Académique Documents

Professionnel Documents

Culture Documents

EJ Series Butterfly Valves

Transféré par

Gia Minh Tieu TuDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

EJ Series Butterfly Valves

Transféré par

Gia Minh Tieu TuDroits d'auteur :

Formats disponibles

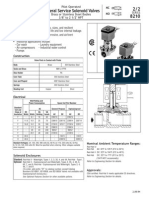

E-236 = 01

EJ Series

Butterfly Valves

KITZ EJ Series Butterfly Valves

Materials

Flange Table

Parts

Standard

Materials

Body

Ductile ironEN-GJS-450-10

Stem

Stainless SteelAISI 410

Disc

Stainless SteelA351 Gr.CF8M

Seat

W-NBRWhite NBR

Size

inch

mm

BS EN 1092

BS10

ASME B16.5

PN6

PN10

PN16

Table E

Class150

50

2 1/2

65

VMQSilicone rubber

80

FKMFluoro rubber

100

O-ring

FKM

125

Bearing

Stainless Steel

150

Stem bearing

Multi-layered bearing*

200

Plug

Zinc die-cast

10

250

Bottom stem

Stainless SteelAISI 410

12

300

* Tetrafluoroethylene resin filled overlayer, a sintered bronze interlayer and

a steel backing.

Standard mounting

Special mounting (Proper centering is required)

Explanation of Product Code

G PN10 EJ M W

2

Lever handle

Gear

4 Disc material

M:

2 Class

1 Valve operation

None:

G:

3 Valve material and design

PN10

EJ:

5 Seat material

316 stainless steel

W:

Q:

F:

W-NBR

VMQ

FKM

Please consult KITZ sales staff or our local agent for details of the seat and the disc combination

Please consult KITZ sales staff or our local agent for vacuum service.

Contents

Design features

Technical specifications

Approved

PN10EJM

G-PN10EJM

Bolting data

Precautions

This catalog uses MPa, a SI unit, for indication of pressures.

Ductile iron EJ series

KITZ EJ Series Butterfly Valves

Design feature

Bearing

ISO5211 Actuator

mounting Flange

O-ring

Stem

High performance

stem bearing

Back up ring

Disc

Body

3 type of Seat material

Bottom stem

Back up ring

High performance

Stem bearing

Plug

3 type of Seat material.

The 3 type of seat material are; VMQ(Silicone rubber) which can be

used for a wide range of temperature applications, W-NBR(White

NBR), which is suitable for use in the food processing industry and

FKM(Fluoro rubber) which has properties such as strength and

durability idea for use on variety of fluid applications. W-NBR and

VMQ meet the requirement of FDA.*

*All the above chemical materials used are approved by FDA, and the seats are

manufactured within the maximum allowable limitations and restrictions.

Suitable for various flanges.

All the sizes are suitable for the flanges of EN1092 PN6, PN10,

PN16 / BS10 Table E / ASME Class125 and Class150

Integral ISO 5211 actuator mounting flange.

Backup ring to maintain the stem sealing.

The backup ring around the stem maintains the performance of the

stem sealing caused by the movement of the stem / disc in the

sealing / seat of valve.

Stainless steel bearing features.

Within the stainless upper body bearing is a multi-layered bearing

embedded to provide smooth stem operation. Housed also within

the stem bearing is a snap ring to provide protection and prevent

blow out of the stem due to internal pressure.

Polished disc.

The polished disc is standard for VMQ and optional for W-NBR

seats for use within the food and pharmaceutical industry.

Any pneumatic or electric valve actuator provided with ISO 5211

valve mounting flange can be easily mounted for actuation of valves

in the field.

High performance stem bearing having additional

strength to withstand high temperature and high

pressure.

The stem bearing of the EJ series is a multilayered backmetal to

provide a high performance bearing surface capable of withstanding

high pressure and temperature.

KITZ EJ Series Butterfly Valves

Technical Specifications

P-T rating

Maximum service pressure

PN10

W-NBR seat

10bar

10bar1.0MPa

Body material

Ductile iron

EN-GJS-450-10, Equivalent to ASTM

A536 Gr. 65-45-12, BS 2789 Gr. 40/10 *1

*1 Obsolete Standard.

