Académique Documents

Professionnel Documents

Culture Documents

FL - Aluminum Doors and Windows

Transféré par

Amro Ahmad AliTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

FL - Aluminum Doors and Windows

Transféré par

Amro Ahmad AliDroits d'auteur :

Formats disponibles

EHAF

085200

085200 ALUMINUM DOORS AND WINDOWS

- ALUMINUM DOORS AND WINDOWS

AL HITMI FOX HILLS RESIDENTIAL A37

Technical Specification

085200 - 1

085200 ALUMINUM DOORS AND WINDOWS

EHAF

SECTION 085200 ALUMINUM DOORS AND WINDOWS

PART 1 - GENERAL

1.1

RELATED DOCUMENTS

A.

1.2

Drawings, Contract Documents and other Division 01 Specification Sections, apply to this Section.

SUMMARY

A.

This Section includes Commercial Grade aluminum doors and windows of the performance class

indicated. Window types required include the following:

1.

2.

3.

4.

5.

1.3

DEFINITIONS

A.

Hinged emergency-access/egress windows are side-hinged units that swing out to provide emergency

exit.

B.

Performance class number, included as part of the window designation system, is the actual design

pressure in pascals used to determine structural test pressure and water test pressure.

1.

2.

1.4

Structural test pressure, wind load test, is equivalent to 150 percent of the design pressure.

Water-leakage-resistance test pressure is equivalent to 15 % of the design pressure with 2.86

Ibf/sq. ft. ( 137 Pa) as minimum .

PERFORMANCE REQUIREMENTS

A.

General: Provide aluminium windows engineered, fabricated, and installed to withstand normal

thermal movement, wind loading, and impact loading without failure, as demonstrated by testing

manufacturer's standard window assemblies representing types, grades, classes, and sizes required for

Project according to test methods indicated.

B.

Test Criteria: Testing shall be performed by a qualified independent testing agency based on the

following criteria:

1.

2.

1.5

Casement windows.

Horizontal-sliding windows.

Bottom & Top-hinged windows.

Fixed windows.

Hinged doors External Heavy Duty Aluminum Door .

Design wind velocity at Project site is 113 km/h.

Heights of window units above grade at window centerline are indicated on or can be

determined from the Drawings. Consult with the Engineer, if necessary, to confirm required

loading and test pressures.

SUBMITTALS

AL HITMI FOX HILLS RESIDENTIAL A37

Technical Specification

085200 - 2

085200 ALUMINUM DOORS AND WINDOWS

EHAF

A.

General: Submit each item in this Article according to the Conditions of the Contract and Division 1

Specification Sections.

B.

Product Data for each type of door and window required, including the following:

1.

2.

3.

4.

C.

Construction details and fabrication methods.

Profiles and dimensions of individual components.

Data on hardware, accessories, and finishes.

Recommendations for maintaining and cleaning exterior surfaces.

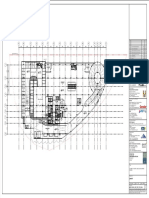

Shop Drawings showing fabrication and installation of each type of window required including

information not fully detailed in manufacturer's standard Product Data and the following:

1.

2.

3.

4.

5.

6.

7.

8.

9.

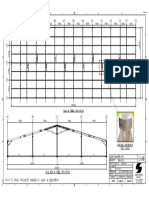

Layout and installation details, including anchors.

Elevations at 1:50 scale and typical window and door unit elevations at 1:20 scale.

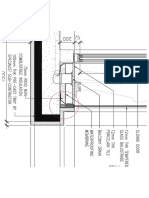

Full-size section details of typical composite members, including reinforcement and stiffeners.

Location of weep holes.

Panning details.

Hardware, including operators.

Window cleaning provisions.

Glazing details.

Accessories.

D.

Samples for initial color selection on 300-mm- long sections of window/door members. Where

finishes involve normal color variations, include Sample sets showing the full range of variations

expected.

E.

Samples for Verification: The Engineer reserves the right to require additional samples that show

fabrication techniques, workmanship, and design of hardware and accessories.

F.

Test reports from a qualified independent testing agency indicating that each type, grade, and size of

window unit complies with performance requirements indicated. Test results based on use of downsized test units will not be accepted.

1.6

QUALITY ASSURANCE

A.

Installer Qualifications: Engage an experienced ISO Certified Installer who has completed

installation of aluminium windows and doors similar in material, design, and extent to those required

for this Project and with a record of successful in-service performance.

B.

Single-Source Responsibility: Obtain aluminium windows and doors from one source and by a

single manufacturer.

C.

Mockups: Prior to installing aluminium windows, construct mockups for each form of construction

and finish required to verify selections made under Sample submittals and to demonstrate aesthetic

effects as well as qualities of materials and execution. Build mockups to comply with the following

requirements, using materials indicated for final unit of Work.

1.

2.

3.

