Académique Documents

Professionnel Documents

Culture Documents

Design Calculation Fuel Gas Scrubber

Transféré par

Peja JusohTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design Calculation Fuel Gas Scrubber

Transféré par

Peja JusohDroits d'auteur :

Formats disponibles

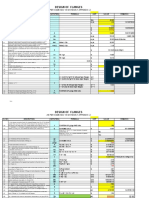

MSET ENGINEERING CORPORATION SDN BHD

DOCUMENT TITLE: DESIGN CALCULATION

DATE: 11.01.2015

DOC. REF. NO.: MSET/M2-251/V-6011/DC

REVISION: 02

SUBJECT: TITLE PAGE

JOB NO: M2-251

SERIAL NO.: 002

DESIGN CALCULATION

Fuel Gas Scrubber

TAG NO: V-6011

PROJECT NAME:

E6 Development Project

CLIENT NAME:

VME Process

02

01

Rev.

No.

11.01.15

10.12.14

Issued for Approval

Issued for Review

Date

Description of Revision

Mohd Faizal

Muhd Faizal

Prepared

by

Yahasliza

Yahasliza

Reviewed

by

Azahar

Azahar

Approved

by

MSET ENGINEERING CORPORATION SDN BHD

DOCUMENT TITLE: DESIGN CALCULATION

DATE: 11.01.2015

DOC. REF. NO.: MSET/M2-251/V-6011/DC

REVISION: 02

SUBJECT: TITLE PAGE

JOB NO: M2-251

SERIAL NO.: M2-234/001

DESIGN DATA

ITEM NO.

FUEL GAS SCRUBBER

ASME SEC.VIII DIV.1, 2013 EDITION +

DEP 31.22. 20.31

DESIGN CODE

DESIGN

OPERATING

TEST PRESSURE

PRESSURE (barg) (Int./Ext.)

18/FV

TEMPERATURE (C) (Max./Min)

50/0

PRESSURE (barg) (Max)

7.1

TEMPERATURE (C) (Max)/(Min)

38.96/24.9

HYDROTEST (barg)

(1.3xMAPxLSR)(note1)

23.754 (Horizontal Position)

PNEUMATIC

NO

MAWP (hot & corroded) (barg)

18.283

MAP (new & cold) (barg)

18.363

OUTSIDE DIAMETER / TL TO FACE (mm)

610/2400

TYPE OF HEAD

MATERIAL OF CONSTRUCTION (SHELL/HEAD & BODYFLANGE)

HEAT TREATMENT

2:1 ELLIP HEAD/BODY

FLANGE

SA 240 GR. 316/316L & SA

182 F 316/316L

NORMALISED

NO

PWHT

NO

IMPACT TEST

NO

MDMT (C)

RADIOGRAPHY

HEAD: 100%, SHELL: 100%

JOINT EFFICIENCY

HEAD:1.0 , SHELL: 1.0

CORROSION ALLOWANCE (mm)

CONTENTS

HC LIQUID/GAS

ERECTION WEIGHT (kg)

850

CAPACITY (m3)

0.69

PRESSURE VESSEL DESIGN CALCULATION

Note: 1.MAP will be used in lieu of MAWP for determining hydro test pressure

(As per DEP 31.22.20.31-Gen, Jan 09)

MSET ENGINEERING CORPORATION SDN BHD

DOCUMENT TITLE: DESIGN CALCULATION

DATE: 11.01.2015

DOC. REF. NO.: MSET/M2-251/V-6011/DC

REVISION: 02

SUBJECT: TITLE PAGE

JOB NO: M2-251

SERIAL NO.: M2-251/001

TABLE OF CONTENT

NO

CONTENT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Input Echo

Flg Calc [Int P] : A1 (flange)

Flg Calc [Int P] : A1 (blind)

Internal Pressure Calculations

External Pressure Calculations

Element and Detail Weights

Nozzle Flange MAWP

Wind Load Calculation

Earthquake Load Calculation

Wind / Earthquake Shear, Bending

Wind Deflection

Stress due Combined Loads

Center of Gravity Calculation

Sup. Lug Calc

Nozzle Calculation

Nozzle Schedule

Nozzle Summary

MDMT Summary

Vessel Design Summary

Attachment 1 : Wind Pressure Calc

Attachment 2 : Transportation Calc

Attachment 3 : Lifting Trunnion Calc

PAGE NO.