0bar

Applicable standards

Valve design

80

VMQ seat

10bar

EN 593:2004

7bar

Coupling flanges

Wafer type

5bar

EN1092 PN6, PN10, PN16

3bar

BS10 Table E

0bar

ASME Class125, Class150

-20 0

100

150

180

FKM seat

Technical Data

10bar

7bar

Pressure loss

10

Pressure dropkPa

50A

55A

80A

100A

125A 150A

200A

0.1

100

130

180

: Continuous service

300A

: Occasional use (Fully open or closed position)

Flow coefficient (Cv)

1

10

100

Flow volumem3/h

1000

Size

mm inch

2

50

2 1/2

65

80

3

100

4

125

5

150

6

200

8

250

10

300

12

Flow characteristics

100

90

80

Flow rate (%)

70

60

50

40

20

30

17

36

45

65

95

138

241

325

493

40

29

60

75

109

160

234

419

575

859

Open degree

50

60

56

42

122

88

165

113

274

172

406

255

598

375

681 1080

950 1510

1410 2260

70

75

172

248

446

655

958

1700

2420

3610

80

86

219

345

689

997

1430

2470

3460

5160

Kv = Cv / 1.167

10

0

20

8

16

21

3

47

68

116

160

258

Cv is defined as the flow in GPM that a valve will carry with a

pressure drop of 1.0 psi, when the media is 60

F water.

30

10 20

30 40 50

60 70 80

Valve operating (degree)

0bar

250A

90

Kv is defined as the flow is in m3/h that valve will carry with a

pressure drop of 1.0 bar, when the media is 5 to 30 water.

90

88

246

415

886

1250

1760

2900

4020

6010

KITZ EJ Series Butterfly Valves

Certificates

KITZ has always firmly believed that its Products and Service must be backed by the most demanding. Approvals and Certificates, as clear

proof of maximum quality assurance. This has resulted in an ongoing detail improvement of our products and service.

ISO 9001

ATEX

KITZ EJ series are meeting FDA requirement

PED-CEATEX

Options

Polished disc.

Gear operated

Size 50 to 200 (standard for 250 and over)

KITZ EJ Series Butterfly Valves

Lever Operated (Size 50 to 200)

Wafer Type

BS PN16 Design

PN10EJM

of product coding

are trim material coding

For trim material coding,

please refer to page 3.

Polished disc is option.

D1

SIZE 80

SIZE 5065

H1

dD

H2

SIZE 125150

SIZE 200

BS PN10 Design

Dimensions

Valve Size

inch

mm

2

50

21/2

65

3

80

4

100

5

125

6

150

8

200

H1

H2

D1

50

65

79

100

125

147

197

191

199

217

227

265

277

287

147

155

173

183

211

223

248

67

75

91

101

127

139

169

43

46

46

52

56

56

60

90

104

124

146

176

206

257

125

145

160

180

210

240

295

180

180

180

180

230

230

350

KITZ EJ Series Butterfly Valves

Gear Operated (Size 250 to 300)

Wafer Type

BS PN16 Design

PN10EJ

of product coding

are trim material coding

For trim material coding,

please refer to page 3.

Polished disc is option.

E

F

L1

D1

H1 H

d D

H2

BS PN10 Design

Dimensions

Valve Size

inch

mm

10

250

12

300

H1

H2

D1

L1

245

295

381

406

304

329

229

254

68

78

316

367

355

410

250

250

250

250

60

60

63

63

KITZ EJ Series Butterfly Valves

Bolting Data

Hexagon head boltHexagon nut

L=mm

Flange

PN6

PN10

PN16

BS 10 TalbeE

inch

Size

No.

Size

No.

Size

No.

50

M12

90

M16

105

M16

105

5 /8

65

21/2

M12

90

M16

105

M16

105

5 /8

80

M16

100

M16

105

M16

105

5 /8

100

M16

110

M16

115

M16

115

5 /8

125

M16

115

M16

115

M16

115

5 /8

150

M16

115

M20

120

M20

120

3 /4

200

M16

125

M20

130

M20

140

12

3 /4

250

10

M16

135

12

M20

140

12

M24

155

12

3 /4

300

12

M20

150

12

M20

155

12

M24

170

12

7 /8

No.

Size

No.

Size

No.

Size

mm

Size

ASME B16.5 Class150

No.

Size

No.

95

5 /8

105

100

5/8

115

100

5/8

115

110

5/8

125

115

3/4

130

115

3/4

135

125

3/4

145

140

12

7/8

160

12

160

12

7/8

170

12

No.

