Académique Documents

Professionnel Documents

Culture Documents

Dp-Ced-32.6 Concrete Asphalt Road

Transféré par

bonnicoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Dp-Ced-32.6 Concrete Asphalt Road

Transféré par

bonnicoDroits d'auteur :

Formats disponibles

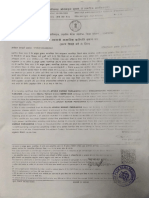

PT.

INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

ORIGINATOR

REV.

00

01

Name

Signature

Didik S

Umi

DS

US

REVIEWED

BY

Name

Signature

Bambang H

BH

APPROVED BY

DATE

Name

Signature

Nyoman M

Pramono

NM

PAP

01 June 1999

08 March 2004

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

REVISION CONTROL SHEET

REV.

DATE

00

01 June 99

01

08 March

04

REVISION DETAILS

Issued for release

Updated to new format standart

This document contains proprietary information and must not be disclosed to a third party without

the prior permission in writing from the company

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

Page 1 of 24

TABLE OF CONTENTS

Page

1. GENERAL

2.

DEFINITIONS OF TERM USED

2.1

2.2

2.3

2.4

3

3

3

3

2.4.1

2.4.2

3.

Sub Grade

Sub Base Coarse

Base Coarse

Surfacing

Binder Coarse

Wearing Coarse

3

3

BASIC INFORMATION

3.1

3.1.1

3.1.2

3.1.3

3.1.4

3.2

3.2.1

3.2.2

3.3

3.3.1

3.3.2

3.3.3

3.4

Climatic Data

Rainfall and Evaporation

Sub Grade Strength

Surface Water Drainage

Temperature

Soil Conditions Data

Aerial and Ground Contour Survey

Boring and Sampling

Test Of Samples Information

Moisture Content Determinations Shall Be Made

On The Sample Stage

Compaction Test

CBR (California Bearing Ratio)

Construction and Volume Of Traffic

4

4

4

4

4

4

4

5

5

5

5

5

4.

CLASSIFICATION OF SOIL PARTICLE

5.

CONSTITUTION OF ASPHALT CONCRETE ROAD

10

6.

PAVEMENT DESIGN PROCEDURE

10

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

6.1

6.2

6.2.1

6.2.2

6.2.3

6.2.4

6.2.5

6.3

6.3.1

6.3.2

Minimum Layer Thickness

Parameters

Terminal Service Ability Index (P)

Design Traffic

Soil Supported Values

Regional Factor

Structural Number (Sn)

Design Application

Type Of Charts

Parameter To Determined

6.3.2.1

6.3.2.2

6.3.2.3

6.3.3

6.3.4

7.

10

11

11

11

11

15

15

16

17

18

18

18

18

Charts Design

Design Summary

19

20

MATERIAL AS ASTMS STANDARD TEST

21

7.1

7.2

21

22

7.2.1

7.2.2

7.3

8.

Index Of Service Ability (P)

Soil Support Values (S)

Traffic Volume And Loads

Page 2 of 24

Material For Sub Base Coarse And Base Coarse

Material For Surface Coarse

Asphaltic Concrete Binder Coarse Base

(Lower Layers)

Asphaltic Concrete Wearing Coarse (Upper Layers)

Blank Charts For Design Purpose

REFERENCES

22

22

23

24

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

Page 3 of 24

1. GENERAL

The purpose of this design is to establish standards and practical information for the design of

asphalt concrete road system for petrochemical and industrial facility plant as IKPTs property

design manual. Items like site clearing, earth moving, drainage system, culvert/bridge or

others which is interrelated to road design shall be referred to each of itself design manual.

2. DEFINITIONS OF TERM USED

2.1

Sub grade shall mean ground to be prepared with sufficient, bearing capacity, leveling,

compared as required by road design terms.

2.2

Sub base coarse shall mean the first layer formation of maximum 65 dia.

graded/crushed stone, thickness after compacted varied in accordance with type of

road design. (see article 6.1).

2.3

Base coarse shall mean the second formation of layer on top of sub base coarse.

Maximum grade is 50 dia. crushed stone. Thickness after compacted varied in

accordance with type of road design. (see Article 6.1).

2.4

Surfacing shall mean the final formation of layer on top of base coarse it could be

Asphalt Concrete Pavement which is usually divided on two sub layers :

2.4.1

Binder Coarse

The formation layer on top of base coarse, thickness after compacted varied in

accordance with type of road design. Maximum grade is 25 dia. mixed with sand,

ash and asphalt (see Article 7.2.1).

2.4.2

Wearing Coarse

The formation layer on top of binder coarse, as the last formation to be contacted

to the fire. Thickness after compacted varied in accordance with type of road

design. Maximum grade is 10, mixed with sand, ash and asphalt. (see Article

7.2.2).

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

3.

Page 4 of 24

BASIC INFORMATION

To completed the designs data the basic information shall be

3.1

3.1.1

Climatic Data

Rainfall and evaporation

Data of rainfall intensity shall be importance to the design related to construction

of earth work included here moisture counter during compaction.

