Académique Documents

Professionnel Documents

Culture Documents

EM P 08 IOT Energy Systems Analysis Slides

Transféré par

Tiago HenriquesCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

EM P 08 IOT Energy Systems Analysis Slides

Transféré par

Tiago HenriquesDroits d'auteur :

Formats disponibles

Energy Management :: 2008/2009

Class # 8P

Process IOT - Energy Systems Modeling

Joo Parente

joao.parente@dem.ist.utl.pt

Energy Management

Energy Systems Analysis using IOT (standard formulation)

The specific consumption of each sub-product can be determined by:

c4 = cST + SST c3 c4 = cST + SST(fST_1 c1 + fST_2 c2 + fST_3 c3 + fST_4 c4 );

c3 = cSE + SSE c2 c3 = cSE + SSE(fSE_1 c1 + fSE_2 c2 + fSE_3 c3 + fSE_4 c4 );

c2 = cOV + SOV c1 c2 = cOV + SOV(fOV_1 c1 + fOV_2 c2 + fOV_3 c3 + fOV_4 c4 );

c1 = cRM + 0

c1 = cRM + SRM(fRM_1 c1 + fRM_2 c2 + fRM_3 c3 + fRM_4 c4 );

The dimension of [k] is mxm!!!!

Class # 8P :: Process IOT - Energy Systems Modeling

Slide 2 of 53

Energy Management

Energy Systems Analysis using IOT (standard formulation)

In the specific case of our example:

Losses

RM

(1)

OVen

(2)

SElection

Losses

(3)

(4) Final Product

STorage

Boundary

Without recycling, every position in the matrix

diagonal and bellow is equal to 0 no backflow!

Class # 8P :: Process IOT - Energy Systems Modeling

Slide 3 of 53

Energy Management

PIO - Basic concepts

Process / Activities

(square matrix)

Product Availability

Activity

Matrix

=

Activity Level

Products

Activity matrix: Defines the amounts of products/energy consumed or produced per unit of

final product in each process. An input to the process (process consumption) is defined as a

negative quantity, while the output is defined as a positive quantity (process production).

Activity level: Defines the production of each process, i. e., the total amount of final product

produced in that process.

Product availability: Defines the amount of final products available at the end of the whole

production process.

Class # 8P :: Process IOT - Energy Systems Modeling

Slide 4 of 53

Energy Management

PIO - Basic concepts

EXAMPLE: Simple energy system with 3 process and 3 products

By definition:

A14 = A24 = A34 = 0 (no product consumption in the energy process)*, and

A11 = A22 = A33 = A44 = 1 (if the final products of process A, B, and C are 1, 2, and 3),

Outputs are positive and inputs negative (in the activity matrix).

* In some particular cases this condition might not be true!!!

Class # 8P :: Process IOT - Energy Systems Modeling

Slide 5 of 53

Energy Management

PIO Mathematical formulation

EXAMPLE: Simple energy system with 3 process and 3 products

So, to determine the activity level required at each process to fulfill a specific final production:

[A]-1 [a] = [T]

If we wish to determine the activity level required to produce one unit of product 3:

[a] = [ 0 0 1 0]T

Class # 8P :: Process IOT - Energy Systems Modeling

Slide 6 of 53

Energy Management

IOT

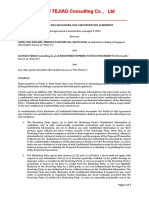

PROBLEM 01

Consider the first company from last class, which produces aluminum profiles. The production process had the

following sequence:

9

REcycling

CE4=CEP +SPCE3+SPTCE7

Extrusion

5

2

8

Reheat

CE2=CEE+SE(f1CE1+f9CE9)

CE9=CERE

CE1=2 * CERE

6

3

Painting

CE7=CET

CE3=CER+SRCE2

Treatment

7

4

In these conditions, indicate how you could determine the specific consumption of the painted profile, using the

input-output model (standard formulation) applied to processes. Clearly present the coefficients of the k matrix.

