Académique Documents

Professionnel Documents

Culture Documents

ABSTRACT Motor Vehicle Suspending System

Transféré par

Balaji BaluCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ABSTRACT Motor Vehicle Suspending System

Transféré par

Balaji BaluDroits d'auteur :

Formats disponibles

As one kind of significant motor vehicle suspending system, the automobile leaf

spring is living the significant position in the automobile manufacture application. The

condition of our country determines vehicle manufacturing cost to be litter high and road

condition is poor in our country, therefore the leaf spring seems more significant. Since

mostly traditional leaf spring is the multi-leaf spring , the fact is that such physical design is

unreasonable, the defect on the different applications was created, in case: waste of the stuff

and adding complete auto weight and lifting fuel uses up. Little leaf spring is relatively with

the multi-leaf spring thanks to there are much kinds of strong point, therefore having become

one of leaf spring development tendency, by widely being employed one by one , and but also

the development in the wake of the little leaf spring manufacture technology , its use scope is

continuously broadening. Yet for quite some time, there is not the fundamental alteration in

the design means of little leaf spring. Contrasted against the developed country, the

tremendous disparity exists in little leaf spring on two respects in unit consumption amount

and service life. Hence researching to the little leaf spring design, adjusting to cut down unit

consumption amount of leaf spring and lift life in service possess the great sense in our

country.

According to the present situation that automobile little leaf spring was designed and

produced in view of our country, and utilizing the well-developed research design measure at

present, this paper explores on these field: little leaf spring optimization design, the little leaf

spring CAD/CAE researches and so on, and acts some research work.First of all, a new

means of little leaf spring design calculation was proposed in the original. That means revises

the

past

when

designing

merely

considersnsa

eA

eawsrfgfgdrgdrfcbcfbgdeaghshgashshshysheyahldbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

some kind of elements, but is much kinds of elements consider in the synthesis, moreover

achieved the electricity to dissolve. The design model choosing effectiveness may be lifted

enormously.Secondly, three dimensions CAD designing, more audio-visual to cause it have

been carried on to the leaf spring. In this paper I talked about CAEsresearch pre-editing

patterns of plate spring which is favorable of three dimensions finite element analysis,

thereby it was convenient for carry on the finite element analysis to the plate spring.Third,

plate spring CAE researches, and also is the stress in the paper. Research respect during the

CAE of the original researches, chiefly emphasizes the fitting stressing force and is getting

near burden and stiffness stress beforehand and so on to little leaf spring.

Finite element problem that the difficulty such as the above-mentioned research is the

stuff nonlinearity and becomes deformed greatly and plastic property and contacts analysis

and so on is made up. For quite some time, people can not be informed how the stress of leaf

spring distributes in process of fitting, can only did the test for inspection, moreover did not

have no idea about how to select near the burden beforehand, can only come to be underway

that the spring is getting near deformation beforehand by means of experience. That the result

created is difficult to make the arc altitude unanimously between current product and required

product thereby causes doing poorly work again and again. In this article, the CAD/CAEs

technique was introduced to this research and compute had been used with current finite

element software ANSYS to resolve above-mentioned problems.

It was proved that CAD/CAEs method may effectively resolve the above-mentioned

issue. What need to point out is, not only as a matter of fact these research means are

applicable to little leaf spring but also are applicable equally to the different leaf springs.The

fact demonstrates, the research in the paper may lift

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Some Proofs DerivationsDocument153 pagesSome Proofs DerivationsBalaji Balu100% (1)

- Annamacharya Institute of Technology & Sciences 2020-2021: Department of Civil EngineeringDocument2 pagesAnnamacharya Institute of Technology & Sciences 2020-2021: Department of Civil EngineeringBalaji BaluPas encore d'évaluation

- Advanced Parts and Assembly PDFDocument5 pagesAdvanced Parts and Assembly PDFBalaji BaluPas encore d'évaluation

- Civil 3D TutorialsDocument840 pagesCivil 3D TutorialsRebecca ZodinpuiiPas encore d'évaluation

- Advanced Parts and AssemblyDocument5 pagesAdvanced Parts and AssemblyBalaji BaluPas encore d'évaluation

- Manual de Autocad BasicoDocument17 pagesManual de Autocad Basicoinfected521Pas encore d'évaluation

- Part BasicDocument4 pagesPart BasicBalaji BaluPas encore d'évaluation

- Annamacharya Institute of Technology and Sciences:: Tirupati (Autonomous) Detailed Syllabi For The Courses of Regular M.Tech (Pe&Ed)Document64 pagesAnnamacharya Institute of Technology and Sciences:: Tirupati (Autonomous) Detailed Syllabi For The Courses of Regular M.Tech (Pe&Ed)Balaji BaluPas encore d'évaluation