3.1.2

Sub Grade strength

The natural moisture content of the soil will determine the subgrade strength of the

pavements design. Site investigation detail data shall be completed before

started to design stage.

3.1.3

Surface water drainage

The time period chosen for rainfall intensity is 2, 5, 10 or 20 years storm. These

time periods should approved by the Client, as well as the design type will be in

accordance to which of this time period and shall be related to safety and

economical value.

3.1.4

Temperature

In the design of flexible pavement, temperature data is important to the stiffness

by bituminous materials in which should affects the design of thickness

requirements.

3.2

3.2.1

Soil Conditions Data

Aerial and ground contour survey

To obtained the gradients shape and shall be minimum interference to existing

building or plant.

3.2.2

Boring and sampling

Shall be sufficiently closed space to indicate significant quantity of unsuitable or

contractually difficult materials present a long the route. Soil strata should be clear

and intermediate bores shall be supplemented in case obvious change at strata

are found between initial bore holes.

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

DP-CED-32.6

CONCRETE ASPHALT ROAD

Page 5 of 24

Sampling content of minimum 2 Kg should be taken out depth interval 500 mm in

fine grained soils for classification test. In granular soils should increase to 10 Kg

and placed in airtight containers and about 0.5 Kg same depth sample shall be

checked the moisture contents. All the bore holes should be temporarily capped

and checked for ground with level intervals until equilibrium conditions is reached.

3.3

3.3.1

Test of Samples Information

Moisture content determinations shall be made on all the sample stage

The appropriate classification should be identified to all samples. The classification

test for cohesive soils are the liquid and plastic limit. Test for granular soils is the

wet sieve particle size.

3.3.2

Compaction test-relating density and moisture content should carried out by

laboratory test.

Both standard test and heavy test should be completed to at least half of the

sample taken.

3.3.3

CBR (California Bearing Ratio) and other test

After the earth work is completed a long the lane, CBR value test should be

informed and also the relationship between CBR value, dry density and moisture

content. Also triaxial test is needed for identified the stability of the embankment

and cutting slope. The consolidation test shall be necessary if highly compressible

soils are present.

3.4

Constitution and Volume of Traffic to be Carried Out

It should be clear the type of traffic and the speed of vehicle. For petrochemical or

industrial plant, more heavy traffic like crane, trailer, trucks shall be accounted. Beside

the traffic velocity is limited from 15 MPH ( 24 Km/hour) to 25 MPH ( 40 Km/hour).

This design data shall be in accordance to classification of the road. Standard of

traffic flow shall be designed in accordance to interim guide for design and pavement

structures, American Associates of Stage Highway and Transportation Officials

(AASHTO). Table of various axle load in petrochemicals or industrial plant as shown in

Figure 1, Table 1 and Table 2.

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

DP-CED-32.6

CONCRETE ASPHALT ROAD

Figure 1

Method of Classifying Axles Types

(Book Reference No. 2, Page 41)

Page 6 of 24

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

Page 7 of 24

Table 1

Regulations Relating to the Maximum Gross Vehicle Weight

And Maximum Overall Length Applicable in the USA

(Book Reference No. 2, Page 44)

Max. Gross Weight

Lb

73 280

33.2

Arkansas, District of Columbia, Illinois, Indiana, Mississippi, Missouri, Tennessee

76 000

34.5

Virginia

79 800

36.2

North Carolina

80 000

36.3

Arizona, California, Connecticut, Delaware, Florida, Georgia, Iowa, Maine, Maryland,

Minnesota, New Hampshire, New Jersey, New York, Ohio, Pennsylvania, Texas, Vermont,

Wisconsin

80 600

36.6

South Carolina

82 000

37.2

Kentucky

85 500

38.8

Kansas

86 400

39.2

New Mexico

88 000

39.9

Louisiana

88 880

40.3

Hawaii

90 000

40.8

West Virginia, Oklahoma

92 400

41.9

Alabama

95 000

43.1

Nebraska, South Dakota

99 000

44.9

Rhode Island

101 000

45.8

Wyoming

104 000

47.2

Massachusetts

105 500

47.9

Idaho, Montana, North Dakota, Oregon, Washington

109 000

49.4

Alaska

122 000

55.3

Utah

129 000

58.5

Nevada

164 000

74.4

Maximum overall length

(Tractor and semi-trailer combinations)

State

Michigan

ft

55

16.8

States

Connecticut, District of Columbia, Florida, Indiana, Kentucky, Maryland, Missouri, New

jersey, North Carolina, Rhode Island, Tennessee, Virginia, Washington, West Virginia

58

17.7

Hawaii

60

18.3

Alabama, Arkansas, California, Delaware, Georgia, Iowa, Maine, Massachusetts,

Michigan, Minnesota, Mississippi, Montana. New Hampshire, New York, Ohio, Oregon,

Pennsylvania, South Carolina, Vermont

65

19.8

Alaska, Arizona, Idaho, Kansas, Louisiana, Nebraska, New Mexico, North Dakota,

Oklahoma, Texas, Utah

70

21.4

Colorado, Nevada, South Dakota

85

25.9

Wyoming

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

Page 8 of 24

Table 2

Regulations Relating to the Maximum Axle Loading Applicable in the USA

(Book Reference No. 2, Page 42)

