Académique Documents

Professionnel Documents

Culture Documents

304 304L Data Sheets 1 28 13 PDF

Transféré par

neerajtrvDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

304 304L Data Sheets 1 28 13 PDF

Transféré par

neerajtrvDroits d'auteur :

Formats disponibles

TECHNICAL DATA SHEET

AISI 304 AISI 304L

Stainless Steel Structural Shapes: 304 and 304L Austenitic (Chromium-Nickel)

INTRODUCTION

There are many grades of austenitic stainless steels, the most popular of which are 304 and 304L. Those

two account for about half of the total stainless steel production in the United States. Those are the two

grades we will address on this data sheet. Other grades include 316 316L, 317, 317L, 321, 347. Stainless

Structurals can manufacture shapes in almost any of the austenitic grades, plus nickel, duplex and exotic

alloys. If you need a particular grade, ask your sales representative.

Stainless Structurals shapes are stripped from plate with lasers, laser fused together, straightened,

ground, de-twisted and passivated. They are produced to ASTM-A-1069, which also includes a number of

other specifications.

Austenitic (18-8) stainless steel alloys possess significant beneficial properties. They are strong, light,

ductile, aesthetically pleasing and readily available in a variety of forms. They resist corrosion and

oxidation; fabricate and clean easily; and prevent contamination of products. They have also exhibited

good strength and toughness when exposed to cryogenic conditions.

Stainless Structurals offers two variations of the 18-8 stainless steels:

AISI 304 (S30400)

AISI 304L (S30403)

Of the two types, 304 is the most widely used alloy, followed by 304L. 304L is typically used for welded

applications that must resist intergranular corrosion. The essential difference is in the carbon content,

which is required to be lower in 304L than 304. These two grades are frequently supplied dual certified as

304/304L. This means that the carbon content, which is expressed as a maximum in both grades, is in

compliance with the maximum carbon content called for by each specification. In addition the dual

certified material meets the minimum mechanical properties, which are required to be higher in 304.

Therefore, the dual certification means the material is in full compliance with both specifications, providing

the higher minimum strength requirements for one grade along with the better intergranular corrosion

resistance of the other.

stainless-structurals.com

gggdgdg

Page |1

TECHNICAL DATA SHEET

AISI 304 AISI 304L

Some popular applications of these two grades are in food processing, appliances and dairy. Standards

and specifications have been developed to guide the manufacture, construction and use of these grades.

The guidelines are listed herewith.

SPECIFICATIONS AND CERTIFICATIONS

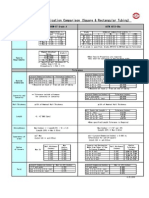

The following table provides the list of US specifications for the two popular grades.

Table 1: ASTM and ASME Specifications

Product Form

Specification

ASTM

ASME

Plate, Sheet and

Strip

A 240

SA-240

Laser Fused

Structural Shapes

A1069

The specifications stipulate allowable stresses for the various product forms of the alloys. Within the

ASME Boiler and Pressure Vessel Code (Section II, Part D), the allowable stresses are given for 304 for

use up to a maximum temperature of 1500F (816C); and 304L up to 800F (426C).

In addition to ASTM and ASME, the National Sanitation Foundation accepts all alloy variations for food

preparation and storage; and the Dairy and Food Industries Supply Association (Sanitary Standards

Committee) approves all variations for contact with dairy products.

stainless-structurals.com

gggdgdg

Page |2

TECHNICAL DATA SHEET

AISI 304 AISI 304L

PROPERTIES

This section outlines the chemical composition, physical and mechanical properties of 304 amd 304L.

1.0 Chemical Composition

ASTM A240 provides the typical chemical compositions for the 18-8 stainless steel variations. Refer to

Table 2 below.

Table 2: Typical Chemical Compositions

Percentage (%) Weight

Periodic

Element

304

304L

Chromium

17.5

19.5

17.5

19.5

Nickel

8.0

10.5

8.0

12.0

Manganese

2.00

2.00

Silicon

0.75

0.75

Carbon

0.07

0.030

Nitrogen

0.10

0.10

Phosphorus

0.045

0.045

Sulfur

0.030

0.030

Maximum value, unless range is specified

2.0 Physical Properties

The physical properties of austenitic stainless steel alloys are given below.