4

18

22

28

33

37

43

44

46

47

48

53

60

61

76

182

185

188

190

193

195

235

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Input Echo :

Step:

1

1:01a Jan 11,2015

PV Elite Vessel Analysis Program: Input Data

Design Internal Pressure (for test)

18.000

Design Internal Temperature

50

Type of Test

bar

C

UG-99(c)

Test Position

Horizontal

Projection of Nozzle from Vessel Top

200.00

mm

Projection of Nozzle from Vessel Bottom

200.00

mm

Minimum Design Metal Temperature

Type of Construction

Welded

Special Service

None

Degree of Radiography

RT 1

Miscellaneous Weight Percent

0.0

Use Higher Longitudinal Stresses (Flag)

Select t for Internal Pressure (Flag)

Select t for External Pressure (Flag)

Select t for Axial Stress (Flag)

Select Location for Stiff. Rings (Flag)

Consider Vortex Shedding

Perform a Corroded Pressure test

Is this a Heat Exchanger

No

User Defined Test Press. (Used if > 0)

0.0000

bar

User defined MAWP

0.0000

bar

User defined MAPnc

0.0000

bar

Load Case 1

NP+EW+WI+FW+BW

Load Case 2

NP+EW+EE+FS+BS

Load Case 3

NP+OW+WI+FW+BW

Load Case 4

NP+OW+EQ+FS+BS

Load Case 5

NP+HW+HI

Load Case 6

NP+HW+HE

4

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Input Echo :

Step:

1

1:01a Jan 11,2015

Load Case 7

IP+OW+WI+FW+BW

Load Case 8

IP+OW+EQ+FS+BS

Load Case 9

EP+OW+WI+FW+BW

Load Case 10

EP+OW+EQ+FS+BS

Load Case 11

HP+HW+HI

Load Case 12

HP+HW+HE

Load Case 13

IP+WE+EW

Load Case 14

IP+WF+CW

Load Case 15

IP+VO+OW

Load Case 16

IP+VE+EW

Load Case 17

NP+VO+OW

Load Case 18

FS+BS+IP+OW

Load Case 19

FS+BS+EP+OW

Wind Design Code

User Defined

Wind Profile Height mm

Pressure

kPa

10000.0000

0.7500

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

Damping Factor (Beta) for Wind (Ope)

0.0100

Damping Factor (Beta) for Wind (Empty)

0.0000

Damping Factor (Beta) for Wind (Filled)

0.0000

Seismic Design Code

G Loading

Seismic Importance Factor

1.000

G Loading Coefficient Gx

0.500

G Loading Coefficient Gz

0.500

5

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Input Echo :

Step:

1

1:01a Jan 11,2015

G Loading Coefficient Gy

-2.000

Percent Seismic for Test

0.000

Design Nozzle for M.A.W.P. (maximum)

Consider MAP New and Cold in Noz. Design

Consider External Loads for Nozzle Des.

Use ASME VIII-1 Appendix 1-9

Material Database Year

Current w/Addenda or Code Year

Configuration Directives:

Do not use Nozzle MDMT Interpretation VIII-1 01-37

No

Use Table G instead of exact equation for "A"

Yes

Shell Head Joints are Tapered

Yes

Compute "K" in corroded condition

No

Use Code Case 2286

No

Use the MAWP to compute the MDMT

Yes

Using Metric Material Databases, ASME II D

No

Complete Listing of Vessel Elements and Details:

Element From Node

10

Element To Node

20

Element Type

Elliptical

Description

Head

Distance "FROM" to "TO"

38.000

mm

Element Outside Diameter

610.00

mm

Element Thickness

5.0000

mm

Internal Corrosion Allowance

0.0000

mm

Nominal Thickness

8.0000

mm

External Corrosion Allowance

0.0000

mm

Design Internal Pressure

18.000

bar

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Input Echo :

