Académique Documents

Professionnel Documents

Culture Documents

Monitoring and Measurement of Qms

Transféré par

amoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Monitoring and Measurement of Qms

Transféré par

amoDroits d'auteur :

Formats disponibles

MONITORING AND MEASUREMENT OF QMS

M/s SADEKAR ENVIRO ENGINEERS PVT. LTD.

Doc. No.

: SEE/QMS

22

Clauses:- ISO : 8.2 /NABET :

-Pages

: 1 of 2

TITLE

I.

QUALITY

MANAGEMENT

SYSTEM MANUAL

Revision No.

: 03

Date of Rev.

: 28.04.201

4

: Jan 2017

Next Rev.

Date

: MONITORING AND MEASUREMENT OF QMS

PURPOSE

To establish & document a process for monitoring & measurement of total

QMS including products /services offered to customer.

II.

SCOPE:

All functions of the organization including EIA /ECM Report, Project,

contractual monitoring [and related] services, Laboratory activities

III. RESPONOSIBILITY: Director, MR, DMR & other concerned HODs.

IV. PROCEDURE:

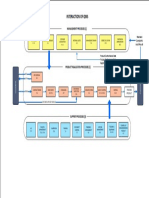

Process: The following methods are employed to measure the suitability of

QMS functions;

1. Customer feedback [refer customer Feed back on page ----- of

-------,SEE?QMS-17 ] has been mentioned in customer related process.

2. Internal Audit

3.MOM with authority dissatisfaction including NCs are used as tool

4.Project Monitoring Report

Impact on conformity as well as nonconformity of QMS are discussed

in MRM or any another forum by authorized persons.

Nonconformities are eliminated by employing CAPA as mentioned in

CAPA Chapter.

Product/Services: As given below :

Sr.

No

.

Product /

service

EIA

studies

Brief Procedure

Checked for

Draft EIA report submitted

to Client & SPCB and Final

EIA report submitted to

SEAC

/SEIAA

for

environmental clearance of

Complete & correct

report using ToR &

required

specification.

Releasin

g

authority

EC

the project are checked for

completeness

&

correctness using ToR &

required specification.

Project

Design,

erection

&

commissioning of ETP /STP

plant

suitable

for

processing waste [domestic

and/or process] water of

customer

using

agreed

design & handover to

customer after successful

test run.

Environme a> Consent application to

ntal

specified authority,

Complianc b> Submission of Form I,

e

IV, V and six monthly

Manageme compliance to specified

nt

authority,

c>

Operation

&

maintenance of ETP plant

Analysis of

samples

for

environme

ntal

parameter

s

V.

As mentioned in QMS

flowcharts of in

QMS------- using authorized

documented procedures or

any

other

suitable

standard. It is to be

ensured

that

only

calibrated equipments are

to

be

used

wherever

required

Erection as per P &

ID

diagram

and

successful validation

report

for

commissioning.

Test Results as per

purchase order

Project

HOD

a>

&

b>Correctness of filled

forms

and

avail

ability

of

all

supporting

documents

as

mentioned in QMS

flowcharts of ECM in

QMS------c>

Compliance

report.

Compliane

of

documented

procedure

&

standards including

calibration

of

equipments.

a> & b>ECM HOD

c>

ECM

HOD

&

Lab HOD

Lab HOD

REFERENCE DOCUMENT:

Specification of Customer /ToR /Checklists

Drawings & P & I diagrams/Validation criteria

Reference Books for Testing Procedures (Refer Doc. No. SEE/MS-07

point No. 7, 8, 9 & 11)

MoEF Guidelines, SPCB guidelines

SOPs /Scedules

VI. GENERATED RECORD:

EIA (Draft) report- (Project wise)

EIA /EMP Report (Final)- (Project wise)

Project Report /Survey Report /Validation report

Laboratory analysis reports

Conscent application/Cess report/ duly filled statutory

Compliance report

forms/

-----------------------------------------------------------------------------------------------------------------------

Vous aimerez peut-être aussi

- Management Review Wasit-1Document7 pagesManagement Review Wasit-1SANUPas encore d'évaluation

- Quality Record Procedure Rev-JDocument4 pagesQuality Record Procedure Rev-JherminPas encore d'évaluation

