Académique Documents

Professionnel Documents

Culture Documents

JSA - Crane Setup

Transféré par

Abdullah GhannamCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

JSA - Crane Setup

Transféré par

Abdullah GhannamDroits d'auteur :

Formats disponibles

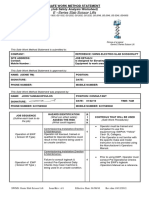

JOB H AZARD ANALYSIS

PFEIFFER Cranes

CONTACT:

Pty Ltd

PFEIFFER CRANES

JOB DESCRIPTION:

SETTING/PACKING UP CRANE ONSITE

Contacts:

Delcie Pfeiffer

Fred Pfeiffer

Daniel Pfeiffer

Craig Pfeiffer

Jack Pfeiffer

Trinity Pfeiffer

Page 1 of 12

Director

Director

Crane Operator

Crane Operator

Engineer

OHS

0427 936 300

0417 057 659

0407 877 340

0407 877 334

0417 362 783

0417 545 813

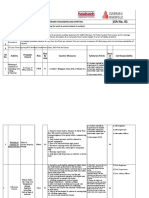

Job Hazard Analysis Study

1. ISSUES/HAZARDS & RECOMMENDATIONS FOR CRANE SETUP

The JHA study minutes are presented in the following pages. The table presents the task step, identified issue or hazard, initial risk, controls

(where necessary), residual risk, to be actioned by, and completion sign off.

Residual

Completion

Task Step

Identified Issue/Hazard

Risk

Controls

Action By

Risk

Sign Off

C,H,M,L

(consider hierarchy of controls)

CHML

Pfeiffer Cranes Pty Ltd

For each hazard or risk, define the control measures that will be

implemented to prevent injury, exposure, incident, damage etc.

Re-assess the risk

(controls in place).

For each step, define the safety hazards,

risks and concerns- by answering the what

if questions about inherent process

hazards.

Level of risk

Break down the task into its

normal sequence of basic

steps. Describe what is done,

not the details of how it is

done.

Assign an

accountable

person for

implementing the

control

Accountable person

to sign to indicate

control is in place.

Job Hazard Analysis Study

Task Step

Identified Issue/Hazard

Risk

Controls

(consider hierarchy of controls)

C,H,M,L

Residual

Risk

Action By

Completion

Sign Off

CHML

1. Mobile Crane to

onsite destination

2. Pre-job meeting

and Toolbox

Faults with Crane

Plant becoming bogged in

sand & mud

Pedestrians

Onsite Traffic/plant

Inexperienced workers

3. Locate crane into

lifting positions on

site

Pfeiffer Cranes Pty Ltd

Pre-start Checks

Plant to stick to designated roadways and turning areas

Personnel on hand to warn others of crane movement in

the vicinity or via radio where available.

Alternate pathway defined by bollards and reflective tape.

Sufficiently skilled employees to complete task

(competencies and Licences)

Inadequate understanding of

equipment

Adequate consultation with all relevant employees

Adequate competent supervision throughout the project

Site hazards and emergency

procedures not known

Proper planning for equipment required for the task

Site & work area inductions compulsory for all personnel

Desired setup area should also be level, unless prior

consultation has been made with the supplier of the crane

Inadequate consultation

Pedestrians

PFEIFFER

CRANES

EMPLOYEE

PFEIFFER

CRANES

EMPLOYYE AND

ONSITE MANAGER

PFEIFFER

CRANES

EMPLOYEE

Job Hazard Analysis Study

Pfeiffer Cranes Pty Ltd

Job Hazard Analysis Study

4. Inspect chains and

or slings, shackles,

hooks and

attachment points in

preparation for use

Pfeiffer Cranes Pty Ltd

The workplace is adequately prepared for the incoming

mobile crane, including where possible a clear predefined

area/crane pad for the crane to position upon

Check and confirm exclusion areas - Barricades, witches

Hats, Danger Tape, Warning Signs

Buildings

Powerlines & underground

Utilities

Access road are available and soundly constructed with

suitable entry points to site

Crew should always inspect site prior to positioning crane

in final position;