Max. loading

Lb

States

Single axles

18 000

8.2

Arkansas, Georgia, Illinois, Indiana, Mississippi, Missouri, Montana, Nebraska, Tennessee

19 000

8.6

North Carolina

20 000

9.1

Alabama, Alaska, Arizona, California, Colorado, Delaware, Florida, Idaho, Iowa, Kansas,

Kentucky, Louisiana, Michigan, Minnesota, Nebraska, Nevada, North Dakota, Ohio,

Oklahoma, Oregon, South Carolina, South Dakota, Texas, Utah, Virginia, Washington, West

Virginia, Wisconsin, Wyoming

21 600

9.8

New Mexico

22 000

10.0

Maine, District of Columbia

22 400

10.2

Connecticut, Hawaii, Maryland, Massachusetts, New Hampshire, New Jersey, New York,

Pennsylvania, Rhode Island, Vermont

Tandem Axles

32 000

14.5

Arkansas, Illinois, Indiana, Mississippi, Missouri, Montana, Tennessee

34 000

15.4

Alaska, Arizona, California, Hawaii, Idaho, Iowa, Kansas, Kentucky, Louisiana, Maine,

Michigan, Minnesota, Nebraska, Nevada, New Jersey, New Mexico, North Dakota, Ohio,

Oklahoma, Oregon, Pennsylvania, South Dakota, Texas, Utah, Virginia, Washington, West

Virginia, Wisconsin

36 000

16.3

Colorado, Connecticut, Georgia, Massachusetts, New Hampshire, New York, North

37 000

16.8

District of Columbia

40 000

18.1

Carolina, Rhode Island, South Carolina, Vermont, Wyoming

Alabama, Delaware, Florida, Maryland

The following static axle loads may be used in preliminary design; i.e., until the project

scope has progressed to a point where more reliable data are established:

Kg

Minimum

Light

Single - Unit Trucks

Heavy trucks and tractor

trailer trucks

5443

5443 to 9072

10886 to 14515

14515 to 18144

Table 3

Axle load

Lb

12000

12000 to 20000

24000 to 32000

32000 to 40000

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

Page 9 of 24

4. CLASSIFICATION OF SOIL PARTICLE

To determined the particle in soil which is ranged from several centimeters stone, sand, silt,

clay down to 0.001 MM diameter particles.

Table 4

Soils Classification

(Book Reference No. 2, Page 104)

Refer to Table 2.

Particle in soils shall be divided to 4 (four) gravels.

Gravels

Sand

Silt

Clay

-----

Particles

Particles

Partical

Smaller than

2 - 60 MM diameters

0.06 - 2 MM diameters

0.002 - 0.06 MM diameters

0.002 MM diameters

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

Page 10 of 24

5. CONSTITUTION OF ASPHALT CONCRETE ROAD

Figure 2

12.22 Neither the AASHTO nor the ASTM specifications give a strength criterion for the

compacted materials, but the Asphalt Institute Thickness Design Manual requires in its Table V3 CBR value of 20 percent for sub-base and 80 percent for base material. These are laboratory

test results carried out at the appropriate moisture content and density conditions, and tested

after 4 (four) days soaking.

6.

PAVEMENT DESIGN PROCEDURE

The following parameters to be considered during the pavement thickness design.

6.1

Minimum Layer Thickness

Consideration shall be applied to construction requirements for placing the pavement layer. By

minimal thickness is 1 1/4 to 1 1/2 times the largest aggregate sizes, a minimum

layers shall be:

Subbase coarse Base coarse

Surface coarse -

6.2

Parameters

minimum thickness

minimum thickness

minimum thickness

= 4 (100)

= 3 (75)

= 1 (38)

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

Page 11 of 24

This design procedure is following AASHTO Interim Guide for Design of Pavement

Structures.

6.2.1

Terminal serviceability index P T

PT is based on the lowest index that will be tolerate before resurfacing or

reconstruction become necessary.

Index PT

Index PT

6.2.2

= 2.5

= 2

is applied for major highway

is applied for highway with small traffic volume.

Design traffic

The procedure in AASHTO Interim Guide for Design of Pavement Structure is to

convert the varying axle load to one design load only. This design load is 18 Kip

single axle load. See Table 5 and Table 6.

6.2.3

Soil supported values

Parameter S is represent the soil support value and already done by empirical.

Grade of S is divided by 10 degrees which is started from degree of hardness

colloin, clay, silty clay, silt, silty sand, sand, sandy gravel, gravel, hard rock.

S = 3 is represent silty clay, sub grade as AASHTO road test and S = 10

represent crushed road base test.

