Académique Documents

Professionnel Documents

Culture Documents

L09 - Annale UDJG 2006 Fascicula V

Transféré par

Carlos ArenasCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

L09 - Annale UDJG 2006 Fascicula V

Transféré par

Carlos ArenasDroits d'auteur :

Formats disponibles

THE ANNALS DUNREA DE JOS UNIVERSITY OF GALAI

FASCICLE V, TECHNOLOGIES IN MACHINE BUILDING, ISSN 1221-4566

2006

A Review of the Sheet Metal Forming Methods

Using Reconfigurable Dies

PhD. Eng. Viorel PUNOIU, PhD. Eng. Alexandru EPUREANU,

PhD. Eng. Dumitru NICOAR, PhD. Eng. Ovidiu CIOCAN

Dunrea de Jos University of Galai, Faculty of Mechanics

E-mail: viorel.paunoiu@ugal.ro

ABSTRACT

Reconfigurable Manufacturing Systems (RMS) are designed for rapid change

in the system configuration, their machines and controls. In the field of sheet

metal forming could be identified a number of such types of methods. In the paper

are analysed these deformation methods, to point out their advantages and

applications.

Key words: reconfigurable manufacturing systems, sheet metal forming,

incremental forming, spinning, hydroforming, multipoint deformation

1. Introduction

Reconf igur ab le Manufactur ing Systems

( R MS) i s de s ign ed for r ap id change i n th e

system conf igur ation, th eir mach in es and

c on tro ls . In th is way RMS off er an

add itional

app roach

of

adjusting

produ ction cap acity and functionality

qu ick ly to n ew produ cts as w ell as in

r espon se to ma r k e t chang es.

Fro m economical p o in t o f v iew, RMS

go beyond th e obj ectiv es of ma ss, le an,

and f lex ible ma nuf actur ing and allow

flex ib ility no t on ly in produ cing a v ariety

of p ar ts, but also in ch ang ing th e system

i t s e lf .

I n the f i e ld o f me t a l f o r mi n g p r o c e s s e s ,

th e app lication of reconfigu rability is

limited

du e

to

the

produ ction

c h ar a c ter i s tic s :

- a great var iety of sh ap es and

d ime ns ion s ;

- a great quantity of parts;

- e a ch p ar t de ma n ds a sp ec if ic too l,

each chang e in par t design d e ma nds

a n ew too l;

- less flex ib ility in co mp arison with

ma c h i n in g , w h er e the s a me s e t o f

cu tting too ls can be used to produce

a w id e v ar iety of f in ish ed shap e s.

In th e las t d e cad es imp or tan t effor ts

were ma d e to in crease the flex ib ility in

me tal forming pro c esses. Th is led tod a y to

cou ld

iden tif y

so me

reconf igur ab le

s y s t e ms f o r t h is te ch n o log y.

As it fo llows it will pr es en ted some o f

th e me tal for ming processes wh ich b e long

to th e r e conf igur ab le techno log y.

2. Incremental Forming

In th is me thod, a simple g eo metr y too l ( a

h e misph er ica l too l) is mo un ted on a

v er t ic a l ax is o f a ma c h i n e and th e mo t i o n

of

th is

too l

along

th e

too l-p ath

progressiv e ly fo rms the sheet me tal to its

f in a l shap e b y in ser tion of small r eg ions of

con tro lled p lastic d eformation s. Fo r the

pro cess, univ ersal 3 or mo re ax is CNC

ma c h in ing ce n tre c an b e u sed .

Two ma in v ar ian ts o f the d ie le ss

in cremen tal for ming pro cess are known :

t h e so - c a l led n ega t iv e f o r mi n g p r o ce ss

and th e positiv e for ming pro cess.

In

neg a tiv e

in cremen tal

forming

( Figu re s 1 and 2) , a b a ll pun ch mo v es on a

sheet me tal, accord ing to a progr amme d

t o o l p a th. Th e she e t i s c l a mp ed a t t h e

p er ipher y by bo lts on a suppor t f rame.

- 45 -

Punch

Blankholder

Frame

Blank

Fig. 1. Negative Incremental Forming Process

[12]

THE ANNALS OF DUNREA DE JOS UNIVERSITY OF GALAI

In positive incremental forming (figure 3)

the blank 2 is put on the upper plate 3, and is

fastened on all sides by a fixed plate 5, which

can move along the guide pillars 7. A forming

tool 1 presses the sheet into a punch core 4 and

moves along the contour line under the control

of the machine until the required shape is

formed.

F ig . 3 . S e t-u p s ys t e m f o r n eg a t iv e

in cremen tal fo rming [13 ]

Dur ing

the

for ming

pro cess,

the

c o mpu ter con tro ls the too l s moveme n t in

x- y d ir ection and the gr adual mo veme n t in

z d ire c tion. W ith in the la yer of th e s a me

h e igh t,

the

fo r ming

too l

ma ke s

a

curv ilinear mo v e me n t on th e x-y p lane.

W hen a la ye r i s f in ishe d, th e too l mo ve s

d o w n a s ma l l d i s tan c e o f h a lo n g the z - ax i s

and con tinues to pro cess th e n ex t la yer till

a l l l a y er s a r e f o r med. 8 is th e p ie c e

ob tained .

1

2

7

6

4

FASCICLE V

1-5 millimeters). Anoth er adv an tage of

d ie le ss formin g is tha t th e too ling co s ts

are 510% of conv en tion al stamp ing. Th e

for min g process is slow. Thu s th is pro cess

is su itab le for low volu me production in

th e ma gn itud e of 1500 p ieces p er mo n th .