Step:

1

1:01a Jan 11,2015

Design Temperature Internal Pressure

50

Design External Pressure

1.0342

Design Temperature External Pressure

50

Effective Diameter Multiplier

C

bar

C

1.2

Material Name

SA-240 316L

Allowable Stress, Ambient

115.15

MPa

Allowable Stress, Operating

115.15

MPa

Allowable Stress, Hydrotest

155.14

MPa

Material Density

8027.2

kg/m

P Number Thickness

0.0000

mm

Yield Stress, Operating

165.40

MPa

External Pressure Chart Name

HA-4

UNS Number

S31603

Product Form

Plate

Efficiency, Longitudinal Seam

1.0

Efficiency, Circumferential Seam

1.0

Elliptical Head Factor

2.0

Element From Node

10

Detail Type

Liquid

Detail ID

LIQUID

Dist. from "FROM" Node / Offset dist

-150.00

mm

Height/Length of Liquid

188.00

mm

Liquid Density

909.98

kg/m

Element From Node

10

Detail Type

Nozzle

Detail ID

N3

Dist. from "FROM" Node / Offset dist

0.0000

Nozzle Diameter

2.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

90.0

7

mm

in.

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Input Echo :

Step:

1

1:01a Jan 11,2015

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

51.995

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

--------------------------------------------------------------------

Element From Node

20

Element To Node

30

Element Type

Cylinder

Description

Shell

Distance "FROM" to "TO"

2209.0

mm

Element Outside Diameter

610.00

mm

Element Thickness

8.0000

mm

Internal Corrosion Allowance

0.0000

mm

Nominal Thickness

8.0000

mm

External Corrosion Allowance

0.0000

mm

Design Internal Pressure

18.000

bar

Design Temperature Internal Pressure

50

Design External Pressure

1.0342

Design Temperature External Pressure

50

Effective Diameter Multiplier

C

bar

C

1.2

Material Name

SA-240 316L

Efficiency, Longitudinal Seam

1.0

Efficiency, Circumferential Seam

1.0

Element From Node

20

Detail Type

Liquid

Detail ID

LIQUID

Dist. from "FROM" Node / Offset dist

0.0000

mm

Height/Length of Liquid

900.00

mm

Liquid Density

910.00

kg/m

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Input Echo :

Step:

1

1:01a Jan 11,2015

Element From Node

20

Detail Type

Nozzle

Detail ID

N1

Dist. from "FROM" Node / Offset dist

1187.0

Nozzle Diameter

2.0

Nozzle Schedule

None

Nozzle Class

600

Layout Angle

270.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

81.537

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-182 F316

Element From Node

20

Detail Type

Nozzle

Detail ID

N5

Dist. from "FROM" Node / Offset dist

1812.0

Nozzle Diameter

2.0

Nozzle Schedule

None

Nozzle Class

150

Layout Angle

270.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

67.101

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-182 F316

Element From Node

20

Detail Type

Nozzle

Detail ID

N6

Dist. from "FROM" Node / Offset dist

162.00

Nozzle Diameter

2.0

Nozzle Schedule

None

Nozzle Class

150

9

mm

in.

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Input Echo :

Step:

1

1:01a Jan 11,2015

Layout Angle

90.0

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

67.101

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-182 F316

Element From Node

20

Detail Type

Nozzle

Detail ID

K1

Dist. from "FROM" Node / Offset dist

1812.0

Nozzle Diameter

2.0

Nozzle Schedule

None

Nozzle Class

150

Layout Angle

315.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

67.101

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-182 F316

Element From Node

20

Detail Type

Nozzle

Detail ID

K2A

Dist. from "FROM" Node / Offset dist

962.00

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

0.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

76.191

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

10

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Input Echo :

Step:

1

1:01a Jan 11,2015

Detail Type

Nozzle

Detail ID

K2B

Dist. from "FROM" Node / Offset dist

162.00

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

0.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

76.191

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

Detail Type

Nozzle

Detail ID

K3A

Dist. from "FROM" Node / Offset dist

712.00

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

135.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

76.191

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

Detail Type

Nozzle

Detail ID

K3B

Dist. from "FROM" Node / Offset dist

162.00

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

135.0

11

mm

in.