Locate mockups on-site in the location and of the size indicated or, if not indicated, as directed

by Engineer.

Notify Engineer one week in advance of the dates and times when mockups will be

constructed.

Demonstrate the proposed range of aesthetic effects and workmanship.

AL HITMI FOX HILLS RESIDENTIAL A37

Technical Specification

085200 - 3

085200 ALUMINUM DOORS AND WINDOWS

EHAF

4.

5.

Obtain Engineer's approval of mockups before start of final unit of Work.

Retain and maintain mockups during construction in an undisturbed condition as a standard

for judging the completed Work.

a.

D.

1.7

Approved mockups in an undisturbed condition at the time of Substantial Completion

may become part of the completed Work.

Product Options: The Drawings indicate sizes, profiles, dimensional requirements, and aesthetic

effects of aluminium windows and doors and are based on the specific types and models indicated.

Other aluminium manufacturers whose products have equal performance characteristics may be

considered provided deviations in size, profile, and dimensions are minor and do not alter the

aesthetic effect. Refer to Division 1 Section "Substitutions."

PROJECT CONDITIONS

A.

Field Measurements: Check openings by field measurements before fabrication and show recorded

measurements on Shop Drawings. Coordinate fabrication schedule with construction progress to

avoid delaying the Work.

1.

1.8

Where field measurements cannot be made without delaying the Work, guarantee opening

dimensions and proceed with fabricating aluminium windows without field measurements.

Coordinate wall construction to ensure that actual opening dimensions correspond to

guaranteed dimensions.

WARRANTY

A.

General Warranty: The special warranty specified in this Article shall not deprive the Employer of

other rights the Employer may have under other provisions of the Contract Documents and shall be in

addition to, and run concurrent with, other warranties made by the Contractor under requirements of

the Contract Documents.

B.

Special Warranty: Submit a written warranty signed by aluminum window and door manufacturer

agreeing to repair or replace components that fail in materials or workmanship within the specified

warranty period. Failures include, but are not limited to, the following:

1.

2.

3.

C.

Structural failures including excessive deflection, water leakage, air infiltration, or

condensation.

Faulty operation of sash and hardware.

Deterioration of metals, metal finishes, and other materials beyond normal weathering.

Warranty Period: 3 years after date of issuing the completion certificate of all works.

PART 2 - PRODUCTS

2.1

MANUFACTURERS

A.

Subject to compliance with requirements, provide products by one of the manufacturers included in

Annexure B, VENDORS LIST of Volume One Tender Particulars of the Tender Documents..

AL HITMI FOX HILLS RESIDENTIAL A37

Technical Specification

085200 - 4

085200 ALUMINUM DOORS AND WINDOWS

EHAF

2.2

MATERIALS

A.

Aluminum Extrusions: Aluminum Extrusions should be from A6063 aluminum alloy with T5

Temper extruded in compliance with BS 1474 , corrosion resistance, and application of required

finish, but not less than 150-MPa ultimate tensile strength and the thickness to be between 1.5mm to

1.8mm at any location for main frame and sash members.

B.

Fasteners: Provide aluminum, nonmagnetic stainless steel, epoxy adhesive, or other materials

warranted by manufacturer to be noncorrosive and compatible with aluminum window members,

trim, hardware, anchors, and other components of window units.

1.

2.

C.

Anchors, Clips, and Window Accessories: Fabricate anchors, clips, and window accessories of

aluminum, nonmagnetic stainless steel, or hot-dip zinc-coated steel or iron complying with

requirements of ASTM B 633; provide sufficient strength to withstand design pressure indicated.

D.

Compression-Type Glazing Strips and Weatherstripping: Unless otherwise indicated, and at

manufacturer's option, provide compressible stripping for glazing and weatherstripping such as

molded EPDM or neoprene gaskets complying with ASTM D 2000 Designation 2BC415 to 3BC620,

or molded PVC gaskets complying with ASTM D 2287, or molded expanded EPDM or neoprene

gaskets complying with ASTM C 509, Grade 4.

E.

Sliding-Type Weatherstripping: Provide woven-pile weatherstripping of wool, polypropylene, or

nylon pile and resin-impregnated backing fabric. Comply with AAMA 701.2.

1.

2.3

Reinforcement: Where fasteners screw anchor into aluminum less than 3.2 mm thick,

reinforce interior with aluminum or nonmagnetic stainless steel to receive screw threads or

provide standard, noncorrosive, pressed-in, splined grommet nuts.

Exposed Fasteners: Except where unavoidable for application of hardware, do not use

exposed fasteners. For application of hardware, use fasteners that match finish of member or

hardware being fastened, as appropriate.

Provide stripping with integral centerline barrier fin of semirigid plastic sheet of

polypropylene.

F.

