Académique Documents

Professionnel Documents

Culture Documents

Pipeline Risk Management Basic Manual

Transféré par

hemnDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pipeline Risk Management Basic Manual

Transféré par

hemnDroits d'auteur :

Formats disponibles

Complimentary Air ticket to Accra for the first 10 Registrations*

Meet your trainer: RAMESH SINGH

RAMESH SINGH, IEng, MWeldI (UK), is a consultant and working as Senior Principal Engineer at Gulf Interstate

Engineering, Houston, TX. With over 40 years of experience, in pipeline integrity, risk assessment, materials,

welding, and corrosion. He is a registered engineer with the British Engineering Council and a member of The

Welding Institute, UK. Ramesh has been associated with several standard bodies, including Canadian Standard

Association where he was associated with Production Group of CSA Z 662-2003. He has long association with NACE,

as member and officer of NACE.

Complimentary Books authored by Mr. RAMESH SINGH

Based on over 40 years of experience in the field, Ramesh Singh goes beyond

corrosion control, providing techniques for addressing present and future integrity

issues. Pipeline Integrity Handbook provides pipeline engineers with the tools to

evaluate and inspect pipelines, safeguard the life cycle of their pipeline asset and

ensure that they are optimizing delivery and capability. Presented in easy-to-use,

step-by-step order, Pipeline Integrity Handbook is a quick reference for day-to-day

use in identifying key pipeline degradation mechanisms and threats to pipeline

integrity. The book begins with an overview of pipeline risk management and

engineering assessment, including data collection and regulatory approaches to

liquid pipeline risk management.

* Terms & Conditions Apply. The airfare will be refunded to the attendee within 14 days of the final event day upon receipt of the attendees air ticket receipt.

The total claimable amount is up to USD600. Final Approval is subjected to Equip Globals decision. Please contact us for more details.

Researched & Developed By:

Email: enquiry@equip-global.com | Tel: +65 6376 0908 | www.equip-global.com for more information

Pipeline Integrity Management & Risk Assessment

Course Overview

Many oil and gas transmission pipelines have exceeded their design life, and several more are nearing their design

life. Incidents of inadvertent release is more common some of them leading to fatalities. Even the best designed and

maintained pipeline are prone to failure. This very fact requires that the operators take necessary steps to mitigate

or at least minimize the potential of failure by controlling the events.

This workshop is an attempt to bring awareness to what constitutes maintenance of pipeline integrity. The

discussion will introduce to the following seven concepts.

1. What is Risk management?

2. What is Integrity Management?

3. What causes affect integrity of pipeline and facilities?

4. What steps could be taken to mitigate or limit risk to pipeline?

5. What are resources that can be used to make the integrity management effective?

6. Discuss Tools used to make effective integrity management system.

7. How to use Risk Based analysis to optimize limited resources?

Pipeline Integrity Management is a continuous improvement process, as demonstrated by the below Integrity

Management Circle, and the management plans are updated on the basis of the acquired data and information.

This seminar will discuss the theories and practices of cost effective pipeline integrity management, and guide the

attendees through the Integrity Management Circle.

Course Objectives

The increasing use of high-technology inspection and maintenance methods are helping pipeline owners to assess

the condition of their lines, and if these modern maintenance methods are combined with modern defectassessment methods, they can provide a very powerful and cost-effective tool. This course will provide attendees

best practices on how to manage gathered data from various inspection techniques and apply them in modelling the

potential failures. It will also teach attendees on how to optimize the inspection and maintenance resources to

develop a comprehensive integrity management program covering both pipelines and their associated facilities.

The necessary elements of such a program are described in detail with examples of typical program content

including an overarching view of where detailed Risk Analysis and Defect Assessment fits in the Program. The course

is highly interactive and takes the form of lectures, workshops, and case studies.

