Académique Documents

Professionnel Documents

Culture Documents

Staburags NBU12 - 300 KP

Transféré par

Tomislav PoslekTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Staburags NBU12 - 300 KP

Transféré par

Tomislav PoslekDroits d'auteur :

Formats disponibles

STABURAGS NBU 12/300 KP

Long-term grease for rolling and plain bearings

Description:

STABURAGS NBU 12/300 KP is a

rolling and plain bearing grease

based on mineral oil and a barium

complex soap thickener. It offers

good wear protection and high loadcarrying capacity.

Pack sizes:

400 g cartridge

1 kg can

25 kg bucket

STABURAGS NBU 12/300 KP

Rolling and plain bearing

grease

Good corrosion protection

High load-carrying capacity

Resistant to water

Long-term grease

Reliable wear protection

STABURAGS NBU 12/300 KP

is resistant to water and protects

reliably against corrosion.

Application:

STABURAGS NBU 12/300 KP is a

rolling bearing grease that has

proven successful for the long-term

and lifetime lubrication of drawing

systems in spinning machines

(upper and lower rollers), tension

and eccentric rollers, cardan shafts

and rolling bearings in fans and

ventilation systems.

Product data:

Base

mineral oil /

barium complex soap

Colour

light brown

Service temperature range*, C, approx.

20 to 140

Density, DIN 51 757, at 20 C, g/cm , approx.

Application notes:

Drop point, DIN ISO 2176, C

The product can be easily applied

by brush, spatula or conventional

metering systems.

Worked penetration, DIN ISO 2137,

at 25 C; 0.1 mm

Minimum shelf life:

Base oil viscosity, DIN 51 561

2

at 40 C, mm /s, approx.

2

at 100 C, mm /s, approx.

The minimum shelf life is approx.

60 months if the product is stored in

the original closed container in a

dry place.

Speed factor** (n x dm), approx.

Apparent viscosity***, Klber viscosity grade

*

0.97

> 220

285 315

225

19

350,000

M

Service temperatures are guide values which depend on the lubricants composition, the intended use and the application method. Lubricants change their consistency, apparent dynamic viscosity or viscosity depending on the mechanodynamical loads, time, pressure and temperature. These changes in product characteristics may affect the function of a

component.

**

Speed factors are guide values which depend on the type and size of the rolling bearing type and the local operating

conditions, which is why they have to be confirmed in tests carried out by the user in each individual case.

*** Klber viscosity grades: EL = extra light lubricating grease; L = light lubricating grease; M = medium lubricating grease;

S = heavy lubricating grease; ES = extra heavy lubricating grease

Product information 5.295 e

Edition 03.00

2

STABURAGS NBU 12/300 KP

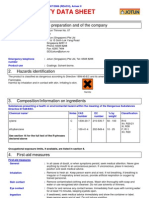

Safety Data Sheet

9.

1.1 Product name: STABURAGS NBU 12/300 KP

Code-No.:

017 062

10.11.2000

1.2 Klber Lubrication Mnchen KG

Emergency telephone no.:

Geisenhausenerstrae 7

++49 - 89 7876 - 0

D-81379 Mnchen

Tel. ++49 - 89 78 76 - 0 telephone exchange

Fax: ++49 - 89 78 76 - 333

2.

Composition / information on ingredients

Chemical characterization (preparation): Mineral oil, barium complex

soap

Hazardous ingredients

Components

Value

Symbols

R-phrases

Barium soap

3.

4.

5.

6.

7.

8.

~ 30%

Xn

22

Hazards identification

Xn Harmful. R phrases: 22. Harmful if swallowed. No further particular

hazards known.

First aid measures

After inhalation: Not applicable

After contact with skin: Wash off with mild cleaners and plenty of water

After contact with eyes: Rinse with plenty of water

After ingestion: Do not induce vomiting. Obtain medical attention

Advice to doctor: Treat symptomatically

Fire-fighting measures

Suitable extinguishing media: Water spray, foam, dry powder,

carbon dioxide (CO2)

Unsuitable extinguishing media: High volume water jet

Special hazards: In case of fire the following can be released: Carbon

monoxide, hydrocarbons

Special protective equipment for firefighters: Standard procedure for

chemical fires

Additional information: Water mist may be used to cool closed

containers. In the event of fire and/or explosion do not breathe fumes

Accidental release measures

Personal precautions: Not required

Environmental precautions: Do not flush into surface water or sanitary

sewer system

Methods for cleaning up / taking up: Use mechanical handling equipment. Dispose of absorbed material in accordance with the regulations