Sealant: For sealants required within fabricated window units, provide type recommended by

manufacturer for joint size and movement. Sealant shall remain permanently elastic, nonshrinking,

and nonmigrating. Comply with Division 7 Section "Joint Sealants" of these Specifications for

selection and installation of sealants.

G.

Wire-Fabric Insect Screen: 1.1-by-1.1-mm, 1.1-by-1.3-mm, or 1.1-by-1.5-mm mesh of 0.3-mmdiameter, coated aluminum wire, complying with FS RR-W-365, Type VII.

External Heavy Duty Aluminum Doors

1.

2.

Unless mentioned elsewhere provide this door for all External Aluminum Doors

Heavy weight fixed and hinged systems profiles , 2mm aluminum thickness, 60 mm

frame depth , designed to accept up to 45mm infill .

3.

All sections and profiles are made of extruded aluminum alloys free from defects

impairing strength or appearance.

4.

Aluminum alloy is 6063 - T5 which has an ultimate tensile strength of 1500 kg/cm2 and

hardness of 70 kg/cm standard.

AL HITMI FOX HILLS RESIDENTIAL A37

Technical Specification

085200 - 5

085200 ALUMINUM DOORS AND WINDOWS

EHAF

5.

Fabrication and Assembly:

a.

b.

c.

d.

e.

f.

All units are shop fabricated and shipped for field erection

Stainless steel screws are used for hardware fixation.

Frame and sashes corner construction are mechanically sealed and clamped by means

of heavy extruded aluminum angles.

A drainage system is provided for rain and cleaning water.

All rubber gasket are made of vulcanized pure neoprene ( E.P.D.M).

Door is provided with three gaskets to prevent air, dust infiltration and help in sound

insulation too, These gaskets are :

1)

2)

3)

g.

6.

Central gasket .

Lateral gasket .

Glass beading gasket .

Use silicone to seal the glass into the sash from the outside and as the Manufacturers

written Instructions.

Glazing: Insulating-Laminating Glass

a.

Glass Type : Clear, insulating laminated glass.

1)

2)

3)

4)

5)

Overall Unit Thickness: 24mm. (6 + 12 + 6).

Thickness of Outdoor Lite: 6.0 mm.

Outdoor Lite: Clear fully tempered float glass.

Interspace Content: Air.

Indoor Lite: Clear laminated glass with two plies of fully tempered float glass.

a)

b)

6)

Physical properties:

a)

7.

8.

Class substrate: clear.

Accessories : Manufacturers standard

Door Installation : Heavy weight aluminum frames, and will be fixed as follow :

a.

9.

Thickness of Each Glass Ply: 3.0 mm.

Interlayer Thickness: 0.76 mm.

Fixation using steel sub frame with max. dimensions of (20*40) mm .

Door Performance Requirements:

a.

b.

Comply with the BS 6375 Part 1

Air Permeability : 1 cubic m/hr per meter length of visible perimeter of glass at a

pressure difference of 200 Pa (N/M2).

c.

d.

Water tightness: No water leakage at a testing pressure of 550 Pa (N/M2).

Deflection : Members retaining an insulating glass unit shall not deflect more

than L/175 over length or height of the glass unit when submitted to the

design wind pressure and allowable factor of safety.

AL HITMI FOX HILLS RESIDENTIAL A37

Technical Specification

085200 - 6

085200 ALUMINUM DOORS AND WINDOWS

EHAF

2.4

HARDWARE, GENERAL

A.

General: Unless otherwise indicated, provide manufacturer's standard hardware fabricated from

aluminum, stainless steel, or other corrosion-resistant material compatible with aluminum and of

sufficient strength to perform the function for which it is intended.

Qty

Hardware Set for Heavy

Hardware set for Heavy

Duty Aluminum Door for

Duty

Aluminum Doors

the Grooms Building

Door

Type

Location

ALUM

DR

Service Door

Main entrance Door

Qty

Unit

6

1

1

1

ea

Pair

ea

ea

Item

Item Code

Description

Mfr.

Finish

B22- 3 parts

2150/300mm

2183

952

3 part hinge with eccentric pin, for aluminium doors

Aluminium flush bolt - 300mm long including cover plate 2151 and rod 2158

Aluminium dust proof strike

Narrow stile Mortise LATCH and DEADBOLT, 8mm spindle follower, 92mm center

distance, for Euro profile cylinder, 24mm square forend, 35mm backset, 20mm

single throw bolt projection, Conforms to DIN 18250-2, Class 3. with strike plate

Dorma

Giesse

Giesse

Dorma

RAL

Alum

SCP

SSS

set Lever Handle

Premium 8830A/

6611/ 6676

Dorma

SSS

ea

Cylinder

430

Dorma

SNP

ea

Door Closer

TS83/PA/HO

Dorma

Silver

2

1

ea

ea

Door stop

Threshold

TZ5000

896S

Dorma

NGP

SSS

Mill

Gasketting

Premium spring assisted cranked Lever handle, flat curved design, with

31x69x9mm rectangular roses and escutcheons, back to back fixing screws,click

&go fast fixing modular mechanism, maintanace free sleeve bearing, compliant

with EN -1906 category 4 and DN18273, non handed

Europrofile Cylinder 35/35mm with knob thumb turn one side, 6 pin tumblers under

GMK

Adjustable power EN 3-6, Conforms to EN 1154, CE Marked, Scissor arm, Rack

and pinion, Full cover, Adjustable Closing and Latching speeds. With Back check

as a standard feature, Push side bracket installatioN, Hold open arm.[NOT FIRE

RATED]

Floor mounted door stop stainless steel, 65mm dia with hard rubber insert.