- CSL Technologies Project Management ProcedureDocument4 pagesCSL Technologies Project Management ProcedureIdrus IsmailPas encore d'évaluation

- Happy Forgings EMS PerformanceDocument3 pagesHappy Forgings EMS Performancemool raj100% (1)

- Dandekar Industries Record Control MatrixDocument3 pagesDandekar Industries Record Control MatrixAlka Bhatpude100% (1)

- COMP-OPP-02 Procedure For Control and Validation of Service ProvisionDocument6 pagesCOMP-OPP-02 Procedure For Control and Validation of Service ProvisionISODCC DSPIPas encore d'évaluation

- Procedure for Purchase SOPDocument6 pagesProcedure for Purchase SOPShakti ShuklaPas encore d'évaluation

- CS P12 Drawing Control ProcedureDocument4 pagesCS P12 Drawing Control Procedurerichard nagilusPas encore d'évaluation

- Standard Operating Process Company Logo: Approved by Verified by Prepared byDocument2 pagesStandard Operating Process Company Logo: Approved by Verified by Prepared byMau TauPas encore d'évaluation

- QSP 02 - Record Control ProcedureDocument5 pagesQSP 02 - Record Control ProcedureVivek V100% (1)

- Scope of The QMSDocument2 pagesScope of The QMSVictor100% (1)

- MAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1Document9 pagesMAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1IT Support - FernanPas encore d'évaluation

- Department Quality & FS Objective (Revision2015) - SampleDocument1 pageDepartment Quality & FS Objective (Revision2015) - SampleRachel YapPas encore d'évaluation

- CS P11 PurchasingDocument4 pagesCS P11 PurchasingIdrus IsmailPas encore d'évaluation

- ISO PlanDocument12 pagesISO PlanTamara Johnson-PariagPas encore d'évaluation

- QP0225-0 Continual Improvement ProcedureDocument6 pagesQP0225-0 Continual Improvement ProcedureNyadroh Clement MchammondsPas encore d'évaluation

- Employee Training RecordDocument19 pagesEmployee Training Recordklinik utama Bali Puri MedikaPas encore d'évaluation

- ProceduresDocument22 pagesProceduresRajVardhan100% (1)

- Management Responsibility Draft 4 10 March 2014Document101 pagesManagement Responsibility Draft 4 10 March 2014mkpqPas encore d'évaluation

- CS-P03-HR Recruitment TrainingDocument5 pagesCS-P03-HR Recruitment TrainingIdrus IsmailPas encore d'évaluation

- Control of NCP ProcedureDocument4 pagesControl of NCP ProcedureAdriana BracamontePas encore d'évaluation

- SOP-03 (Employee Performance Monitoring)Document6 pagesSOP-03 (Employee Performance Monitoring)FarhanPas encore d'évaluation

- Cs-P06-Ca & PaDocument3 pagesCs-P06-Ca & PaIdrus IsmailPas encore d'évaluation

- Continual ImprovementDocument3 pagesContinual ImprovementMohanad100% (1)

- Internal Audit Checksheet ReviewDocument32 pagesInternal Audit Checksheet ReviewRambir KaushikPas encore d'évaluation

- Internal Audit ReportsDocument1 pageInternal Audit ReportsCQMS 5S DivisionPas encore d'évaluation

- Shipping ProcedureDocument3 pagesShipping ProcedurematrixmazePas encore d'évaluation

- Procedure For Selection and Supplier DevelopmentDocument5 pagesProcedure For Selection and Supplier DevelopmentQuality Unit 1 Ajay Pandey100% (3)

- R&D Procedure - Control of Drawing Engg Specification P2Document1 pageR&D Procedure - Control of Drawing Engg Specification P2sumanPas encore d'évaluation

- 9.3 Procedure For Management ReviewDocument7 pages9.3 Procedure For Management ReviewValantina JamilPas encore d'évaluation

- MTC-IMS-PR-15-Procedure For Externally Provided ProductsDocument5 pagesMTC-IMS-PR-15-Procedure For Externally Provided ProductssouravrobinPas encore d'évaluation

- Quality ManualDocument26 pagesQuality ManualGerardo Gómez SalasPas encore d'évaluation