W ith th is n ew proc e ss , too ls cou ld b e

d is c ard ed and d ie les s f or ming ma c h ine s

can be emp lo yed to produ ce par ts upon

d e ma nd. This system is id eally suited for

r ap id pro to typ ing a s dev e lop me nt time a nd

tr you t co s ts ar e gr e a tly r educ ed.

No h ard too ling is r equ ir ed and de s ign

CAD d ata c an b e tr ansf err ed to th e

mach ine con tro ller easily. D epending on

th e par t s ize , a p ro to typ e pan e l cou ld b e

produ ced in approx imately one week upon

r ec e ip t o f the CAD d a ta .

Th e ac cur acy is aff e c ted b y spr ing b ack ,

t h e sh ap e o f t h e f o r me d p ar t, th e sha p e an d

s iz e of the too l, th e for min g too l p a th,

ma ter ial and thickn ess of th e b lank.

A ccur a c ie s o f b e twe en 1 , 5 m m a n d 2 mm

h ave be en ac h iev ed.

3. Spinning with Reconfigurable Mandrel

Sp inn ing sh eet me tal is an ex cellen t

me th od fo r qu ick ly pro to typ ing r ound

ho llow me tal shap es.

A fo rce is app lied un ifor mly to th e

s h e e t me t a l b y r o ta t in g th e b l an k a n d i ts

in tended form ( mandr el) at v er y h igh rp ms ,

thus th e sheet me tal is d eformed ev en ly

w ithou t any wr ink ling or w arble. Th e

s pinn ing pro ce ss a llow s for the r ap id

p r o d u c t ion o f mu l t i p le p ar t s a s w e l l a s

qu ick reiteration since on ly the ma n dr e l

n eed be mod if ied.

To ov er come th is dr awba ck, it wa s

propo sed a n ew me thod o f d efor mation in

wh ich th e ma n dr e l is r e conf igur ab le

(f igur e 4 ).

Fig. 3. Positive Incremental Forming Process

[20]

Co mp ar ed to th e tr ad ition a l for ming

p r o ce ss , inc r e me n t a l f o r mi n g p r o c e ss h a s

h igh er

ex tensib ility,

finen e ss

and

smo o thness of th e wo rk p iece. In add ition,

i t c a n b e u s ed f o r ma c h in ing co mp l i ca t ed

c u r v ed su r f a c es , w h i ch c a n n o t b e d o n e b y

t h e trad i t io n a l me t h o d ( co mp l ex sha p e o u t

of me tal sh eet up to 2.4 me ters b y 1.4

me ter s at var iou s th icknesses r ang ing fro m

- 46 -

Fig . 4. Sp inn ing w ith reconf igur ab le

ma n dr e l [23]

FASCICLE V

THE ANNALS OF DUNREA DE JOS UNIVERSITY OF GALAI

Fo r th is , the ma n dr e l is co mp os ed f ro m

a nu mb er of telescop ic bu shes, wh ic h mov e

ax ia l, accord ing to presen t conf igur ation.

Th e

conf igur ation

is

estab lished

nu me r ical, d epend ing upon th e p iece

g eo metry.

Th e

me thod

is

still

in

e xper ime n tal s tag e.

4. Hydroforming with

Reconfigurable Punch

H ydrofo r ming constitutes a subgroup of

sheet me tal forming pro cesses u tilizing a

pr es sur ized f or ming me d iu m. Th e p roc es s

of

sh eet

h ydrofor min g,

un lik e

conven tionnal

stamp ing,

invo lv es

suppor ting th e bo tto m of the sh eet w ith a

b ed of v iscou s f lu id dur ing the for ming

pro cess.

Th e

ad v an t age s

of

the

sh ee t

h ydrofor mi ng process are nu me rou s and

th e process is receiv ing sign if ican t

a tten tion fro m bo th th e au to mo tiv e and

a er o sp ac e in d u str ie s. A d v an tag es , i n c lu d e

imp rov ed formab ility of th e b lank du e to

th e app lied pr es sur e b y th e f lu id , low we ar

r a te o f d ies and pun ch, a better

d is tr ibu tion o f p las tic d efor ma tion wh en

c o mp ared to conv en tion a l she e t me ta l

for min g, sign if ican t econo mic sav ing s

a s soc i a t ed w i th the d ec r e a sed too li n g , an d

th e po ten tia l for reducing th e amo un t of

f in ish ing work requ ir ed.

A

A

A-A

po lyme r or rubb er to p reven t th e d imp ling

ph eno menon. Th e me thod is also in

e xper ime n tal s tag e.

5. Multipoint Deformation

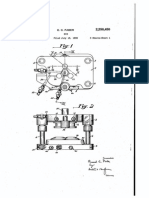

D iscr e te die for ming is an eng in eer ing

concep t d ev e loped mor e th an f if ty year s

ago, in itially design ed for sh eet me tal

for min g.

Using

a

geo metr ically

r econ f igurab le d ie, pr eciou s produ ction

time is sav ed b e cau se several d ifferen t

produ cts can be ma d e w ithou t ch ang ing

t o o ls . A l so a l o t o f e x p en se s are s av ed

b ecause

th e

ma nufactur ing

of

ver y

expen s ive r ig id d ies is reduced.

Th e w o r k ing sur f a ce o f th e d ie is ma d e

up of h e misph er ical ends of ind iv idu al

p ins , wh er e e a ch p in h as a squ are c ros s

s e c tion

and

can

be

indep end en tly

d isp la ced .