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

Page 12 of 24

a. Single Axles. Pt = 2.0

Axle loads,

kips

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

0.0002

0.002

0.01

0.03

0.08

0.16

0.32

0.59

1.00

1.61

2.49

3.71

5.36

7.54

10.38

14.00

18.55

24.20

31.14

39.57

0.0002

0.003

0.01

0.04

0.08

0.18

0.34

0.60

1.00

1.59

2.44

3.62

5.21

7.31

10.03

13.51

17.87

23.30

29.95

38.02

Structural Number SN

3

4

0.0002

0.002

0.01

0.04

0.09

0.19

0.35

0.61

1.00

1.56

2.35

3/43

4.88

6.78

9.24

12.37

16.30

21.16

27.12

34.34

0.0002

0.002

0.01

0.03

0.08

0.18

0.35

0.61

1.00

1.55

2.31

3.33

4.68

6.42

8.65

11.46

14.97

19.28

24.55

30.92

0.0002

0.002

0.01

0.03

0.08

0.17

0.34

0.60

1.00

1.57

2.35

3.40

4.77

6.52

8.73

11.48

14.87

19.02

24.03

30.04

0.0002

0.002

0.01

0.03

0.08

0.17

.033

0.60

1.00

1.60

2.41

3.51

4.96

6.83

9.17

12.17

15.63

19.93

25.10

31.25

0.01

0.01

0.02

0.04

0.07

0.11

0.16

0.24

0.34

0.47

0.63

0.83

1.08

1.38

1.73

2.16

2.66

3.24

3.91

4.68

0.01

0.01

0.02

0.04

0.07

0.10

0.16

0.23

0.33

0.46

0.62

0.82

1.07

1.38

1.74

2.18

2.70

3.31

4.02

4.83

b. Tandem Axles Pt = 2.0

Axle load

kips

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

0.01

0.01

0.02

0.04

0.07

0.10

0.16

0.23

0.32

0.45

0.61

0.81

1.06

1.38

1.76

2.22

2.77

3.42

4.20

5.10

0.01

0.02

0.03

0.05

0.08

0.12

0.17

0.24

0.34

0.46

0.62

0.82

1.07

1.38

1.75

2.19

2.73

3.36

4.11

4.98

Structural Number SN

3

4

0.01.

0.02

0.03

0.05

0.08

0.12

0.18

2.26

0.36

0.49

0.65

0.84

1.08

1.38

1.73

2.15

2.64

3.23

3.92

4.72

0.01

0.01

0.03

0.05

0.08

0.12

0.17

0.25

0.35

0.48

0.64

0.84

1.08

1.38

1.72

2.13

2.62

3.18

3.83

4.58

Table 5

Traffic Expression to Equivalent 18 Kip Single Axle Load

(Book Reference No. 1, Page 16-44)

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

Figure 3

Conversion of Axle Load to Equivalent Standard Axle

(Book Reference No. 2, Page 70)

c. Single Axles Pt = 2.5

Axle load

Structural Number SN

Page 13 of 24

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

Page 14 of 24

kips

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

0.0004

0.003

0.01

0.03

0.08

0.17

0.33

0.59

1.00

2.61

2.48

3.69

5.33

7.49

10.31

13.90

18.41

24.02

30.90

39.26

0.0004

0.004

0.02

0.05

0.10

0.20

0.36

0.61

1.00

1.57

2.38

3.49

4.99

6.98

9.55

12.82

16.94

22.04

28.30

35.89

0.0003

0.004

0.02

0.05

0.12

0.23

0.40

0.65

1.00

1.49

2.17

3.09

4.31

5.90

7.94

10.52

13.74

17.73

22.61

28.51

0.0002

0.003

0.01

0.04

0.10

0.21

0.39

0.65

1.00

1.47

2.09

2.89

3.91

5.21

6.83

8.85

11.34

14.38

18.06

22.50

0.0002

0.003

0.01

0.03

0.09

0.19

0.36

0.62

1.00

1.54

2.18

3.03

4.09

5.39

6.97

8.88

11.18

13.93

17.20

21.08

0.0002

0.002

0.01

0.03

0.08

0.18

0.34

0.61

1.00

1.55

2.30

3.27

4.48

5.98

7.79

9.95

12.51

15.50

18.98

23.04

d. Tandem axles Pt = 2.5

Axle load

Structural Number SN

kips

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

0.01

0.02

0.03

0.04

0.07

0.11

0.16

0.23

0.33

0.45

0.61

0.81

1.06

1.38

1.75

2.21

2.76

3.41

4.18

5.08

0.10

0.02

0.04

0.07

0.10

0.14

0.20

0.27

0.37

0.49

0.65

0.84

1.08

1.38

1.73

2.16

2.67

3.27

3.98

4.80

0.01

0.02

0.04

0.07

0.11

0.16

0.23

0.31

0.42

0.55

0.70

0.89

1.11

1.38

1.69

2.06

2.49

2.99

3.58

4.25

0.01

0.02

0.03

0.06

0.09

0.14

0.21

0.29

0.40

0.53

0.70

0.89

1.11

1.38

1.68

2.03

2.43

2.88

3.40

3.98

0.01

0.01

0.03

0.05

0.08

0.12

0.18

0.26

0.36

0.50

0.66

0.86

1.09

1.38

1.70

2.08

2.51

3.00

3.55

4.17

0.01

0.01

0.02

0.04

0.07

0.11

0.17

0.24

0.34

0.47

0.63

0.83

1.08

1.38

1.73

2.14

2.61

3.16

3.79

4.49

Table 6

Traffic Expression to Equivalent 18 Laps Single Axle Load

(Book Reference No. 1, Page 16-44)

6.2.4

Regional factor

This parameter R (= Regional Factor) is described climatic and environmental factors.