Email: enquiry@equip-global.com | Tel: +65 6376 0908 | www.equip-global.com for more information

Pipeline Integrity Management & Risk Assessment

Key Topics Covered

Pipeline Engineering Principles & Pipeline Integrity Management

Principles and Practice of Data Collection and Management

Causes of Pipeline Failure

Risk Assessment & Development of Management Plans

Pipeline Inspections

Difficult to inspect Pipelines and Direct Assessment

Defect Assessment Methods

Repair and Remediation

Reporting and Performance Measurement

You will enhance your skills to:

Identify Pipeline hazards as threat to integrity.

Develop plans to address the identified threats

Conduct appropriate inspections to determine the condition of the pipeline

Assess the results of the inspections

Adopt A risk- based approach to maintenance

Update the risk assessments and management plans

Perform appropriate repair & rehabilitation activities

Who should attend?

Heads, Senior Managers, Managers, Specialists, Senior Engineers, Engineers, Risk analysts, Statistical analysts,

responsible for following activities:

Pipeline Integrity

Pipeline Engineering

Inspection

Pipeline Risk

Pipeline Operations

Pipeline Design

Pipeline Installation & Commissioning

Pipeline Maintenance & Repair

Pipeline Systems Management

QA/QC

Reliability & Asset Integrity

Corrosion/Coating/Cathodic Protection

Technical Services

Program Schedule (Day1 to Day3)

08.30am

09.00am

10.30am 11.00am

12.30am

13.30pm

15.00pm 15.30pm

17.00pm

Registration and welcome coffee

Morning session begins

Morning teas break

Lunch

Afternoon session begins

Afternoon tea break

End of Day/Course

Would you like to run this course in-house? (Save up to 35%)

This course can be presented exclusively for your organisation on an in-house basis, tailored to meet your specific

needs, at a place and time of your convenience. If you have a team of 10 or more interested in this course, lets

discuss how we can work together to meet your training needs. Please contact us and we will be pleased to assist.

Email: enquiry@equip-global.com | Tel: +65 6376 0908 | www.equip-global.com for more information

Pipeline Integrity Management & Risk Assessment

Course Format

This course will be held in a highly interactive workshop format with Role Simulation Exercises based on real world

examples. Places are limited to ensure all participants gain maximum insight into world class strategic thinking.

Pre - Course

A Pre-Course Questionnaire will be sent to you prior to the workshop. The Trainer will customize the training to suit

your specific needs.

Certificate

Upon completion of the course, you will receive a Certificate of Attendance bearing the signatures of both the

Trainer and the Course Organizer. This Certificate will testify to your professional development and assist in your

advancement.

About your Expert trainer: RAMESH SINGH

RAMESH SINGH, IEng, MWeldI (UK), is a consultant and working as Senior Principal Engineer at Gulf Interstate

Engineering, Houston, TX. He specializes in materials, welding, and corrosion. Ramesh has an M.S. degree in

engineering management from California Coast University and has gained his basic metallurgical education from Air

Force Technical Institute, India.

He is a registered engineer with the British Engineering Council and a member of The Welding Institute, UK. Ramesh

has been associated with several standard bodies, including a member of Canadian Standard Association where he

was associated with Production Group of CSA Z 662-2003. He has long association with NACE, as member and officer

of NACE; Mr. Singh has served on various technical committees where he has served as Treasurer and Vice Chair of

NACE Houston Chapter. He has participated in various technical groups and committees on Metallurgy, Material,

Welding and Fabrication of Corrosion-Resistant Alloys (Vice Chair), Double Cantilever Test Committee, Oversight and

Maintenance Committee of MR 0175, (ISO 15156).

He has authored of several books and published articles in industry journal articles and presented papers.

Ramesh consults as subject matter expert through his Consulting firm Nadoi Management, Inc.

Email: enquiry@equip-global.com | Tel: +65 6376 0908 | www.equip-global.com for more information

Pipeline Integrity Management & Risk Assessment

Agenda: Training Day 1 - Day 3

Pipeline Engineering Principles& Pipeline Integrity Management

This introductory module is intended to provide the basics pipeline engineering principles which will

help you better understand the pipeline integrity management. It will be also introduce the concept of

the integrity management.

Why use pipelines?