D epend ing on a typ e of application,

d iscrete d ie forming is app lied in two

v arian ts:

- for s tr e tch f or mi ng. In t h i s c as e on l y a

sing le d ie is n e cessary (f igur e 6). Th e

ma t e r i a l i s d ef o r me d a c co r d in g t o two

ma in typ es of me thod s d epend ing upon th e

for c e sequ en ce s. Th e f ir s t is s imp le s tr etch

for min g in wh ich the ma te r ia l is s imp ly

wr apped around the too l and is used for

s imp ly curv ed g eo me tr y. The me thod is

r ar e ly u sed because th e b lank is no t

un ifor mly d e for med and th e spr ing b ack is

v er y importan t. Th e second is stretch

for min g w ith a supp le me n tar y ma ter ial

d efor ma tion a nd cou ld b e app lied in th re e

ma n n ers :

a . p re- s tr e tch and w rap , ( f igure 7, a). In

th is me thod sh eet me tal is first p restretch ed with fo rce F 1 above its yield

stress, and th en is w rapp ed around th e too l

wh ile ma in ta in ing the force F 1 constan t;

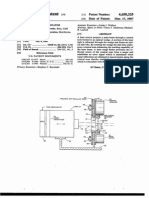

Fig . 5. H ydrofor min g w ith r e conf igur ab le

pun ch [23 ]

A me thod, who offers a gr eat

flex ib ility

in

co mp arison

with

the

conven tion al on e, is presen ted in figur e 5.

In th is me thod, th e pun ch is co mpo sed

f r o m a n a r r a y o f p in s , w h i ch ar e

ind epend en tly sh if ted in v er tic a l dir ec tion ,

a c co r d in g w i th the p i ec e p r o f ile . Th e

conf igur ation is estab lish ed numer ical,

d epend ing upon the piece g eo metr y. The

activ e par t of th e p ins is cov ered w ith a

- 47 -

Fig. 6. Discrete Die for stretch forming [4]

THE ANNALS OF DUNREA DE JOS UNIVERSITY OF GALAI

b. wr ap and po st stretch (dr ap e

formin g), (figure 7, b). The sh eet me tal is

f ir s t wr app ed around the too l and af ter th at

an add itional tensile stress is impo sed on

th e p art;

c. pr e-stretc h, wr ap and post- str e tch

( s tre t ch-wr ap for mi ng) (f igur e 7 , c). Sh ee t

me tal is first pre-stretc hed with force F 1

above its yield str ess, and th en is wr apped

around the too l and f in a lly an add ition al

tensile stress F2 (po s t- stretch) is imp o sed

on th e p ar t;

F1

F1

F1

M

F1

M

M

F1

F1

F1

a.

F2

F1

F2

b.

F2

c.

F2

Fig . 7. Typ es of op er ation s in stretch

for min g [17]

- for d e ep dr aw ing. In th is c ase in

l i t e r a tur e th e n a me o f me t h o d is c a l led

mu ltipo in t d eformation (MPF) and is u sed

two oppo site d ies (f igure 8).

Th e mov eme n t of each punch is

con tro lled ind epend en tly b y MPF pr ess,

a n d M P F i s a f l e x ib le p r o ce ss in g

te chn iqu e. On e of the ma in adv anta ge s of

MP F is tha t th e fo rmin g pa th of me ta l

s h e e t c an b e adj u s t ed f r e e l y, an d a sh e e t

produ ct can be ma nuf actu red along an

op timu m f or ming p a th w ith le a s t r isk o f

for mi n g f a i lur e.

FASCICLE V

d efor mation is th e predo min an t defor mation ; con tact bound ary is a mu lti-po in t,

d iscon tinuou s on e between sheet and

pun ches

dies,

and

is

mu ch

mor e

c o mp l i ca t ed th an th a t o f f o r mi n g .

Th is me thod is most suitab le fo r the

for min g of larg e d ime n s ion sh e ll- like

p ar ts , such a s the she ll of sh ips and larg e

v es se l s, e t c.

6. Conclusions

An alys e pr esen ted in th is p aper , b ased

on imp or tan t nu mb er s of referen c es,

c lar if ied the new tenden c ie s in the f ie ld of

s uc ce ss

ma n uf ac tu re

by

p las tic

d eformation o f curved , mu lti-ax ial, mu ltip ly

p ar ts .

Th e se

n ew

me thod s

of

d eformation ev en actu ally are u sed ma in ly

a s rap id pro to typ ing te chn iqu es , h ave a

g r ea t n u mbe r o f adv an t a g e s b e caus e the i r

r econ f igurab le char a c ter.

7. Acknowledgements

Th e work repor ted h ere w as an activ ity

in the frame o f the CE EX Ro ma n ia

P rogra m

( CEEX-P-CD

no.

22/10.10.05)

Mod eling, simu lation me th ods and v ir tu a l

ma n uf ac tu ring ba sed on co mmu n ica tion

a nd infor ma tion te chno log y d ed ic a ted to

th e n ew g ener a tion of r econf igur ab le

ma n u f ac tu r ing . The aut h o r s ap p r e ci a t e th e

con tinu ing encour ag emen t and suppor t of

th is progr am.

Bibliography

Fig. 8. Multipoint deformations die [24]

Mu ltipo in t formin g of sh eet me tal h a s

th e fo llowing ch aracteristics: d eformation

of ma terials in MPF is no t as larg e as th at

i n f o r mi n g ; i n - p l a n e f o r c e s a r e s ma l l e r

th an those in for ming and b end ing

1. Hardt, D.E., Siu, T.-S., Cycle to Cycle Manufacturing

Process Control, First Annual SMA Symposium, Singapore, Jan.