- Roles and Resposiblity-SampleDocument7 pagesRoles and Resposiblity-SampleELANTHENDRALPas encore d'évaluation

- QMS Work PlanDocument4 pagesQMS Work PlanWael BouabdellahPas encore d'évaluation

- List of Customer Supplied Items for Devdatt IndustriesDocument1 pageList of Customer Supplied Items for Devdatt IndustriesAl Rammohan0% (1)

- ABC ABC Company: Internal Audit PlanDocument1 pageABC ABC Company: Internal Audit PlanCQMS 5S DivisionPas encore d'évaluation

- Procedure of Document ControlDocument5 pagesProcedure of Document ControlNguyễn Văn GiápPas encore d'évaluation

- CS-P14-Control of NC Product (KIV)Document4 pagesCS-P14-Control of NC Product (KIV)Idrus IsmailPas encore d'évaluation

- Qa-R-07 Nonconformity and Corrective ActionDocument2 pagesQa-R-07 Nonconformity and Corrective ActionvinothPas encore d'évaluation

- VQA - PR.06 Customer Satisfaction ProcedureDocument2 pagesVQA - PR.06 Customer Satisfaction ProcedureNyadroh Clement Mchammonds100% (1)

- Contract Review ProceureDocument11 pagesContract Review ProceureJOHNK100% (1)

- List of Records - Formats & RegistersDocument1 pageList of Records - Formats & RegistersSuraj KadamPas encore d'évaluation

- Turtle Diagram - Document ControlDocument1 pageTurtle Diagram - Document Controlsyahir etPas encore d'évaluation

- Quality Audit Checklist - Revised - 01Document10 pagesQuality Audit Checklist - Revised - 01Mustafa Hassan MalikPas encore d'évaluation

- Minutes of Management Review MeetingDocument5 pagesMinutes of Management Review Meetingwinston11Pas encore d'évaluation

- Document Control ProcedureDocument13 pagesDocument Control ProcedureSALES AL ABERPas encore d'évaluation

- QMS of The Company As Per IsoDocument62 pagesQMS of The Company As Per IsogalavaPas encore d'évaluation

- QMS Record Control ProcedureDocument2 pagesQMS Record Control ProcedureHammad GhauriPas encore d'évaluation

- 14 Communication ProcedureDocument6 pages14 Communication ProcedureHisham YousriPas encore d'évaluation

- MKT Procedure - Evaluating Customer Satisfaction P1Document1 pageMKT Procedure - Evaluating Customer Satisfaction P1sumanPas encore d'évaluation

- Quality Management System Master18 February 2014Document27 pagesQuality Management System Master18 February 2014shani5573Pas encore d'évaluation

- MRM Agenda For Dated Jan09Document4 pagesMRM Agenda For Dated Jan09uvhajarePas encore d'évaluation

- Form04 - External Master List of DocumentsDocument1 pageForm04 - External Master List of DocumentsAna Hidayah SyuhadaPas encore d'évaluation

- Control of Nonconforming Output ProcedureDocument4 pagesControl of Nonconforming Output Procedureandi wahyudin50% (2)

- Qms Interaction ChartDocument1 pageQms Interaction Chartpnagarajj0% (1)

- SOP - 01 - Structure Organization ChartDocument10 pagesSOP - 01 - Structure Organization ChartSuci YatiningtiyasPas encore d'évaluation

- Quality Plan for Dahej Standby Jetty ProjectDocument40 pagesQuality Plan for Dahej Standby Jetty ProjectPuneet Vikram Singh100% (5)

- Construction Quality Management System Booklet For Cross Country Pipeline ProjectDocument10 pagesConstruction Quality Management System Booklet For Cross Country Pipeline ProjectRakesh Ranjan100% (1)

- Presentation On NTPC Inspection ServicesDocument34 pagesPresentation On NTPC Inspection ServicesAshwani Dogra100% (3)

- Epa Water Treatment Manual Primary Secondary Tertiary1Document131 pagesEpa Water Treatment Manual Primary Secondary Tertiary1Pamela RichardsonPas encore d'évaluation

- Epa Water Treatment Manual Primary Secondary Tertiary1Document131 pagesEpa Water Treatment Manual Primary Secondary Tertiary1Pamela RichardsonPas encore d'évaluation