2.1 General

The following are accepted general physical properties of austenitic stainless steel alloys:

3

Density

0.285 lb/in

(7.90 g/cm )

Melting Range

2550 - 2590F (1399 - 1421C)

Modulus of Elasticity

29 Mpsi

(200 GPa)

(in Tension)

stainless-structurals.com

gggdgdg

Page |3

TECHNICAL DATA SHEET

AISI 304 AISI 304L

2.2 Thermal

The following are accepted thermal properties of the alloys:

Specific Heat:

F

Btu/lb/F

J/kg.K

32 - 212

0 - 100

0.12

500

Linear Coefficient of Thermal Expansion:

Temperature Range

F

Coefficients

in/in/F

cm/cm/C

-6

68 - 212

20 - 100

9.2 x 10

68 - 212

20 - 100

11.0 x 10

-6

16.6 x 10

-6

19.8 x 10

-6

Thermal Conductivity

Temperature Range

Btu/hr.ft.F

W/m.K

100

9.4

16.3

500

12.4

21.4

212

932

Although other metals exhibit higher thermal conductivities, the stainless steel alloys are able to more

efficiently transfer heat through the maintenance of smooth, clean surfaces.

2.3 Electrical

Electrical resistivity properties include:

Temperature Range

Microhm-in

Microhm-cm

20

28.3

72

212

100

30.7

78

392

200

33.8

86

752

400

39.4

100

1112

600

43.7

111

1472

800

47.6

121

1652

900

49.6

126

68

stainless-structurals.com

gggdgdg

Page |4

TECHNICAL DATA SHEET

AISI 304 AISI 304L

2.4 Magnetic

Austenitic stainless steel alloys are not typically magnetic in the annealed condition (magnetic

permeability <1.02 at 200H). While cold work will increase the magnetic permeability, Stainless

Structurals shapes are manufactured from annealed material.

Magnetic Permeability

Percent Cold

Work

304

304L

1.005

1.015

10

1.009

1.064

3.0 Mechanical Properties

The mechanical properties of austenitic stainless steel alloys are as noted below.

3.1 At Room Temperature

ASTM A240 and ASME SA-240 require the following minimum properties for plate, sheet and strip forms

of the annealed alloy variations. A1069 laser fused structurals are in compliance.

Table 3: Minimum Mechanical Properties

Property

Minimum Mechanical Properties

304

304L

0.2% Offset Yield Strength:

psi

30,000

25,000

MPa

205

170

psi

MPa

75,000

515

70,000

485

Percent Elongation in

2 in. or 51 mm

40.0

40.0

201

92

201

92

Ultimate Tensile Strength:

Hardness, Max.:

Brinell

RB

1

In accordance with ASTM A240 and ASME SA-240

3.2 Cold Work

As the alloys are cold worked (deformed) at room temperature or thereabout, partial transformation of

austenite (in the alloys) to martensite can occur. As this happens, the alloys tend to increase in yield and

stainless-structurals.com

gggdgdg

Page |5

TECHNICAL DATA SHEET

AISI 304 AISI 304L

ultimate strength while decreasing in elongation. Austenitic stainless structural shapes are not supplied in

the cold worked condition. .

3.3 Properties at Low and Elevated Temperatures

The effects of low and elevated temperatures on short-term tensile properties are displayed below. Creep

and stress ruptures should be considered at temperatures equivalent to or higher than 100F (538C).

Typical information is as follows.

Table 4: Tensile Properties at Varying Temperatures

Test Temperature

0.2%Yield Strength

Tensile Strength

Elongation

psi

(MPa)

psi

(MPa)

Percent in 2" or

51 mm

-423

-253

100,000

690

250,000

1725

25

-320

-196

70 000

485

230 000

1585

35

-100

-79

50 000

345

150 000

1035

50

70

21

35 000

240

90 000

620

60

400

205

23 000

160

70 000

485

50

800

427

19 000

130

66 000

455

43

1200

650

15 500

105

48 000

330

34

1500

815

13 000

90

23 000

160

46

3.4 Impact Resistance

Stainless steel, in the annealed condition, shows very high resistance to impact even at cryogenic levels.

This makes it a candidate for applications such as earthquake resistance, LNG facilities and cryogenics.

Typical results from Charpy V-notch impact tests are provided as follows:

Charpy V-Notch Energy

Absorbed

Temperature

F

Foot-pounds

Joules

75

23

150

200

-320

-196

85

115

-425

-234

85

115

stainless-structurals.com

gggdgdg

Page |6

TECHNICAL DATA SHEET

AISI 304 AISI 304L

3.5 Fatigue Strength

The fatigue strength, or endurance limit, represents the maximum amount of stress below which the

material is unlikely to fail after 10 million cycles in the air environment. For the austenitic stainless steels,

this figure is typically 35% of the tensile strength. A number of factors affect fatigue strength. A smooth

surface will provide greater strength than a rough or corroded surface. Fatigue strength is dependent on

many factors, so the quoted value can vary significantly.