Size

No.

120

5 /8

120

120

5/8

130

Stud boltHexagon nut

L=mm

PN6

Flange

Size

PN10

L

PN16

L

BS 10 TalbeE

mm

inch

50

M12

110

M16

125

M16

125

5/8

65

21/2

M12

110

M16

130

M16

130

5 /8

ASME B16.5 Class150

80

M16

120

M16

130

M16

130

5 /8

120

5/8

130

100

M16

130

M16

135

M16

135

5 /8

130

5/8

150

125

M16

140

M16

140

M16

140

5 /8

140

3/4

160

150

M16

140

M20

145

M20

145

3 /4

140

3/4

160

200

M16

150

M20

155

M20

165

12

3 /4

150

3/4

170

250

10

M16

160

12

M20

170

12

M24

185

12

3 /4

160

12

7/8

190

12

300

12

M20

180

12

M20

185

12

M24

200

12

7 /8

190

12

7/8

200

12

KITZ EJ Series Butterfly Valves

Precautions for Trouble-free Operation of

KITZ Butterfly Valves

Valve Selection

1. Ensure to select a valve with design specifications

which meet the fluid type and the pressure and

temperature conditions required.

2. Lubricants are applied to discs and rubber seats

and PTFE seats as standard to protect their surfaces.

3. Contact KITZ Corporation or its local distributors for

service with pulverulent bodies.

Storage and Handling

Valves must be stored in dry, clean and corrosion-free

environment with no direct exposure to the sun, leaving

valves open by 10 for prevention of permanent distortion

of resilient seats. Refrain from overloading valves and

their actuators, such as storing them in piles or placing

other objects on them.

Mounting on Pipelines

1. Valves must be mounted on flanges only after flanges

have been welded to pipes and cooled down to the

atmospherical temperature. Otherwise, welding heat

may affect the quality of resilient seats.

2. Edges of welded flanges must be machined for smooth

surface finish so that they may not damage resilient

seats during valve mounting. Flange faces must be

free from damage or deformation, and be cleaned to

remove rust or any other foreign objects so that there

will be no concern of external leakage through valve

and flange connections. Gaskets are not required for

mounting KITZ EJ series butterfly valves.

3. Clean flanges and pipe bores to thoroughly remove

welding spatters, scales and other foreign objects

which may have been left inside.

4. Accurate centering of each couple of upstream and

downstream pipes is essential for trouble-free

operation of valves mounted between them. Incorrect

centering shown in Fig. 1 must be by all means

avoided.

5. For valve mounting, set jack bolts under the pipes for

flat support at the same height, and adjust the flangeto-flange distance so that some 6 mm to 10 mm room

may be allowed beside the both sides of the valve

body.

Remember that valves here must be left open only by

10 from the fully closed position.

6. Mount Valve carefully so that flange faces may not

damage resilient seats. (Fig. 2)

7. Then set bolts into the guides of a valve, ensuring

the correct centering between pipes and the valve.

8. Trially open the valve to check to see if there is no

disturbing contact between the valve disc and the

flanges.

Recommended torque values

9. Remove the jack bolts,

Nm (kgfm)

DN

tighten bolts alternately

50

and diagonally till the

65

63(6)

flanges contact the valve

80

body (Fig. 3 and 4).

100

125

Refer to the table shown

111(11)

150

right for recommended

200

torque values.

250

300

Fig. 2

177(18)

Fig. 3

Fig. 1

(a)

Fig. 4

(b)

KITZ EJ Series Butterfly Valves

10.For mounting actuated valves, provide valve supports

to prevent bending of valve necks and reduce valve

and pipe vibration.

11.Dont step on valve necks or valve handwheels.

12.Dont mount valves of DN350 and larger with their

operations upside down.

13.Dont mount butterfly valves directly to check valves or

pumps, which may cause damage to them by the disc

contacts.

14.Dont mount valves to downstream sides of elbows,

reducers or regulating valves where fluid velocity

changes. It is recommended to install valves approximately 10 times of the valve nominal sizes away from

them for such cases.

15.Mount valves taking consideration of the effects which

discs are given by fluid velocity or pressure chages in

the pipings. Refer to the illustrations. ( Fig.5)

Contact KITZ Corporation or its local distributors for

the details.