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

Page 15 of 24

Based on road test information R values should be :

6.2.5

Sub grade material frozen to a depth 5 inch (125) or more R = 0.2 to 1.0

Sub grade material, dry, summer and fall : R = 0.3 to 1.5

Sub grade material, wet, spring thaw R = 4.0 to 5.0

Structural number SN

This parameter SN (Structural Number) is indicate the structural strength of pavement required

to a given combination of soil support value, with total equivalent 18 Kips, single axle

load, terminal serviceability index, and regional factor. The required SN must be

converted to actual thickness of surfacing, base coarse, and sub base coarse with

each of appropriate layer coefficient.

SN

a

a

a

1

2

3

D1

D2

D3

a1 D1 a2 D2 a3 D3

= Layer coefficient for surfacing

= Layer coefficient for base coarse

= Layer coefficient for sub base coarse

= Actual thickness (Inch) of surface

= Actual thickness (Inch) of base coarse

= Actual thickness (Inch) of sub base coarse

On Table 7 various layers coefficient proposed by AASHTO test.

Coefficients proposed by AASHTO committee on design )

Pavement component

Coefficient

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

a1

a2

a3

*

Surface coarse

Road mix(low stability)

Plant mix(High stability)

Stand asphalt

Subbase coarse

Sandy gravel

Sand or sandy clay

Design Application

In accordance with 2 (two) types of serviceability index

PT = 2.0 and PT = 2.5

6.3.1

0.07

0.14

0.23

0.20

0.15

0.34

0.30

0.15 - 0.30

0.11

0.05 - 0.10

From Interim guide for design of pavement structures, American Association of State Highway and

Transportation Officials, 1972

Established from AASHTO road test

Compressive strength at 7 days

This value has been estimated from AASHTO road tests, but not to the accuracy of those factors

marked with

Table 7

Layers Coefficient a1, a2, a3

(Book Reference No. 1, Page 16-52)

6.3

0.20

0.44

0.40

Base coarse

- Sandy gravel

- Crushed stone

- Cement-treated (no soil cement)

Compressive strength @ 7 days

650 psi or more

400 psi to 650 psi

400 psi or less

- Bituminous-treated

Coarse-graded

Sand asphalt

Lime-treated

Page 16 of 24

Type of charts

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

DP-CED-32.6

CONCRETE ASPHALT ROAD

Page 17 of 24

Figure 4

Design Chart for Flexible Pavement, with pt = 2.0

(Interim Guide for Design of Pavement Structures.

American Assosiation of State Highway and Transportation Official)

(See Book Reference No. 1, Page 16-56)

Figure 5

Design Chart for Flexible Pavement with Terminal Serviceability

index pt = 2.5 (Interim Guide for Design of Pavement Structures

American Assosiation of State Highway and Transportation Official)

(See Book Reference No. 1, Page 16-53)

6.3.2

6.3.2.1

Parameters to determined

Index of serviceability Pt

In accordance to the requirements of concrete asphalt road in petrochemical

on industrial plant. The design in majority shall be concerned to the heavy

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

Page 18 of 24

loading truck or trailer to serve the maintenance, loading or unloading of

production. In other way, if the road is limited only to the plant vehicle its

mean the traffic volume will be lesser than if public vehicle is included. To

decide index of serviceability Pt = 2.0 is reasonable. Otherwise whenever the

public vehicle will accounted to enter the road wages plant, index of

serviceability will be using Pt = 2.5.

6.3.2.2

Soil support values S

Refer to the soil condition data, (See Article 3.2 and Article 6.2.3). The natural

soil in subgrade already determined and values of soil support values S is

taken.

6.3.2.3

Traffic volume and loads

For preliminary traffic volume and loads, the static axle loads of Article 3.4 is

our first estimate design capacity, before more reliable data according to the

Project Scope already formal released.

Vehicle Type

1.

2.

Plant transport

Light truck

service/ product

3. Single unit truck

product - load/

unload

4. Trailer - tractor

very heavy truck

12000

20000

Single

Single

Coeff. equiv.

18Kip

Single axis

load

0.19

1.56

32000

Tandem

40000

Tandem

Axle load (LBS)

Axle type

Traffic/days

Total X coeff

20 years

Total load X 103

400

100

76

156

554.8

1138.8

0.84

75

63

459.9

2.15

40

86

627.8

Total

650

381

2781.3

Table 9

Estimation of Traffic Volume and Loads

Condition :

6.3.3

Location petrochemical/Industrial plant, public vehicle not entered.