Class # 8P :: Process IOT - Energy Systems Modeling

Slide 7 of 53

Energy Management

CPROD

CPROC

[K]

CPROD

RM

RM

RE'5

RE'5

RE'6

RE'6

RE'8

RE'8

RE

RE

Class # 8P :: Process IOT - Energy Systems Modeling

Slide 8 of 53

Energy Management

CPROD

CPROC

[K]

CPROD

RM

RM

RE'5

RE'5

RE'6

RE'6

RE'8

RE'8

RE

RE

CPROD

CPROC

[K]

CPROD

RM

RM

f1ESE

f9ESE

f2RSR

f3PSP

ft7PStPT

RE'5

RE'5

RE'6

RE'6

RE'8

RE'8

RE

RE

f5RESRE

f6RESRE

f7RESRE

Class # 8P :: Process IOT - Energy Systems Modeling

Slide 9 of 53

Energy Management

IOT

PROBLEM 02

Consider the second company from last class, which produces steel bottles to store gasses. The production

process had the following sequence:

RM

CE8=CEPT+SPTCE7+SPT_TCEt9

CE7=CEF+SFCE6

DC

CUT

CE6=CEEW+SEW(f5CE5+f3CE3+f11CE11)

CE5=CERW+SRWCE4

RW

CUP

3

CE4=CECUT+SCUTCE1

5

11

EW

CE3=CECUP+SCUPCE2

CE2=CEDC+SDCCE1

6

10

CEt9=CEtT

PT

Final product

CE11=CER=0

CE10=0

In these conditions, indicate how you could determine the specific consumption of the painted profile, using the

input-output model (standard formulation) applied to processes. Clearly present the coefficients of the k matrix.

Class # 8P :: Process IOT - Energy Systems Modeling

Slide 10 of 53

Energy Management

CPROD = CPROC +

[K]

10

11

* CPROD

RM

DC

CUP

CUT

RW

EW

F

PT

T

R'

R

Class # 8P :: Process IOT - Energy Systems Modeling

Slide 11 of 53

Energy Management

CPROD = CPROC +

10

11

* CPROD

[K]

RM

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

0

10

0

11

0

* CPROD

DC

f1DCSDC

CUP

f2CUPSCUP

CUT

f1CUTSCUT

RW

f4RWSRW

EW

f3EWSEW

f5EWSEW

f11EWSEW

f6FSF

PT

f7PTSPT

ft9PTStPT

R'

f10RSR

[K]

RM

DC

CUP

CUT

RW

EW

F

PT

T

R'

R

CPROD = CPROC +

Class # 8P :: Process IOT - Energy Systems Modeling

Slide 12 of 53

Energy Management

IOT

PROBLEM 03

Consider the first company from last class, which produces aluminum profiles. The production process had the

following sequence:

9

REcycling

CE4=CEP +SPCE3+SPTCE7

Extrusion

5

2

8

Reheat

CE2=CEE+SE(f1CE1+f9CE9)

CE9=CERE

CE1=2 * CERE

6

3

Painting

CE7=CET

CE3=CER+SRCE2

Treatment

7

4

In these conditions, indicate how you could determine the specific consumption of the painted profile, using the

process input-output model. Clearly present the coefficients of the activity matrix (A).

Class # 8P :: Process IOT - Energy Systems Modeling

Slide 13 of 53

Energy Management

Solution Problem 03

Class # 8P :: Process IOT - Energy Systems Modeling

Slide 14 of 53

Energy Management

Solution Problem 03

Class # 8P :: Process IOT - Energy Systems Modeling

Slide 15 of 53

Energy Management

IOT

PROBLEM 04

Consider the second company from last class, which produces steel bottles to store gasses. The production

process had the following sequence:

RM

CE8=CEPT+SPTCE7+SPT_TCEt9

CE7=CEF+SFCE6

DC

CUT

CE6=CEEW+SEW(f5CE5+f3CE3+f11CE11)

CE5=CERW+SRWCE4

RW

CUP

3

CE4=CECUT+SCUTCE1

5

11

EW

CE3=CECUP+SCUPCE2

CE2=CEDC+SDCCE1

6

10

CEt9=CEtT

PT

Final product

CE11=CER=0

CE10=0

In these conditions, indicate how you could determine the specific consumption of the painted profile, using the

process input-output model. Clearly present the coefficients of the activity matrix (A).