Fig.5

Mounting to bent pipe

Mounting to pump outlet

Pump

shaft

GOOD

Centrifugal pump

(Vertical shaft)

GOOD

10D

Centrifugal pump

(Horizontal shaft)

Do not use

GOOD

Pump

shaft

10D

Pump

shaft

Do not use

GOOD

10D

Axial flow pump

Valve Operation

1.Valves equipped with manual operators such as

levers, and handles of gears must be ONLY

MANUALLY operated. Application of an excessive

exter nal force to operate valves may result in

malfunction of valves and their operators.

2.Ensure to fully open valves before a loop test of the

piping system is carried out with line pressure higher

than the nominal pressure of tested valves. Never use

closed valves in place of blind flanges.

3.When valves need to be dismantled from pipes for

maintenance or any other cause, ensure to thoroughly

releave the line pressure beforehand. Loosening

piping bolts under line pressure causes a danger. Any

residual fluid left inside the pipeline must be

completely drained.

4.Users should contact KITZ Corporation or its local

distributors for technical advice, when valves should

be continuously pressurized while left open by 30 or

less.

5.Don't use position indicators to operate valves, or

overload position indicators. This may cause damage

to indicators.

6.Ensure to use blind flanges when butterfly valves are

mounted at the end of pipelines.

7.Standard actuators are referenced in this catalog for

actuated valve operation. Contact KITZ Corporation or

its local distributors for mounting optional actuators.

8.Contact KITZ Corporation for service at hopper or

pump outlets.

9.Avoid touching gear operators and actuator stopper

bolts accidentally.

10.It is recommended to perform periodical inspection for

Making sure of valve opening degree

Checking loosened bolts and leakage at each

connection

Checking vibration and noise

11.Refer to instruction manual for other precautions. Also

refer to actuator catalogs and instruction manuals for

actuated valves.

0908ITP

Vous aimerez peut-être aussi

- Válvulas Bola SegmentadaDocument12 pagesVálvulas Bola SegmentadarehynaldoPas encore d'évaluation

- MasterSeries 850 Specification SheetDocument2 pagesMasterSeries 850 Specification SheetFEBCOPas encore d'évaluation

- Block & Bleed Valve: High Technology Valve & Fitting SeriesDocument20 pagesBlock & Bleed Valve: High Technology Valve & Fitting SeriesMayur PatelPas encore d'évaluation

- Valvulas de Bola - JAMESBURYDocument4 pagesValvulas de Bola - JAMESBURYcasv9Pas encore d'évaluation

- MasterSeries 880V Specification SheetDocument4 pagesMasterSeries 880V Specification SheetFEBCOPas encore d'évaluation

- Full Lift Spring Loaded Open PDFDocument4 pagesFull Lift Spring Loaded Open PDFVenkatespatange RaoPas encore d'évaluation

- Bulletin B150-5 - Ball Valve For H2O2Document0 pageBulletin B150-5 - Ball Valve For H2O2pdaga19691383Pas encore d'évaluation

- PG 43-44 Butterfly Valve PDFDocument2 pagesPG 43-44 Butterfly Valve PDFChamitha MadushanPas encore d'évaluation

- RedvalvE 90 01Document4 pagesRedvalvE 90 01Rizal FalevyPas encore d'évaluation

- V9271 Fivalco 2902eDocument6 pagesV9271 Fivalco 2902eharenas7Pas encore d'évaluation

- Prochem Ball ValvesDocument5 pagesProchem Ball Valvesmd_taheriPas encore d'évaluation

- Dezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bDocument24 pagesDezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bjasonlaiymPas encore d'évaluation

- Technical Bulletin: Valtek Mark One Control ValvesDocument20 pagesTechnical Bulletin: Valtek Mark One Control ValvesOscar CruzPas encore d'évaluation

- Valves AccessoriesDocument14 pagesValves AccessoriesnajiruddinshaikPas encore d'évaluation

- Control Valve System: PN 16 / 40 DN 15 - 150 ApplicationDocument0 pageControl Valve System: PN 16 / 40 DN 15 - 150 Applicationcico_ctPas encore d'évaluation

- PressureDocument84 pagesPressureHangloque GabanoPas encore d'évaluation

- Horizon Series - Single Stage (SS) / Two Stage (TS) : Reciprocating Air CompressorsDocument1 pageHorizon Series - Single Stage (SS) / Two Stage (TS) : Reciprocating Air CompressorsAnkur Yash100% (1)