- Training on OH&S Risks and EmergenciesDocument11 pagesTraining on OH&S Risks and EmergenciesamoPas encore d'évaluation

- Bombay Minor Mineral Ext Rules-1955Document37 pagesBombay Minor Mineral Ext Rules-1955amo100% (1)

- Guidelines on Environmental Management of C&D WasteDocument81 pagesGuidelines on Environmental Management of C&D WasteamoPas encore d'évaluation

- General Standards Industry Effluents Emissions Pollution - CPCB IndiaDocument16 pagesGeneral Standards Industry Effluents Emissions Pollution - CPCB IndiaVaishnavi JayakumarPas encore d'évaluation

- Rain Water Harvesting CPWD MANUAL PDFDocument84 pagesRain Water Harvesting CPWD MANUAL PDFRv SinghPas encore d'évaluation

- Epa Water Treatment Manual Primary Secondary Tertiary1Document131 pagesEpa Water Treatment Manual Primary Secondary Tertiary1Pamela RichardsonPas encore d'évaluation

- Tata Report Aug8Document66 pagesTata Report Aug8amoPas encore d'évaluation

- Solvents Economic Study ReportDocument129 pagesSolvents Economic Study Reportamo100% (1)

- MOEF Guideline For Env LabDocument122 pagesMOEF Guideline For Env LabamoPas encore d'évaluation

- CUSTIC software noise pollution map generatorDocument43 pagesCUSTIC software noise pollution map generatoramoPas encore d'évaluation

- Dispersion Air Pollution ModellingDocument44 pagesDispersion Air Pollution ModellingamoPas encore d'évaluation

- Chapter-Cooling TowersDocument17 pagesChapter-Cooling TowersSAGIS ETIENNEPas encore d'évaluation

- Hazardous Wastes Management Handling and Transboundary Movement Rules 2008Document40 pagesHazardous Wastes Management Handling and Transboundary Movement Rules 2008anpuselvi125Pas encore d'évaluation

- NABET Scheme Version 3 INFORMATIONDocument60 pagesNABET Scheme Version 3 INFORMATIONamo0% (1)

- Nabet Version 3Document156 pagesNabet Version 3amoPas encore d'évaluation

- IDRISI Software ManualDocument32 pagesIDRISI Software Manualamo100% (1)

- EIA ReportDocument183 pagesEIA ReportamoPas encore d'évaluation

- Aloha TechDocument96 pagesAloha Techrufino.perea.2Pas encore d'évaluation

- EIA EMP Report of JSW SteelDocument879 pagesEIA EMP Report of JSW Steelamo75% (4)

- Coal Treatment For Ash ContentDocument6 pagesCoal Treatment For Ash ContentamoPas encore d'évaluation

- EIA Process Flow Chart - Project Identification to Implementation & Follow UpDocument2 pagesEIA Process Flow Chart - Project Identification to Implementation & Follow Upshreek16Pas encore d'évaluation

- OSHA 2236 - Materials Handling and StorageDocument41 pagesOSHA 2236 - Materials Handling and StorageWahed Mn ElnasPas encore d'évaluation

- Boiler CalculationsDocument19 pagesBoiler CalculationsamoPas encore d'évaluation

- New Standard TOR - 5 (F)Document8 pagesNew Standard TOR - 5 (F)amoPas encore d'évaluation

- Cooling Tower Capacity CalculationDocument2 pagesCooling Tower Capacity CalculationPurusotaman BarthibanPas encore d'évaluation

- Sustainable Cities: Canadian Reality or Urban Myth?Document10 pagesSustainable Cities: Canadian Reality or Urban Myth?amoPas encore d'évaluation

- AAQM GuidelinesDocument164 pagesAAQM GuidelinesKrishna KumarPas encore d'évaluation

- New NABET SchemeDocument168 pagesNew NABET SchemeamoPas encore d'évaluation

- Critical Thinking WorkbookDocument14 pagesCritical Thinking WorkbookLa Roi Williams100% (10)

- Primary Teacher MethodsDocument49 pagesPrimary Teacher MethodsMinahil ManoPas encore d'évaluation