2002.;

2. Hardt, D.E., Rzepniewski, A., Pi, A., Cycle-to-Cycle

Feedback Control and its Application to Sheet Metal Forming,

Proceedings of the JSME/ASME International Conference on

Materials and Processing, Oct. 2002;

3. Webb, R.D., Hardt, D.E., A Transfer Function Description

of Sheet Metal Forming for Process Control, ASME Journal of

Engineering for Industry, 1990;

4. Papazian, J., Tools of Change. Mechanical Engineering,

Feb. 2002, pp. 31-40;

5. Hardt, D.E., Norfleet, N.A., Valentin, V.M, Parris, A.,

In-Process Control of Strain in a Stretch Forming Process,

Transactions of the ASME, Vol. 123, octombrie 2001;

6. Valjavec, M. and Hardt, D.E., Closed-loop Shape Control

of the Stretch Forming Process over a Reconfigurable Tool:

Precision Airframe Skin Fabrication, Proceedings of the ASME

Symposium on Advances in Metal Forming, Nashville, Nov. 1999;

7. Socrate, S., Boyce, M.C., A Finite Element Based Die

Design Algorithm for Sheet Metal Forming on Reconfigurable

Tools, Proceedings of the ASME Symposium on Advances in

Metal Forming, Orlando, Nov. 2000;

8. Hardt, D. E., Boyce, M. C., Ousterhout, K. B., Karafillis,

A., Eigen, G. M., A CAD Driven Flexible Forming System for

Three-Dimensional Sheet Metal Parts, Sheet Metal and Stamping

- 48 -

THE ANNALS DUNREA DE JOS UNIVERSITY OF GALAI

FASCICLE V, TECHNOLOGIES IN MACHINE BUILDING, ISSN 1221-4566

2006

Symposium, Int. Cong. and Exp., Detroit, MI, SAE Technical

Paper Series 930282, pp. 6976, 1993;

9. Karafillis, A. P., and Boyce, M. C., Tooling Design in

Sheet Metal Forming using Springback Calculations, Int. J. Mech.

Sci., 34, pp. 113131,1992;

10. Karafillis, A. P., and Boyce, M. C., Tooling and Binder

Design for Sheet Metal Forming Processes Compensating

Springback Error, Int. J. Mach. Tools Manuf., 36, pp. 503526,

1996;

11. Webb, R. D. and Hardt, D. E., A Transfer Function

Description of Sheet Metal Forming for Process Control, ASME J.

Eng. Ind., 113, pp. 4454, 1991;

12. M. Strano, Incremental forming processes: current and

potential applications, SME technical, paper No. MF03-114, 2003;

13. Pohlak, M., Majak, J. & Kyttner, R. Manufacturability

Issues in Incremental Sheet Forming, 5th International DAAAM

Baltic Conference "Industrial Engineering Adding Innovation

Capacity of Labour Force and Entrepreneurs" 2022 April 2006,

Tallinn, Estonia;

14. Punoiu, V., Oancea, N., Nicoara, D. Simulation of

Plates Deformation Using Discrete Surfaces, Materials Processing

and Design: Simulation and Application, NUMIFORM, 2004,

OHIO State University, American Institute of Physics 0-73540188-8, pag. 1007-1010;

15. Gavan, E., Paunoiu, V., Dimache, A. Comparative

Study for Single-Curved Plates Forming with Continuous and

Reconfigurable Die-Punch Assembly, Analele Universitii

Dunrea de Jos din Galai, Fasc. V, 2004, pag. 81-85, ISSN 12214566 ;

16. Gavan, E., Paunoiu, V., Dimache, A, Cylindrical

Thick Plate Forming with Reconfigurable Die-Punch Tool,

TMCR, Chiinu, 20035, pag. 400-404, ISBN 9975-99753-2

17. Modiga, M., Dimache, A., Paunoiu, V., Model matematic

al procesului de deformare a tablelor pe dorn, A XXVI-a

Conferin Naional de Mecanica Solidelor, Brila, ISBN 9738132-28-2, pag. 49-54, 2002;

18.

Owodunni, O.O., Diaz-Rozo, J., Hinduja, S.,

Development and Evaluation of a Low-Cost Computer Controlled

Reconfigurable Rapid Tool, Computer-Aided Design and

Applications, 1, 1-4, 2004, 101-108;

19. Papazian, J. M., Anagnostou, E.L., Christ, R. J.,

Hoitsma Jr.D., Ogilvie, P., Schwarz, R.C., Tooling For Rapid

Sheet Metal Parts Production, 6th Joint FAA/DoD/NASA Conf. on

Aging Aircraft, San Francisco, CA, USA, September 16-19, 2002.

20. Hirt, G., Ames, J., Bambach, M. Kopp, R., Forming

strategies and Process modelling for CNC Incremental sheet

forming, Annals of the CIRP, 53, 1, 2004, 203-206.

21. Leach, D., Green, A.J,. Bramley, A.N., Sheet production

without dies or special punches, Metallurgia, 68, 2, 2001, p. FT12;

22. Ambrogio, G., De Napoli, Filice, L., Muzzupappa, M.,

Improvement Geometrical Precision In Sheet Incremental Forming

Processes, Proc. of ESDA04, 7th Biennial conf. on Engrg Systems

Design and Analysis, July 19-22, 2004 Manchester, United

Kingdom;

23. Finckenstein, E.V., Kleiner, M., Flexible Numerically &

Controlled Tool System for Hydro-Mechanical Deep Drawing,

Annals of the CIRP, v40, n1, 1991, p. 311-314;

24. Cai Z.Y., Li, M.Z., Digitized die forming system for sheet

metal and springback minimizing technique, Int J Adv Manuf

Technol (2006) 28: 10891096, p. 1089-1096.