- Keystone F4060 enDocument2 pagesKeystone F4060 enRezi SyahputraPas encore d'évaluation

- Butterfly ValveDocument20 pagesButterfly Valvenazar750Pas encore d'évaluation

- Mech Van Catalogue PDFDocument26 pagesMech Van Catalogue PDFVan Nguyen Huu VanPas encore d'évaluation

- Butterfly ValveDocument10 pagesButterfly ValvevtpsPas encore d'évaluation

- Full Port Stainless Steel Single Chamber Basic ValveDocument2 pagesFull Port Stainless Steel Single Chamber Basic ValveWattsPas encore d'évaluation

- Valvula Bola Sarco m40Document3 pagesValvula Bola Sarco m40radacoPas encore d'évaluation

- Ratio Pressure Reducing ValvesDocument4 pagesRatio Pressure Reducing Valveskanem1Pas encore d'évaluation

- Reduced Port Ductile Iron Dual Chamber Basic Valve: Mustang Series Basic ValvesDocument2 pagesReduced Port Ductile Iron Dual Chamber Basic Valve: Mustang Series Basic ValvesWattsPas encore d'évaluation

- High Performance ButterflyDocument19 pagesHigh Performance ButterflyEmily NguyenPas encore d'évaluation

- Flowserve Vlatb001Document20 pagesFlowserve Vlatb001Selva KumarPas encore d'évaluation

- AMRI ISORIA Broad Market Type Series Booklet DataDocument12 pagesAMRI ISORIA Broad Market Type Series Booklet Datarudiskw456Pas encore d'évaluation

- 06 SCT Extended PDFDocument40 pages06 SCT Extended PDFSlobodan Antic100% (2)

- Valvula Borboleta Lug z614 ADocument6 pagesValvula Borboleta Lug z614 AWellington S. FrançaPas encore d'évaluation

- MasterSeries 876V Specification SheetDocument4 pagesMasterSeries 876V Specification SheetFEBCOPas encore d'évaluation

- Econ Gate ValvesDocument22 pagesEcon Gate ValvesRiyas Udheen100% (1)

- ValvesDocument3 pagesValveshummingbird4uPas encore d'évaluation

- Butterfly Valve Lug TypeDocument6 pagesButterfly Valve Lug TypeMr. APas encore d'évaluation

- Swagwlok Lap Flange PDFDocument6 pagesSwagwlok Lap Flange PDFPraveen KumarPas encore d'évaluation

- 11502Document9 pages11502balajivangaruPas encore d'évaluation

- Item 6 Ebro Feed Valve Z011-A-150Document4 pagesItem 6 Ebro Feed Valve Z011-A-150ehngiePas encore d'évaluation

- MPVN BrochureDocument32 pagesMPVN Brochurefernando_naciamentPas encore d'évaluation

- 11422Document10 pages11422balajivangaruPas encore d'évaluation

- Two BallDocument5 pagesTwo Ballchartwithsam0041653Pas encore d'évaluation

- AV-C Butterfly ValveDocument20 pagesAV-C Butterfly ValveSopon SrirattanapiboonPas encore d'évaluation

- Eko4000-4100 WebDocument4 pagesEko4000-4100 WebSubramanian SaravananPas encore d'évaluation

- Gate Valve CataogueDocument4 pagesGate Valve CataogueAditya B. RyantoPas encore d'évaluation

- FoxPro V723 e - 09.99Document0 pageFoxPro V723 e - 09.99cico_ctPas encore d'évaluation

- Spirax BSA TDocument4 pagesSpirax BSA TNang DapiPas encore d'évaluation

- ABZ ValveDocument8 pagesABZ ValveJavierfox98Pas encore d'évaluation

- Afco - CV01 Series - Swing Check ValveDocument4 pagesAfco - CV01 Series - Swing Check Valveafie pio pioPas encore d'évaluation

- ASV 10 20 BrochureDocument8 pagesASV 10 20 BrochureThomas Duane DavidsonPas encore d'évaluation

- Control Choke Valve 9000Document8 pagesControl Choke Valve 9000sabi_shi100% (2)

- B V M CatalogueDocument24 pagesB V M CatalogueAyhan AyhnPas encore d'évaluation

- Valvula Borboleta Wafer z011 AsDocument6 pagesValvula Borboleta Wafer z011 AsWellington S. FrançaPas encore d'évaluation