Bumper Seal Threshold 5" x 1/2", 0.105" thick material,, ADA complaint, with

silicone(S) bumper seal , Acoustical tested, UL Listed for fire rating, Positive

pressure, Air infiltration tested, ANSI/BHMA certified, length as per Door width.

Jamb and header seals by Aluminum door Supplier

Hinges

Flush Bolt

D.P.Strike

Lock (Narrow

Stile)

2.5

ACCESSORIES

A.

General: Provide manufacturer's standard accessories that comply with indicated standards.

B.

Insect Screens: Provide insect screens for each operable exterior sash or ventilator. Locate screens

on inside or outside of window sash or ventilator, depending on window type. Design windows and

hardware to accommodate screens in a tight-fitting, removable arrangement, with a minimum of

exposed fasteners and latches.

1.

C.

Weatherstripping: Provide sliding-type weatherstripping where sash rails slide horizontally or

vertically along unit frame. Provide compression-type weatherstripping at perimeter of each

operating sash where sliding type is inappropriate.

1.

D.

2.6

Screen Frames: Fabricate frames of tubular-shaped, extruded- or formed-aluminum members

of 1-mm- minimum wall thickness, with mitered or coped joints and concealed mechanical

fasteners. Finish frames to match window units.

Provide weatherstripping locked into extruded grooves in sash.

Louvre: Provide manufacturer integrated louvre where shown on drawings.

FABRICATION

AL HITMI FOX HILLS RESIDENTIAL A37

Technical Specification

085200 - 7

085200 ALUMINUM DOORS AND WINDOWS

EHAF

A.

General: Fabricate aluminium window units to comply with indicated standards. Include a complete

system for assembly of components and anchorage of window units.

1.

2.

B.

2.7

Provide units that are reglazable without dismantling sash or ventilator framing.

Prepare window sash or ventilators for glazing, except where preglazing at the factory is

indicated.

Preglazed Fabrication: Preglaze window units at the factory where possible and practical for

applications indicated. Comply with glass and glazing requirements of Division 8 Section "Glazing"

of these Specifications and AAMA 101.

FINISHES

A.

Polyester Powder Coating System: Manufacturer's standard coat, thermocured system color coat

containing not less than 60 microns(between 60 80 microns); complying with BS 6496.

1.

Color and Gloss: As selected by Engineer from manufacturer's full range of choices for color

and gloss.

PART 3 - EXECUTION

3.1

INSPECTION

A.

Inspect openings before installation. Verify that rough or masonry opening is correct and sill plate is

level.

1.

2.

3.

3.2

Masonry surfaces shall be visibly dry and free of excess mortar, sand, and other construction

debris.

Wood frame walls shall be dry, clean, sound, well nailed, free of voids, and without offsets at

joints. Ensure nail heads are driven flush with surfaces in opening and within 75 mm of

opening.

Metal surfaces shall be dry; clean; free of grease, oil, dirt, rust and corrosion, and welding

slag; without sharp edges or offsets at joints.

INSTALLATION

A.

Comply with manufacturer's specifications and recommendations for installing window units,

hardware, operators, and other components of the Work.

B.

Set window and doors units plumb, level, and true to line, without warp or rack of frames or sash.

Provide proper support and anchor securely in place.

1.

C.

Separate aluminum and other corrodible surfaces from sources of corrosion or electrolytic

action at points of contact with other materials by complying with requirements specified

under "Dissimilar Materials" Paragraph in appendix to AAMA 101.

Set sill members and other members in a bed of sealant or with joint fillers or gaskets, as shown on

Shop Drawings, to provide weathertight construction. Refer to Division 7 Section "Joint Sealants"

for compounds, fillers, and gaskets to be installed concurrently with window units. Coordinate

installation with wall flashings and other components of the Work.

AL HITMI FOX HILLS RESIDENTIAL A37

Technical Specification

085200 - 8

085200 ALUMINUM DOORS AND WINDOWS

EHAF

1.

3.3

Sealants, joint fillers, and gaskets to be installed after installation of window units are

specified in another Division 7 Section.

FIELD QUALITY CONTROL

A.