Access

Elements to observe include

Ground Conditions

Load location and scope of lift

Location of any overhead obstructions including wires,

trees, buildings, restricted airspace (i.e. near airport)

Location of any underground services and/or trenches

including utilities and drainage arrangements that may

affect integrity of ground

Adequate room for rigging and erection of mobile crane

(i.e. support trucks, fly jibs)

Adequate tail (counterweight/winch) swing clearance

Ability to cordon off area with suitable barricading

resources

Check slings for rips and tears and remove from service is

faults are found

Check chains, shackles, hooks and rings for cracks,

corrosion, wears, mechanism faults etc and remove from

service if faults are found

Lifting gear/equipment inspected and tagged with

appropriate monthly colour tag

Make certain personnel are sufficiently trained with

appropriate certificates/ licences.

Pedestrians

Lift radius

Traffic

Other Plant

Other Equipment

Tears in Slings

Dropping of load due to faulty

lifting gear or faulty

attachment points

Cracks in chains, shackles,

rings and hooks

PFEIFFER

CRANES

EMPLOYEE

PFEIFFER

CRANES

EMPLOYEE

Job Hazard Analysis Study

5. Locate crane in

lifting position on site

place timbers

(pads) and set

outriggers

Crane overturning due to

unstable ground conditions

Personnel being crushed by

outriggers

Outriggers must be positioned on a flat surface, using

timbers or suitable material for pads to evenly distribute the

load to the ground

Crane to be located within the radius for the loads being

lifted.

Outriggers should only be extended on the side where the

operator is positioned or with a suitable spotter.

Where space permits, outriggers shall always be fully

extended

Where space is limited, crane should be configured to

maximum capacity this may require the use of reduced

outriggers or on rubber; when permitted by the

manufacturer

Outriggers shall always be extended to manufacturers

procedures and specifications, including the requirement to

fit manual pins

All outriggers-jacks should be utilized at all time (i.e. Front

jack)

Generally Standard Safe Working Load capacity charts are

based on all outriggers fully extended and set with wheels

clear of ground.

PFEIFFER

CRANES

EMPLOYEE

Outrigger Packing

Pfeiffer Cranes Pty Ltd

Additional packing should always be utilized under

outrigger floats (exceptions may include engineered setups

where other means of distributing loads are adopted)

Commonly used (steel fabricated or otherwise) Outrigger

Mats should carry design information and be subject to

periodic inspection

When timber packing is utilized, it should be in a pigstypacking arrangement

Job Hazard Analysis Study

Rule of Thumb formulae and calculations should be

observed;

Area (m2) = 0.65 x (Cm + L)

------------V

Cm = Total mass of crane (KN)

6.Attaching Fly or Pin

Jib to Crane

7. Running wire

through Sheeves

8. Position

counterweight truck

in an easily

accessible spot for

the crane to load its

counterweights

Pfeiffer Cranes Pty Ltd

Working at heights/falling

Pinch points/cut or jammed

hands

General Plant striking other

plant, equipment, personnel,

materials etc

Dropping counterweights

Falls from height whilst

positioning and loading

counterweights

= Total mass of load (KN)

= maximum permissible bearing pressure of soil (kpa)

Follow W/H permit use appropriate attachment point &

safety harness when walking along crane boom

Use an EWP or ladder for this task & follow safe work

practices

Wear correct PPE

Plant to be positioned in area clear of obstruction. roads

Traffic control in place if required

Once crane is elevated and level, a trial operation should

be completed by the operator; this may include

Luffing boom to high angle, and slewing 360 degrees with

spotter in position purpose to review tail swing and

outrigger packing suitability

Executing dry-run where load is required to be picked up

and placed Purpose to ensure crane is capable of task

and set required limits

PFEIFFER

CRANES

EMPLOYEE

PFEIFFER

CRANES

EMPLOYEE

Job Hazard Analysis Study

9. Re-assessing

Situation throughout

job

10.Packing up and/or

leaving crane onsite

Pfeiffer Cranes Pty Ltd

Changes in weather

conditions

Continual safe operation can be aided by periodic

inspection throughout the project of the following;