Class # 8P :: Process IOT - Energy Systems Modeling

Slide 16 of 53

Energy Management

Solution Problem 04

Class # 8P :: Process IOT - Energy Systems Modeling

Slide 17 of 53

Energy Management

Solution Problem 04

Class # 8P :: Process IOT - Energy Systems Modeling

Slide 18 of 53

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- QLT m10 Asl Parts Book 2012Document46 pagesQLT m10 Asl Parts Book 2012Tiago Henriques100% (1)

- Atlas Copco RH 656 PartsDocument16 pagesAtlas Copco RH 656 PartsTiago HenriquesPas encore d'évaluation

- XH200 Spec Sheet USLETTER PrintDocument2 pagesXH200 Spec Sheet USLETTER PrintTiago HenriquesPas encore d'évaluation

- EM P 08 Process Input-Output Analysis SlidesDocument16 pagesEM P 08 Process Input-Output Analysis SlidesTiago HenriquesPas encore d'évaluation

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesPas encore d'évaluation

- EM P 05 Energy Systems Analysis SlidesDocument14 pagesEM P 05 Energy Systems Analysis SlidesTiago HenriquesPas encore d'évaluation

- EM P 12 MicrogenerationDocument7 pagesEM P 12 MicrogenerationTiago HenriquesPas encore d'évaluation

- 2935 0724 30 - tcm30-1628027Document54 pages2935 0724 30 - tcm30-1628027Hossam Mohi EldinPas encore d'évaluation

- Applied Thermal Engineering: Minje Park, Daebong Jung, Minjae Kim, Kyoungdoug MinDocument9 pagesApplied Thermal Engineering: Minje Park, Daebong Jung, Minjae Kim, Kyoungdoug MinTiago HenriquesPas encore d'évaluation

- EM P 09 Process Input-Output Analysis SlidesDocument12 pagesEM P 09 Process Input-Output Analysis SlidesTiago HenriquesPas encore d'évaluation

- EM P 06 Energy Systems Analysis SlidesDocument14 pagesEM P 06 Energy Systems Analysis SlidesTiago HenriquesPas encore d'évaluation

- EM P 06 Energy Systems Analysis SlidesDocument14 pagesEM P 06 Energy Systems Analysis SlidesTiago HenriquesPas encore d'évaluation

- EM P 02 Assignment 1 Example SlidesDocument11 pagesEM P 02 Assignment 1 Example SlidesTiago HenriquesPas encore d'évaluation

- EM P 03 Energy Prices SlidesDocument14 pagesEM P 03 Energy Prices SlidesTiago HenriquesPas encore d'évaluation

- Energy Management Diagrams and AnalysisDocument4 pagesEnergy Management Diagrams and AnalysisTiago HenriquesPas encore d'évaluation

- EM P 01 Energy Statistics & Emergy Prices SlidesDocument49 pagesEM P 01 Energy Statistics & Emergy Prices SlidesTiago HenriquesPas encore d'évaluation

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesPas encore d'évaluation

- EM P 01 Energy Statistics SlidesDocument40 pagesEM P 01 Energy Statistics SlidesTiago HenriquesPas encore d'évaluation

- EM P 06 Energy Systems Analysis SlidesDocument14 pagesEM P 06 Energy Systems Analysis SlidesTiago HenriquesPas encore d'évaluation

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesPas encore d'évaluation

- EM Ass 04Document1 pageEM Ass 04Tiago HenriquesPas encore d'évaluation

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesPas encore d'évaluation

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesPas encore d'évaluation

- S Intermediate Input Final Demand: 0 #Value! #Value!Document2 pagesS Intermediate Input Final Demand: 0 #Value! #Value!Tiago HenriquesPas encore d'évaluation

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesPas encore d'évaluation

- S Intermediate Input Final DemandDocument2 pagesS Intermediate Input Final DemandTiago HenriquesPas encore d'évaluation

- EM Ass 04 Annex 2 DataDocument3 pagesEM Ass 04 Annex 2 DataTiago HenriquesPas encore d'évaluation

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesPas encore d'évaluation

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesPas encore d'évaluation

- April 26, 2019 Strathmore TimesDocument16 pagesApril 26, 2019 Strathmore TimesStrathmore Times100% (1)

- Water Jet CuttingDocument15 pagesWater Jet CuttingDevendar YadavPas encore d'évaluation

- DNA Gel Electrophoresis Lab Solves MysteryDocument8 pagesDNA Gel Electrophoresis Lab Solves MysteryAmit KumarPas encore d'évaluation

- Whisper Flo XF 3 PhaseDocument16 pagesWhisper Flo XF 3 Phasehargote_2Pas encore d'évaluation