Gas vs Oil pipelines ASME B 31.8 and 31.4

Pipeline design

Construction of Pipelines

Class Locations

Threats to a Pipeline

Pipeline defects and failure

Stresses in pipelines

Basic pipeline operating and maintenance parameters

Inspection and Maintenance methods

Introduction to the Integrity Management

Manage ageing pipeline infrastructure with an Integrity Management system.

Data collection

Risk and Consequence

Internal and External corrosion

Pipeline Failures

This module aims to provide an introduction to some of the known failure modes of pipeline and

facilities. An introduction to facture mechanics will be made with reference to BS 7910.

Failures associated with sour service, SCC, HIC etc.

Failures associated with CO2

Failures associated with Microbiological bacteria

Failures associated with welding

Metallurgical aspect of failures

Manufacturing defects

Failure modes and how pipelines fail (ductile/brittle fracture)

Crack propagation,

Methods to assess cracks (Ref. BS 7910, API 579)

Repair and Remediation

The objective of this module is to describe the main pipeline repair techniques. The applicability of each

of the techniques for the repair of defects will be discussed. The following techniques will be included:

Repair and rehabilitation strategy

Response to discovering defects

What are the cost implications?

Types of repair and rehabilitation methods

Grinding, Weld deposition

Composite wraps

Cut outs

Mechanical clamps/connectors

Time to repair

Email: enquiry@equip-global.com | Tel: +65 6376 0908 | www.equip-global.com for more information

Pipeline Integrity Management & Risk Assessment

Agenda: Training Day 1 - Day 3

Pipeline Inspection

The in-line pipeline inspection technologies that are available to detect the defects found in pipelines

will be reviewed in this module. The module will include:

API Standard 1163: In Line Inspection Systems

Key terms and definitions

Systems qualification process

In Line inspection system selection

Magnetic Flux Leakage tools (including MagneScan, TranScan and Elastic Wave)

Ultrasonic tools (including UltraScanWM, UltraScan CD, EMAT)

Caliper vehicles (including CalScan)

Pipeline location vehicles (including ScoutScan)

Direct assessment procedures and methodologies

Above ground survey techniques (CIPS, DCVG etc.)

Identify new technologies and applications

Defect Assessment Methods

This module will review, and illustrate with practical worked examples, the assessment methods which

are applicable each of the different pipeline defects and will include:

Corrosion assessment methods (Ref. ASME B31.G, RStreng,)

Methods to assess manufacturing metal loss defects

Methods to assess dents

Methods to assess gouges and dent/gouge combinations

Using inspection data to carry out integrity assessments

Reporting and Performance Measurement

This module draws the course together and will provide information on how data collected during the

process is integrated back into the management system.

Recap of training and final Q&A session

The training session will be interactive and spread with some in class calculations to bring home the

points.

Participants are encouraged to interact and ask questions and clarifications during and at the end of the

training sessions. They can also ask questions to expert trainer any final burning questions.

There are no bad questions in the world and any question you have is very likely what someone else in

the training course also wants to ask. Participants are encouraged to take full advantage of this

interactive Q&A session and get practical ideas for solving your pipeline integrity management

problems!

Email: enquiry@equip-global.com | Tel: +65 6376 0908 | www.equip-global.com for more information

Vous aimerez peut-être aussi

- HLA HART Concept of LawDocument19 pagesHLA HART Concept of LawHarneet KaurPas encore d'évaluation

- Understanding PumpDocument113 pagesUnderstanding Pumpnyr1981_942955963100% (5)

- GF-WPK-J-CA-2001 - WP-K Calculation Note For Piping Stress Analysis - Rev 1 - RDocument32 pagesGF-WPK-J-CA-2001 - WP-K Calculation Note For Piping Stress Analysis - Rev 1 - RRami KsidaPas encore d'évaluation

- Ultrasonic Testing of Steel CastingDocument38 pagesUltrasonic Testing of Steel CastingPARK, SANGYEOLPas encore d'évaluation

- WTSDA2021 TSDBlack Belt ManualDocument160 pagesWTSDA2021 TSDBlack Belt ManualJesus HernandezPas encore d'évaluation