4.0 Corrosion Resistance

4.1 General Corrosion

All variations of the austenitic stainless steel alloys show desirable resistance to corrosion within

moderately oxidizing and reducing environments. This resistance is due to the high chromium content in

these alloys, in which a microscopic layer of chromium oxide seals the surface.

As a consequence, the applicability of the alloys range from food processing equipment and utensils in

food, beverage and dairy industries, to heat exchangers, piping, tanks and other process equipment for

human consumables. The alloys are used to contain household and industrial chemicals; and are used in

non-marine environments as architectural and structural materials such as handrails and building

facades.

Examples of 304/304L resistance to oxidizing (acidic) environments is given below

% Nitric Acid

Temperature

F (C)

Corrosion Rate

Mils/Yr (mm/a)

10

300 (149)

5.0 (0.13)

20

300 (149)

10.1 (0.25)

30

300 (149)

17.0 (0.43)

Other laboratory data for 304 and 304L in the table below illustrate that these alloys are also resistant to

moderately aggressive organic acids such as acetic, citric and even reducing acids such as phosphoric.

The relatively high nickel content of these alloys helps provide resistance to moderately reducing

environments. The more highly reducing environments such as boiling dilute hydrochloric and sulfuric

acids are too aggressive for these materials. Other grades such as 316/316L should be considered.

Boiling 50 percent caustic is likewise too aggressive for 304/304L. Consult your sales representative if

you need assistance.

stainless-structurals.com

gggdgdg

Page |7

TECHNICAL DATA SHEET

AISI 304 AISI 304L

General Corrosion in Boiling Chemicals

Corrosion Rate, Mils/Yr (mm/a)

Boiling

Environment

304

304L

20% Acetic Acid: Base Metal

Welded*

0.1

1.0

(<0.01)

(0.03)

0.1

0.1

(<0.01)

(<0.01)

45% Formic Acid, Base Metal

55

(1.4)

15

(0.4)

Welded*

52

(1.3)

19

(0.5)

10% Sulfamic Acid, Base Metal

Welded*

144

144

(3.7)

(3.7)

50

57

(1.3)

(1.4)

1% Hydrochloric, Base Metal

Welded

98

112

(2.5)

(2.8)

85

143

(2.2)

(3.6)

20% Phosphoric Acid, Base Metal

Welded

<1.0

<1.0

(<0.03)

(0.03)

65% Nitric Acid, Base Metal

9.2

(0.2)

8.9

(0.2)

Welded

9.4

(0.2)

7.4

(0.2)

10% Sulfuric Acid, Base Metal

Welded

445

494

(11.3)

(12.5)

662

879

(16.8)

(22.3)

50% Sodium Hydroxide, Base Metal

Welded

118

130

(3.0)

(3.3)

71

87

(1.8)

(2.2)

---

---

*Autogenous weld on base metal sample.

In some cases, the low carbon 304L may show a lower corrosion rate than the higher carbon 304, as

shown by the data for formic acid, sulfamic acid and sodium hydroxides. Otherwise, the 304 and 304L

may be considered to perform equally in most corrosive environments. A notable exception is in

environments sufficiently corrosive to cause intergranular corrosion of welds and heat-affected zones on

susceptible alloys. 304L is preferred for use in such media in the welded condition since the low carbon

level resists carbide precipitation in the heat affected zone, and thereby enhances resistance to

intergranular corrosion.

4.2 Intergranular Corrosion

At high temperatures (800F - 1500F or 427C to 816C) during service conditions, these stainless steel

alloys may experience chromium carbide precipitation in the grain boundaries. This is typically referred to

sensitization and, when exposed to very harsh, aggressive conditions, the steel alloys may undergo

intergranular corrosion. It is the carbon content in 304 that causes sensitization under thermal processes;

as is the case for autogenous welds and heat-affected weld zones. Lower carbon content prolongs, but

does not eliminate, the likelihood for precipitation of harmful level of chromium carbides.

stainless-structurals.com

gggdgdg

Page |8

TECHNICAL DATA SHEET

AISI 304 AISI 304L

Consequently, 304L with its lower carbon content is better suited for situations where the alloy is

commissioned in the as-welded condition. Dual certified 304/304L will have the same maximum carbon

limits as 304L, and is therefore allowable. Refer to the evidence provided below.

