Académique Documents

Professionnel Documents

Culture Documents

F 065 Liu F PDF

Transféré par

Fari PratomosiwiDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

F 065 Liu F PDF

Transféré par

Fari PratomosiwiDroits d'auteur :

Formats disponibles

XVII International Symposium on High Voltage Engineering, Hannover, Germany, August 22-26, 2011

LIFE ASSESSMENT MODEL OF THE POWER TRANSFORMERS

BASED ON CONDITION ASSESSMENT

Z.L. Liu1, L.H. Yang1, H.Huang1,C.Z. Fu1, X. Zhang2 and E. Gockenbach2

1

East China Electric Power Test & Research Institute Co. Ltd, No.171 Handan road,

Shanghai, 200437 China

2

Institute of Electric Power Systems (Schering-Institute) Leibniz University Hanover,

Callin Strasse 25A, Hanover, 30167 Germany

Abstract: Statistical analysis of 500kV power equipments in East China Grid is

performed in this paper. The transformer reliability life modelling method is then proposed

based on condition characteristic evaluation technology. The elements and data sources

are determined for sub-model. The overall model is established and verified through

Monte-Carlo analysis.

Keywords: Life assessment model, power transformers, condition assessment

INTRODUCTION

Due to the competition of the electricity market, the

life assessment technology of power transformers

has drawn more and more attention. Despite of the

technical difficulties, many achievements have

been made by the researchers from all over the

world. Based on the current condition assessment

method, this paper proposed a life model of the

power transformers based on characteristic data,

combined with performance experience.

The study of life assessment model includes three

aspects:1) establishing the models combination

representing the thermal, mechanical and electrical

characteristics of equipment based on operation

experience; 2) making utility of existing data and

operation experience, selecting key information

representing the initial and current status of the

equipment.

Through

calculation,

analysis,

weighting and expert system scoring, the

submodels are valued; 3) making combination of

the submodels by probability method. Through trial

calculation of several equipment, modification and

adjustment could be made to the combination and

value of the submodels. Finally the life assessment

model of the power transformers based on status

evaluation could be built.

2

OVERALL STUDY APPROACH

The concept reliability life evaluation is used in

this study. It refers to the estimate of the period,

during which the equipment maintains continuously

steady operation within a specified reliability level

(or fault rate). Reliability life evaluation takes into

account combinations of various categories of

faults resulted from electrical, mechanical or

thermal aging. These faults may require

replacement of main components or supplemental

parts of the equipment.

The process of reliability life modeling is described

as follows. First, characteristic indices that

represent transformers operation conditions are

identified based on statistical analysis of

transformer failure and prevention tests data.

Second, relationship between the indices and

operation time or that between the indices and

failure rate (reliability) is established. Third,

variation of each single characteristic index is

evaluated according to the technical standards,

operation practices and research results. Finally,

adjustment for various fault types is performed

based on operation experiences, particularly

through analysis of failure information. The

reliability life model is then built up. Reliability life of

a transformer is determined in accordance with the

operation requirements.

3

3.1

STATISTICAL ANALYSIS OF SUPPORTING

DATA

Data overview

Typical substations with various years of operation

experience are investigated in this study. Through

the

investigation,

information

related

to

transformers manufacturing, transit, operation,

maintenance and defects is collected for 185

transformers and reactors installed in over 40

substations. Both the substations of over 15 years

operation experience and those of only 5 years

operation experience are investigated.

3.2

Analysis methods

Four different statistical methods as listed below

are used to analyze various types of characteristic

data. Method One and method Two are used for

insulation tests and bushing related data analysis.

Method Three and method Four are employed for

incidents statistics and short-circuit related

computation.

XVII International Symposium on High Voltage Engineering, Hannover, Germany, August 22-26, 2011

Method One: Determine the variation principles of

the characteristic indices through statistical

analysis of a large quantity of samplings. The

major aspects of the analysis are as follows.