- Pressure Testing of Pipeline Systems (Version 1.1.0, MAY 2013)Document46 pagesPressure Testing of Pipeline Systems (Version 1.1.0, MAY 2013)Amit SharmaPas encore d'évaluation

- Ipc2012 90620Document17 pagesIpc2012 90620Marcelo Varejão CasarinPas encore d'évaluation

- LBV PDFDocument136 pagesLBV PDFaliPas encore d'évaluation

- SAEJ987 V 001Document22 pagesSAEJ987 V 001hemnPas encore d'évaluation

- The Feasibility of Transporting Hydrogen in Existing PipelinesDocument9 pagesThe Feasibility of Transporting Hydrogen in Existing PipelinesomiitgPas encore d'évaluation

- GTAG-14 Edited With Ad 05-20-20101 PDFDocument32 pagesGTAG-14 Edited With Ad 05-20-20101 PDFpiornelPas encore d'évaluation

- Design of Cross PipelineDocument33 pagesDesign of Cross Pipelineannu300Pas encore d'évaluation

- Consumable by AWS D5.1Document8 pagesConsumable by AWS D5.1Fuaz Sukarya Abu Fatih100% (1)

- Sketch NotesDocument32 pagesSketch NotesFilipe Rovarotto100% (8)

- Gas RegulationsDocument168 pagesGas RegulationsJijo GeorgePas encore d'évaluation

- Design of Parallel Pipelines in Second West-East Natural Gas Pipeline ProjectDocument10 pagesDesign of Parallel Pipelines in Second West-East Natural Gas Pipeline ProjectAleksObrPas encore d'évaluation

- Contemplation (Murāqaba) and Spiritual Focus/attention (Tawajjuh) in The Pre-Mujaddidi Naqshibandi OrderDocument5 pagesContemplation (Murāqaba) and Spiritual Focus/attention (Tawajjuh) in The Pre-Mujaddidi Naqshibandi OrderShahmir ShahidPas encore d'évaluation

- Wall Theo PDFDocument23 pagesWall Theo PDFFranklin UkaohaPas encore d'évaluation

- Applicable Version (S) : Flarenet Sonic Vel Check - HSC (100 K)Document2 pagesApplicable Version (S) : Flarenet Sonic Vel Check - HSC (100 K)behnazrzPas encore d'évaluation

- SPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High PressureDocument1 pageSPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High PressureAris KancilPas encore d'évaluation

- 4-PU101-PR-DI-029 14 SheetsDocument16 pages4-PU101-PR-DI-029 14 SheetsBurhan Ayub100% (1)

- Pigging in Pipeline Pre-Commissioning PDFDocument8 pagesPigging in Pipeline Pre-Commissioning PDFhemn100% (2)

- SEPA15014 MFSTF CV 00 SPC 004 - Specification For Grouting - Rev ADocument15 pagesSEPA15014 MFSTF CV 00 SPC 004 - Specification For Grouting - Rev APruthviraj JuniPas encore d'évaluation

- Offshore Pipeline Hydraulic and Mechanical AnalysesDocument25 pagesOffshore Pipeline Hydraulic and Mechanical AnalysesEslam RedaPas encore d'évaluation

- 9273E-300-CN-3531-613 - Attachment 3: About Upheaval and Lateral Buckling of Embedded PipelinesDocument12 pages9273E-300-CN-3531-613 - Attachment 3: About Upheaval and Lateral Buckling of Embedded PipelinesAnjani Prabhakar100% (1)

- NGMSA TQ Fence Levels 122Document2 pagesNGMSA TQ Fence Levels 122Sehna SerajPas encore d'évaluation

- Hydrogen Piping Pipeline Hardness TestingDocument19 pagesHydrogen Piping Pipeline Hardness TestingsaravananPas encore d'évaluation

- E PM 385Document25 pagesE PM 385masoudPas encore d'évaluation

- Pipe RoutingDocument38 pagesPipe RoutingHadisupriadiPas encore d'évaluation

- PCVL Pigging Procedure (RB-B To RB-A)Document9 pagesPCVL Pigging Procedure (RB-B To RB-A)hai dang maiPas encore d'évaluation