Index of serviceability Pt = 2.0

Regional factor R = 4.0

Support of soil subgrade, Silty sandy S = 5

Structural number SN = Estimate = 3

Surface asphalt concrete: coefficient 0.44

Base coarse/subbase coarse - crushed stone coefficient 0.14

Charts design

Using the Figure 6 (chart)

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

Step 1

Step 2

=

=

Step 3

Step 4

Step 5

Page 19 of 24

Enter values soil support S = 5 to graph No.1

Enter total coefficient = 381 to graph No.3 or total 20 years =

2,781.3 x 103 to Graph No. 2

Extent the straight line to touch graph No.4 we found S

=@

3.1 (our Estimate R = 3)

Refer to regional factor R = 4 (Graph 5) Extent Graph 4 and 5

and touched Graph 6 Weighed Structural Number SN = 3.7

Refer to Article 6.2.5

SN = a1 D1 + a2 D2 + a3 D3

By using Table 7

Layers coefficient

a1 = Plant mix

a2 = Crushed stone

a3 = Crushed stone

= 0.44

= 0.14

= 0.14

Trial (1) for reference minimum thickness see Article 6.1

D1 = Surface Wearing coarse 1

(=38)

Binder coarse

2

(=50)

Total 3

(=88)

D2 = Base coarse 6 = 150

D3 = Sub base coarse 10 = 250

Enter to equation

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

Page 20 of 24

SN = a1 D1 + a2 D2 + a3 D3

SN = 0.44 x 3 + 0.14 x 6 + 0.14 x 10

= 1.54

+ 0.84 + 1.40

= 3.78 > weighted structural number SN = 3.7 design of pavement is

OK

6.3.4

Design Summary

Location

Petrochemical/Industrial Plant, No Public Vehicle

Traffic volume :

Plant transport car

Light truck

Unit truck

Trailer, tractor, very heavy truck

Parameter used :

Index of serviceability

Regional factor

Support of soil subgrade silty sandy

1st estimate structural number

Surface asphalt concrete

Base/subbase coarse graded

crushed stone

Axle

- Single 12000 LBS

- Single 20000 LBS

- Tandem 32000 LBS

- Tandem 40000 LBS

Total

No/Days

400

100

75

40

615

Pt = 2.0

R=4

S=5

SN = 3

Coefficient 0.44

Coefficient 0.14

Design result: (start from subgrade)

1) Bed

Sub grade

2) 1st Layer

Sub base coarse

2nd Layer

base coarse

3rd Layer

surface coarse

treated well to compacted to 90 % of dry

density, CBR 4 or bigger

graded crushed stone max dia 2 (50),

CBR 20, thickness 10(=250)

graded crushed stone max dia 1 1/2(38)

CBR = 80

Thickness = 6 (=150)

lower lays-- Binder coarse 2 (=50) Thk

Upper layer-- wearing coarse 1 (38) Thk

Asphalt concrete surfacing 3 (=88) Thk

For detailed formation see Figure 2 (one of already executed design)

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

DP-CED-32.6

CONCRETE ASPHALT ROAD

Page 21 of 24

7. MATERIAL AS ASTM STANDARD TEST

7.1

Material for Sub Base Coarse and Base Coarse

Table 10

Grading Requirements for Bases and Sub Bases for Highways

and Airports to ASTM Designation D2940-74

(Reapproved 1985)

Grading: Percentage

passing

Sieve size

Bases

Sub - bases

50 mm

37.5 mm

19 mm

9.5 mm

4.75 mm

600 m

75 m

100

95 - 100

70 - 92

50 - 70

35 - 55

12 - 25

0-8

100

90 - 100

--------30 - 60

----0 - 12

Other Requirements :

1. Coarse aggregate to be hard and durable

2. Fraction passing the 75-m sieve not to exceed 60 per cent of the fraction

passing the 600-m sieve.

3. Fraction passing the 425-m sieve shall have a liquid limit no greater than

25 per cent and a plasticity index not greater than 4 per cent.

Figure 7

Materials for Unbound Sub-base and Base --- ASTM Designation D2940-74

(Book Reference No. 2, Page 207)

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

7.2

7.2.1

Page 22 of 24

Material for Surface Coarse as ASTM C 117 and ASTM C 136

Asphaltic concrete binder coarse base (lower layers)

Item

Aggregate and filler

Aggregate and filler

Aggregate and filler

Aggregate and filler

Aggregate and filler

Aggregate and filler

Aggregate and filler

Aggregate and filler

Passing

Percent

1-1/2 inch sieve

1 Inch sieve

1/2 Inch sieve

No.4 sieve

No. 10 sieve

No. 40 sieve

No. 80 sieve

No. 200 sieve

100

80 - 100

60 - 80

40 - 55

30 - 45

15 - 30

8 - 20

2 - 8

Asphalt amount : 4.5 to 6.5% of aggregate weight

Asphalt penetration

: 60 to 100 (1/10 mm)

7.2.2

Asphaltic concrete wearing coarse (upper layer)

Item

Passing

Percent

Aggregate and filler

Aggregate and filler

Aggregate and filler

Aggregate and filler

Aggregate and filler

Aggregate and filler

Aggregate and filler

1/2 inch sieve

3/8 inch sieve

No. 4 sieve

No. 10 sieve

No. 40 sieve

No. 80 sieve

No 200 sieve

100

80 - 100

55 - 75

40 - 55

18 - 33

10 - 22

1 - 10

Asphalt amount

Asphalt penetration

: 5.0 to 7.0% of aggregate weight

: 80 to 120 (1/10 mm)

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

DP-CED-32.6

7.3

CONCRETE ASPHALT ROAD

Page 23 of 24

Blank Charts for Design Purpose

Chart 1

Design Chart for Flexible Pavement with Pt = 2.0

(Interim Guide for Design of Pavement Structures.