Changes in operators

Outrigger Jacks Leaking oil/retraction of shaft

Changes in ground suitability

Outrigger Mats excessive settlement and/or sinking into

ground; i.e., loadings increasing beyond estimated capacity

of ground such as unknown back-filling

Outrigger Floats Cracking or critical damage

Evidence of water content in ground i.e. Potential

ruptured pipeline

Should requirements change during operation, then crew

shall re-assess and review crane capacity and wider

environment to ensure revised work practice is within limits

and safe to continue operation

Upon completion of project, or specific stage the crane

equipment and site shall be left in a secure and safe

manner

If the crane is to be left onsite;

Retract Boom, remove keys from the ignition and

secure/lock

Outriggers should be inspected prior to next use

Barricading should remain in place around the crane and

any work area deemed necessary

Unauthorised person access

crane site

Damage to crane

Injury to public

PFEIFFER

CRANES

EMPLOYEE

PFEIFFER

CRANES

EMPLOYEE

Job Hazard Analysis Study

11.Packing up and

cleaning up work site

12. Exit site and return

to Depot

Pfeiffer Cranes Pty Ltd

Trip hazards

Manual handling injuries

Crush & Pinch injuries

Equipment damage

Counterweights coming off

the back of the truck

Crush & pinch injuries

Falls

Overhead Powerlines

Collision with

people/personnel and other

vehicles/plant when exiting

site

Counterweights sliding off

during travel

Traffic Accidents

Use correct manual handling techniques

Wear appropriate PPE

Rubbish to be placed in bins

Tools & Equipment to be packed

Lifting gear packed

Timbers packed

Pads loaded

Make certain counterweights are stacked on rubber mats

and correctly tied down for trip

Guide counterweights onto the truck tray with taglines

Where possible use EWP or Platform Ladder Access

otherwise be cautious of footing

Crane boom to be down when traveling under power lines

Maintain site speed limit when exiting work site

Communicate with other vehicles onsite is necessary

Observe road rules and take into consideration drivers and

riders who dont understand the nature of cranes and

trucks.

PFEIFFER CRANES

EMPLOYEE

PFEIFFER CRANES

EMPLOYEE

PFEIFFER CRANES

EMPLOYEE

Job Hazard Analysis Study

2. SIGN ON SHEET

Participant Acknowledgement: I, the undersigned, have read and understand the hazards and recommendations and agree to conform with the controls that have been implemented as identified

in this JHA.

NAME: (please print)

Pfeiffer Cranes Pty Ltd

Signature

Company

Date

10

Job Hazard Analysis Study

PLEASE SEND A COPY TO FAX NUMBER OR EMAIL ADDRESS:_________________________________________________________________________

Pfeiffer Cranes Pty Ltd

11

Job Hazard Analysis Study

11. RISK ASSESSMENT MATRIX

A

Critical

Critical

Critical

Critical

High

Critical

Critical

Critical

High

High

Critical

High

High

Medium

Medium

High

High

Medium

Low

Low

High

Medium

Low

Low

Low

or Step 1 - Plant, Property, Process / Environmental Consequences

Step 1 - People Consequences

5 = More than $500K Damage or production disruption. . Catastrophic environmental impact.

5=

Fatality or Permanent Disability

4 = $100K - $500K Damage and/or production. Major environmental impact.

4=

Lost Time Injury or Illness

3 = $50K - $100K Damage and/or production disruption. Major environmental impact.

3=

Restricted Duties Injury

2 = $5K - $50K Damage and/or slight production disruption. Temporary environmental damage.

2=

Medical Treatment Injury

1 = Under $5k Damage and minimal productivity disruption. Minor environmental damage.