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Input Echo :

Step:

1

1:01a Jan 11,2015

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

76.191

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

Detail Type

Nozzle

Detail ID

K4A

Dist. from "FROM" Node / Offset dist

1002.0

Nozzle Diameter

2.0

Nozzle Schedule

None

Nozzle Class

150

Layout Angle

315.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

67.101

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-182 F316

Element From Node

20

Detail Type

Nozzle

Detail ID

K4B

Dist. from "FROM" Node / Offset dist

162.00

Nozzle Diameter

2.0

Nozzle Schedule

None

Nozzle Class

150

Layout Angle

315.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

67.101

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-182 F316

Element From Node

20

Detail Type

Nozzle

12

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Input Echo :

Step:

1

1:01a Jan 11,2015

Detail ID

K5A

Dist. from "FROM" Node / Offset dist

962.00

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

30.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

76.191

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

Detail Type

Nozzle

Detail ID

K5B

Dist. from "FROM" Node / Offset dist

512.00

Nozzle Diameter

3.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

30.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

76.191

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

Detail Type

Nozzle

Detail ID

HH

Dist. from "FROM" Node / Offset dist

162.00

Nozzle Diameter

4.0

Nozzle Schedule

80S

Nozzle Class

150

Layout Angle

250.0

Blind Flange (Y/N)

Y

13

mm

in.

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Input Echo :

Step:

1

1:01a Jan 11,2015

Weight of Nozzle ( Used if > 0 )

185.10

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-312 TP316L

Element From Node

20

Detail Type

Lug

Detail ID

LUG

Dist. from "FROM" Node / Offset dist

1771.0

Number of Lugs

mm

Dist. from OD to Lug Cntrline(dlug)

128.00

mm

Height of Gusset Plates (hgp)

306.00

mm

Force Bearing Width (wfb)

204.00

mm

Weight of Lug

150.00

Lug Start Angle (degrees)

0.0

Element From Node

20

Detail Type

Weight

Detail ID

MIST ELIMINATOR

Dist. from "FROM" Node / Offset dist

2100.0

mm

Miscellaneous Weight

980.60

Offset from Element Centerline

0.0000

mm

--------------------------------------------------------------------

Element From Node

30

Element To Node

40

Element Type

Flange

Description

Body Flange

Distance "FROM" to "TO"

152.40

mm

Flange Inside Diameter (OD for Blinds)

593.60

mm

Element Thickness

47.752

mm

Internal Corrosion Allowance

0.0000

mm

Nominal Thickness

8.0000

mm

14

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Input Echo :

Step:

1

1:01a Jan 11,2015

External Corrosion Allowance

0.0000

mm

Design Internal Pressure

18.000

bar

Design Temperature Internal Pressure

50

Design External Pressure

1.0342

Design Temperature External Pressure

50

Effective Diameter Multiplier

C

bar

C

1.2

Material Name

SA-182 F316

Allowable Stress, Ambient

137.90

MPa

Allowable Stress, Operating

137.90

MPa

Allowable Stress, Hydrotest

186.17

MPa

Material Density

8027.2

kg/m

P Number Thickness

0.0000

mm

Yield Stress, Operating

217.74

MPa

External Pressure Chart Name

HA-2

UNS Number

Class / Thickness / Grade

S31600

:: > 5

Product Form

Forgings

Perform Flange Stress Calculation (Y/N)

Weight of ANSI B16.5/B16.47 Flange

0.0000

Class of ANSI B16.5/B16.47 Flange

Grade of ANSI B16.5/B16.47 Flange

--------------------------------------------------------------------

Element From Node

40

Element To Node

50

Element Type

Flange

Description

Blind

Distance "FROM" to "TO"

68.000

mm

Flange Inside Diameter (OD for Blinds)

812.80

mm

Element Thickness

68.000

mm

Internal Corrosion Allowance

0.0000

mm

Nominal Thickness

8.0000

mm

15

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Input Echo :

Step:

1

1:01a Jan 11,2015

External Corrosion Allowance

0.0000

mm

Design Internal Pressure

18.000

bar

Design Temperature Internal Pressure

50

Design External Pressure

1.0342

Design Temperature External Pressure

50

Effective Diameter Multiplier

C

bar

C

1.2

Material Name

SA-182 F316

Perform Flange Stress Calculation (Y/N)

Weight of ANSI B16.5/B16.47 Flange

0.0000

Class of ANSI B16.5/B16.47 Flange

Grade of ANSI B16.5/B16.47 Flange

Element From Node

40

Detail Type

Nozzle

Detail ID

N2

Dist. from "FROM" Node / Offset dist

205.00

Nozzle Diameter

2.0

Nozzle Schedule

None

Nozzle Class

150

Layout Angle

180.0

Blind Flange (Y/N)

mm

in.

Weight of Nozzle ( Used if > 0 )

67.101

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-182 F316

Element From Node

40

Detail Type

Nozzle

Detail ID

N4

Dist. from "FROM" Node / Offset dist

205.00

Nozzle Diameter

2.0

Nozzle Schedule

None

Nozzle Class

150

Layout Angle

0.0

16

mm

in.

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Input Echo :

Step:

1

1:01a Jan 11,2015

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

61.752

Grade of Attached Flange

GR 2.2

Nozzle Matl

SA-182 F316

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

17

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Flg Calc [Int P] : A1 (flange)

Flng:

11

1:01a Jan 11,2015

Flange Input Data Values

Description: A1 (flange) :

Body Flange

Description of Flange Geometry (Type)

Design Pressure

Integral Weld Neck

P

18.00

Design Temperature

bar

50

Internal Corrosion Allowance

ci

0.0000

mm

External Corrosion Allowance

ce

0.0000

mm

Use Corrosion Allowance in Thickness Calcs.

No

Flange Inside Diameter

593.600

mm

Flange Outside Diameter

812.800

mm

Flange Thickness

47.7520

mm

Thickness of Hub at Small End

go

8.0000

mm

Thickness of Hub at Large End

g1

34.9240

mm

104.6480

mm

Length of Hub

Flange Material

SA-182 F316

Flange Material UNS number

S31600

Flange Allowable Stress At Temperature

Sfo

137.90

MPa

Flange Allowable Stress At Ambient

Sfa

137.90

MPa

Bolt Material

SA-193 B7

Bolt Allowable Stress At Temperature

Sb

172.38

MPa

Bolt Allowable Stress At Ambient

Sa

172.38

MPa

Diameter of Bolt Circle

749.300

mm

Nominal Bolt Diameter

31.7500

mm

Type of Threads

TEMA Thread Series

Number of Bolts

20

Flange Face Outside Diameter

Fod

692.150

18

mm

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Flg Calc [Int P] : A1 (flange)

Flng:

11

1:01a Jan 11,2015

Flange Face Inside Diameter

Fid

Flange Facing Sketch

593.600

mm

1, Code Sketch 1a

Gasket Outside Diameter

Go

685.800

mm

Gasket Inside Diameter

Gi

628.650

mm

Gasket Factor

0.0000

Gasket Design Seating Stress

0.00

Column for Gasket Seating

2, Code Column II

Gasket Thickness

tg

3.1750

ANSI Flange Class

150

ANSI Flange Grade

GR 2.2

MPa

mm

ASME Code, Section VIII, Division 1, 2010, 2011a

Hub Small End Required Thickness due to Internal Pressure:

= (P*(D/2+Ca))/(S*E-0.6*P) per UG-27 (c)(1)

= (18.00*(593.6000/2+0.0000))/(137.90*1.00-0.6*18.00)+Ca

= 3.9053 mm

Hub Small End Hub MAWP:

= (S*E*t)/(R+0.6*t) per UG-27 (c)(1)

= (137.90 * 1.00 * 8.0000 )/(296.8000 + 0.6 * 8.0000 )