1) Data distribution characteristic may be used as

criteria for data filtering.

short-circuit effect accumulation and etc.). The

influence of each type of factors is evaluated

based on analysis of failure events and design

check. The approach and procedures for

estimation of equipment short-circuit fault

probability.

4

2) Correlation analysis of data with various factors

(years of operation not included) may be used for

identification of characteristic indices. For instance,

if a correlates highly with b and in principle, a and b

represent the same characteristic, only one of

them (either a or b) will be taken as input for the

model.

3) Correlation analysis of characteristic indices with

years of operation, as core of reliability life model,

determines whether the model is time extendable.

In other words, correlation analysis will show

whether the reliability life is predictable or not.

Method Two: The variation tendencies for the

characteristic indices of single equipment are

studied based on statistical analysis of a large

quantity of samplings. The major considerations

are as follows.

1) The number of the samplings with over 10

years operation is very limited. Therefore, their

variation characteristics might be submerged.

2) The prevention tests data are obtained mainly

through limits checking. Its measurement part is

affected by various uncertain factors. However, the

factors and the errors might be relatively fixed for

single equipment, which helps the investigation of

the tendency.

3) Operation experience shows that the

characteristic data varies considerably for

equipments with different design, manufacturing

and operation conditions. For example, the

fundamental tendencies are similar for the media

loss curves while the starting points and the

variation rates for these curves are remarkably

different.

Method Three (fault statistics): Perform failure

events statistics based on operation and

management experience. Transformer faults are

categorized according to the caused of fault

occurrence. The categorized fault statistics results

will then be employed as important basis for

reliability life modeling.

Method Four (estimate of short-circuit fault

probability): Employ the research results to identify

the factors that affect the anti-short-circuit

capability. The factors mainly involve design

margin, manufacturing technology and operation

environment (relay protection and multiple times

ESTABLISHMENT OF SUB-MODEL

4.1

Main components of the model

Through statistical analysis, the major structure

and data sources of the reliability life model are

determined. As shown in Table 1, the sub-models

are grouped into four categories, which are related

to electrical performance, mechanical performance,

supplemental

performance

and

operation

scenarios respectively. The data sources involve

failure events, equipment transiting and prevention

tests.

Table 1:Main components of transformer reliability

life model

Submodel

Characteristic

parameters

Overall

insulation

electrical

oil

DGA

Dc resistance

anti-short-circuit

capability

mechanical

Winding

deformation

bushing

supplemental

operation

4.2

tap

oil

Over-voltage

and etc

Index

dielectric loss, absorption ratio,

polarized index

Withstand voltage,

water,contamination,TCG,gas,

C2H2

Imbalance rate

Design reliability

short-circuit impedance

variation rate

capacitance variation rate

dielectric loss,capacitance

Fault rate

Fault rate

Physical index

Fault rate

Analysis method

In the sub-models, the characteristic indices are

employed in three ways, which are time extending,

limits checking and fixed parameter method.

1) Time extending

Time extending method is applicable for the

characteristic indices that are correlated with

operation time. To use this method, single

equipment data shall demonstrate certain

principles which may be approximated through

primary polynomials or exponentials. When

assuming

relationship

exists

between

characteristic index and accumulative fault rates,

the variation tendency of the fault rates

corresponding to the characteristic index is then

acquired. The sub-model is then time extendable.

Statistics results show that the characteristic

indices with time extending ability include the

overall dielectric loss, dielectric loss of bushing and

oil, CH4, micro-water, and PH value of oil.

2) Limits checking

XVII International Symposium on High Voltage Engineering, Hannover, Germany, August 22-26, 2011

Limits checking method is applicable when neither

characteristic indices-operation time correlation nor

certain principle of the characteristic indices for

single equipment exists. Through the assumption

that relationship exists between the characteristic

index limit and the accumulative fault rates, the

fault rate corresponding to the characteristic index

is then acquirable. At present, the characteristic

indices suitable for limits checking include

absorption ratio, polarized index, C2H2, shortcircuit impedance variation rate, capacitance

variation rate and voltage withstand ability of

insulation oil.