Additional information: None

Handling and storage

Advice on safe handling: No special handling advice required

Advice on protection against fire and explosion: No special precautions

required

Requirements on storage rooms and vessels: No special storage

conditions required

Incompatible materials: Incompatible with oxidizing agents. Do not store

together with food

Further information on storage conditions: Store at room temperature in

the original container

Exposure controls / personal protection

Additional advice on system design: Not applicable

Ingredients and specific control parameters: None

Respiratory protection: No special protective equipment required

Hand protection: No special protective equipment required

Eye protection: No special protective equipment required

Body protection: No special protective equipment required

Other protection measures: No special protective equipment required

General protection and hygiene measures: Avoid prolonged and/or

repeated contact with skin. Remove soiled or soaked clothing immediately. Clean skin thoroughly after work; apply skin cream

Physical and chemical properties

Form

paste

Colour

light brown

Odour

characteristic

Drop point

> 220 C, DIN ISO 2176

Flash point

> 250 C (base oil)

Flammability

not applicable

Ignition temperature

not applicable

Autoflammability

not applicable

Lower explosion limit

not applicable

Upper explosion limit

not applicable

Vapour pressure-first

not applicable

Density

approx. 0.97 g/cm3, 20 C

Water solubility

insoluble

pH value

not applicable

Kinematic viscosity

not applicable

Further information

none

10. Stability and reactivity

Conditions to avoid: None

Materials to avoid: Strong oxidizing agents

Hazardous decomposition products: None under normal use

Additional information: None

11. Toxicological information

The toxicological data has been taken from products of similar

composition

Acute toxicity: LD50/oral/rat = > 2 g/kg (literature data)

Chronic toxicity: None

Human experience: Prolonged skin contact may cause skin irritation

and/or dermatitis

12. Ecological information

Information on elimination (persistence and degradability): Product is

insoluble in water. May be separated out mechanically in purification

plants

Behaviour in environmental compartments: Ecological injuries are not

known or expected under normal use

Ecotoxic effects: Aquatic toxicity is unlikely due to low solubility

Additional information: Should not be released into the environment

13. Advice on Disposal

Disposal: Can be incinerated when in compliance with local, state and

federal regulations

Dispose of contaminated packaging and recommended cleaning: Offer

rinsed packaging material to local recycling facilities

14. Transport information

GGVS / GGVE:

not applicable

ADN / ADNR:

not applicable

IMDG-Code:

not applicable

ICAO / IATA-DGR:

not applicable

Further information: Not classified as dangerous in the meaning of

transport regulations

15. Regulatory information

Labelling according to EU-guidelines: The product is classified and

labelled in accordance with EC-directives/German regulations on

dangerous substances

Hazard(s): Xn Harmful

Hazardous component(s) to be indicated on label: Barium soap

R phrases: 22. Harmful if swallowed.

S phrases: 28. After contact with skin, wash immediately with plenty of

water and mild cleaners

National regulations: Labelling according to the Swiss regulations:

No toxicological class, BAGT-no. 83038

16. Other information

Issue-department of Safety Data Sheet:

Chemical Documentation,Tel.: ++49 - 89 7876 - 564

The data in this product information is based on our general experience and knowledge at the time of printing and is intended to give information of possible applications to a

reader with technical experience. It constitutes neither an assurance of product properties nor does it release the user from the obligation of performing preliminary tests with the

selected product. We recommend contacting our Technical Consulting Staff to discuss your specific application. If required and possible we will be pleased to provide a sample

for testing. Klber products are continually improved. Therefore, Klber Lubrication reserves the right to change all the technical data in this product information at any time

without notice.

Klber Lubrication Mnchen KG, a member of the Freudenberg group

Publisher and Copyright:

Klber Lubrication Mnchen KG

Reprints, total or in part, are permitted if source

is indicated and voucher copy is forwarded.