- 49 -

THE ANNALS OF DUNREA DE JOS UNIVERSITY OF GALAI

FASCICLE V

Studiu privind tehnologiile de deformare cu matrite

reconfigurabile

Rezumat

Sistemele reconfigurabile (RMS) de fabricare permit adugarea, nlturarea sau

modificarea unor capabiliti de proces specifice controlului, software-lui sau

structurii mainii pentru a rspunde modificrilor cerute de tehnologie sau de pia.

n domeniul tehnologiilor de deformare plastic se pot identifica cteva astfel de

procedee. n lucrare se prezint o detaliere a acestor tehnologii, cu evidenierea

principalelor avantaje i domenii de aplicaii.

Ein Berichte des Blechs, das Methoden Mit

Reconfigurable Matrize Bildet

Zusammenfassung

Reconfigurable Fertigungssysteme (RMS) sind fr schnelle nderung in der

Anlagenkonfiguration, in ihren Maschinen und in den Kontrollen bestimmt. In

auffangen des Blechs konnte der Formung gekennzeichnet werden eine Anzahl von

solchen Arten Methoden. Im Papier werden diesen Deformation Methoden, ihre

Vorteile und Anwendungen zu unterstreichen analysiert.

- 50 -

Vous aimerez peut-être aussi

- Machine Vision: Algorithms, Architectures, and SystemsD'EverandMachine Vision: Algorithms, Architectures, and SystemsPas encore d'évaluation

- Us 3995557Document6 pagesUs 3995557drive2345Pas encore d'évaluation

- Arpita Sharma Assignment 5Document9 pagesArpita Sharma Assignment 5Ritesh SinghPas encore d'évaluation

- Artificial Hand Using Embedded SystemDocument8 pagesArtificial Hand Using Embedded SystemSK Sayeed Sid0% (3)

- Micro/bit: Control Vectorial de Motores Síncronos Mediante DSPDocument8 pagesMicro/bit: Control Vectorial de Motores Síncronos Mediante DSPvladialvarezPas encore d'évaluation

- Advances in Control Systems: Theory and ApplicationsD'EverandAdvances in Control Systems: Theory and ApplicationsPas encore d'évaluation

- Us 5146749Document6 pagesUs 5146749Juan Sebastian AguirrePas encore d'évaluation

- Computer Integrated ConstructionD'EverandComputer Integrated ConstructionH. WagterPas encore d'évaluation

- (1987) Bartlett, John T. - Process Simulation and Optimization Using MetsimDocument12 pages(1987) Bartlett, John T. - Process Simulation and Optimization Using MetsimLuis La TorrePas encore d'évaluation

- (Plate Ut Check Procedure (For Lamination Check) - 1Document6 pages(Plate Ut Check Procedure (For Lamination Check) - 1Deepan RajPas encore d'évaluation

- Ieee On TorontoDocument4 pagesIeee On TorontojonathanmartinPas encore d'évaluation

- Tec. Qx. Russell Taylor HumeralDocument32 pagesTec. Qx. Russell Taylor HumeralAlvaro_086Pas encore d'évaluation

- United States Patent (19) : Murata Et Al. (11) Patent NumberDocument12 pagesUnited States Patent (19) : Murata Et Al. (11) Patent NumberCatanescu Alexandru-LaurentiuPas encore d'évaluation

- Hydrocarbonate Reservoir Characterization Constrained To 3D Seismic AttributesDocument10 pagesHydrocarbonate Reservoir Characterization Constrained To 3D Seismic AttributesseanmohdPas encore d'évaluation

- 20-32 Quantitative Prediction of Transformation Hardening in Steels PDFDocument13 pages20-32 Quantitative Prediction of Transformation Hardening in Steels PDFUlises Quintana CarhuanchoPas encore d'évaluation

- United States Patent (191: (11) Patent Number: (45) Date of PatentDocument5 pagesUnited States Patent (191: (11) Patent Number: (45) Date of PatentSalmanPashaPas encore d'évaluation

- United States Patent (191: Bieniosek (45) Date of Patent: May 23, 1989Document4 pagesUnited States Patent (191: Bieniosek (45) Date of Patent: May 23, 1989harishkumarsinghPas encore d'évaluation

- Alt-O. : Indlvlduelly /@Document7 pagesAlt-O. : Indlvlduelly /@drivinerPas encore d'évaluation

- Hidden Factory - Harry - TextDocument13 pagesHidden Factory - Harry - Textashesh5388Pas encore d'évaluation

- ¿J Fowuv C'ansn SNR-RW: F Íled April 23, 1943Document8 pages¿J Fowuv C'ansn SNR-RW: F Íled April 23, 1943sorin.dragosPas encore d'évaluation

- Roane, James B. - The Balanced Force Concept, JOE, 11, 5, May 1985Document9 pagesRoane, James B. - The Balanced Force Concept, JOE, 11, 5, May 1985Härôld BäthôryPas encore d'évaluation

- 2840Document231 pages2840Nachawon PrasongthamPas encore d'évaluation

- United States Patent (19) : Gray, SRDocument7 pagesUnited States Patent (19) : Gray, SRMary AndersonPas encore d'évaluation