- HMS Business PracticeDocument19 pagesHMS Business Practiceadvantage025Pas encore d'évaluation

- Chapter 6 Mixed Methods ResearchDocument18 pagesChapter 6 Mixed Methods ResearchMr XPas encore d'évaluation

- CSEC Physics Record of MarksDocument2 pagesCSEC Physics Record of MarkseddmanPas encore d'évaluation

- Quality QDocument3 pagesQuality Qaryanboxer786Pas encore d'évaluation

- PDFDocument12 pagesPDFrubel-buPas encore d'évaluation

- L6 CTSE STO023 EPA AG Issue 2.1 - New Amended Version of Apprentice Handbook (6) (Part Version - Extracts Only)Document7 pagesL6 CTSE STO023 EPA AG Issue 2.1 - New Amended Version of Apprentice Handbook (6) (Part Version - Extracts Only)Laura CuestaPas encore d'évaluation

- Exam ManualDocument48 pagesExam ManualNilakshi Barik MandalPas encore d'évaluation

- Chap 13Document28 pagesChap 13Aamir ChohanPas encore d'évaluation

- Corporate Governance in the Public SectorDocument124 pagesCorporate Governance in the Public Sectorbinod_hada6975Pas encore d'évaluation

- Identifying Family PrioritiesDocument4 pagesIdentifying Family Prioritiesemrod1185Pas encore d'évaluation

- 31-Astm C1077-16Document9 pages31-Astm C1077-16Rolando de GuzmanPas encore d'évaluation

- Objective: National Council For Teacher Education Act, 1993 (No. 73 of 1993)Document19 pagesObjective: National Council For Teacher Education Act, 1993 (No. 73 of 1993)naresh chandraPas encore d'évaluation

- Notes BedDocument24 pagesNotes Bedअमरेश झाPas encore d'évaluation

- 7 BusinessDissertationsDocument1 772 pages7 BusinessDissertationsshreeshail_mp60090% (1)

- Evaluation HandbookDocument33 pagesEvaluation Handbookpayankey100% (1)

- 05 Handout 1Document4 pages05 Handout 1Shedy GalorportPas encore d'évaluation

- NCBTS For School HeadsDocument44 pagesNCBTS For School HeadsSheril B. ParaynoPas encore d'évaluation

- The Decision Making Process: MGT 101 - Principles of Management and BusinessDocument18 pagesThe Decision Making Process: MGT 101 - Principles of Management and BusinessHaseeb KhattakPas encore d'évaluation

- Screening Who Instructions PDFDocument72 pagesScreening Who Instructions PDFpbta punjabPas encore d'évaluation

- Factors Influencing Evaluation of Teaching and LearningDocument5 pagesFactors Influencing Evaluation of Teaching and LearningrzPas encore d'évaluation

- Study On Application of Value Engineering On Construction DesignDocument4 pagesStudy On Application of Value Engineering On Construction DesignAhmed JeddaweePas encore d'évaluation

- Managing Own PerformanceDocument34 pagesManaging Own PerformanceLyka Mae Palarca Irang100% (2)

- Unit-9 Job Analysis, Recruitment and Selection PDFDocument15 pagesUnit-9 Job Analysis, Recruitment and Selection PDFbhar4tpPas encore d'évaluation

- Cordillera A+ College research course syllabusDocument6 pagesCordillera A+ College research course syllabusAveryl LadipPas encore d'évaluation

- CCCJ Social Work Practicum Guide 2017Document24 pagesCCCJ Social Work Practicum Guide 2017Brittany OliphantPas encore d'évaluation

- ICONE10-22763: A Complete Piping Analysis With Thermal Stratification LoadsDocument8 pagesICONE10-22763: A Complete Piping Analysis With Thermal Stratification LoadsMilton DongPas encore d'évaluation

- Critical Success Factors in Six Sigma ImplementationDocument5 pagesCritical Success Factors in Six Sigma ImplementationMarco Antonio MacielPas encore d'évaluation

- Simulator Training Course STW 43-3-4 - Model Course - Train The Simulator Trainer and Assessor (Secretariat)Document125 pagesSimulator Training Course STW 43-3-4 - Model Course - Train The Simulator Trainer and Assessor (Secretariat)geims1180% (5)