Klber Lubrication Mnchen KG

Postfach 70 10 47, D-81310 Mnchen

Tel. (0 89) 78 76-0, Telefax (0 89) 78 76-333

Vous aimerez peut-être aussi

- Taper Roller BearingsDocument94 pagesTaper Roller BearingsJurun_BidanshiPas encore d'évaluation

- Bearing Load CalculationDocument9 pagesBearing Load CalculationArunJoelPas encore d'évaluation

- SJ Petro LGF-500 Mud Pump Operation ManualDocument52 pagesSJ Petro LGF-500 Mud Pump Operation ManualSEAZONE EXIM100% (1)

- Advantra® PHC-9256: Safety Data SheetDocument8 pagesAdvantra® PHC-9256: Safety Data SheetYash JoshanPas encore d'évaluation

- Safety Data Sheet for Berudraw AL 20 LubricantDocument4 pagesSafety Data Sheet for Berudraw AL 20 LubricantNur Cholis Hadi100% (2)

- Mirasil DM 350Document2 pagesMirasil DM 350Walter MartinezPas encore d'évaluation

- ISO 10816 Vibration Severity LevelsDocument7 pagesISO 10816 Vibration Severity Levelsgsaiprasath100% (2)

- 1552989005406-Question Bank On LHB Design Coaches PDFDocument32 pages1552989005406-Question Bank On LHB Design Coaches PDFKashul Kumar90% (10)

- Detergent (Accepta) PDFDocument6 pagesDetergent (Accepta) PDFNiluh Komang Putri PurnamantiPas encore d'évaluation

- Hertz Contact Points For Machines PDFDocument478 pagesHertz Contact Points For Machines PDFNicholas FeatherstonPas encore d'évaluation

- Data SheetDocument11 pagesData SheetelPas encore d'évaluation

- Grasa Kluber Asonic Ghy 72Document2 pagesGrasa Kluber Asonic Ghy 72mireyaPas encore d'évaluation

- Tsudakoma Rotary Tables CatalogDocument88 pagesTsudakoma Rotary Tables Catalognoh.miyunPas encore d'évaluation

- MSDS for TECHNOMELT EM 362 Hotmelt AdhesiveDocument6 pagesMSDS for TECHNOMELT EM 362 Hotmelt AdhesivecharbelPas encore d'évaluation

- 1000 Serivce Manual BombasDocument34 pages1000 Serivce Manual BombasCarlos Manuel Pérez RodríguezPas encore d'évaluation

- p5m6k-080 MsdsDocument8 pagesp5m6k-080 MsdsSteric ZeytraPas encore d'évaluation

- MSDS PC Duron Geo LD 15W-40 PDFDocument7 pagesMSDS PC Duron Geo LD 15W-40 PDFaliosk8799Pas encore d'évaluation

- Protect yourself from isobutanol SDSDocument11 pagesProtect yourself from isobutanol SDSArjunPas encore d'évaluation

- Jotafloor Glass FlakeDocument4 pagesJotafloor Glass FlakeShankar CoolPas encore d'évaluation

- Roller Press FundamentalsDocument72 pagesRoller Press FundamentalsverdadoilgasPas encore d'évaluation

- Majestic True Beauty SheenDocument4 pagesMajestic True Beauty SheenYUSRIPas encore d'évaluation

- IEC61400-4 Ed1.0 DEC2012Document160 pagesIEC61400-4 Ed1.0 DEC2012picaro2010100% (1)

- MSDS Mita Emery Oil 6007509Document7 pagesMSDS Mita Emery Oil 6007509jesuscasasPas encore d'évaluation

- MSDS Javel en NewDocument7 pagesMSDS Javel en NewlvhaquyenPas encore d'évaluation

- Hempalin Enamel 52140Document2 pagesHempalin Enamel 52140ΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣ100% (1)

- 11 - Roto-Glide Green - Atlas CopcoDocument7 pages11 - Roto-Glide Green - Atlas CopcoMiguel BjrnPas encore d'évaluation

- Polypropylene (Homopolymer)Document4 pagesPolypropylene (Homopolymer)Fadilla Soraya IsfahaniPas encore d'évaluation

- SDS BYK-1610 US enDocument10 pagesSDS BYK-1610 US enelgendawyPas encore d'évaluation

- SDS for Fixapret F-ECO textile auxiliaryDocument8 pagesSDS for Fixapret F-ECO textile auxiliarySajida HafeezPas encore d'évaluation

- Safety Data Sheet IngredientsDocument5 pagesSafety Data Sheet Ingredientsalinus4y100% (1)

- MSDS Vooki Hand Sanitizer MSDS PDFDocument9 pagesMSDS Vooki Hand Sanitizer MSDS PDFarun100% (2)

- SL 1301 Eco FLZ 20Document8 pagesSL 1301 Eco FLZ 20alinus4yPas encore d'évaluation