= 36.573 bar

Corroded Flange ID,

Bcor = B+2*Fcor

593.600

mm

Corroded Large Hub,

g1Cor = g1-ci

34.924

mm

Corroded Small Hub,

g0Cor = go-ci

8.000

mm

Code R Dimension,

R = (C-B)/2 - g1

42.926

mm

Gasket Contact Width,

N = (Go - Gi) / 2

28.575

mm

14.287

mm

Basic Gasket Width,

bo = N / 2

19

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Flg Calc [Int P] : A1 (flange)

Flng:

11

1:01a Jan 11,2015

Effective Gasket Width,

b = Cb sqrt(bo)

Gasket Reaction Diameter,

G = Go (Self-Energizing)

Basic Flange and Bolt Loads:

Hydrostatic End Load due to Pressure [H]:

= 0.785 * G * Peq

= 0.785 * 685.8000 * 18.000

= 664941.500 N

Contact Load on Gasket Surfaces [Hp]:

= 2 * b * Pi * G * m * P

= 2 * 9.5250 * 3.1416 * 685.8000 * 0.0000 * 18.00

= 0.000 N

Hydrostatic End Load at Flange ID [Hd]:

= Pi * Bcor * P

/ 4

= 3.1416 * 593.6000 *18.0000/4

= 498168.531 N

Pressure Force on Flange Face [Ht]:

= H - Hd

= 664941 - 498168

= 166773.000 N

Operating Bolt Load [Wm1]:

= max( H + Hp + H'p, 0 )

= max( 664941 + 0 + 0 , 0 )

= 664941.500 N

Gasket Seating Bolt Load [Wm2]:

= y * b * Pi * G

+ yPart * bPart * lp

= 0.00*9.5250*3.141*685.800+0.00*0.0000*0.00

= 0.000 N

Required Bolt Area [Am]:

= Maximum of Wm1/Sb, Wm2/Sa

= Maximum of 664941/172 , 0/172

= 3857.857 mm

20

9.525

mm

685.800

mm

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Flg Calc [Int P] : A1 (flange)

Flng:

11

1:01a Jan 11,2015

ASME Maximum Circumferential Spacing between Bolts per App. 2 eq. (3) [Bsmax]:

= 2a + 6t/(m + 0.5)

= 2 * 31.750 + 6 * 47.752/(0.00 + 0.5)

= 636.524 mm

Actual Circumferential Bolt Spacing [Bs]:

= C * sin( pi / n )

= 749.300 * sin( 3.142/20 )

= 117.216 mm

ASME Moment Multiplier for Bolt Spacing per App. 2 eq. (7) [Bsc]:

= max( sqrt( Bs/( 2a + t )), 1 )

= max( sqrt( 117.216/( 2 * 31.750 + 47.752 )), 1 )

= 1.0265

Bolting Information for TEMA Imperial Thread Series (Non Mandatory):

----------------------------------------------------------------------------Minimum

Actual

Maximum

----------------------------------------------------------------------------Bolt Area, mm

Radial distance bet. hub and bolts

3857.857

11987.072

44.450

42.926

Radial distance bet. bolts and the edge

31.750

31.750

Circumferential spacing between bolts

71.450

117.216

636.524

-----------------------------------------------------------------------------

Flange Design Bolt Load, Gasket Seating [W]:

= Sa * ( Am + Ab ) / 2

= 172.38 * ( 3857.8567 + 11987.0723 )/2

= 1365518.75 N

Gasket Load for the Operating Condition [HG]:

= Wm1 - H

= 664941 - 664941

21

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Flg Calc [Int P] : A1 (flange)

Flng:

11

1:01a Jan 11,2015

= 0.00 N

Moment Arm Calculations:

Distance to Gasket Load Reaction [hg]:

= (C - G ) / 2

= ( 749.3000 - 685.8000 )/2

= 31.7500 mm

Distance to Face Pressure Reaction [ht]:

= ( R + g1 + hg ) / 2

= ( 42.9260 + 34.9240 + 31.7500 )/2

= 54.8000 mm

Distance to End Pressure Reaction [hd]:

= R + ( g1 / 2 )

= 42.9260 + ( 34.9240/2.0 )

= 60.3880 mm

Summary of Moments for Internal Pressure:

Loading

Force

Distance Bolt Corr

Moment

End Pressure,

Md

498169.