American Assosiation of State Highway and Transportation Official)

(See Book Reference No. 1, Page 16-56)

Chart 2

Design Chart for Flexible Pavement with Terminal Serviceability Index Pt = 2.5

(Interim Guide for Design of Pavement Structures.

American Assosiation of State Highway and Transportation Official)

(See Book Reference No. 1, Page 16-53)

PT. INTI KARYA PERSADA TEHNIK

CIVIL ENGINEERING DEPARTMENT

DESIGN PRACTICE

CONCRETE ASPHALT ROAD

DP-CED-32.6

8.

Page 24 of 24

REFERENCE

BOOK REFERENCES

1)Standard Handbook For Civil Engineer

By Frederick S. Merrit; Third Edition 1983

2)The Design and Performance of Road pavements

By Daved Croneu and Paul Croneu, Second Edition

Mc. Graw Hill International series in Civil Engineering

STANDARD REFERENCES

1)AASHTO

American Association of State Highway and Transportation Officials

2)ASTM American Society for Testing and Materials

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Perhitungan Analysis Angkur Bolt-ExcelDocument26 pagesPerhitungan Analysis Angkur Bolt-ExcelbonnicoPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- 0031R 50 D PR 004 Hydrotest Pre Commissioning Procedure Rev. 0Document45 pages0031R 50 D PR 004 Hydrotest Pre Commissioning Procedure Rev. 0bonnico100% (1)

- Piling RequirementsDocument80 pagesPiling Requirementsthusi67% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- 16 Juli 201616 Juli 2016 Tak Berkategori Tinggalkan KomentarDocument10 pages16 Juli 201616 Juli 2016 Tak Berkategori Tinggalkan KomentarbonnicoPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Pile Cap Design - ColumnsDocument6 pagesPile Cap Design - Columnsntah8450% (2)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- 16 Juli 201616 Juli 2016 Tak Berkategori Tinggalkan KomentarDocument10 pages16 Juli 201616 Juli 2016 Tak Berkategori Tinggalkan KomentarbonnicoPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Perhitungan Struktur TangkiDocument12 pagesPerhitungan Struktur TangkiNelson Panjaitan100% (1)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Perhitungan Dinding PenahanDocument22 pagesPerhitungan Dinding PenahanbonnicoPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- 7.4 Tower Design: Bracing SystemsDocument49 pages7.4 Tower Design: Bracing SystemsBoisterous_Girl100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design CalculationsMohammed EljammalPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Horizontal BraceDocument11 pagesHorizontal BracebonnicoPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Concrete Weight CoatingDocument50 pagesConcrete Weight Coatingbonnico75% (4)

- V C I W: Seismic Load CalculationDocument8 pagesV C I W: Seismic Load CalculationbonnicoPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- 0032 50 S CA 002 A4 E Attach 2 Box ValveDocument14 pages0032 50 S CA 002 A4 E Attach 2 Box ValvebonnicoPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- C 84524 PS KK1 CAL ST 3K 0020 - R1 Pipeline Buoyancy Control AnalysisDocument7 pagesC 84524 PS KK1 CAL ST 3K 0020 - R1 Pipeline Buoyancy Control AnalysisbonnicoPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- BridgeT BeamDocument23 pagesBridgeT BeamMochammad Syafi UddinPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Perhitungan Pipe Culvert #1-#2rev1-For Issued - Staad - WingDocument108 pagesPerhitungan Pipe Culvert #1-#2rev1-For Issued - Staad - Wingbonnico0% (1)

- Pipeline Buoyancy Analysis 6 inDocument8 pagesPipeline Buoyancy Analysis 6 inbonnicoPas encore d'évaluation

- Manual Concrete For Administration BuildDocument42 pagesManual Concrete For Administration BuildbonnicoPas encore d'évaluation

- Pile Foundation Concrete Column DesignDocument27 pagesPile Foundation Concrete Column DesignSaid FauziePas encore d'évaluation

- Calculation Chemical Storage (Steel)Document38 pagesCalculation Chemical Storage (Steel)bonnicoPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Calculation CCR (RC)Document123 pagesCalculation CCR (RC)bonnicoPas encore d'évaluation

- C Pipe SupportDocument25 pagesC Pipe Supportsanjay421100% (2)

- Calculation For Control Building Structure Foundation Rev CDocument69 pagesCalculation For Control Building Structure Foundation Rev CbonnicoPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Pipeline Buoyancy Analysis R1 6 inDocument4 pagesPipeline Buoyancy Analysis R1 6 inbonnicoPas encore d'évaluation

- Load Cases and CombinationDocument22 pagesLoad Cases and CombinationbonnicoPas encore d'évaluation