Intergranular Corrosion Tests

ASTM A 262 Evaluation

Test

Practice B Base Metal

Welded

Practice E Base Metal

Welded

PracticeA Base Metal

Welded

Corrosion Rate, Mils/Yr (mm/a)

304

304L

20 (0.5) Intergranular

23 (0.6) Corrosion

20 (0.5)

20 (0.5)

No Fissures on Bend Some

Fissures on Weld

(unacceptable)

Step Structure Ditched

(unacceptable)

No Fissures

No Fissures

Step Structure

Step Structure

4.3 Stress Corrosion Cracking (SCC)

The likelihood of stress corrosion cracking in the presence of halide ions is highest in 304 and 304L

alloys. This is due of their lower nickel content. Other conditions required for SCC include residual tensile

stress in the alloys and temperatures exceeding 120F (49C).

Residual stresses may occur from cold deformation during forming and thermal cycles during welding.

The stresses may be reduced via annealing or stress-relieving heat treatments following cold

deformation, although this is impractical for most shapes.

Refer to the table below for the behavior of the alloys during halide (chloride) stress corrosion testing.

Note that, although times are specified, failure is inevitable under these conditions.

Halide (Chloride) Stress Corrosion Tests

Test

U-Bend (Highly Stressed) Samples

304, 304L

42% Magnesium

Chloride, Boiling

Base Metal

Welded

Cracked, 1 to 20 hours

Cracked, to 21 hours

33% Lithium

Chloride, Boiling

Base Metal

Welded

Cracked, 24 to 96 hours

Cracked, 18 to 90 hours

26% Sodium

Chloride, Boiling

Base Metal

Welded

Cracked, 142 to 1004 hours

Cracked, 300 to 500 hours

40% Calcium

Base Metal

Cracked, 144 Hours

stainless-structurals.com

gggdgdg

Page |9

TECHNICAL DATA SHEET

AISI 304 AISI 304L

Halide (Chloride) Stress Corrosion Tests

Test

U-Bend (Highly Stressed) Samples

304, 304L

Chloride, Boiling

Ambient Temperature

Seacoast Exposure

-Base Metal

Welded

No Cracking

No Cracking

4.4 Pitting/ Crevice Corrosion

Although SCC occurs in concentrated halide conditions, the alloys are suitable for fresh water and low

halide applications. 304 has been successfully used in surface condensers for cooling water with

concentrations of 1000 ppm chloride in power plants. Careful maintenance, cleaning and constant flow

were necessary.

Therefore, the halide concentration limit is typically taken as 100 ppm chloride; especially when crevices

may be present in the alloys. Evidence for this stems from 304 and 304L alloys showing no signs of

rusting or staining after the 100 hour, 5 percent neutral salt spray tests (ASTM B117). However, 304

stainless building facades, when exposed to sea blast or salt mists, exhibit pitting, crevice corrosion and

discoloration. So, at concentrations higher than 100ppm, crevice corrosion and pitting may occur; which is

why these alloys are not suitable for marine environments. Alloys containing molybdenum, e.g.,

316/316L, 317/317L, AL-6XN or 254SMOare better suited for high chloride, acidic or heated

environments. . Stainless Structurals can provide all these grades, and more.

5.0 Weldability

Of all the high-alloy steels, the austenitic stainless steel alloys have been found to be the most weldable;

and all fusion and resistance welding processes may be used. However, care during welding must be

shown to prevent cracking and preserve the corrosion resistant properties of the alloys.

During welding, temperature gradients occur in the alloys. The temperatures range from the melting

temperature in the molten pool to the ambient temperature in the extremities. Higher carbon content in

the alloys means there is a greater chance that the welding thermal cycles will cause chromium carbide

precipitation. And this will reduce the corrosion resistant properties. To counteract precipitation, 304 or

304/304L dual should be used for applications in the welded condition. Conversely, full annealing can be

done to remove the precipitant and improve the corrosion resistance. In most cases, however, full

annealing is not practical for a structural shape or construct. Laser fused stainless structurals are not

generally susceptible to the temperature gradient problems as noted above. That is because the fusion is

stainless-structurals.com

gggdgdg

P a g e | 10

TECHNICAL DATA SHEET

AISI 304 AISI 304L

very quick, the heat affected zone is much smaller than a conventional weld, and the joint cools much

more quickly.