Conduct on-site tests for air and water infiltration with manufacturer's representative present. The

Engineer will select units to be tested. Tests not meeting specified requirements and units having

similar deficiencies shall be corrected at no cost to the Employer. Testing shall be performed by a

qualified independent testing agency selected by the Engineer.

1.

2.

3.4

Air-Infiltration Tests: Conduct tests according to requirements of ASTM E 783. Allowable

infiltration shall not exceed 1.5 times the amount indicated.

Water-Resistance Tests: Conduct tests according to requirements of ASTM E 1105. No

water leakage is permitted.

ADJUSTING

A.

3.5

Adjust operating sash and hardware to provide a tight fit at contact points and at weatherstripping for

smooth operation and a weathertight closure.

CLEANING

A.

Clean aluminum surfaces promptly after installing windows. Exercise care to avoid damage to

protective coatings and finishes. Remove excess glazing and sealant compounds, dirt, and other

substances. Lubricate hardware and other moving parts.

B.

Clean glass of preglazed units promptly after installing windows. Comply with requirements of

Division 8 Section "Glazing" for cleaning and maintenance.

3.6

PROTECTION

A.

Provide final protection and maintain conditions, in a manner acceptable to aluminum window

manufacturer, that ensure window units are without damage or deterioration at the time of Substantial

Completion.

END OF SECTION 085200

AL HITMI FOX HILLS RESIDENTIAL A37

Technical Specification

085200 - 9

Vous aimerez peut-être aussi

- S Door HardwareDocument15 pagesS Door Hardwaresandia_docsPas encore d'évaluation

- Aluminium Curtain WalDocument28 pagesAluminium Curtain WaljatinPas encore d'évaluation

- Specifying Windows and Doors Using Performance Standards PDFDocument78 pagesSpecifying Windows and Doors Using Performance Standards PDFbatteekh100% (1)

- 6 - SAP - PP Level I TrainingDocument45 pages6 - SAP - PP Level I TrainingkalykumPas encore d'évaluation

- External CladdingDocument15 pagesExternal CladdingKamble RaviPas encore d'évaluation

- ACP Standards Saudi ArabiaDocument29 pagesACP Standards Saudi ArabiaRoland James Arimado50% (2)

- Proposed 4-Door Apartment BuildingDocument3 pagesProposed 4-Door Apartment BuildingLimar Setatra100% (1)

- Astm E547-00Document5 pagesAstm E547-00ELENA NAVAS100% (1)

- A1-60 Stone CladdingDocument35 pagesA1-60 Stone CladdingZYWPas encore d'évaluation

- Aluminum CladdingDocument21 pagesAluminum CladdingLouie Jazper Jho MolinaPas encore d'évaluation

- The Effect of Changes of AAMA 502 StandardDocument6 pagesThe Effect of Changes of AAMA 502 Standardy2karein100% (1)

- Water Testing For GlazingDocument32 pagesWater Testing For GlazingNaren VmdPas encore d'évaluation

- Aluminum WindowsDocument6 pagesAluminum Windowsjack.simpson.changPas encore d'évaluation

- Doors and Hardware Comments and RectificationDocument6 pagesDoors and Hardware Comments and RectificationAhmed KhalifaPas encore d'évaluation

- Astm C 841-03 Standard Specifications For The Installation PDFDocument10 pagesAstm C 841-03 Standard Specifications For The Installation PDFCharwin PicaoPas encore d'évaluation

- Fire Resistance of Gypsum Board Wall AssembliesDocument4 pagesFire Resistance of Gypsum Board Wall AssembliesArchitectPas encore d'évaluation

- Itp Lot 28Document94 pagesItp Lot 28Wahyu Rohmad DiantoPas encore d'évaluation

- Doors and Frames Guide Specifications 1601107Document6 pagesDoors and Frames Guide Specifications 1601107Marvin SironPas encore d'évaluation

- Petroleum Refining Notes 1Document5 pagesPetroleum Refining Notes 1api-304149645Pas encore d'évaluation

- Aci 306.1Document5 pagesAci 306.1safak kahramanPas encore d'évaluation

- Ansi Apa PRG 320 2018Document46 pagesAnsi Apa PRG 320 2018civiliiiPas encore d'évaluation

- ScrewsDocument6 pagesScrewsmurdicksPas encore d'évaluation

- Large Moment ExampleDocument5 pagesLarge Moment ExampleAmro Ahmad AliPas encore d'évaluation

- Aluminum WindowsDocument14 pagesAluminum Windowshayat49000Pas encore d'évaluation

- Test Method for Water Penetration of Metal Roof PanelsDocument2 pagesTest Method for Water Penetration of Metal Roof PanelsQadir MohideenPas encore d'évaluation

- Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Uniform Static Air Pressure DifferenceDocument5 pagesWater Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Uniform Static Air Pressure DifferenceBUTCH FAJARDOPas encore d'évaluation

