenance of BoilersDocument3 pagesBoiler Blow Down: Workshop On Efficient Operation & Maintenance of Boilerskcp1986Pas encore d'évaluation

- Friction of Pipe 2Document5 pagesFriction of Pipe 2Ranu GamesPas encore d'évaluation

- Fired HeatersDocument40 pagesFired HeatersAhmad Riaz KhanPas encore d'évaluation

- What Is A Boiler? What Are Parts of A Boiler?Document24 pagesWhat Is A Boiler? What Are Parts of A Boiler?dharanistrikezPas encore d'évaluation

- PumpsDocument54 pagesPumpsMark SantosPas encore d'évaluation

- Presentation of Internship ProjectDocument34 pagesPresentation of Internship ProjectReinaldo Ongky Billy AnandoPas encore d'évaluation

- DistillationDocument22 pagesDistillationAhmed Omar Amine100% (1)

- Boiler:: Working Principle of A BoilerDocument22 pagesBoiler:: Working Principle of A BoilerZeshan AbdullahPas encore d'évaluation

- What Is DistillationDocument25 pagesWhat Is DistillationashirPas encore d'évaluation

- Chemical Design of Heat Exchanger TerdesakDocument22 pagesChemical Design of Heat Exchanger TerdesakNor Ain100% (4)

- Process Utility: By: Anupam Manoj B.Tech (Chemical Engg) 6 SemesterDocument14 pagesProcess Utility: By: Anupam Manoj B.Tech (Chemical Engg) 6 SemesterAnupam Manoj0% (1)

- Furnace Control SystemDocument9 pagesFurnace Control SystemMUHAMMAD ASJAD AAMIR AAMIR AMINPas encore d'évaluation

- Vertical VaporizersDocument2 pagesVertical VaporizersMeravigliorso76Pas encore d'évaluation

- Cped p2Document1 pageCped p2Queenie Balisong0% (1)

- Refrigeration (VCRS &VARS)Document19 pagesRefrigeration (VCRS &VARS)Vinesh TalpankarPas encore d'évaluation

- CH 3520 Heat and Mass Transfer Laboratory: Title of The Experiment: Plate Column DistillationDocument7 pagesCH 3520 Heat and Mass Transfer Laboratory: Title of The Experiment: Plate Column DistillationVijay PrasadPas encore d'évaluation

- CSTRDocument20 pagesCSTRSharing Caring100% (1)

- Double Pipe Heat ExchangerDocument10 pagesDouble Pipe Heat ExchangerJaldhi PatelPas encore d'évaluation

- Two Reboiler Simultaneously RunDocument16 pagesTwo Reboiler Simultaneously RunteddyPas encore d'évaluation

- Failure of Boiler Tubes Due To EROSIONDocument9 pagesFailure of Boiler Tubes Due To EROSIONShiVa20155244Pas encore d'évaluation

- Industrial BoilersDocument81 pagesIndustrial BoilersRavi PrajapatiPas encore d'évaluation

- Plate Type Heat ExchangerDocument5 pagesPlate Type Heat ExchangerLaxmi PrasannaPas encore d'évaluation

- DistillationDocument89 pagesDistillationjokish33% (3)

- BoilersDocument39 pagesBoilersVinay Balineni100% (1)

- Distillation Column Design Lab ReportDocument31 pagesDistillation Column Design Lab ReportGracylla RosePas encore d'évaluation

- Double Pipe Heat Exchanger2Document11 pagesDouble Pipe Heat Exchanger2حسين عمريPas encore d'évaluation

- Trays in RefineryDocument22 pagesTrays in RefineryHammad HashmiPas encore d'évaluation

- Reboiler and VaporiserDocument56 pagesReboiler and Vaporiserjihad jamareiPas encore d'évaluation

- Distillation PrinciplesDocument71 pagesDistillation PrinciplesMelania Grigore100% (1)

- Chapter - 2 DistillationDocument75 pagesChapter - 2 DistillationJACOB DAVEPas encore d'évaluation

- CDUDocument16 pagesCDUDeepak Sharma100% (1)

- HEAT TRANSFER PYQ (2000-2020) by Yogesh Tyagi Sir: IIT KharagpurDocument33 pagesHEAT TRANSFER PYQ (2000-2020) by Yogesh Tyagi Sir: IIT KharagpurRomil GandhiPas encore d'évaluation

- Steam Jet Refrigeration and Vapour Absorption SystemDocument21 pagesSteam Jet Refrigeration and Vapour Absorption SystemmohitPas encore d'évaluation

- Two Marks CH 6603 Mass TransferDocument17 pagesTwo Marks CH 6603 Mass Transfersampathkumar100% (1)

- R5102306 Process Engineering PrinciplesDocument1 pageR5102306 Process Engineering PrinciplessivabharathamurthyPas encore d'évaluation

- 4.1 BoilerDocument40 pages4.1 BoilermechgokulPas encore d'évaluation

- Materials: Pressure Vessel Steel Wrought Iron Stainless Steel Live Steam Copper Brass Fireboxes Steam LocomotivesDocument10 pagesMaterials: Pressure Vessel Steel Wrought Iron Stainless Steel Live Steam Copper Brass Fireboxes Steam LocomotivesVelampalli AshokPas encore d'évaluation

- BLR - Operation & Maintenance Q&A - 2017Document50 pagesBLR - Operation & Maintenance Q&A - 2017RAJKUMARPas encore d'évaluation

- ATD Unit-4 NotesDocument44 pagesATD Unit-4 NotesSanjay KatreddyPas encore d'évaluation

- Subscriberinvoice 21 12 2022Document1 pageSubscriberinvoice 21 12 2022Anand DPas encore d'évaluation