304 and 304L grades will typically re-solidify with a small amount of post-weld ferrite. This is to minimize

the cracking susceptibility that austenitic steels show during welding.

308 (20% Cr-11% Ni) alloy is the preferred filler metal for welding 304/304L as it does not produce

martensite following multi-pass welds. And, to decrease to the tendency for hot cracking, the welding

environment is controlled in order to ensure the formation of a small amount of ferrite. 309 alloy (23%

chromium, 13.5% nickel) or nickel based filler metals are recommended in joining the austenitic alloys to

carbon steel. No filler metal is used in the production of A1069 laser fused structurals. The joints are

autogenous.

6.0 Heat Treatment

Heat treating these alloys may be performed in order to remove the negative effects of cold forming

and/or to remove precipitated chromium carbides from their surfaces. To get both results, the alloys are

annealed, which occurs in the range of 1850F (1010C) to 2050F (1121C). To prevent the chromium

carbides from re-precipitating, cooling from these temperatures must be accomplished at high rates

through 1500-800F (816C 427C). As previously mentioned, heat treating is not practical for most

structural shapes due to their configuration and due also to their propensity for warping.

304 and 304L, like other austenitic grades, are not hardenable by heat treatment.

7.0 Cleaning

Special care must be undertaken when these stainless steel alloys are fabricated. Likewise, routine

maintenance must be conducted while in use to ensure the alloys remain aesthetically pleasing and

corrosion resistant.

Fabrication:

During fabrication, the following cleaning habits should be employed:

Use inert gas processes in welding.

Use only stainless steel wire brushes to remove scale and slag, as carbon steel brushes can lead

to rusting of the surface.

Use passivating (descaling) solutions (e.g. mixture of nitric and hydrofluoric acids) for more

severe scale build-up during welding. The solutions should be quickly washed off after

application. This removes free iron from the surface, which could lead to surface corrosion.

stainless-structurals.com

gggdgdg

P a g e | 11

TECHNICAL DATA SHEET

AISI 304 AISI 304L

Use:

Pressure washing is recommended for normal maintenance on inland, light industrial and mild

applications.

More frequent washing should be used for heavy industrial application to prevent deposits that

could lead to corrosion and dullness.

Use non-abrasive cleaners, fiber brushes, sponge, or stainless steel wool to scrub off spots and

other deposits. If the material is polished, or if the appearance is important, limit the force used

with the stainless steel wool as it can leave permanent scratches on the stainless steel.

Clean and sterilize surfaces accordingly for critical applications. Use specially designed caustic

soda, organic solvent or mild acid solutions for additional cleaning in areas such as food

processing or pharmaceutical manufacturing. All such solutions must be washed off quickly.

Note that the products designs can impact on cleaning of the stainless steel alloys. Having equipment

free from sharp corners, crevices and rough welds can make cleaning. Polishing the surface of the

product also has a similar impact on cleanliness.

8.0 Surface Finishes

Surface finishes for stainless steel structural shapes are noted below.

#1 Finish

hot rolled, annealed, and de-scaled surface. This is the standard;

available in plate and sheet and all structural applications

used in applications where smooth, bright finishes are not mandatory.

Polished finishes on structurals are available but may be costly Consult your Stainless Structurals

sales person for the most economical solution for your end use.

stainless-structurals.com

gggdgdg

P a g e | 12

Vous aimerez peut-être aussi

- Gold Refining (How To)Document40 pagesGold Refining (How To)adiomanovic193% (14)

- ASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelDocument2 pagesASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelBernice JohnsonPas encore d'évaluation

- Second Quarter Test With Answer in Grade 9 ScienceDocument5 pagesSecond Quarter Test With Answer in Grade 9 ScienceRenalyn F. Andres80% (15)

- Design Charts For Bolts With Combined Shear and Tension: MechanicalfastenerswhicharesubjecttoacombinedDocument4 pagesDesign Charts For Bolts With Combined Shear and Tension: MechanicalfastenerswhicharesubjecttoacombinedcmkohPas encore d'évaluation

- A4-80 Stainless Steel Grade Specification - Midland Bright SteelsDocument4 pagesA4-80 Stainless Steel Grade Specification - Midland Bright SteelsramonagherghePas encore d'évaluation

- Grades of Steel ChartDocument3 pagesGrades of Steel ChartKimPas encore d'évaluation