3) Fixed parameters

Fixed parameters are the ones that repent the

equipment characteristics and remain unchanged

in operation. Fixed parameters include anti-shortcircuit capability evaluation index and average fault

rates which are used in random fault simulation.

4.3

Assumptions of accumulative fault

rates and reliability

The assumptions of accumulative fault rates and

reliability are mainly based on related standards

and operation experience.

5

5.1

ESTABLISHMENT OF THE OVERALL

MODEL

Development of the problem

According to reliability fundamentals, transformer

reliability

is

determined

by

series-wound

connection of the reliability of each part.

Transformer reliability is then represented as the

product of the reliability from each sub-model

(Ra*Rb*Rc*Rd), where Ra, Rb, Rc and Rd are the

reliability for sub-models related to electrical

performance,

mechanical

performance,

supplemental

performance

and

operation

scenarios respectively. Statistical results show that

the fault rate for transformers of 110kV and higher

voltage levels in East China is only 0.11 per

hundred units per year. Therefore, the reliability

index for each sub-model shall be about 99.9%

according to the above analysis. However, this

brings forward two problems.

1) The present sub-models can not meet this

precision requirement, which may directly result in

the establishment failure of the overall reliability life

model.

2) It is difficult to identify the major restriction

factors (fault types) of transformer reliability life.

Correspondingly, the development of the strategies

followed will be affected.

The present research and data sources make it

difficult to establish sub-models of considerably

higher precision. To solve the problems above,

improvement has to be made to mitigate the

influence of sub-models precision problem.

5.2

Modification and integration approach

for sub-models

1) Basic considerations

Sub-model modification is based on operation

experience. It refers to modification of sub-model

reliability indices through reasonable assumptions

and technical measures. The transformer reliability

life is then determined through series-wound

combination of sub-models. The reliability indices

may be modified in three ways: multiplying a

coefficient, adding a value or using exponentials.

Considering the former two ways may result in

increased reliability indices of over 1.0 or

remarkable increase / decrease of the reliability

indices, exponentials are selected in this study to

avoid such unreasonable modification results. After

modification, the reliability index is as follows.

Rtotal = Ra a Rbb Rc c Rd

(1)

2) Summarization of operation experience

Summarization of operation experience mainly

refers to acquisition of average transformer fault

rate and the relative ratio of each type of fault.

Fault statistical results for transformers of 330 kV

and above in State Grid of China are used for

summarization.

3) Solution of modification factors

According to Table 1, Ra, Rb, Rc and Rd are

calculated respectively. Now, according to

definition of reliability, single equipment fault rate

may be represented as 1-RtotalI. When the number

of the equipment samplings is large enough, the

n

overall fault rate

(1 Rtotal ,i ) / N

corresponds to the

i =1

number

of

faulted

equipments.

Accordingly,

(1 Rb,i b Rc,i c Rd ,i

)/ N

corresponds

to

the

i =1

number of faulted equipments without electrical

fault (factor a), and etc. These should consistent

with the operation experience as described in 2)

Summarization of operation experience. The

modification factors may be acquired through

Monte-Carlo approach.

Related solution parameters and results are listed

in Table 2 Results show that all values of the

modification factors are less than 1.0. a and b are

especially smaller. It is mainly due to strict setting

of fault rates and large number of input parameters.

XVII International Symposium on High Voltage Engineering, Hannover, Germany, August 22-26, 2011

Table 2: Solution results

parameters

results

0.05

0.45

0.1

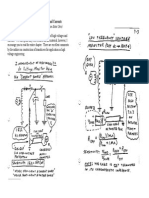

The overall reliability distribution of 500 kV

transformers in East China is shown in Fig.1 and

Fig.2.

Figure 1:Overall reliability distribution

Fig.2: Variation of overall reliability means and

variances with respect to time

It is observed from the figures above that:

1) There is no much variation of mean and

variance values, which matches the fact that the

equipments are in stable operation.