- MIRR ALMA SUPER API SL SAE 15W-40 Safety Data SheetDocument8 pagesMIRR ALMA SUPER API SL SAE 15W-40 Safety Data SheetAbdul GhafoorPas encore d'évaluation

- MSDS of REN 60Document7 pagesMSDS of REN 60GopiPas encore d'évaluation

- Lubrizol (R) 4980a MsdsDocument7 pagesLubrizol (R) 4980a MsdsVania BaradiPas encore d'évaluation

- BGQYNDocument3 pagesBGQYNdalton2003Pas encore d'évaluation

- Chemicals Zetag MSDS Beads Zetag 7557 - 0510Document6 pagesChemicals Zetag MSDS Beads Zetag 7557 - 0510PromagEnviro.comPas encore d'évaluation

- Tds Uk 905tx (Urethane Thinner A) v1Document1 pageTds Uk 905tx (Urethane Thinner A) v1HAFIDZ100% (1)

- Olive Oil MsdsDocument5 pagesOlive Oil Msdsshella168Pas encore d'évaluation

- Mega Wijayah Caustic Soda Flakes SDS - Rev. 2018Document9 pagesMega Wijayah Caustic Soda Flakes SDS - Rev. 2018Osh 0717Pas encore d'évaluation

- MSDS Sodium Hydrosulfite 90% Ex GuangdiDocument7 pagesMSDS Sodium Hydrosulfite 90% Ex GuangdidianPas encore d'évaluation

- Gsbme Autoclave Training v3Document43 pagesGsbme Autoclave Training v3madosb5133Pas encore d'évaluation

- Arkema MSDS for Dimethyl DisulfideDocument7 pagesArkema MSDS for Dimethyl Disulfidefarooq798100% (1)

- Ig 55 Material Safety Data SheetDocument4 pagesIg 55 Material Safety Data SheetJason BartramPas encore d'évaluation

- MSDS 2Document14 pagesMSDS 2henry.anthirayas100% (2)

- Sag 10 ShowTechnicalDataSheetDocument2 pagesSag 10 ShowTechnicalDataSheetGustavo E Aguilar EPas encore d'évaluation

- SDS - Jotun Thinner No. 07 - Marine - Protective - English (Uk) - SingaporeDocument5 pagesSDS - Jotun Thinner No. 07 - Marine - Protective - English (Uk) - SingaporeAmi Terecef Gamboa MirandaPas encore d'évaluation

- Chemicals Zetag MSDS Powder Zetag 4105 - 0810Document6 pagesChemicals Zetag MSDS Powder Zetag 4105 - 0810PromagEnviro.com0% (1)

- MSDS Linalool PDFDocument7 pagesMSDS Linalool PDFSyafira Indah JulianaPas encore d'évaluation

- Safety Data Sheet: Product Name: MOBILGEAR SHC XMP 460Document12 pagesSafety Data Sheet: Product Name: MOBILGEAR SHC XMP 460Om Prakash RajPas encore d'évaluation

- MSDS Therminol VP-1Document8 pagesMSDS Therminol VP-1prannoy100% (1)

- Pom MSDS PDFDocument3 pagesPom MSDS PDFebercuePas encore d'évaluation

- MSDS Prilled UreaDocument6 pagesMSDS Prilled UreaLutfi IsmailPas encore d'évaluation

- Veradel Pellets PDFDocument7 pagesVeradel Pellets PDFkirandevi1981100% (1)

- SDS BYK-037 US enDocument10 pagesSDS BYK-037 US enForeverPas encore d'évaluation

- Hazardous Materials Storage and Process ControlsDocument3 pagesHazardous Materials Storage and Process Controlssagar6688Pas encore d'évaluation

- MSDS for Mexel 432/0 Water Treatment AdditiveDocument5 pagesMSDS for Mexel 432/0 Water Treatment Additivewongpengchiong7205Pas encore d'évaluation

- Msds - Chimec 7268 - BactericideDocument5 pagesMsds - Chimec 7268 - BactericideAnonymous LfeGI2hMPas encore d'évaluation

- Crosslinker CX100 MsdsDocument59 pagesCrosslinker CX100 MsdsMimi rastamPas encore d'évaluation

- Chemicals Zetag MSDS LDP Zetag 7875 FS 40 - 0610Document7 pagesChemicals Zetag MSDS LDP Zetag 7875 FS 40 - 0610PromagEnviro.comPas encore d'évaluation