- Designing A Flex Ible Enga Gem Ent M Odel: CCSM-30 4Document7 pagesDesigning A Flex Ible Enga Gem Ent M Odel: CCSM-30 4Aiden PantryPas encore d'évaluation

- On OperationsDocument57 pagesOn OperationsHANNAH CHARIS CANOYPas encore d'évaluation

- Studies of The Motion of The Brain at A Suddenly Applied Rotation of The SkullDocument8 pagesStudies of The Motion of The Brain at A Suddenly Applied Rotation of The SkullDeepsPas encore d'évaluation

- Acmtos 13Document26 pagesAcmtos 13Kashif SaeedPas encore d'évaluation

- Dev Eloping Persona L Pla Ybooks: CCSM-30 5Document7 pagesDev Eloping Persona L Pla Ybooks: CCSM-30 5Aiden PantryPas encore d'évaluation

- High Intensity Ultrasonic GeneratorDocument10 pagesHigh Intensity Ultrasonic GeneratorHai NguyenPas encore d'évaluation

- Leveragingadvanced Ca Pa City M Odeling: CCSM-30 6Document7 pagesLeveragingadvanced Ca Pa City M Odeling: CCSM-30 6Aiden PantryPas encore d'évaluation

- United States Patent (191: Moriya Et A1Document8 pagesUnited States Patent (191: Moriya Et A1a5216730Pas encore d'évaluation

- RestrictionsDocument5 pagesRestrictionsDhana Jaya WardanaPas encore d'évaluation

- MB0047Document35 pagesMB0047abhishek13481Pas encore d'évaluation

- Shell Omala S2 G 2202Document2 pagesShell Omala S2 G 2202Sholhan AzizPas encore d'évaluation

- 2011 Strehmel MSCDocument139 pages2011 Strehmel MSCrsiqueirasantos5711Pas encore d'évaluation

- Report in Entrep-G2Document25 pagesReport in Entrep-G2AltheaPas encore d'évaluation

- APICS CPIM Study Notes MPR ModuleDocument17 pagesAPICS CPIM Study Notes MPR Modulecwh92770% (10)

- United States Patent (191: Crowder (11) Patent Number: (45) Date of PatentDocument5 pagesUnited States Patent (191: Crowder (11) Patent Number: (45) Date of Patentgtr56Pas encore d'évaluation

- United States Patent (191 4,927,800: Nishiki Et AlDocument7 pagesUnited States Patent (191 4,927,800: Nishiki Et AlchecolonoskiPas encore d'évaluation

- HAARP PatentDocument12 pagesHAARP PatentGordon DuffPas encore d'évaluation

- Jenike108 PDFDocument322 pagesJenike108 PDFHanns Flies KPas encore d'évaluation

- Workbook CCSM103EffectiveOnboardingDocument13 pagesWorkbook CCSM103EffectiveOnboardingsriniPas encore d'évaluation

- A General Unified Approach To Modelling Switching-Converter Power StagesDocument14 pagesA General Unified Approach To Modelling Switching-Converter Power StagesalucardlipknotPas encore d'évaluation

- Modelado de Pymes Con IDEF0Document14 pagesModelado de Pymes Con IDEF0ckruger1Pas encore d'évaluation

- Consumer Online PrivacyDocument14 pagesConsumer Online Privacymabelle901Pas encore d'évaluation

- Thinc - Aloud: - Volume IiDocument13 pagesThinc - Aloud: - Volume Iipushkarsingh27Pas encore d'évaluation

- Introduction To Advance Product Quality Planning (Apqp)Document16 pagesIntroduction To Advance Product Quality Planning (Apqp)mak4funPas encore d'évaluation

- United States Patent: MinetDocument7 pagesUnited States Patent: Minetkees321Pas encore d'évaluation

- Us 2250450Document8 pagesUs 2250450RajVardhanPas encore d'évaluation

- Generator: United States Patent (191Document11 pagesGenerator: United States Patent (191Niki MikiPas encore d'évaluation

- Structural Optimization of Landing Gears Using STARSTRUC: A.M. Elsaie R. Santillan, JRDocument8 pagesStructural Optimization of Landing Gears Using STARSTRUC: A.M. Elsaie R. Santillan, JRManoj Paul JohnPas encore d'évaluation

- Abb Sras 1-07-72dpiDocument100 pagesAbb Sras 1-07-72dpiahmetgumus1900Pas encore d'évaluation

- Rheological Fundamentals of Soil Mechanics - VyalovDocument19 pagesRheological Fundamentals of Soil Mechanics - Vyalovmkon79Pas encore d'évaluation

- Planning and Implementing USDDocument2 pagesPlanning and Implementing USDparama.mPas encore d'évaluation

- Creep - Investigation To Soil Creep1981 - 01 - 0100Document5 pagesCreep - Investigation To Soil Creep1981 - 01 - 0100TONNY LESMANAPas encore d'évaluation

- Deflection of Two-Way Reinforced Concrete Systems: State-Of-Theart ReportDocument24 pagesDeflection of Two-Way Reinforced Concrete Systems: State-Of-Theart ReportKaram AlbarodyPas encore d'évaluation

- Understanding Caspian Region's Role in Ensuring Central Asia's Energy Security Prospects For Cooperation and InterdependenceDocument20 pagesUnderstanding Caspian Region's Role in Ensuring Central Asia's Energy Security Prospects For Cooperation and InterdependenceADBI EventsPas encore d'évaluation