- MEPG - Repurposing Existing Pipeline For CO2 TransportDocument33 pagesMEPG - Repurposing Existing Pipeline For CO2 TransportAmmarul NafikPas encore d'évaluation

- Appendix 9E Longhorn Mitigation Plan Mandated Studies SummariesDocument33 pagesAppendix 9E Longhorn Mitigation Plan Mandated Studies SummariesFemi Richard FakoyaPas encore d'évaluation

- Natural Gas Transmission Pipeline Temperature Drop CalculationDocument5 pagesNatural Gas Transmission Pipeline Temperature Drop CalculationCarina QuibinitPas encore d'évaluation

- Plf-jms-031 - r0 - Jms of Lifting, Shifting, Stringing, Lowering-In and Transportation Using Excavator - SignedDocument85 pagesPlf-jms-031 - r0 - Jms of Lifting, Shifting, Stringing, Lowering-In and Transportation Using Excavator - SignedHafiz YunusPas encore d'évaluation

- Alberta Pipeline ActDocument56 pagesAlberta Pipeline ActFredrick Martin100% (1)

- BOG Rate CalculationDocument1 pageBOG Rate CalculationNgoVietCuongPas encore d'évaluation

- In-Line Inspection of Multi-Diameter Pipelines: Standardized Development and Testing For A Highly Efficient Tool FleetDocument10 pagesIn-Line Inspection of Multi-Diameter Pipelines: Standardized Development and Testing For A Highly Efficient Tool FleetNikhil Mohan100% (1)

- Bettis - Line Break Detection - Lineguard2100Document6 pagesBettis - Line Break Detection - Lineguard2100andy175Pas encore d'évaluation

- Pipe Stress Analysis Complete Course From PassDocument2 pagesPipe Stress Analysis Complete Course From Passsleiman shokr100% (1)

- Ips G Pi 280Document23 pagesIps G Pi 280MahdiPas encore d'évaluation

- Pipeline Operations Manual: Including Perational Tandards and RoceduresDocument4 pagesPipeline Operations Manual: Including Perational Tandards and RoceduresOreolPas encore d'évaluation

- Quality Requirements For Line Pipe: JanuaryDocument14 pagesQuality Requirements For Line Pipe: JanuaryJose Anisio Silva100% (1)

- Engineered Engineered: Thermal Maintenance S Stems For Urea Systems For Urea Applications PPDocument31 pagesEngineered Engineered: Thermal Maintenance S Stems For Urea Systems For Urea Applications PPdzungPas encore d'évaluation

- Saes L 131Document10 pagesSaes L 131samsurendran_mech4020Pas encore d'évaluation

- Riopipeline2019 1093 201905221205final Paper Overpi PDFDocument12 pagesRiopipeline2019 1093 201905221205final Paper Overpi PDFMarcelo Varejão Casarin100% (1)

- Double Block and Bleed With Ultra-Low Emission Options: Catalog 4190-FPDocument17 pagesDouble Block and Bleed With Ultra-Low Emission Options: Catalog 4190-FPAnandPas encore d'évaluation

- Enbridge Revised Pipeline Backfill Plan 20100817Document14 pagesEnbridge Revised Pipeline Backfill Plan 20100817adeoye_okunoyePas encore d'évaluation

- Porous Sparger SizingDocument4 pagesPorous Sparger Sizingprav.saradaPas encore d'évaluation

- Liquid Pipeline HydraulicsDocument74 pagesLiquid Pipeline HydraulicsSimon Kapoma100% (1)

- GSR541 Indian RegulationDocument20 pagesGSR541 Indian Regulationsathish_iyengar100% (1)

- ESI-Case-Study-Enagas-PLM-Pipeline TrainerDocument5 pagesESI-Case-Study-Enagas-PLM-Pipeline TrainerMuhammad ImranPas encore d'évaluation

- Determining Back Pressure When Sizing For PRV - Relief Devices Forum - Cheresources - Com CommunityDocument5 pagesDetermining Back Pressure When Sizing For PRV - Relief Devices Forum - Cheresources - Com CommunityKyriakos MichalakiPas encore d'évaluation