- Ball Valve Flange TypeDocument7 pagesBall Valve Flange TypeperoooPas encore d'évaluation

- SELENOIDE-Valv Solen 8210Document6 pagesSELENOIDE-Valv Solen 8210MARACO46Pas encore d'évaluation

- Valve0114 PDFDocument14 pagesValve0114 PDFbinhjukiPas encore d'évaluation

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Viking ProjectDocument8 pagesViking ProjectGia Minh Tieu TuPas encore d'évaluation

- Guide To Managing Risks of Industrial Rope Access Systems 0Document38 pagesGuide To Managing Risks of Industrial Rope Access Systems 0Gia Minh Tieu TuPas encore d'évaluation

- InsulationDocument12 pagesInsulationGia Minh Tieu TuPas encore d'évaluation

- Scaffolding - Fixed and Mobile: Potential HazardsDocument1 pageScaffolding - Fixed and Mobile: Potential HazardsGia Minh Tieu TuPas encore d'évaluation

- CraneDocument4 pagesCraneGia Minh Tieu TuPas encore d'évaluation

- HSE SWP 033 Ladders Scaffold SafetyDocument4 pagesHSE SWP 033 Ladders Scaffold SafetyGia Minh Tieu TuPas encore d'évaluation

- File 1600161898Document2 pagesFile 1600161898Gia Minh Tieu TuPas encore d'évaluation

- Osha Scaffolding GuidelinesDocument73 pagesOsha Scaffolding GuidelinesHemang Shukla100% (2)

- Model Code of Practice How To Manage and Control Asbestos in The WorkplaceDocument81 pagesModel Code of Practice How To Manage and Control Asbestos in The WorkplaceGia Minh Tieu TuPas encore d'évaluation

- Outin Bbraun Correspondence 08 NovDocument1 100 pagesOutin Bbraun Correspondence 08 NovGia Minh Tieu TuPas encore d'évaluation

- Code of Practice - Construction Work 21102022 0Document92 pagesCode of Practice - Construction Work 21102022 0Gia Minh Tieu TuPas encore d'évaluation

- ScaffoldingDocument42 pagesScaffoldingGia Minh Tieu TuPas encore d'évaluation

- DS DS9939 en Co 2374Document5 pagesDS DS9939 en Co 2374Gia Minh Tieu TuPas encore d'évaluation

- Corrugated Aluminum Jacketing CladdingDocument3 pagesCorrugated Aluminum Jacketing CladdingGia Minh Tieu TuPas encore d'évaluation

- SampleDocument11 pagesSampleGia Minh Tieu TuPas encore d'évaluation

- Cold InsulationDocument24 pagesCold InsulationGia Minh Tieu Tu100% (1)

- Catalogue Van Houcke UKDocument28 pagesCatalogue Van Houcke UKGia Minh Tieu TuPas encore d'évaluation

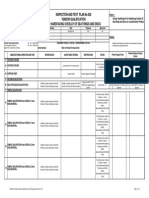

- ITP For Piping SystemsDocument6 pagesITP For Piping SystemsGia Minh Tieu TuPas encore d'évaluation

- Basic of Scaffolding3Document11 pagesBasic of Scaffolding3Gia Minh Tieu TuPas encore d'évaluation

- Black Cat Insulation Fabrication BrochureDocument26 pagesBlack Cat Insulation Fabrication BrochureGia Minh Tieu TuPas encore d'évaluation

- Model Scaffolding Program - 0Document10 pagesModel Scaffolding Program - 0Gia Minh Tieu TuPas encore d'évaluation

- Benning Constuction Health and Safety PolicyDocument198 pagesBenning Constuction Health and Safety PolicyGia Minh Tieu TuPas encore d'évaluation

- Blucher Pipe PDFDocument232 pagesBlucher Pipe PDFtruong sanh Nguyen0% (1)

- 24M Motor Grader Electrical System: Harness and Wire Electrical Schematic SymbolsDocument4 pages24M Motor Grader Electrical System: Harness and Wire Electrical Schematic SymbolsRicardo HarringtonPas encore d'évaluation

- BR87 User Manual PDFDocument21 pagesBR87 User Manual PDFLuisYFer1Pas encore d'évaluation

- Manual de Partes RT-8609Document30 pagesManual de Partes RT-8609Jorge Castillo Hdz100% (1)