- Apr Id24776Document22 pagesApr Id24776Carlos ArenasPas encore d'évaluation

- Mvjfur 94749843Document2 pagesMvjfur 94749843Carlos ArenasPas encore d'évaluation

- Radial Basis Functional Model of Multi-Point Dieless Forming Process For Springback Reduction and CompensationDocument1 pageRadial Basis Functional Model of Multi-Point Dieless Forming Process For Springback Reduction and CompensationCarlos ArenasPas encore d'évaluation

- 34 FTR 45Document10 pages34 FTR 45Carlos ArenasPas encore d'évaluation

- Mat 6453-9854PDocument78 pagesMat 6453-9854PCarlos ArenasPas encore d'évaluation

- Diels AlderDocument10 pagesDiels AlderJorge LizcanoPas encore d'évaluation

- Rev 04Document32 pagesRev 04Rene Ramos MenesesPas encore d'évaluation

- FG 023Document8 pagesFG 023Carlos ArenasPas encore d'évaluation

- Icmp2014 5014Document3 pagesIcmp2014 5014Carlos ArenasPas encore d'évaluation

- 3D Model Based Boat Hull Design and Manufacturing: - InformatikaDocument3 pages3D Model Based Boat Hull Design and Manufacturing: - InformatikaCarlos ArenasPas encore d'évaluation

- Finite Element Simulation of Residual Stress Profiles in Peen Forming ProcessDocument1 pageFinite Element Simulation of Residual Stress Profiles in Peen Forming ProcessCarlos ArenasPas encore d'évaluation

- Friction Stir Incremental Forming of A2017 Aluminum SheetsDocument6 pagesFriction Stir Incremental Forming of A2017 Aluminum SheetsCarlos ArenasPas encore d'évaluation

- Seamless Superconducting RF CavitiesDocument4 pagesSeamless Superconducting RF CavitiesCarlos ArenasPas encore d'évaluation

- Jamech: Numerical and Experimental Analysis and Optimization of Process Parameters of AA1050 Incremental Sheet FormingDocument11 pagesJamech: Numerical and Experimental Analysis and Optimization of Process Parameters of AA1050 Incremental Sheet FormingCarlos ArenasPas encore d'évaluation

- New Tools For The Selection of Technologies Application To Sheet Metal FormingDocument5 pagesNew Tools For The Selection of Technologies Application To Sheet Metal FormingCarlos ArenasPas encore d'évaluation

- 864565324Document10 pages864565324Carlos ArenasPas encore d'évaluation

- Nmir 20130729161758Document290 pagesNmir 20130729161758Carlos ArenasPas encore d'évaluation

- Dieless Forming Using 3D Printer of Carbon Fibre Reinforced Plastic Parts PDFDocument9 pagesDieless Forming Using 3D Printer of Carbon Fibre Reinforced Plastic Parts PDFIjcemJournalPas encore d'évaluation

- DDM - InstructionsDocument9 pagesDDM - InstructionsCarlos ArenasPas encore d'évaluation

- United States Patent (19) : Park Et Al. (11) Patent NumberDocument10 pagesUnited States Patent (19) : Park Et Al. (11) Patent NumberCarlos ArenasPas encore d'évaluation

- Review On Various Kinds of Die Less Forming Methods: Sayed Mojtaba Tabibian, Maryam Khanian NajafabadiDocument5 pagesReview On Various Kinds of Die Less Forming Methods: Sayed Mojtaba Tabibian, Maryam Khanian NajafabadiCarlos ArenasPas encore d'évaluation

- Design of Metallic Expansion Joints PDFDocument8 pagesDesign of Metallic Expansion Joints PDFASHISH GUPTAPas encore d'évaluation

- 9809 0566Document98 pages9809 0566Carlos ArenasPas encore d'évaluation

- ZV M665Document32 pagesZV M665Carlos ArenasPas encore d'évaluation

- Wyyt 97y4Document16 pagesWyyt 97y4Carlos ArenasPas encore d'évaluation

- Proc Ese 1233Document4 pagesProc Ese 1233Carlos ArenasPas encore d'évaluation

- Z-18 GTTRRDocument12 pagesZ-18 GTTRRCarlos ArenasPas encore d'évaluation

- ZCVN Kiut774Document14 pagesZCVN Kiut774Carlos ArenasPas encore d'évaluation

- ZX 03-TDocument29 pagesZX 03-TCarlos ArenasPas encore d'évaluation

- VMF 096uDocument11 pagesVMF 096uCarlos ArenasPas encore d'évaluation

- Casting notes-EME-1Document23 pagesCasting notes-EME-1AndrewPas encore d'évaluation

- Hes B100-99 Dimensional Tolerances For Threaded FastenerDocument6 pagesHes B100-99 Dimensional Tolerances For Threaded FastenerPreetam KumarPas encore d'évaluation

- Class 2B Internal ThreadsDocument2 pagesClass 2B Internal ThreadsLaural MarshallPas encore d'évaluation

- Introduction of Manufacturing ProcessesDocument44 pagesIntroduction of Manufacturing Processesdhruvmistry300Pas encore d'évaluation

- NPD Parts SheetDocument2 pagesNPD Parts SheetAbhishek DahiyaPas encore d'évaluation

- Permanent Mold Casting Processes: Usually Made From Metal Gas Pressure or A Vacuum UsedDocument57 pagesPermanent Mold Casting Processes: Usually Made From Metal Gas Pressure or A Vacuum UsedJacob KussiaPas encore d'évaluation