- 04AC - OBC Concepts and Code Analysis - Part 2Document158 pages04AC - OBC Concepts and Code Analysis - Part 2anas jbain100% (1)

- Facade-Alumimum & Glazing Works Scope-Technical SpecificationsDocument5 pagesFacade-Alumimum & Glazing Works Scope-Technical SpecificationsHasnain SafdarPas encore d'évaluation

- Submital & Method Statement - Loading BracketsDocument1 pageSubmital & Method Statement - Loading BracketsvtalexPas encore d'évaluation

- Anchorage Pullout Strength in Granite Design and Fabrication Influences by David G. West and Marc HeinleinDocument14 pagesAnchorage Pullout Strength in Granite Design and Fabrication Influences by David G. West and Marc Heinleingulilero_yoPas encore d'évaluation

- File 40 - Doors and WindowsDocument44 pagesFile 40 - Doors and WindowsdvduronPas encore d'évaluation

- AAMA 501.2 - Hose Nozzle Water Spray TestingDocument4 pagesAAMA 501.2 - Hose Nozzle Water Spray TestingNoz KiPas encore d'évaluation

- Technical Training Guide LinconDocument48 pagesTechnical Training Guide LinconiwantfreePas encore d'évaluation

- SDI - 130 - Standard Steel Doors and FramesDocument4 pagesSDI - 130 - Standard Steel Doors and FramesIsang BertingPas encore d'évaluation

- CAMERON France S.A.S: Front SheetDocument27 pagesCAMERON France S.A.S: Front SheetkrishnsgkPas encore d'évaluation

- A Study On Supply Chain Excellence Future Scenario in Profesional CourierDocument97 pagesA Study On Supply Chain Excellence Future Scenario in Profesional CourierananthakumarPas encore d'évaluation

- Glass Standards (Draft) PDFDocument5 pagesGlass Standards (Draft) PDFCristian TofanPas encore d'évaluation

- Exterior Wall TestingDocument32 pagesExterior Wall Testingtkm20040% (1)

- The Toyota Way 1Document32 pagesThe Toyota Way 1kumamech100% (4)

- 5120544-Spo-A-5906-0 (T)Document1 page5120544-Spo-A-5906-0 (T)Amro Ahmad AliPas encore d'évaluation

- Aluminum SpecsDocument8 pagesAluminum SpecsDinesh RathorPas encore d'évaluation

- NFPA 285 Fire Testing For Exterior Walls: Code Requirements and Design ChallengesDocument1 pageNFPA 285 Fire Testing For Exterior Walls: Code Requirements and Design ChallengesaialosangelesPas encore d'évaluation

- Bhma - CPD Feb. 2013Document468 pagesBhma - CPD Feb. 2013civileng_girlPas encore d'évaluation

- System Data SheetsDocument59 pagesSystem Data SheetsIng Admir MatoshiPas encore d'évaluation

- Seismic Technical Guide Seismic Expansion Joints en SC2496Document15 pagesSeismic Technical Guide Seismic Expansion Joints en SC2496carrimonn11Pas encore d'évaluation

- Finishes Section Provides Details on Plaster, Tiles, Stones and MoreDocument54 pagesFinishes Section Provides Details on Plaster, Tiles, Stones and MoresothilingamnPas encore d'évaluation

- National Gypsum Construction GuideDocument164 pagesNational Gypsum Construction Guidelglfan42Pas encore d'évaluation

- ICC-ES Legacy Report NER-405 (James Hardie Building Products, Inc.)Document35 pagesICC-ES Legacy Report NER-405 (James Hardie Building Products, Inc.)Karma Pema DorjePas encore d'évaluation

- Check List For Doors and WindowsDocument3 pagesCheck List For Doors and WindowsMuneer AhmedPas encore d'évaluation

- Architectural Wood Casework SpecificationDocument11 pagesArchitectural Wood Casework SpecificationGilang PratamaPas encore d'évaluation

- Astm C-1178-1 PDFDocument3 pagesAstm C-1178-1 PDFibrahim0% (1)

- ASTM E283-1991 (04-2012) - Standard Test Method For Determinig The Rate of Air LeakageDocument7 pagesASTM E283-1991 (04-2012) - Standard Test Method For Determinig The Rate of Air LeakageArnaud NetoPas encore d'évaluation

- A156.4 - 2008 Door Control-Closers Hardware HighlightsDocument1 pageA156.4 - 2008 Door Control-Closers Hardware HighlightsteramodPas encore d'évaluation

- Semi Unitized SystemDocument11 pagesSemi Unitized SystemDEEKSHI MPas encore d'évaluation

- Barat Ghar - GF Plan PDFDocument1 pageBarat Ghar - GF Plan PDFRAJ KUMAR SAGARPas encore d'évaluation

- Designs CatalogDocument77 pagesDesigns CatalogGen MendozaPas encore d'évaluation