- ASTM A572 Grade 50 Plate: AnalysisDocument2 pagesASTM A572 Grade 50 Plate: Analysisdaniel moreno jassoPas encore d'évaluation

- Mech Malleable Iron Fittings Catalogue PDFDocument12 pagesMech Malleable Iron Fittings Catalogue PDFics companyPas encore d'évaluation

- Outokumpu Forta Range Stainless Steel DatasheetDocument16 pagesOutokumpu Forta Range Stainless Steel DatasheetNicola D'ettolePas encore d'évaluation

- Super Duplex Stainless SteelDocument3 pagesSuper Duplex Stainless SteelNisa_nishePas encore d'évaluation

- Astm A6 A6m 22Document15 pagesAstm A6 A6m 22Ruman IrfaniPas encore d'évaluation

- Fusion Bead XRFDocument6 pagesFusion Bead XRFAnindya RoyPas encore d'évaluation

- Steel StandardsDocument63 pagesSteel StandardsNagarjun ReddyPas encore d'évaluation

- Aplicações em Fábrica de Cloro.Document72 pagesAplicações em Fábrica de Cloro.marketing engezerPas encore d'évaluation

- DS45A - (1972) Compilation and Index of Trade Names, Specifications, and Producers of Stainless Alloys and Superalloys PDFDocument60 pagesDS45A - (1972) Compilation and Index of Trade Names, Specifications, and Producers of Stainless Alloys and Superalloys PDFJacques BlueqPas encore d'évaluation

- Rubber FillersDocument28 pagesRubber FillersD.W.W.SewwandiPas encore d'évaluation

- Stainless Steel Bars and Shapes: Standard Specification ForDocument8 pagesStainless Steel Bars and Shapes: Standard Specification ForkrkmurthyPas encore d'évaluation

- Asme B18.2.6 2003Document11 pagesAsme B18.2.6 2003Jesse ChenPas encore d'évaluation

- Astm A29Document16 pagesAstm A29Nacer KisyPas encore d'évaluation

- Chapter 3 Study Guide KeyDocument3 pagesChapter 3 Study Guide KeyKaren YPas encore d'évaluation

- Kaiser Aluminum Soft Alloy Tube PDFDocument31 pagesKaiser Aluminum Soft Alloy Tube PDFgerrzen64Pas encore d'évaluation

- Aisi 1008Document2 pagesAisi 1008GANESH GPas encore d'évaluation

- Astm A312 PDFDocument12 pagesAstm A312 PDFStephen TilleyPas encore d'évaluation

- SIGA CT1 Est Manual Instalacion SH IngenieriaDocument3 pagesSIGA CT1 Est Manual Instalacion SH IngenieriaedgarPas encore d'évaluation

- ASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFDocument7 pagesASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFJA KPas encore d'évaluation

- Astm A192 Asme Sa192Document4 pagesAstm A192 Asme Sa192Mingo EvaPas encore d'évaluation

- GB T 699 1988 Quality Carbon Structural SteelsDocument17 pagesGB T 699 1988 Quality Carbon Structural SteelsPHUONGPas encore d'évaluation

- Astm F3125 F3125M 18Document6 pagesAstm F3125 F3125M 18Amine ait talebPas encore d'évaluation

- A434Document3 pagesA434alirioPas encore d'évaluation

- Specification For Seamless Medium-Carbon Steel Boiler and Superheater TubesDocument4 pagesSpecification For Seamless Medium-Carbon Steel Boiler and Superheater TubesMauricio Esteban Fernandez RamirezPas encore d'évaluation

- A500 Vs A513Document2 pagesA500 Vs A513Angelo CubillosPas encore d'évaluation

- Hot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesDocument11 pagesHot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesNilton Santillan OrtegaPas encore d'évaluation

- IFRDocument27 pagesIFRneerajtrvPas encore d'évaluation

- 011-Astm A 131 2008 Structural Steel For Ships PDFDocument7 pages011-Astm A 131 2008 Structural Steel For Ships PDFgraduatePas encore d'évaluation

- AISI Type 304L Stainless Steel Material Data - 12676Document1 pageAISI Type 304L Stainless Steel Material Data - 12676Ian Pillay100% (1)

- General Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessDocument9 pagesGeneral Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessCarlos Ramirez BaltazarPas encore d'évaluation