1=

First Aid Injury

Step 2 Determine Probability

Step 3 Calculate Risk

A=

Common or frequent occurrence (daily)

B=

Is known to occur or it has happened (weekly)

Once determining the probability and consequence, the risk level can be determined by using the matrix above. The

categories within the matrix are categorised according to the level of risk as follows;

C=

Could occur or Ive heard of it happening

D=

Not likely to occur (yearly)

E=

Practically impossible (ten yearly)

Pfeiffer Cranes Pty Ltd

(monthly)

Critical

Consider discontinuing operation

High

Immediate correction required

Medium

Correction needed

Low

Risk is perhaps acceptable as is

12

Vous aimerez peut-être aussi

- Safe Work Permit Rev. 06: BASF Corporation Title: Beaumont Site Function: Health & Safety Procedure No.: Page: 1 ofDocument22 pagesSafe Work Permit Rev. 06: BASF Corporation Title: Beaumont Site Function: Health & Safety Procedure No.: Page: 1 ofIvan BaracPas encore d'évaluation

- Mobile Elevated Work Platforms (MEWP) Program: Provo, UtahDocument14 pagesMobile Elevated Work Platforms (MEWP) Program: Provo, UtahStephanie ScottPas encore d'évaluation

- Fall Protection Survey of RIG 40Document3 pagesFall Protection Survey of RIG 40Kevin Josh Bonales100% (1)

- JHA Jack Hydraulic PalletDocument1 pageJHA Jack Hydraulic PalletIndranil Mitra100% (1)

- Confined Space Entry Program 11 2021Document16 pagesConfined Space Entry Program 11 2021zaka ullahPas encore d'évaluation

- Akk Jha Installation of Diesel TankDocument3 pagesAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- OHS PROC 113 BarricadesDocument9 pagesOHS PROC 113 BarricadesPhillip L100% (1)

- Suspended From Man-Rider (Vertical Rescue Plan)Document1 pageSuspended From Man-Rider (Vertical Rescue Plan)Paul100% (1)

- Dismantling of Concrete Pump TowerDocument1 pageDismantling of Concrete Pump TowerChandruPas encore d'évaluation

- Job Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureDocument2 pagesJob Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureM Waqas HabibPas encore d'évaluation

- 2.1 - Machine GuardingDocument6 pages2.1 - Machine Guardingkumar100% (1)

- 10 Questions For Line of FireDocument2 pages10 Questions For Line of FireGary Moses100% (1)

- Jsa No-01 Container UnloadingDocument4 pagesJsa No-01 Container Unloadingsumith s100% (1)

- Job Safety Analysis: S.No Activities Hazard Risk Control MeasuresDocument2 pagesJob Safety Analysis: S.No Activities Hazard Risk Control Measureskhaja asifuddinPas encore d'évaluation

- Schedule For Inspection Nov 19Document1 pageSchedule For Inspection Nov 19Siddharth RanaPas encore d'évaluation

- Genie E Series Slab Scissor Lift Operation PDFDocument11 pagesGenie E Series Slab Scissor Lift Operation PDFRajesh gpPas encore d'évaluation

- Jsa Fan Coil Unites MaintenanceDocument5 pagesJsa Fan Coil Unites MaintenanceASLAM MULANIPas encore d'évaluation

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Document5 pagesCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaPas encore d'évaluation

- Basic Safety Instructions For All Employees Visiting or Working in The Construction of The HgpepDocument42 pagesBasic Safety Instructions For All Employees Visiting or Working in The Construction of The Hgpepmalik jahanPas encore d'évaluation

- Fan InstallationDocument2 pagesFan InstallationKrishna PatilPas encore d'évaluation

- CamScanner 03-22-2023 07.44Document2 pagesCamScanner 03-22-2023 07.44Umar AliPas encore d'évaluation

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument11 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh kumar yadav100% (1)

- JSA CT Cement (Example)Document2 pagesJSA CT Cement (Example)aneshsePas encore d'évaluation

- Loading & Lifting ProcedureDocument5 pagesLoading & Lifting Procedurekhurram shahzadPas encore d'évaluation

- JSA For Pressure Test 2ND REVISIONDocument10 pagesJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- Safe excavation works plan for Cherrywood Project Phase 1Document46 pagesSafe excavation works plan for Cherrywood Project Phase 1Sajid ShahPas encore d'évaluation