- 19AES0302 Design Thinking and Product Innovation 2 0 0 2Document2 pages19AES0302 Design Thinking and Product Innovation 2 0 0 2Balaji BaluPas encore d'évaluation

- FDPDocument13 pagesFDPBalaji BaluPas encore d'évaluation

- JNTUA Curriculum: B.Tech Course Structure & Syllabus under R19Document93 pagesJNTUA Curriculum: B.Tech Course Structure & Syllabus under R19Balaji BaluPas encore d'évaluation

- Important Questions For MidDocument2 pagesImportant Questions For MidBalaji BaluPas encore d'évaluation

- Tutorial 3d Cad Pemula Buat BelajarDocument228 pagesTutorial 3d Cad Pemula Buat BelajarNur KhoirPas encore d'évaluation

- Civil 3D TutorialsDocument840 pagesCivil 3D TutorialsRebecca ZodinpuiiPas encore d'évaluation

- JNTUA Curriculum: B.Tech Course Structure & Syllabus under R19Document93 pagesJNTUA Curriculum: B.Tech Course Structure & Syllabus under R19Balaji BaluPas encore d'évaluation

- Te-1 Objective GKDocument5 pagesTe-1 Objective GKBalaji BaluPas encore d'évaluation

- ACFrOgBfycqbOXazb1U4Qhz9Mte0HgOppPLHyQpg9skgD0fWOrQh7JrZHaBiGOhzS890juPjn0Y4fUTt237 P1 OrulEHbSLet7uFHm2A5V5LlYmQ8nRK - Idm51MHcsDocument88 pagesACFrOgBfycqbOXazb1U4Qhz9Mte0HgOppPLHyQpg9skgD0fWOrQh7JrZHaBiGOhzS890juPjn0Y4fUTt237 P1 OrulEHbSLet7uFHm2A5V5LlYmQ8nRK - Idm51MHcsNagendraPas encore d'évaluation

- R13 Mechanics of Fluids ExamDocument2 pagesR13 Mechanics of Fluids ExamarunPas encore d'évaluation

- Scales: Construct Plain Scales and Solve ProblemsDocument66 pagesScales: Construct Plain Scales and Solve ProblemsBalaji BaluPas encore d'évaluation

- Annamacharya Institute of Technology and Sciences Cad IntroductionDocument14 pagesAnnamacharya Institute of Technology and Sciences Cad IntroductionBalaji BaluPas encore d'évaluation

- ME6602 NotesDocument30 pagesME6602 NotesmuthurajaPas encore d'évaluation

- CurvesstandardDocument34 pagesCurvesstandardBalaji BaluPas encore d'évaluation

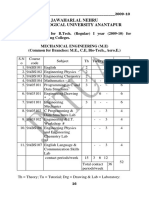

- JNTU Anantapur BTech Mechanical Engineering Course StructureDocument130 pagesJNTU Anantapur BTech Mechanical Engineering Course StructureBalaji BaluPas encore d'évaluation

- LayoutDocument1 pageLayoutBalaji BaluPas encore d'évaluation

- ClutchesDocument42 pagesClutchesBalaji BaluPas encore d'évaluation

- Assistant - Engineers - Model Question - Paper PDFDocument22 pagesAssistant - Engineers - Model Question - Paper PDFAnonymous jb8Rrf1gPas encore d'évaluation

- Source Publication List For Web of Science: Science Citation Index ExpandedDocument143 pagesSource Publication List For Web of Science: Science Citation Index ExpandedGarima GuptaPas encore d'évaluation

- Jawaharlal Nehru Technological University Anantapur Course Structure For Mechanical Engineering B. Tech Course (2015-16)Document15 pagesJawaharlal Nehru Technological University Anantapur Course Structure For Mechanical Engineering B. Tech Course (2015-16)Balaji BaluPas encore d'évaluation

- B.tech. - R09 - Mech Engg - Academic Regulations SyllabusDocument167 pagesB.tech. - R09 - Mech Engg - Academic Regulations SyllabusaerorockPas encore d'évaluation

- Evaluation Guidelines Tier II v0Document27 pagesEvaluation Guidelines Tier II v0HarminderSingh BindraPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Industrial Silos: Technical SheetDocument31 pagesIndustrial Silos: Technical Sheetred patriotPas encore d'évaluation

- Investigation and Analysis of Cold Shut Casting Defect ReductionDocument3 pagesInvestigation and Analysis of Cold Shut Casting Defect Reductionvivek1312Pas encore d'évaluation