- Os PPT-1Document12 pagesOs PPT-1Dhanush MudigerePas encore d'évaluation

- Free Radical TheoryDocument2 pagesFree Radical TheoryMIA ALVAREZPas encore d'évaluation

- KPMG Inpection ReportDocument11 pagesKPMG Inpection ReportMacharia NgunjiriPas encore d'évaluation

- Case StudyDocument2 pagesCase StudyBunga Larangan73% (11)

- PRODUCTDocument82 pagesPRODUCTSrishti AggarwalPas encore d'évaluation

- Leaked David Fry II Conversation Regarding Loopholes and Embezzlement at AFK Gamer LoungeDocument6 pagesLeaked David Fry II Conversation Regarding Loopholes and Embezzlement at AFK Gamer LoungeAnonymous iTNFz0a0Pas encore d'évaluation

- Marketing Plan for Monuro Clothing Store Expansion into CroatiaDocument35 pagesMarketing Plan for Monuro Clothing Store Expansion into CroatiaMuamer ĆimićPas encore d'évaluation

- GLF550 Normal ChecklistDocument5 pagesGLF550 Normal ChecklistPetar RadovićPas encore d'évaluation

- DMDW Mod3@AzDOCUMENTS - inDocument56 pagesDMDW Mod3@AzDOCUMENTS - inRakesh JainPas encore d'évaluation

- Evaluating Sources IB Style: Social 20ib Opvl NotesDocument7 pagesEvaluating Sources IB Style: Social 20ib Opvl NotesRobert ZhangPas encore d'évaluation

- BIBLIO Eric SwyngedowDocument34 pagesBIBLIO Eric Swyngedowadriank1975291Pas encore d'évaluation

- Case Study Hotel The OrchidDocument5 pagesCase Study Hotel The Orchidkkarankapoor100% (4)

- Artist Biography: Igor Stravinsky Was One of Music's Truly Epochal Innovators No Other Composer of TheDocument2 pagesArtist Biography: Igor Stravinsky Was One of Music's Truly Epochal Innovators No Other Composer of TheUy YuiPas encore d'évaluation

- Mercedes BenzDocument56 pagesMercedes BenzRoland Joldis100% (1)

- Experiences from OJT ImmersionDocument3 pagesExperiences from OJT ImmersionTrisha Camille OrtegaPas encore d'évaluation

- 2nd Pornhub Awards - WikipediaaDocument13 pages2nd Pornhub Awards - WikipediaaParam SinghPas encore d'évaluation

- Cold Rolled Steel Sections - Specification: Kenya StandardDocument21 pagesCold Rolled Steel Sections - Specification: Kenya StandardPEng. Tech. Alvince KoreroPas encore d'évaluation

- LM1011 Global ReverseLogDocument4 pagesLM1011 Global ReverseLogJustinus HerdianPas encore d'évaluation

- Motor Master 20000 SeriesDocument56 pagesMotor Master 20000 SeriesArnulfo Lavares100% (1)

- Striedter - 2015 - Evolution of The Hippocampus in Reptiles and BirdsDocument22 pagesStriedter - 2015 - Evolution of The Hippocampus in Reptiles and BirdsOsny SillasPas encore d'évaluation

- Wasserman Chest 1997Document13 pagesWasserman Chest 1997Filip BreskvarPas encore d'évaluation

- Non Circumvention Non Disclosure Agreement (TERENCE) SGDocument7 pagesNon Circumvention Non Disclosure Agreement (TERENCE) SGLin ChrisPas encore d'évaluation

- 5054 w11 QP 11Document20 pages5054 w11 QP 11mstudy123456Pas encore d'évaluation

- AATCC 100-2004 Assesment of Antibacterial Dinishes On Textile MaterialsDocument3 pagesAATCC 100-2004 Assesment of Antibacterial Dinishes On Textile MaterialsAdrian CPas encore d'évaluation

- Planning A Real Estate ProjectDocument81 pagesPlanning A Real Estate ProjectHaile SilasiePas encore d'évaluation

- Pradhan Mantri Gramin Digital Saksharta Abhiyan (PMGDISHA) Digital Literacy Programme For Rural CitizensDocument2 pagesPradhan Mantri Gramin Digital Saksharta Abhiyan (PMGDISHA) Digital Literacy Programme For Rural Citizenssairam namakkalPas encore d'évaluation