- Confined Space SlideDocument65 pagesConfined Space SlideSyahrul AnisPas encore d'évaluation

- SWP 5 Excavations Shoring and Trenches PDFDocument4 pagesSWP 5 Excavations Shoring and Trenches PDFThanesh ManogaranPas encore d'évaluation

- Hip & Jsa For Abqq-472Document13 pagesHip & Jsa For Abqq-472javithPas encore d'évaluation

- Ramapo College Vehicle Fueling SOPDocument1 pageRamapo College Vehicle Fueling SOPAnees EkPas encore d'évaluation

- Guidelines Flagmen - Banksmen (English)Document1 pageGuidelines Flagmen - Banksmen (English)Pirlo PoloPas encore d'évaluation

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 pagesPTW JHA Prayer Garment Hanging Rack InstallationPHH9834Pas encore d'évaluation

- Lockout/Tagout Refresher Training SummaryDocument25 pagesLockout/Tagout Refresher Training SummaryuaarPas encore d'évaluation

- Shailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentDocument21 pagesShailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentNandini RajPas encore d'évaluation

- Rigging Safety TipsDocument2 pagesRigging Safety Tipspruncu.alianmPas encore d'évaluation

- Jsa Bearing Replacement-OverhaulingDocument2 pagesJsa Bearing Replacement-Overhaulingashish engineeringPas encore d'évaluation

- Working at Height Rescue Plan: WHS-FM-008Document2 pagesWorking at Height Rescue Plan: WHS-FM-008Purwo PrihartonoPas encore d'évaluation

- Asian Paints - Prem Gloss EnamelDocument1 pageAsian Paints - Prem Gloss EnamelwilliumstPas encore d'évaluation

- Jha Crane OperationsDocument2 pagesJha Crane OperationsJaycee Bareng Pagador100% (1)

- Lifting Hoisting Hazard HuntDocument1 pageLifting Hoisting Hazard Hunt曹庆园100% (1)

- JSA - LOAD TEST PILE No. 1Document6 pagesJSA - LOAD TEST PILE No. 1Sanjeet SinghPas encore d'évaluation

- Suspended Loads Safety Tips (39Document3 pagesSuspended Loads Safety Tips (39my_agautamPas encore d'évaluation

- JSA-03 Shed DismantlingDocument3 pagesJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- Blinding and De-blinding Safety EssentialsDocument42 pagesBlinding and De-blinding Safety EssentialsMayur NaikPas encore d'évaluation

- Topic For TBMDocument19 pagesTopic For TBMdauxomPas encore d'évaluation

- JHA For Installation 2 Inch Nozzle..Document6 pagesJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- NASDA WIND POWER SUB-STATION EXCAVATION SAFETYDocument2 pagesNASDA WIND POWER SUB-STATION EXCAVATION SAFETYRaza Muhammad SoomroPas encore d'évaluation

- MSDS - Asada Threading Oiil Red - ENDocument7 pagesMSDS - Asada Threading Oiil Red - ENnghiaPas encore d'évaluation

- Breaker Machine Safety ChecklistDocument1 pageBreaker Machine Safety ChecklistNair R RakeshPas encore d'évaluation

- All JSAsDocument88 pagesAll JSAsQamar KhanPas encore d'évaluation

- Instructions For Using The Risk Assessment FormDocument9 pagesInstructions For Using The Risk Assessment FormMalik Khuram ShazadPas encore d'évaluation

- Fire Water TankDocument1 pageFire Water TankAnonymous yCpjZF1rFPas encore d'évaluation

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferPas encore d'évaluation

- Building De-Dusting JSADocument3 pagesBuilding De-Dusting JSAJayesh J PillaiPas encore d'évaluation

- A002 C NightclubDocument6 pagesA002 C NightclubBlas de LezoPas encore d'évaluation

- Work at Height Safety AnalysisDocument2 pagesWork at Height Safety AnalysiszebmechPas encore d'évaluation

- Bulldozer SOP FinalDocument10 pagesBulldozer SOP Finaljean claude BledouPas encore d'évaluation