- 20160316162112020Document2 pages20160316162112020ahmedPas encore d'évaluation

- LMC Tablosu-AirbusDocument1 pageLMC Tablosu-AirbusefilefilPas encore d'évaluation

- A Way To Deal With The Project Crashing Problem: Hamdjatou Kane Gilbert NkubiliDocument14 pagesA Way To Deal With The Project Crashing Problem: Hamdjatou Kane Gilbert Nkubilimangalam manjuPas encore d'évaluation

- Stacbloc BrochureDocument4 pagesStacbloc Brochuresathish77sPas encore d'évaluation

- Volvo Cars Sustainability Report 2013Document64 pagesVolvo Cars Sustainability Report 2013JM MANOJKUMARPas encore d'évaluation

- CA7 CommandsDocument9 pagesCA7 CommandsArvindUpadhyayPas encore d'évaluation

- JSW Steel Coated Products Test CertificatesDocument10 pagesJSW Steel Coated Products Test CertificatesBernice AkotoPas encore d'évaluation

- Section (1) : 1. With Respect To Loading Timber Cargo in Question A) Explain Under What Circumstances, Vessel Is Able To Load To Lumber Load LinesDocument6 pagesSection (1) : 1. With Respect To Loading Timber Cargo in Question A) Explain Under What Circumstances, Vessel Is Able To Load To Lumber Load Linescanigetaccess100% (1)

- Work at HeightDocument10 pagesWork at HeightShoaib RazzaqPas encore d'évaluation

- Planning of Rural Roads in IndiaDocument14 pagesPlanning of Rural Roads in IndiaSubin GeevarghesePas encore d'évaluation

- Complaint Service Report (Striker Note)Document16 pagesComplaint Service Report (Striker Note)Kheme VitoumetaPas encore d'évaluation

- Banner Buffalo BullDocument3 pagesBanner Buffalo Bullanon_579800775Pas encore d'évaluation

- Table Of: PPAP Package ForDocument64 pagesTable Of: PPAP Package Forrudy pumacahuaPas encore d'évaluation

- Presentation Automobile HistoryDocument17 pagesPresentation Automobile HistoryWaleed WasimPas encore d'évaluation

- ServiceManuals LG Washing WD1015FB WD-1015FB Service ManualDocument35 pagesServiceManuals LG Washing WD1015FB WD-1015FB Service ManualMicu Adrian DanutPas encore d'évaluation

- China Vaseline White Petroleum Jelly - Snow White Vaseline - China Vaseline White, Petroleum Jelly PDFDocument3 pagesChina Vaseline White Petroleum Jelly - Snow White Vaseline - China Vaseline White, Petroleum Jelly PDFIstianah Achy HaeruddinPas encore d'évaluation

- Hero MotocorpDocument11 pagesHero MotocorpHarshit GuptaPas encore d'évaluation

- SAP Landscape Design - V24Document47 pagesSAP Landscape Design - V24vishnu_kota58Pas encore d'évaluation

- MAX17077AETM 1tDocument1 pageMAX17077AETM 1tAlejandro clericoPas encore d'évaluation

- Abdul Rauf - Mechanical Engineer-Production ManagerDocument3 pagesAbdul Rauf - Mechanical Engineer-Production ManagercdeekyPas encore d'évaluation

- HUDA Policy Allowing Four BasementsDocument3 pagesHUDA Policy Allowing Four BasementsRahul JindalPas encore d'évaluation

- Guide To Stability Design Criteria For Metal Structures-6ed Zeiman 2010 1117pDocument1 117 pagesGuide To Stability Design Criteria For Metal Structures-6ed Zeiman 2010 1117pcgingenieros94% (31)

- Product Overview - LeuschDocument32 pagesProduct Overview - Leuschprihartono_diasPas encore d'évaluation

- Sample Interview Questions For Planning EngineersDocument16 pagesSample Interview Questions For Planning EngineersPooja PawarPas encore d'évaluation

- d59687gc10 Toc GLMFDocument14 pagesd59687gc10 Toc GLMFmahmoud_elassaPas encore d'évaluation

- Project Completion, Handover and Operations GuideDocument11 pagesProject Completion, Handover and Operations GuideJustine Sheinna SebleroPas encore d'évaluation

- StructuralSupportCat CA 105701Document156 pagesStructuralSupportCat CA 105701mansour14100% (1)

- A Comparison Between Silver Book and The Enaa Model FormDocument8 pagesA Comparison Between Silver Book and The Enaa Model FormMdms Payoe100% (1)