2) The overall reliability rises first and then

decreases. The reliability of year 2010is high which

may result from the completion of equipments

state adaptation period.

3) The variance rises first and then decreases. It

shows that equipments reliability gets close after

years of operation. Management of these

equipments may be of high generality.

4) Correlation of various parts with time differs,

which provides technical basis for differentiated

management in life-cycle.

5) There is difference between the variation of

overall reliability and that of single equipment.

CONCLUSION

This paper presents state characteristics

evaluation-based

approach

for

transformer

reliability life modeling. Components and data

sources are determined for the sub-models.

Modification and integration of the sub-models are

performed through Monte-Carlo method. The lifecycle management of the equipments is expected

to be enhanced through this study.

Vous aimerez peut-être aussi

- Maintenance Mannual of Chery Karry - MK60 ABSDocument33 pagesMaintenance Mannual of Chery Karry - MK60 ABSSuckmytickPas encore d'évaluation

- IEE Wiring RegulationsDocument40 pagesIEE Wiring RegulationsAhmed Kamal Othman100% (4)

- Basics of 4-20ma Current LoopDocument7 pagesBasics of 4-20ma Current LoopsandystaysPas encore d'évaluation

- S285 Fozmula Capacitance Coolant Level Switch Data JP 24 Nov 15 3.1 Rev 2 PDFDocument1 pageS285 Fozmula Capacitance Coolant Level Switch Data JP 24 Nov 15 3.1 Rev 2 PDFfaraidunPas encore d'évaluation

- SAFOPDocument53 pagesSAFOPMaly199067% (3)

- Health Index Gorgan PDFDocument6 pagesHealth Index Gorgan PDFBogdanPas encore d'évaluation

- Transient Over VoltagesDocument38 pagesTransient Over Voltagesraghav4life8724Pas encore d'évaluation

- Jadual Pembahagian Penilaian Kerja Kursus (PKK) C261-001-3:2020-C03 Electronic Components and Boards Troubleshooting and SupervisionDocument24 pagesJadual Pembahagian Penilaian Kerja Kursus (PKK) C261-001-3:2020-C03 Electronic Components and Boards Troubleshooting and SupervisionNURAFZAPas encore d'évaluation

- Reliability PredictionDocument7 pagesReliability PredictionbederinadmlPas encore d'évaluation

- Is Iec 60034 8 2002Document31 pagesIs Iec 60034 8 200291thiyagarajan100% (1)

- Reliability Centered Asset Mgmet For Power SystemDocument8 pagesReliability Centered Asset Mgmet For Power Systemmilne_christopherPas encore d'évaluation

- Evaluating The Condition & Remaining Life of Older Power PlantsDocument12 pagesEvaluating The Condition & Remaining Life of Older Power PlantsDanie-ElsPas encore d'évaluation

- Universal Technical Standard For Solar Home SystemsDocument61 pagesUniversal Technical Standard For Solar Home SystemsleolopluPas encore d'évaluation

- Condition Monitoring and Diagnostics of Power TransformersDocument11 pagesCondition Monitoring and Diagnostics of Power TransformersloliveiPas encore d'évaluation

- Condition Assessment of BoilerDocument8 pagesCondition Assessment of BoilerEzhil Vendhan PalanisamyPas encore d'évaluation

- A Semi-Quantitative Pipeline Risk Assessment Tool For Piggable and Un-Piggable PipelinesDocument12 pagesA Semi-Quantitative Pipeline Risk Assessment Tool For Piggable and Un-Piggable PipelinesgeeawhizPas encore d'évaluation

- Transient Testing of Protection Relays Results, Methodology and Tools, Ipst2003Document7 pagesTransient Testing of Protection Relays Results, Methodology and Tools, Ipst2003Mohamed Daw HamoudaPas encore d'évaluation

- Analysis of Asset Management Models ForDocument12 pagesAnalysis of Asset Management Models Forchandraippa2Pas encore d'évaluation