- Assessment Task 1: Activity Acts & Building Code of Australia Relevant AustralianDocument14 pagesAssessment Task 1: Activity Acts & Building Code of Australia Relevant AustralianrishiPas encore d'évaluation

- Vermont Underground Storage Tank Installation ChecklistDocument7 pagesVermont Underground Storage Tank Installation ChecklistmhillebrennerPas encore d'évaluation

- Kinlong-2021Door Control Hardware Typical Product Catalogue (Thuy Luc)Document154 pagesKinlong-2021Door Control Hardware Typical Product Catalogue (Thuy Luc)vantanbkdnPas encore d'évaluation

- Door Sealing Systems: Product CatalogueDocument184 pagesDoor Sealing Systems: Product CatalogueFábio AndréPas encore d'évaluation

- AS 2818-1993 Guide To Swimming Pool Safety PDFDocument8 pagesAS 2818-1993 Guide To Swimming Pool Safety PDFSAI Global - APACPas encore d'évaluation

- Bathroom 3Document4 pagesBathroom 3mohdshahrircheabdulPas encore d'évaluation

- Window, Door and Skylights-Residential, Sold in Canada-ENERGY STAR Technical SpecificationsDocument53 pagesWindow, Door and Skylights-Residential, Sold in Canada-ENERGY STAR Technical SpecificationsBaoNguyenPas encore d'évaluation

- TDS005-Grade 2 and ASTM A307 BoltingDocument2 pagesTDS005-Grade 2 and ASTM A307 BoltingKrish DoodnauthPas encore d'évaluation

- Fire Resistant Assemblies Brochure en Sa100 CanDocument76 pagesFire Resistant Assemblies Brochure en Sa100 CanBach DinhPas encore d'évaluation

- Ea230 - Astm E2357 - E331Document11 pagesEa230 - Astm E2357 - E331Deco DluxePas encore d'évaluation

- 01-Architectural Specs - 04.19.2018Document68 pages01-Architectural Specs - 04.19.2018Lorena TanPas encore d'évaluation

- I-501.11 (c00) XD Penthouse - Lower Floor - Power-Data - Part BDocument1 pageI-501.11 (c00) XD Penthouse - Lower Floor - Power-Data - Part BAmro Ahmad AliPas encore d'évaluation

- A 308 Service Block Sections Details1578487928531Document1 pageA 308 Service Block Sections Details1578487928531techPas encore d'évaluation

- A 204 Elevation d1578487924094Document1 pageA 204 Elevation d1578487924094Amro Ahmad AliPas encore d'évaluation

- A 503 Window Schedule1699537950122Document1 pageA 503 Window Schedule1699537950122Amro Ahmad AliPas encore d'évaluation

- A 204 Elevation d1578487924094Document1 pageA 204 Elevation d1578487924094Amro Ahmad AliPas encore d'évaluation

- I-501.17 (c00) XD Penthouse - Upper Floor RCP - Part ADocument1 pageI-501.17 (c00) XD Penthouse - Upper Floor RCP - Part AAmro Ahmad AliPas encore d'évaluation

- Anchor Analysis - HorizontalDocument7 pagesAnchor Analysis - HorizontalAmro Ahmad AliPas encore d'évaluation

- Mathcad - Inputs Design As Per DEWADocument3 pagesMathcad - Inputs Design As Per DEWAAmro Ahmad AliPas encore d'évaluation

- Work in Progress: Dubai Creek ResidencesDocument1 pageWork in Progress: Dubai Creek ResidencesAmro Ahmad AliPas encore d'évaluation

- Podium Section ModelDocument1 pagePodium Section ModelAmro Ahmad AliPas encore d'évaluation

- M-GW-03-51dB DOOR-proposal Model PDFDocument1 pageM-GW-03-51dB DOOR-proposal Model PDFAmro Ahmad AliPas encore d'évaluation

- Updated Schematic Design Rev10Document1 pageUpdated Schematic Design Rev10Amro Ahmad AliPas encore d'évaluation

- Aed130164 00 DD SD 0404 CDocument1 pageAed130164 00 DD SD 0404 CAmro Ahmad AliPas encore d'évaluation

- Aed130164 00 DD SD 0427 CDocument1 pageAed130164 00 DD SD 0427 CAmro Ahmad AliPas encore d'évaluation

- Aed130164 00 DD SD 0403 CDocument1 pageAed130164 00 DD SD 0403 CAmro Ahmad AliPas encore d'évaluation

- UuhtgDocument1 pageUuhtgAmro Ahmad AliPas encore d'évaluation

- Ar 13 SectionDocument1 pageAr 13 SectionAmro Ahmad AliPas encore d'évaluation

- Work in Progress: Dubai Creek ResidencesDocument1 pageWork in Progress: Dubai Creek ResidencesAmro Ahmad AliPas encore d'évaluation