- Astm A53Document2 pagesAstm A53DeepakPas encore d'évaluation

- Carbon Steel Piping Comp. StandardsDocument2 pagesCarbon Steel Piping Comp. StandardsSoumitra GuptaPas encore d'évaluation

- Comparisons of Materials Between JIS and Foreign Standards 1Document1 pageComparisons of Materials Between JIS and Foreign Standards 1kittikhun_simleePas encore d'évaluation

- B729Document3 pagesB729LambertWaynePas encore d'évaluation

- AISI Steel Code TablesDocument12 pagesAISI Steel Code TablesWahyu DiPas encore d'évaluation

- ISO1133 Melt Volume Flow Rate MVRDocument2 pagesISO1133 Melt Volume Flow Rate MVRMichele Preghenella100% (1)

- Astm A240 Uns S32205Document3 pagesAstm A240 Uns S32205Mintone Sajayah BekabekaPas encore d'évaluation

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)Deepak ChaurasiaPas encore d'évaluation

- Domex 100 XF Data SheetDocument2 pagesDomex 100 XF Data Sheetzubblwump5063Pas encore d'évaluation

- Jis G3466Document9 pagesJis G3466魏雨辰Pas encore d'évaluation

- Steel, Sheet, Hot Rolled, Carbon, Commercial, Structural, and High-Strength Low-Alloy, Produced by Twin-Roll Casting ProcessDocument9 pagesSteel, Sheet, Hot Rolled, Carbon, Commercial, Structural, and High-Strength Low-Alloy, Produced by Twin-Roll Casting ProcessDarwin DarmawanPas encore d'évaluation

- Astm 434Document3 pagesAstm 434Fabián MartínezPas encore d'évaluation

- A 1008 - A 1008M - 02 Qtewmdgtmdjfmq - PDFDocument7 pagesA 1008 - A 1008M - 02 Qtewmdgtmdjfmq - PDFTiến Lượng NguyễnPas encore d'évaluation

- JIS C 3406 (1971) - Auto CablesDocument1 pageJIS C 3406 (1971) - Auto CablesBrandon BroPas encore d'évaluation

- En 10025 S235JR SteelDocument2 pagesEn 10025 S235JR SteelAgung Nak OtomotifPas encore d'évaluation

- Astm A659-18Document3 pagesAstm A659-18Ryan ZhangPas encore d'évaluation

- TCVN7571-11 - 2019 - Thép CDocument14 pagesTCVN7571-11 - 2019 - Thép CBui Chi TamPas encore d'évaluation

- S275JRDocument1 pageS275JRpsaayoPas encore d'évaluation

- ASM Material Data SheetDocument2 pagesASM Material Data SheetShankar PranavPas encore d'évaluation

- Steel IndexDocument24 pagesSteel IndexAnonymous AlhzFE9EVNPas encore d'évaluation

- Stainless Steel, cf8, cf3, cf8m, cf3m, Ca15, Ca40, 17 - 4, 15 - 5, cd4m 1a, cg8mDocument2 pagesStainless Steel, cf8, cf3, cf8m, cf3m, Ca15, Ca40, 17 - 4, 15 - 5, cd4m 1a, cg8mDewandanuPas encore d'évaluation

- Tabla Torqueo de PernosDocument1 pageTabla Torqueo de PernosErnesto LinaresPas encore d'évaluation

- A 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFDocument16 pagesA 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFshakeelahmadjsrPas encore d'évaluation

- ASTM D 2000: Specification NumberDocument3 pagesASTM D 2000: Specification NumberjanarthananPas encore d'évaluation

- 010 Sa29 Sa29mDocument26 pages010 Sa29 Sa29mWeniton OliveiraPas encore d'évaluation

- Steel Grades HandbookDocument6 pagesSteel Grades Handbookbhavin178Pas encore d'évaluation

- Ansteel Product CatalogueDocument13 pagesAnsteel Product Cataloguerashid isaarPas encore d'évaluation

- 304 DDQ SpecificationDocument1 page304 DDQ Specificationdac_angelovPas encore d'évaluation

- Tata Steel - YMPRESS S500MC - Data SheetDocument2 pagesTata Steel - YMPRESS S500MC - Data SheetpnagarajjPas encore d'évaluation

- Age-Hardening Alloy Steel Forgings For Pressure Vessel ComponentsDocument4 pagesAge-Hardening Alloy Steel Forgings For Pressure Vessel ComponentsGustavo SuarezPas encore d'évaluation

- Headings and Subheadings - Word 2007Document20 pagesHeadings and Subheadings - Word 2007neerajtrvPas encore d'évaluation