- Novel Methods For The Condition Based Maintenance of Distribution NetworksDocument6 pagesNovel Methods For The Condition Based Maintenance of Distribution NetworkspourushgargPas encore d'évaluation

- Exploitation Perspective Index As A Support of The ManagementDocument15 pagesExploitation Perspective Index As A Support of The ManagementAdrian SiePas encore d'évaluation

- Thesis Jur ErbrinkDocument245 pagesThesis Jur Erbrinkgmb09140Pas encore d'évaluation

- An Intelligent System For Monitoring Useful Life Transformer ReductionDocument6 pagesAn Intelligent System For Monitoring Useful Life Transformer ReductionItalo ChiarellaPas encore d'évaluation

- CIGRE-Ciclo de Vida de InterruptoresDocument8 pagesCIGRE-Ciclo de Vida de InterruptoresRoland AvlsPas encore d'évaluation

- Energies: Failure Detection by Signal Similarity Measurement of Brushless DC MotorsDocument23 pagesEnergies: Failure Detection by Signal Similarity Measurement of Brushless DC MotorsJose Daniel Sacoto PeraltaPas encore d'évaluation

- Energies 12 00953Document18 pagesEnergies 12 00953Giovanni EsguerraPas encore d'évaluation

- 1 s2.0 S2215016123003515 MainDocument14 pages1 s2.0 S2215016123003515 Mainsccp.mzapata01Pas encore d'évaluation

- Electrical Aging of The Insulation of Low Voltage Machines: Model Definition and Test With The Design of ExperimentsDocument11 pagesElectrical Aging of The Insulation of Low Voltage Machines: Model Definition and Test With The Design of ExperimentsBinh TaiPas encore d'évaluation

- Validation and Updating of FE Models For Structural AnalysisDocument10 pagesValidation and Updating of FE Models For Structural Analysiskiran2381Pas encore d'évaluation

- Comsy - SoftwareDocument9 pagesComsy - SoftwareAlberto Carel SimanjuntakPas encore d'évaluation

- JOAPE21361678566600Document9 pagesJOAPE21361678566600benlahnechePas encore d'évaluation

- Reliability Investigation of LED Devices for Public Light ApplicationsD'EverandReliability Investigation of LED Devices for Public Light ApplicationsPas encore d'évaluation

- Development and Application of New Condition Assessment Methods For Power TransformersDocument10 pagesDevelopment and Application of New Condition Assessment Methods For Power TransformersRoy Dz HutapeaPas encore d'évaluation

- Comparison of Reliability Prediction Methods Using Life Cycle Cost AnalysisDocument7 pagesComparison of Reliability Prediction Methods Using Life Cycle Cost AnalysisSuman MaharanaPas encore d'évaluation

- Strategy For End of Life Assessment For High Voltage Circuit BreakersDocument10 pagesStrategy For End of Life Assessment For High Voltage Circuit Breakersmihalcea45Pas encore d'évaluation

- A General Framework For Voltage Sag Performance Analysis of Distribution NetworksDocument14 pagesA General Framework For Voltage Sag Performance Analysis of Distribution Networkstien chau minhPas encore d'évaluation

- Maintenance Engineering: Reliability Centered Maintenance (RCM)Document28 pagesMaintenance Engineering: Reliability Centered Maintenance (RCM)Muhammad KamranPas encore d'évaluation

- Zhang Ieee 08Document16 pagesZhang Ieee 08Kiriakos SiderakisPas encore d'évaluation

- 0Rgho%Dvhg'Ldjqrvwlfviru$Lu+Dqgolqj8Qlwv: Tim Salsbury and Rick DiamondDocument12 pages0Rgho%Dvhg'Ldjqrvwlfviru$Lu+Dqgolqj8Qlwv: Tim Salsbury and Rick DiamondyalllikPas encore d'évaluation

- Zhang Ieee 08Document16 pagesZhang Ieee 08hamidrezaPas encore d'évaluation

- Uncertain Parameter Numerical Model Updating According To Variable Modal Test Data in Application of Large Composite Fuselage PanelDocument16 pagesUncertain Parameter Numerical Model Updating According To Variable Modal Test Data in Application of Large Composite Fuselage Paneligomez19Pas encore d'évaluation