- 600 Glass Balustrade ARCH DET 3-2-2016Document1 page600 Glass Balustrade ARCH DET 3-2-2016Amro Ahmad AliPas encore d'évaluation

- Plan & ElevationDocument1 pagePlan & ElevationAmro Ahmad AliPas encore d'évaluation

- Bill No.3Document14 pagesBill No.3Amro Ahmad AliPas encore d'évaluation

- Plate MatDocument12 pagesPlate MatPrantik Adhar SamantaPas encore d'évaluation

- Eff AreaDocument1 pageEff AreaAmro Ahmad AliPas encore d'évaluation

- M GW 03 51dB DOOR Proposal ModelDocument1 pageM GW 03 51dB DOOR Proposal ModelAmro Ahmad AliPas encore d'évaluation

- Grid & Detail ModelDocument1 pageGrid & Detail ModelAmro Ahmad AliPas encore d'évaluation

- KWT NG 01 03 00Document1 pageKWT NG 01 03 00Amro Ahmad AliPas encore d'évaluation

- Ar-39 Wall SecDocument1 pageAr-39 Wall SecAmro Ahmad AliPas encore d'évaluation

- Metallographic Sample Preparation and Microstructure ObservationDocument11 pagesMetallographic Sample Preparation and Microstructure Observationafnanhanany50% (2)

- Pusher CentrifugeDocument4 pagesPusher Centrifugeberkay100% (1)

- F Grind AH - Surface Grinder MachineDocument10 pagesF Grind AH - Surface Grinder MachineKaast Machine ToolsPas encore d'évaluation

- Pengenalan Teknik MesinDocument21 pagesPengenalan Teknik MesinReinaldy MaslimPas encore d'évaluation

- Manguera de Poliester 5elemDocument2 pagesManguera de Poliester 5elemCesar RomeroPas encore d'évaluation

- Ppe Unit 2Document25 pagesPpe Unit 2rp0212Pas encore d'évaluation

- Inter Shield 300 PICDocument2 pagesInter Shield 300 PICRifqi Fajri PrayudiPas encore d'évaluation

- Textile Printing: Sri Lanka Institute of Texte & ApparelDocument40 pagesTextile Printing: Sri Lanka Institute of Texte & ApparelAjith SatyapalaPas encore d'évaluation

- Flexible ElectronicsDocument21 pagesFlexible ElectronicsNeeraj JawadwarPas encore d'évaluation

- ME8352-Manufacturing Technology - I (MT-I) With QBDocument91 pagesME8352-Manufacturing Technology - I (MT-I) With QBMohana KrishnanPas encore d'évaluation

- Design and Fabrication of Apple Peeler GreenEngineeringDocument5 pagesDesign and Fabrication of Apple Peeler GreenEngineeringInternational Journal of Innovative Science and Research Technology100% (1)

- Jaycocrete p6JDocument3 pagesJaycocrete p6JVirah Sammy ChandraPas encore d'évaluation

- Steel NumbersDocument3 pagesSteel NumbersAhmadiBinAhmadPas encore d'évaluation

- Overview of Construction IndustryDocument39 pagesOverview of Construction IndustryHariz AkhmalPas encore d'évaluation

- Scenport Constructions Company ProfileDocument12 pagesScenport Constructions Company ProfileWaqas AbroPas encore d'évaluation

- Research On Effect of Beijing Post-Olympic Sports Industry To China's Economic DevelopmentDocument6 pagesResearch On Effect of Beijing Post-Olympic Sports Industry To China's Economic DevelopmentAlexandru ReleaPas encore d'évaluation

- Halene P Technical Data Sheet for Polypropylene Homopolymer F110Document1 pageHalene P Technical Data Sheet for Polypropylene Homopolymer F110Dharmendrasinh ZalaPas encore d'évaluation

- PT Teknocal Energi Bersinar Company ProfileDocument3 pagesPT Teknocal Energi Bersinar Company ProfileJamal LamajPas encore d'évaluation

- CATIA V5 Composites Part DesignDocument1 pageCATIA V5 Composites Part DesignZahin RahmanPas encore d'évaluation

- Straight Talk With Karen Scrivener On Cements, CO2 and Sustainable DevelopmentDocument4 pagesStraight Talk With Karen Scrivener On Cements, CO2 and Sustainable DevelopmentnamazuPas encore d'évaluation

- Effect of Tempering On The Microstructure and Mechanical Properties of Resistance of Spot Welded DP 980 SteelDocument6 pagesEffect of Tempering On The Microstructure and Mechanical Properties of Resistance of Spot Welded DP 980 SteelShameekaPas encore d'évaluation

- Saravanan KDocument13 pagesSaravanan KDeiva SigamaniPas encore d'évaluation

- A32Document2 pagesA32Ivan GarzonPas encore d'évaluation

- Taig Lathe ManualDocument12 pagesTaig Lathe Manualpeter smithPas encore d'évaluation