- Stress and Displacement Analysis of Aerial Oil GasDocument17 pagesStress and Displacement Analysis of Aerial Oil GasDaniel Gómez100% (1)

- 3 Lead Engineer For Subsea Pipeline Systems LDNDocument2 pages3 Lead Engineer For Subsea Pipeline Systems LDNVijay_DamamPas encore d'évaluation

- PPSC - Product Data Sheet Concrete Weight CoatingsDocument1 pagePPSC - Product Data Sheet Concrete Weight CoatingsjulianpirahPas encore d'évaluation

- Insulating Gaskets & Its Practical DifficultiesDocument6 pagesInsulating Gaskets & Its Practical Difficulties4A28Sparsh JainPas encore d'évaluation

- CPI CPI-BrochureDocument22 pagesCPI CPI-BrochureMazwan Che MansorPas encore d'évaluation

- CPP-EKL-1.0-MFM-MCK-P-0001-0 - Hydraulic Analysis ReportDocument16 pagesCPP-EKL-1.0-MFM-MCK-P-0001-0 - Hydraulic Analysis ReportBILAL ILYASPas encore d'évaluation

- GasPipelineSafetyOIR Plea WildGoose 20130628 280481 PDFDocument320 pagesGasPipelineSafetyOIR Plea WildGoose 20130628 280481 PDFcartarPas encore d'évaluation

- Submarine Pipeline Route Selection Upheaval Buckling External Pressure CollapseDocument19 pagesSubmarine Pipeline Route Selection Upheaval Buckling External Pressure CollapseSampurnanand PandeyPas encore d'évaluation

- Gas Pipeüne Rupture Detection and ControlDocument8 pagesGas Pipeüne Rupture Detection and ControlRaiBernardoPas encore d'évaluation

- Flanges With External LoadDocument15 pagesFlanges With External LoadMohan VarkeyPas encore d'évaluation

- Engineered Spring SupportsDocument43 pagesEngineered Spring SupportsNestor Barranco RadaPas encore d'évaluation

- Test Report Long-Term Ring Bending Strain (SB)Document4 pagesTest Report Long-Term Ring Bending Strain (SB)Diana QuinteroPas encore d'évaluation

- Egp ReportDocument109 pagesEgp ReportvyshnapramodPas encore d'évaluation

- ASME B31.8 Course OutlineDocument1 pageASME B31.8 Course OutlinePrakhar Deep KulshreshthaPas encore d'évaluation

- Pipeline Hydraulic Design Proposal PDFDocument62 pagesPipeline Hydraulic Design Proposal PDFDhia SlamaPas encore d'évaluation

- Anchor FlangeDocument1 pageAnchor FlangeHector MejiaPas encore d'évaluation

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988D'EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockPas encore d'évaluation

- Failure Assessment and Safe Life Prediction of Corroded Oil and Gas PipelinesDocument20 pagesFailure Assessment and Safe Life Prediction of Corroded Oil and Gas PipelineshemnPas encore d'évaluation

- 101 Metal Repair Paste PS PDFDocument2 pages101 Metal Repair Paste PS PDFhemnPas encore d'évaluation

- Improving The Efficiency of HVACDocument20 pagesImproving The Efficiency of HVAChemnPas encore d'évaluation

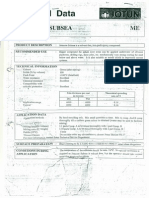

- پوشش زیر دریاDocument2 pagesپوشش زیر دریاhemnPas encore d'évaluation

- Research World Landmarks To Create A Global Calendar: Microsoft in Education Lesson PlansDocument4 pagesResearch World Landmarks To Create A Global Calendar: Microsoft in Education Lesson PlanshemnPas encore d'évaluation

- ASTM Pipe Schedule DimensionsDocument5 pagesASTM Pipe Schedule DimensionshemnPas encore d'évaluation

- Underwater Painting SystemsDocument2 pagesUnderwater Painting SystemshemnPas encore d'évaluation