- Features of Steam Turbines DiagnosticsDocument6 pagesFeatures of Steam Turbines DiagnosticspradityaPas encore d'évaluation

- LITreview and RefDocument3 pagesLITreview and RefSAHILPas encore d'évaluation

- Israel IECRDocument17 pagesIsrael IECRAbijith MenonPas encore d'évaluation

- Ewshm2018 Enviro v2Document9 pagesEwshm2018 Enviro v2Kaleeswaran EinsteinPas encore d'évaluation

- Ish2017 361 PDFDocument6 pagesIsh2017 361 PDFRebeca VargasPas encore d'évaluation

- Energies 17 00352Document15 pagesEnergies 17 00352Abdullah KaracaoğluPas encore d'évaluation

- Dynamo - Software For Vibration Based Structural Health MonitoringDocument8 pagesDynamo - Software For Vibration Based Structural Health MonitoringFrancisco CalderónPas encore d'évaluation

- Flotation Circuit Optimization Using Modelling and SimulationDocument14 pagesFlotation Circuit Optimization Using Modelling and SimulationOnesime MutebaPas encore d'évaluation

- AIAA-2000-1437 Validation of Structural Dynamics Models at Los Alamos National LaboratoryDocument15 pagesAIAA-2000-1437 Validation of Structural Dynamics Models at Los Alamos National LaboratoryRomoex R RockPas encore d'évaluation

- Reliability Research of Vacuum Circuit Breaker BasDocument6 pagesReliability Research of Vacuum Circuit Breaker BasShandukani VhulondoPas encore d'évaluation

- Condition-Based Maintenance: Model vs. Statistics A Performance ComparisonDocument7 pagesCondition-Based Maintenance: Model vs. Statistics A Performance ComparisonLourds Egúsquiza EscuderoPas encore d'évaluation

- Monitoring Power Quality Beyond EN50160 and IEC 61000-4-30Document13 pagesMonitoring Power Quality Beyond EN50160 and IEC 61000-4-30i.freddiPas encore d'évaluation

- Process Corrosion Simulation PaperDocument19 pagesProcess Corrosion Simulation PaperMohammad Fouladi100% (1)

- The Determination of Uncertainties in Charpy Impact TestingDocument19 pagesThe Determination of Uncertainties in Charpy Impact TestingAfriandiBayuPas encore d'évaluation

- IET Electric Power Appl - 2017 - Ballal - Online Condition Monitoring System For Substation and Service TransformersDocument10 pagesIET Electric Power Appl - 2017 - Ballal - Online Condition Monitoring System For Substation and Service TransformersbenlahnechePas encore d'évaluation

- Setting The Processing Parameters in InjDocument8 pagesSetting The Processing Parameters in InjLuminita GeorgetaPas encore d'évaluation

- Pgjonline-Com-MagaDocument14 pagesPgjonline-Com-MagaJagdish mogaPas encore d'évaluation

- Role of Statistics: in Mathematical ModellingDocument7 pagesRole of Statistics: in Mathematical ModellingKumar ShantanuPas encore d'évaluation

- Principal Component Analysis For Monitoring ElectrDocument11 pagesPrincipal Component Analysis For Monitoring ElectrEmanuel MaracajáPas encore d'évaluation

- REF. 8 Diagnostics of Current Technical State of Transformer Equipment Using The Analytic Hierarchy ProcessDocument6 pagesREF. 8 Diagnostics of Current Technical State of Transformer Equipment Using The Analytic Hierarchy ProcessCap Scyte Victor MariscalPas encore d'évaluation

- Software Models For RelaysDocument8 pagesSoftware Models For RelaysDCSAWPas encore d'évaluation

- Processes 06 00200 PDFDocument35 pagesProcesses 06 00200 PDFJerry CapaciaPas encore d'évaluation