- CAT Torque Specifications EnglishDocument5 pagesCAT Torque Specifications EnglishSergeyPas encore d'évaluation

- 3475331Document41 pages3475331Nguyen Trong TanPas encore d'évaluation

- Article - Screw Threads DesignDocument16 pagesArticle - Screw Threads DesignPRADEEPPas encore d'évaluation

- Advance Metal Forming ProcessDocument12 pagesAdvance Metal Forming ProcessRemo RamPas encore d'évaluation

- UNC Thread ANSI/ASME B1.1: Last Chance To Invest at 500kDocument2 pagesUNC Thread ANSI/ASME B1.1: Last Chance To Invest at 500kAtul BedekarPas encore d'évaluation

- Schduled For Month July-2022Document53 pagesSchduled For Month July-2022Bolzen ProductionPas encore d'évaluation

- Casting DefectsDocument12 pagesCasting DefectsPushkar GopalPas encore d'évaluation

- 5113Document4 pages5113jineesha p jPas encore d'évaluation

- Description and Taxonomy of The Manufacturing Processes PDFDocument5 pagesDescription and Taxonomy of The Manufacturing Processes PDFBhupesh GuptaPas encore d'évaluation

- Polymer Processing Operation: "Sheet Extruding Machine"Document9 pagesPolymer Processing Operation: "Sheet Extruding Machine"zarqullah javaidPas encore d'évaluation

- Types of ThreadsDocument20 pagesTypes of Threadsrethinamk50% (2)

- AMT - CastingDocument44 pagesAMT - CastingUddhav ArothePas encore d'évaluation

- Parts List PDP-KitDocument5 pagesParts List PDP-KitMq Sita QuispePas encore d'évaluation

- Sand CastingDocument2 pagesSand CastingAhmad NabilPas encore d'évaluation

- Metal Forming Processes: Dr. Sunil JhaDocument16 pagesMetal Forming Processes: Dr. Sunil JhaarulmuruguPas encore d'évaluation

- Casting - WikipediaDocument4 pagesCasting - WikipediaKyaw Bhone WinPas encore d'évaluation

- Dhanalakshmi College of Engineering Department of Mechanical Engineering Me 6302 Manufacturing Technology - 1 (Question Bank)Document10 pagesDhanalakshmi College of Engineering Department of Mechanical Engineering Me 6302 Manufacturing Technology - 1 (Question Bank)arulPas encore d'évaluation

- MCQS For Manfactering Process PDFDocument10 pagesMCQS For Manfactering Process PDFGet Soon WellPas encore d'évaluation

- Extrusion Blow Molding Process PDFDocument2 pagesExtrusion Blow Molding Process PDFPetePas encore d'évaluation

- Types of Pattern and Its ApplicationDocument27 pagesTypes of Pattern and Its ApplicationKarthik GanesanPas encore d'évaluation

- Tonnage CalculationDocument1 pageTonnage Calculationsumit chatterjeePas encore d'évaluation

- BSP Thread ChartDocument4 pagesBSP Thread ChartSaidas sekaran70% (10)

- 1546 1572Document27 pages1546 1572claudioandrevalverdePas encore d'évaluation

- Shell Mold Casting Is A Metal Casting Process Similar To Sand CastingDocument2 pagesShell Mold Casting Is A Metal Casting Process Similar To Sand Castingria19Pas encore d'évaluation

- Transformed: Moving to the Product Operating ModelD'EverandTransformed: Moving to the Product Operating ModelÉvaluation : 4 sur 5 étoiles4/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceD'EverandAnalog Design and Simulation Using OrCAD Capture and PSpicePas encore d'évaluation

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tD'EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tÉvaluation : 4.5 sur 5 étoiles4.5/5 (27)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceD'EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceÉvaluation : 4 sur 5 étoiles4/5 (19)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureD'EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsD'EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsD'EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsPas encore d'évaluation

- Laws of UX: Using Psychology to Design Better Products & ServicesD'EverandLaws of UX: Using Psychology to Design Better Products & ServicesÉvaluation : 5 sur 5 étoiles5/5 (9)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneD'EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Design for How People Think: Using Brain Science to Build Better ProductsD'EverandDesign for How People Think: Using Brain Science to Build Better ProductsÉvaluation : 4 sur 5 étoiles4/5 (8)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchD'EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchÉvaluation : 4 sur 5 étoiles4/5 (10)

- Lean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsD'EverandLean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsÉvaluation : 4 sur 5 étoiles4/5 (2)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersD'EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersÉvaluation : 4 sur 5 étoiles4/5 (13)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableD'EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginablePas encore d'évaluation

- 507 Mechanical Movements: Mechanisms and DevicesD'Everand507 Mechanical Movements: Mechanisms and DevicesÉvaluation : 4 sur 5 étoiles4/5 (28)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsD'EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsPas encore d'évaluation

- Understanding Automotive Electronics: An Engineering PerspectiveD'EverandUnderstanding Automotive Electronics: An Engineering PerspectiveÉvaluation : 3.5 sur 5 étoiles3.5/5 (16)

- Basic Electric Circuits: Pergamon International Library of Science, Technology, Engineering and Social StudiesD'EverandBasic Electric Circuits: Pergamon International Library of Science, Technology, Engineering and Social StudiesÉvaluation : 3 sur 5 étoiles3/5 (1)

- Design Recipes for FPGAs: Using Verilog and VHDLD'EverandDesign Recipes for FPGAs: Using Verilog and VHDLÉvaluation : 2 sur 5 étoiles2/5 (1)