- C Pipe SupportDocument25 pagesC Pipe Supportsanjay421100% (2)

- Pipe Stress Analysis ReportsDocument11 pagesPipe Stress Analysis ReportsTony100% (13)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Stress Analysis ConceptsDocument41 pagesStress Analysis Conceptsvermaakash22Pas encore d'évaluation

- 05 SSPL SPC U 0001 - 0Document99 pages05 SSPL SPC U 0001 - 0bonnicoPas encore d'évaluation

- Netapp Cabling and Hardware BasicsDocument14 pagesNetapp Cabling and Hardware BasicsAnup AbhishekPas encore d'évaluation

- Drag of Conical Nose at Supersonic Speeds (Arthur Saw, EURECA 2013)Document2 pagesDrag of Conical Nose at Supersonic Speeds (Arthur Saw, EURECA 2013)Arthur Saw Sher-QenPas encore d'évaluation

- Abid Ali SAP Resume (Experience)Document3 pagesAbid Ali SAP Resume (Experience)Abid AliPas encore d'évaluation

- CT v2.0 UnderstandingDocument36 pagesCT v2.0 UnderstandingAbel Chaiña GonzalesPas encore d'évaluation

- Joraform JK Series Operating PrinciplesDocument6 pagesJoraform JK Series Operating Principlesapi-236782993Pas encore d'évaluation

- Torre Sauter 0 - 5 - 320 - 025 - 4 PDFDocument27 pagesTorre Sauter 0 - 5 - 320 - 025 - 4 PDFGuiPas encore d'évaluation

- Denmark Bye LawsDocument10 pagesDenmark Bye LawshimaniwatalPas encore d'évaluation

- Understanding IBR 1950Document7 pagesUnderstanding IBR 1950sammar_10Pas encore d'évaluation

- Aircraft Construction, Repair & Modification Mock Board Exam 10Document5 pagesAircraft Construction, Repair & Modification Mock Board Exam 10July TadePas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- I J E C B S Issn (O) : 2230-8849: Cloud Computing: An AnalysisDocument15 pagesI J E C B S Issn (O) : 2230-8849: Cloud Computing: An AnalysisnoddynoddyPas encore d'évaluation

- Random PDFDocument15 pagesRandom PDFgreeblemeeblePas encore d'évaluation

- HARMAN Infinity Processing White PaperDocument2 pagesHARMAN Infinity Processing White PaperSound Technology LtdPas encore d'évaluation

- Pacom S72724+PDR32-RMT-HYB+ManualDocument130 pagesPacom S72724+PDR32-RMT-HYB+ManualDavidChisholmPas encore d'évaluation

- Concrete Solutions-ProgramDocument18 pagesConcrete Solutions-ProgramEfthymios TatsisPas encore d'évaluation

- HP4Document88 pagesHP4Alexander Neyra100% (4)

- Argus Dual System Pi enDocument2 pagesArgus Dual System Pi enfahmi1987Pas encore d'évaluation

- Analysis and Design of MOSFET Based Amplifier in Different ConfigurationsDocument8 pagesAnalysis and Design of MOSFET Based Amplifier in Different ConfigurationsPraveen KumarPas encore d'évaluation

- FC-M6100 SM-BB52: DEORE CranksetDocument1 pageFC-M6100 SM-BB52: DEORE CranksetDon JonesPas encore d'évaluation

- Pdca Cycle Problem SolvedDocument3 pagesPdca Cycle Problem Solvedjose luisPas encore d'évaluation

- PayrollBatchLoader v4Document158 pagesPayrollBatchLoader v4MaheshPas encore d'évaluation

- 82 To 88 CompleteDocument6 pages82 To 88 CompleteUmer KhanPas encore d'évaluation

- Am 3517Document221 pagesAm 3517mudit9_mPas encore d'évaluation

- Kubota Dual Fuel Series SpecificationDocument10 pagesKubota Dual Fuel Series Specificationפטריה מוזרPas encore d'évaluation

- Integrated Cost and Risk Analysis Using Monte Carlo Simulation of A CPM ModelDocument4 pagesIntegrated Cost and Risk Analysis Using Monte Carlo Simulation of A CPM ModelPavlos Vardoulakis0% (1)

- Finals DSP WithMinimalErrors PDFDocument64 pagesFinals DSP WithMinimalErrors PDFanembam putobungbongPas encore d'évaluation

- Grasshopper Optimization Algorithm Based Design of StructuresDocument1 pageGrasshopper Optimization Algorithm Based Design of Structuresinvisible25Pas encore d'évaluation

- Resume AkuDocument4 pagesResume AkukeylastPas encore d'évaluation

- Company ProfileDocument6 pagesCompany ProfileFaidzil ChabibPas encore d'évaluation

- Work, Kinetic Energy and Potential EnergyDocument28 pagesWork, Kinetic Energy and Potential EnergyMaey AkimPas encore d'évaluation

- Notificatio N (Rese Rvation) Gove Rnment: A Cu) UTDocument1 pageNotificatio N (Rese Rvation) Gove Rnment: A Cu) UT122-Ayush Kumar ParganihaPas encore d'évaluation