- Subscriberinvoice 21 12 2022Document1 pageSubscriberinvoice 21 12 2022Anand DPas encore d'évaluation

- Subscriberinvoice 21 12 2022Document1 pageSubscriberinvoice 21 12 2022Anand DPas encore d'évaluation

- Subscriberinvoice 21 12 2022Document1 pageSubscriberinvoice 21 12 2022Anand DPas encore d'évaluation

- Lec Chem461sulfonation and SulfationDocument6 pagesLec Chem461sulfonation and SulfationStalinNarayanasamyPas encore d'évaluation

- Subscriberinvoice 21 12 2022Document1 pageSubscriberinvoice 21 12 2022Anand DPas encore d'évaluation

- Renewable and Sustainable Energy Reviews: Kiros Hagos, Jianpeng Zong, Dongxue Li, Chang Liu, Xiaohua LuDocument12 pagesRenewable and Sustainable Energy Reviews: Kiros Hagos, Jianpeng Zong, Dongxue Li, Chang Liu, Xiaohua LuFelipe RomaniPas encore d'évaluation

- ICEEE14Document3 pagesICEEE14StalinNarayanasamyPas encore d'évaluation

- Material and Energy Balance in Industrial PlantDocument26 pagesMaterial and Energy Balance in Industrial Plantconan45Pas encore d'évaluation

- Glycol Recovery Plant PFD - Hamriya UnitDocument1 pageGlycol Recovery Plant PFD - Hamriya Unitpriyanka barikPas encore d'évaluation

- Unit-3 Material Balance Without Chemical ReactionsDocument95 pagesUnit-3 Material Balance Without Chemical ReactionsRishiPas encore d'évaluation

- Flash Separation: Review of Vapour Liquid EquilibriumDocument15 pagesFlash Separation: Review of Vapour Liquid EquilibriummanishPas encore d'évaluation

- Me Lab Final ReviewerDocument17 pagesMe Lab Final ReviewerXharlene HernandezPas encore d'évaluation

- Chemistry 1 - 11 - Q1 - M3Document15 pagesChemistry 1 - 11 - Q1 - M3Deez Nuts100% (1)

- WWW Msubbu inDocument2 pagesWWW Msubbu inShyam BambalPas encore d'évaluation

- Conceptual DesignDocument95 pagesConceptual DesignGabriele CentiPas encore d'évaluation

- Organic Exam QuestionsDocument8 pagesOrganic Exam QuestionsKhadijahPas encore d'évaluation

- Material BalanceDocument93 pagesMaterial BalanceANGELA RIOJAPas encore d'évaluation

- Liquor TrainingDocument3 pagesLiquor Trainingapi-246293177Pas encore d'évaluation

- Chemical Engineering Review QuestionsDocument19 pagesChemical Engineering Review QuestionsMarcela Godoy100% (16)

- Problem 02 - Distillation Curve ConversionDocument28 pagesProblem 02 - Distillation Curve ConversionJorge Enciso AcuñaPas encore d'évaluation

- Rotating Packed Bed ReactorDocument17 pagesRotating Packed Bed ReactorVarun pandeyPas encore d'évaluation

- Heuristics For ProcessDocument46 pagesHeuristics For ProcessMuhammad SyafiiePas encore d'évaluation

- Cee Practical ReportDocument24 pagesCee Practical ReportPheletso Andrias MoloantoaPas encore d'évaluation

- Instrumentation and Control of Distillation TowersDocument20 pagesInstrumentation and Control of Distillation TowersHenry OkoyePas encore d'évaluation

- Transport ProcessDocument32 pagesTransport Processpidexhitam67% (3)

- GAPS Guidelines: Distillation of Flammable or Combustible LiquidsDocument7 pagesGAPS Guidelines: Distillation of Flammable or Combustible LiquidsLorena DávilaPas encore d'évaluation

- Technology and Specifications of CPD-500 PlantsDocument19 pagesTechnology and Specifications of CPD-500 PlantsallsaniPas encore d'évaluation

- Increased Margin From Updated Internals and CatalystDocument7 pagesIncreased Margin From Updated Internals and CatalystBamrung SungnoenPas encore d'évaluation

- Pengaruh Rentang Suhu Distilasi Fraksinasi Terhadap Kadar Patchouli Alcohol (PA) Pada Minyak NilamDocument7 pagesPengaruh Rentang Suhu Distilasi Fraksinasi Terhadap Kadar Patchouli Alcohol (PA) Pada Minyak NilamBagusSatriyaPas encore d'évaluation

- Lowland Distillery GuideDocument9 pagesLowland Distillery GuideNino Armstrong MarchettiPas encore d'évaluation

- Indian Forest Service Examination SyllabusDocument46 pagesIndian Forest Service Examination SyllabusamulrajvincentPas encore d'évaluation

- BASF Process Butadiene SeparationDocument6 pagesBASF Process Butadiene SeparationNatko47Pas encore d'évaluation

- A Model Recycling Process For Low Density PolyethyleneDocument8 pagesA Model Recycling Process For Low Density Polyethylenekartik521Pas encore d'évaluation

- Extraction of Essential Oils Present in Aniseed, Carom, CardamonDocument8 pagesExtraction of Essential Oils Present in Aniseed, Carom, CardamonkritikPas encore d'évaluation

- How Refinery WorksDocument7 pagesHow Refinery WorksmuraliPas encore d'évaluation

- Uop TocDocument8 pagesUop TocKatan T. ShamranPas encore d'évaluation

- Synthite-Recipes For SuccessDocument17 pagesSynthite-Recipes For SuccessAbhishek SinghalPas encore d'évaluation

- Fundamentals of Petroleum Refining - Assignment-01Document23 pagesFundamentals of Petroleum Refining - Assignment-01Abhijeet Patkar100% (1)