- R-HI DTS 5-373 (01) - Technomelt Supra 100 IDDocument4 pagesR-HI DTS 5-373 (01) - Technomelt Supra 100 IDjhonni sigiroPas encore d'évaluation

- Msds Codex 661 - Rev-01MSDS CODEX 661Document6 pagesMsds Codex 661 - Rev-01MSDS CODEX 661manlekPas encore d'évaluation

- VpCI-105 VpCI-111 MSDS PDFDocument5 pagesVpCI-105 VpCI-111 MSDS PDFJose Alberto Uribe Minier100% (1)

- Safety Data Sheet for Photographic Fixing SolutionDocument5 pagesSafety Data Sheet for Photographic Fixing SolutionPrasetya SiregarPas encore d'évaluation

- Material Safety Data Sheet: 1. Company and Product IdentificationDocument8 pagesMaterial Safety Data Sheet: 1. Company and Product IdentificationYan MoraesPas encore d'évaluation

- Cazar K 2Document10 pagesCazar K 2David LiePas encore d'évaluation

- Catalyst MsdsDocument3 pagesCatalyst MsdsJaime MendozaPas encore d'évaluation

- Restore MSDSDocument7 pagesRestore MSDSspadafora77Pas encore d'évaluation

- Klüberplex BEM 41-132: High-Temperature Long-Term Grease For Rolling BearingsDocument2 pagesKlüberplex BEM 41-132: High-Temperature Long-Term Grease For Rolling Bearingsmarcalasan0% (1)

- 496 GDJGGJGFDocument2 pages496 GDJGGJGFRaluca FarcasPas encore d'évaluation

- End Term Report PS-1 Copy 2 PDFDocument24 pagesEnd Term Report PS-1 Copy 2 PDFPranjal WadhwaPas encore d'évaluation

- Ecalc Manual PDFDocument58 pagesEcalc Manual PDFNguyenThanhdungPas encore d'évaluation

- Bearing specification tables for machine designDocument240 pagesBearing specification tables for machine designJan Michael VecillesPas encore d'évaluation

- WRB OIL BATH v1.1Document8 pagesWRB OIL BATH v1.1Nuno SimbinePas encore d'évaluation

- 2021 BearingNewsJune WebfnDocument112 pages2021 BearingNewsJune Webfnancelot99Pas encore d'évaluation

- Unified DodgeDocument132 pagesUnified DodgeMichael ThomasPas encore d'évaluation

- BOART LF90D - PartsDocument318 pagesBOART LF90D - PartsCarlos Osorio IngaPas encore d'évaluation

- Antifriction Bearings - 2Document2 pagesAntifriction Bearings - 2MahmoudKamalElshazlyPas encore d'évaluation

- Brands Vilter Manual VSM VSS CompressorDocument125 pagesBrands Vilter Manual VSM VSS Compressorperrydhondt0% (1)

- Impak 2Document11 pagesImpak 2Vasudev AgrawalPas encore d'évaluation

- CATALOGO FGS Internet-Katalog-EngDocument106 pagesCATALOGO FGS Internet-Katalog-Engjunico76Pas encore d'évaluation

- Iso 76 1987 - 2Document8 pagesIso 76 1987 - 2Jitesh DhimanPas encore d'évaluation

- Generating Electricity from Speed BreakersDocument21 pagesGenerating Electricity from Speed BreakersMohanRaju VenkatRajuPas encore d'évaluation

- 2017 Dec. ME369-A Tribology - Ktu QbankDocument2 pages2017 Dec. ME369-A Tribology - Ktu QbankAir SevakkPas encore d'évaluation

- 6-Speed Manual Gearbox 02Q, Front-Wheel DriveDocument224 pages6-Speed Manual Gearbox 02Q, Front-Wheel Driveberenice togaPas encore d'évaluation

- MD 2 (Me 424) FormulasDocument14 pagesMD 2 (Me 424) FormulasLancePacioPas encore d'évaluation

- Case Study For SKFDocument3 pagesCase Study For SKFpawanumarji1Pas encore d'évaluation

- Us5753799 PDFDocument17 pagesUs5753799 PDFDeepak DeepuPas encore d'évaluation

- M19 LatheDocument36 pagesM19 LatheVinay Kumar Neelam100% (1)

- Design of Nug Oil Extracting Machine: AcknowledgementDocument67 pagesDesign of Nug Oil Extracting Machine: AcknowledgementSibhat GebregziabherPas encore d'évaluation