- Innovative Techniques in Non-Destructive Testing and Industrial Applications On Pressure EquipmentDocument13 pagesInnovative Techniques in Non-Destructive Testing and Industrial Applications On Pressure EquipmentJavier Alejandro RodriguezPas encore d'évaluation

- The ISO 13381-1 Standard's Failure Prognostics Process Through An ExampleDocument12 pagesThe ISO 13381-1 Standard's Failure Prognostics Process Through An ExampleJom BonhayagPas encore d'évaluation

- Practical Control of Electric Machines: Model-Based Design and SimulationD'EverandPractical Control of Electric Machines: Model-Based Design and SimulationPas encore d'évaluation

- 0708 0369Document27 pages0708 0369iledinamo1Pas encore d'évaluation

- State-Of-The-Art Review On Asset Management Methodologies For Oil-Immersed Power TransformersDocument18 pagesState-Of-The-Art Review On Asset Management Methodologies For Oil-Immersed Power TransformersAdrian SiePas encore d'évaluation

- Online Monitoring Technology of Power Transformer Based On Vibration AnalysisDocument10 pagesOnline Monitoring Technology of Power Transformer Based On Vibration AnalysisDrRajeev ChauhanPas encore d'évaluation

- Dynamic Properties of Dielectrics E F (T) : P + P (T) 0 P (T) (P P)Document24 pagesDynamic Properties of Dielectrics E F (T) : P + P (T) 0 P (T) (P P)Fari PratomosiwiPas encore d'évaluation

- Surface DischargesDocument18 pagesSurface DischargesFari PratomosiwiPas encore d'évaluation

- Indonesia Solar Power Mapping Study Using Secondary Data Paulus Agus Winarso Supriadi LeginoDocument7 pagesIndonesia Solar Power Mapping Study Using Secondary Data Paulus Agus Winarso Supriadi LeginoFari PratomosiwiPas encore d'évaluation

- Electric Breakdown in Gases: Department of Electric Power EngineeringDocument30 pagesElectric Breakdown in Gases: Department of Electric Power EngineeringFari PratomosiwiPas encore d'évaluation

- Materials in High Voltage TechnologyDocument27 pagesMaterials in High Voltage TechnologyFari PratomosiwiPas encore d'évaluation

- Electric Fields: - Exact Methods - Approximate Solutions - Computer SimulationsDocument17 pagesElectric Fields: - Exact Methods - Approximate Solutions - Computer SimulationsFari PratomosiwiPas encore d'évaluation

- HVT 7 Pedrow Measurement o High Voltages and CurrentsDocument5 pagesHVT 7 Pedrow Measurement o High Voltages and CurrentsFari PratomosiwiPas encore d'évaluation

- Use of The BRESSER MikroCam AdaptersDocument2 pagesUse of The BRESSER MikroCam AdaptersFari PratomosiwiPas encore d'évaluation

- HVT 7 Pedrow Insulation CoordinationDocument4 pagesHVT 7 Pedrow Insulation CoordinationFari PratomosiwiPas encore d'évaluation

- Numerical and Experimental Investigation On Salt-Fog Aging of Silicone InsulatorsDocument4 pagesNumerical and Experimental Investigation On Salt-Fog Aging of Silicone InsulatorsFari PratomosiwiPas encore d'évaluation

- The Invisible Supply of Reliable Power Power Cables MV, HV & EhvDocument44 pagesThe Invisible Supply of Reliable Power Power Cables MV, HV & EhvFari Pratomosiwi100% (1)

- F 048 CHM F PDFDocument5 pagesF 048 CHM F PDFFari PratomosiwiPas encore d'évaluation

- A Study of Switching Overvoltages On Block Power TransformerDocument4 pagesA Study of Switching Overvoltages On Block Power TransformerFari PratomosiwiPas encore d'évaluation

- B 049 Wie F PDFDocument4 pagesB 049 Wie F PDFFari PratomosiwiPas encore d'évaluation