- Types of SoilDocument35 pagesTypes of SoilhemnPas encore d'évaluation

- Underwater Painting SystemsDocument2 pagesUnderwater Painting SystemshemnPas encore d'évaluation

- How To Read Welding GaugesDocument8 pagesHow To Read Welding GaugeshemnPas encore d'évaluation

- Standard Spiral Wound Gaskets and Their Temperature LimitsDocument1 pageStandard Spiral Wound Gaskets and Their Temperature LimitshemnPas encore d'évaluation

- Christine Remembered That Today Is The Birthday of Her BossDocument1 pageChristine Remembered That Today Is The Birthday of Her BossA.Pas encore d'évaluation

- 50 Interview Question Code Galatta - HandbookDocument16 pages50 Interview Question Code Galatta - HandbookSai DhanushPas encore d'évaluation

- Application Tracking System: Mentor - Yamini Ma'AmDocument10 pagesApplication Tracking System: Mentor - Yamini Ma'AmBHuwanPas encore d'évaluation

- 1991 Hanaor - DOUBLE-LAYER TENSEGRITY GRIDS - STATIC LOADDocument15 pages1991 Hanaor - DOUBLE-LAYER TENSEGRITY GRIDS - STATIC LOADDaniel MartinsPas encore d'évaluation

- 10 1 3 RMDDocument5 pages10 1 3 RMDRay GalfianPas encore d'évaluation

- How To Spend An Hour A Day in Prayer - Matthew 26:40-41Document1 pageHow To Spend An Hour A Day in Prayer - Matthew 26:40-41Steve GainesPas encore d'évaluation

- Cause List 2.1.2023Document4 pagesCause List 2.1.2023あいうえおかきくけこPas encore d'évaluation

- Anansi and His Six Sons An African MythDocument3 pagesAnansi and His Six Sons An African MythShar Nur JeanPas encore d'évaluation

- Math Cad 15Document3 pagesMath Cad 15Kim ChanthanPas encore d'évaluation

- Technology For Duck - Fish Integrated Farming System in GoaDocument4 pagesTechnology For Duck - Fish Integrated Farming System in GoagavinilaaPas encore d'évaluation

- CN Blue Love Rigt Lyrics (Romanized)Document3 pagesCN Blue Love Rigt Lyrics (Romanized)Dhika Halet NinridarPas encore d'évaluation

- Faculty of AyurvedaDocument9 pagesFaculty of AyurvedaKirankumar MutnaliPas encore d'évaluation

- IAU Logbook Core 6weeksDocument7 pagesIAU Logbook Core 6weeksbajariaaPas encore d'évaluation

- VectorCAST QA Factsheet ENDocument2 pagesVectorCAST QA Factsheet ENChaos XiaPas encore d'évaluation

- Questionnaire OriginalDocument6 pagesQuestionnaire OriginalJAGATHESANPas encore d'évaluation

- Metro Depot: (Aar 422) Pre-Thesis SeminarDocument3 pagesMetro Depot: (Aar 422) Pre-Thesis SeminarSri VirimchiPas encore d'évaluation

- STRESS HealthDocument40 pagesSTRESS HealthHajra KhanPas encore d'évaluation

- SBU PlanningDocument13 pagesSBU PlanningMohammad Raihanul HasanPas encore d'évaluation

- Ibridge Product Spec SheetDocument2 pagesIbridge Product Spec SheetanupamPas encore d'évaluation

- REM630 Broch 756825 LRENdDocument6 pagesREM630 Broch 756825 LRENdsihamuPas encore d'évaluation

- British Airways Culture and StructureDocument29 pagesBritish Airways Culture and Structure陆奕敏Pas encore d'évaluation

- M14 PManualDocument382 pagesM14 PManualnz104100% (2)

- Ruby Onyinyechi Amanze - Werte Magazine - 2019Document2 pagesRuby Onyinyechi Amanze - Werte Magazine - 2019José LaertonPas encore d'évaluation

- TuberkulosisDocument285 pagesTuberkulosisTeuku M. FebriansyahPas encore d'évaluation