- Inspection and Test Plan No 826 Vendor Qualification For Hardfacing Overlay of Seat Rings and DiscsDocument3 pagesInspection and Test Plan No 826 Vendor Qualification For Hardfacing Overlay of Seat Rings and DiscsGohilakrishnan ThiagarajanPas encore d'évaluation

- Work Sequence and Methodology 1.1. Storage and HandlingDocument12 pagesWork Sequence and Methodology 1.1. Storage and Handlingdmuneer131187Pas encore d'évaluation

- Dfy - Coating Quality Key PointsDocument1 pageDfy - Coating Quality Key PointsMohammed SadiqPas encore d'évaluation

- Manual HC 10 ServicioDocument69 pagesManual HC 10 Servicioernesto Arteaga80% (5)

- CH18-CH25, CH620-CH730, CH740, CH750 Service ManualDocument88 pagesCH18-CH25, CH620-CH730, CH740, CH750 Service ManualIvan CaicedoPas encore d'évaluation

- Advanced Hydraulics: Chapter 1: Quiz 1-Hydraulic Motor ApplicationsDocument10 pagesAdvanced Hydraulics: Chapter 1: Quiz 1-Hydraulic Motor ApplicationsJoyce Gregorio Zamora50% (4)

- V NotchDocument2 pagesV NotchSunil SinghPas encore d'évaluation

- Consolidated Safety Valve 19110 PDFDocument48 pagesConsolidated Safety Valve 19110 PDFJose FloresPas encore d'évaluation

- C98IB001EN D Carbo510 InstManDocument48 pagesC98IB001EN D Carbo510 InstManMICHAEL100% (3)

- PICA Hose Problem - Sept-Nov 2012Document20 pagesPICA Hose Problem - Sept-Nov 2012Edwin FitrianPas encore d'évaluation

- 4.1 Murphy Fuel ValveDocument5 pages4.1 Murphy Fuel ValveCARLOS SARMIENTOPas encore d'évaluation

- KF Ball Iom Series p3 m3Document13 pagesKF Ball Iom Series p3 m3Arifin ZakyPas encore d'évaluation

- Pgcil-Latest Testing FormatDocument149 pagesPgcil-Latest Testing FormatVeeranki Bharath80% (5)

- BIFOLD - Pilot, Mechanical and Reset BXS Valves and High Flow SPR and PPV Valves Issue BFD000 January 2015Document36 pagesBIFOLD - Pilot, Mechanical and Reset BXS Valves and High Flow SPR and PPV Valves Issue BFD000 January 2015Tuan NguyenPas encore d'évaluation

- D155A-2 Parts BookDocument354 pagesD155A-2 Parts BookOecox Cah Djadoel100% (5)

- Nueva Lista de Piezas Excavadora 325 BLDocument3 pagesNueva Lista de Piezas Excavadora 325 BLWilmert TRPas encore d'évaluation

- Bomba de Alta Presion Denso HP2 PDFDocument4 pagesBomba de Alta Presion Denso HP2 PDFDiegoD'AmbrosioPas encore d'évaluation

- KZJ70 HZJ PZJ Chassis Body PDFDocument680 pagesKZJ70 HZJ PZJ Chassis Body PDFmasakpPas encore d'évaluation

- Buterfly Valve Wafer Type Jis 10K DN 20 - DN 1000Document13 pagesButerfly Valve Wafer Type Jis 10K DN 20 - DN 1000Tabita Jane SiburianPas encore d'évaluation

- KZ750sport 83 86Document106 pagesKZ750sport 83 86Diego ZaragozaPas encore d'évaluation

- COT1-SOLPESCC25200 MezcladorDocument60 pagesCOT1-SOLPESCC25200 MezcladorJhon PalaciosPas encore d'évaluation

- VST TBV Non-Contact CATALOG 2021-HDDocument7 pagesVST TBV Non-Contact CATALOG 2021-HDJaydeep PanchalPas encore d'évaluation

- Rev 2 Ducting Spec - ASMErevDocument76 pagesRev 2 Ducting Spec - ASMErevromerobernaPas encore d'évaluation

- Orca Torch InstructionsDocument3 pagesOrca Torch InstructionsMaratimus LionPas encore d'évaluation

- Proyecto Gasificacion TecnicoDocument32 pagesProyecto Gasificacion TecnicocarlosPas encore d'évaluation