- Simulation of Earth Termination Systems For Lightning Protection Systems Regarding Step VoltagesDocument4 pagesSimulation of Earth Termination Systems For Lightning Protection Systems Regarding Step VoltagesFari PratomosiwiPas encore d'évaluation

- Part2 Maxwell Ultracapacitors TechnologyAtGlanceDocument80 pagesPart2 Maxwell Ultracapacitors TechnologyAtGlanceruhulPas encore d'évaluation

- 1 RCS-985B Generator Protection Instruction Manual PDFDocument473 pages1 RCS-985B Generator Protection Instruction Manual PDFM ANNAS ALBAB FAUZI100% (1)

- CV - Electrical EngineerDocument4 pagesCV - Electrical EngineerMD WARISPas encore d'évaluation

- MTX Audio MTX Monitor Series Monitor60i Monitor6c Monitor5i Monitor600iDocument6 pagesMTX Audio MTX Monitor Series Monitor60i Monitor6c Monitor5i Monitor600iAnonymous XgX8kTPas encore d'évaluation

- IZD10/IZE11: The Importance of The Static Electric Control Is Put On Confirming The "Actual Status"Document16 pagesIZD10/IZE11: The Importance of The Static Electric Control Is Put On Confirming The "Actual Status"Le TamPas encore d'évaluation

- Question Paper Winter 2019Document3 pagesQuestion Paper Winter 2019ELECTRICAL DEPARTMENTPas encore d'évaluation

- Impedance TransformationDocument4 pagesImpedance TransformationabubakarshaPas encore d'évaluation

- Use of Solar Energy in Electricity GenerationDocument10 pagesUse of Solar Energy in Electricity GenerationAfraim HasanPas encore d'évaluation

- Bravia kdl40v2500 PDFDocument88 pagesBravia kdl40v2500 PDFSùng Seo TriểnPas encore d'évaluation

- 1SDA068251R1 xt3n 250 TMG 63 400 3p F FDocument4 pages1SDA068251R1 xt3n 250 TMG 63 400 3p F FJosé CarlosPas encore d'évaluation

- Quasi Z SourceDocument9 pagesQuasi Z SourceMark-George RuthaPas encore d'évaluation

- Constant Current Regulators - Dry: CompliancesDocument2 pagesConstant Current Regulators - Dry: CompliancesPardeep KhosaPas encore d'évaluation

- Data Sheet 6ED1052-2HB00-0BA6: Installation Type/mountingDocument2 pagesData Sheet 6ED1052-2HB00-0BA6: Installation Type/mountingMARIAMPas encore d'évaluation

- Spartan2 OEM ManualDocument3 pagesSpartan2 OEM ManualChristian BodanezePas encore d'évaluation

- A Relation Between Filter Parameters of The Tow-Thomas-BiquadDocument6 pagesA Relation Between Filter Parameters of The Tow-Thomas-Biquadcarlocinfol_itPas encore d'évaluation

- EEE MaterialDocument2 pagesEEE Materialsingee songPas encore d'évaluation

- HV10 Serisi Klavuz V5.0Document67 pagesHV10 Serisi Klavuz V5.0daniel hughesPas encore d'évaluation

- Service Manual: NX-340, NX-340 (U)Document42 pagesService Manual: NX-340, NX-340 (U)A&A LABORATORIOPas encore d'évaluation

- PacemakersDocument22 pagesPacemakersapi-3757838Pas encore d'évaluation

- Isolated and Regulated 5 WATT Modular DC/DC Converters: SeriesDocument3 pagesIsolated and Regulated 5 WATT Modular DC/DC Converters: SeriesDiego SerranoPas encore d'évaluation

- Klockner Moeller EASY 512 Programming InstructionsDocument10 pagesKlockner Moeller EASY 512 Programming InstructionscdmcPas encore d'évaluation

- New Design of Traction Transformers For Fixed InstallationsDocument10 pagesNew Design of Traction Transformers For Fixed InstallationssumitPas encore d'évaluation