- 1.3.4. PRODUCT: at Shop and Inspection and Test Plan at SiteDocument1 page1.3.4. PRODUCT: at Shop and Inspection and Test Plan at SiteneerajtrvPas encore d'évaluation

- Improper Painting On Weld JointsDocument3 pagesImproper Painting On Weld JointsneerajtrvPas encore d'évaluation

- Quality Assurance PlanDocument1 pageQuality Assurance Planneerajtrv100% (1)

- Sample Paper-2013 Class - XIIDocument5 pagesSample Paper-2013 Class - XIIneerajtrvPas encore d'évaluation

- R X Fof: Sample Paper - 2012 Class - XII MathematicsDocument6 pagesR X Fof: Sample Paper - 2012 Class - XII MathematicsneerajtrvPas encore d'évaluation

- Test 1 FormulasDocument1 pageTest 1 FormulasneerajtrvPas encore d'évaluation

- Marking Scheme Science XIIDocument342 pagesMarking Scheme Science XIIneerajtrvPas encore d'évaluation

- Formula SheetDocument2 pagesFormula SheetneerajtrvPas encore d'évaluation

- Clxichewk 091Document7 pagesClxichewk 091neerajtrvPas encore d'évaluation

- Answer Key HMWK - 1 CHPT 9 - 10Document11 pagesAnswer Key HMWK - 1 CHPT 9 - 10jts399Pas encore d'évaluation

- Mock 1Document14 pagesMock 1محمد زعبلاوىPas encore d'évaluation

- Nucleon Number ReferenceDocument6 pagesNucleon Number ReferenceNazihah NordinPas encore d'évaluation

- UK Manufacturer of Steel Strip - Ben Bennett JR - Spring SteelDocument2 pagesUK Manufacturer of Steel Strip - Ben Bennett JR - Spring SteelVivek GoudPas encore d'évaluation

- Gal Val Um East M Steel PropertiesDocument5 pagesGal Val Um East M Steel PropertiesAhmed BelalPas encore d'évaluation

- 1ionic Reactions2Document2 pages1ionic Reactions2Michael MitchellPas encore d'évaluation

- Chapter 7Document5 pagesChapter 7Choco LocoPas encore d'évaluation

- Chm4701 Catalysis Methanol SynthesisDocument27 pagesChm4701 Catalysis Methanol SynthesisErwinnie EllyiaPas encore d'évaluation

- Or IngDocument160 pagesOr IngvinibePas encore d'évaluation

- Definition and Classification of RefractoriesDocument2 pagesDefinition and Classification of RefractoriesFahad AhmmedPas encore d'évaluation

- Corson AlloyDocument4 pagesCorson AlloyPhung Tuan AnhPas encore d'évaluation

- Analysis of Fruit and Vegetable JuicesDocument3 pagesAnalysis of Fruit and Vegetable JuicesAditya Rajendran50% (2)

- Thesis DefenseDocument22 pagesThesis Defenseleamagana967Pas encore d'évaluation

- SF 0654Document4 pagesSF 0654QA LAB ISMPas encore d'évaluation

- Cambridge Assessment International Education: Combined Science 0653/31 May/June 2019Document10 pagesCambridge Assessment International Education: Combined Science 0653/31 May/June 2019Kristina FilipovićPas encore d'évaluation

- 2023 Specimen Paper 1Document18 pages2023 Specimen Paper 1maryy.army.77Pas encore d'évaluation

- Influence of Lead Zinc Iron III and ChroDocument7 pagesInfluence of Lead Zinc Iron III and ChroFrancisco GarayoPas encore d'évaluation

- Rail CorrosionDocument71 pagesRail CorrosionkishanrwtPas encore d'évaluation

- Kineski Limovi Q PDFDocument10 pagesKineski Limovi Q PDFssteticPas encore d'évaluation

- Chemistry: Classification of MatterDocument29 pagesChemistry: Classification of MatterRamzen Raphael DomingoPas encore d'évaluation

- CH 8. P-Block (Chem - 2)Document77 pagesCH 8. P-Block (Chem - 2)Pradeep KumarPas encore d'évaluation

- Chromic Acid Chromium Trioxide Flake: PropertiesDocument3 pagesChromic Acid Chromium Trioxide Flake: PropertiesAnggiPas encore d'évaluation

- Element Baby Book ProjectDocument8 pagesElement Baby Book ProjectLauryn100% (1)