60.3880

1.0265

30892. N-m

Face Pressure,

Mt

166773.

54.8000

1.0265

9385. N-m

Gasket Load,

Mg

0.

31.7500

1.0265

0. N-m

1365519.

31.7500

1.0265

44520. N-m

Gasket Seating, Matm

Total Moment for Operation,

Mop

40277. N-m

Total Moment for Gasket seating, Matm

44520. N-m

Note: User choose not to perform Stress Calculations on this ANSI Flange.

Pressure rating of the flange will be used to check code compliance.

Estimated Finished Weight of Flange at given Thk.

127.6

kgm

Estimated Unfinished Weight of Forging at given Thk

296.2

kgm

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

22

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Flg Calc [Int P] : A1 (blind)

Flng:

12

1:01a Jan 11,2015

Flange Input Data Values

Description: A1 (blind)

Blind

Description of Flange Geometry (Type)

Blind

Design Pressure

18.00

Design Temperature

bar

50

Internal Corrosion Allowance

ci

0.0000

mm

External Corrosion Allowance

ce

0.0000

mm

Use Corrosion Allowance in Thickness Calcs.

Yes

Flange Outside Diameter

812.800

mm

Flange Thickness

68.0000

mm

Flange Material

SA-182 F316

Flange Material UNS number

S31600

Flange Allowable Stress At Temperature

Sfo

137.90

MPa

Flange Allowable Stress At Ambient

Sfa

137.90

MPa

Bolt Material

SA-193 B7

Bolt Allowable Stress At Temperature

Sb

172.38

MPa

Bolt Allowable Stress At Ambient

Sa

172.38

MPa

Span

0.000

mm

Diameter of the Load Reaction, Short Span

0.000

mm

Perimeter along the Center of the Bolts

2353.995

mm

Diameter of Bolt Circle

749.300

mm

Nominal Bolt Diameter

31.7500

mm

Diameter of the Load Reaction, Long

Type of Threads

TEMA Thread Series

Number of Bolts

20

Flange Face Outside Diameter

Fod

692.150

23

mm

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Flg Calc [Int P] : A1 (blind)

Flng:

12

1:01a Jan 11,2015

Flange Face Inside Diameter

Fid

Flange Facing Sketch

590.550

mm

1, Code Sketch 1a

Gasket Outside Diameter

Go

685.800

mm

Gasket Inside Diameter

Gi

628.650

mm

Gasket Factor

0.0000

Gasket Design Seating Stress

0.00

Column for Gasket Seating

2, Code Column II

Gasket Thickness

tg

3.1750

Evaluate Patterned Holes in Blind Cover

MPa

mm

Yes

Hole Diameter D1

77.200

mm

Hole Diameter D2

77.200

mm

Edge Distance to D1

163.000

mm

Edge Distance to D2

163.000

mm

Pitch Distance

410.000

mm

Checking Multiple Openings on Flat Head per ASME Sec. VIII Div. 1 UG-39

Head dia = 749.30 Opening dia, d1 = 77.20 d2 = 77.20 mm

UG-39(e)(1) Spacing 410.00 is >= 2*Avg. dia. 154.40 OK.

ASME Code, Section VIII, Division 1, 2010, 2011a

Gasket Contact Width,

Basic Gasket Width,

N = (Go - Gi) / 2

bo = N / 2

Effective Gasket Width,

b = Cb sqrt(bo)

Gasket Reaction Diameter,

G = Go (Self-Energizing)

24

28.575

mm

14.287

mm

9.525

mm

685.800

mm

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Flg Calc [Int P] : A1 (blind)

Flng:

12

1:01a Jan 11,2015

Basic Flange and Bolt Loads:

Hydrostatic End Load due to Pressure [H]:

= 0.785 * G * Peq

= 0.785 * 685.8000 * 18.000

= 664941.500 N

Contact Load on Gasket Surfaces [Hp]:

= 2 * b * Pi * G * m * P

= 2 * 9.5250 * 3.1416 * 685.8000 * 0.0000 * 18.00

= 0.000 N

Operating Bolt Load [Wm1]:

= max( H + Hp + H'p, 0 )

= max( 664941 + 0 + 0 , 0 )

= 664941.500 N

Gasket Seating Bolt Load [Wm2]:

= y * b * Pi * G

+ yPart * bPart * lp

= 0.00*9.5250*3.141*685.800+0.00*0.0000*0.00

= 0.000 N

Required Bolt Area [Am]:

= Maximum of Wm1/Sb, Wm2/Sa

= Maximum of 664941/172 , 0/172

= 3857.857 mm

ASME Maximum Circumferential Spacing between Bolts per App. 2 eq. (3) [Bsmax]:

= 2a + 6t/(m + 0.5)

= 2 * 31.750 + 6 * 68.000/(0.00 + 0.5)

= 879.500 mm

Actual Circumferential Bolt Spacing [Bs]:

= C * sin( pi / n )

= 749.300 * sin( 3.142/20 )

= 117.216 mm

25

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Flg Calc [Int P] : A1 (blind)

Flng:

12

1:01a Jan 11,2015

ASME Moment Multiplier for Bolt Spacing per App. 2 eq. (7) [Bsc]:

= max( sqrt( Bs/( 2a + t )), 1 )

= max( sqrt( 117.216/( 2 * 31.750 + 68.000 )), 1 )

= 1.0000

Bolting Information for TEMA Imperial Thread Series (Non Mandatory):

----------------------------------------------------------------------------Minimum

Actual

Maximum

----------------------------------------------------------------------------Bolt Area, mm

3857.857

11987.072

Radial distance bet. bolts and the edge

31.750

31.750

Circumferential spacing between bolts

71.450

117.216

879.500

-----------------------------------------------------------------------------

Flange Design Bolt Load, Gasket Seating [W]:

= Sa * ( Am + Ab ) / 2

= 172.38 * ( 3857.8567 + 11987.0723 )/2

= 1365518.75 N

Gasket Load for the Operating Condition [HG]:

= Wm1

= 664941.50 N

Moment Arm Calculations:

Distance to Gasket Load Reaction [hg]:

= (C - G ) / 2

= ( 749.3000 - 685.8000 )/2

= 31.7500 mm

Tangential Flange Stress, Flat Head (UG-34), Operating [STo]:

= 2 * ( 1.9 * Wm1 * hG * Bsc/(t * G) + C * Z * Peq * G/t )

= 2*(1.9*664941*31.7500*1.0000/(68.0000*685.8000)+

0.30*1.0000*18.00*685.8000/68.0000)

= 135.17 MPa Doubled per UG-39(d)(2).

26

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Flg Calc [Int P] : A1 (blind)

Flng:

12

1:01a Jan 11,2015

Tangential Flange Stress, Flat Head (UG-34), Seating [STa]:

= 2 * 1.9 * W * hG * Bcor / (t * G)

= 2*1.9*1365518*31.7500*1.000/(68.0000*685.8000)

= 51.96 MPa Doubled per UG-39(d)(2).

Bolt Stress, Operating [BSo]:

= ( Wm1 / Ab )

= (664941/11987.0723)

= 55.48 MPa

Bolt Stress, Seating [BSa]:

= ( Wm2 / Ab )

= (0/11987.0723)

= 0.00 MPa

Flange Stress Analysis Results:

Operating

Actual

Allowed

Gasket Seating

Actual

Allowed

--------------------------------------------------------------------Tangential Flange

Bolting

135.

138.

52.

138. MPa

55.

172.

0.

172. MPa

---------------------------------------------------------------------

Reqd. Blind Flange Thickness at Center

67.323

mm

Reqd. Blind Flange Thickness at Gasket

29.514

mm

Estimated M.A.W.P. ( Operating )

18.4

bar

Estimated Finished Weight of Flange at given Thk.

283.2

kgm

Estimated Unfinished Weight of Forging at given Thk

283.2

kgm

SA-182 F316, Min Metal Temp without impact per UHA-51: -196 C

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

27

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Internal Pressure Calculations :

Step:

5

1:01a Jan 11,2015

Element Thickness, Pressure, Diameter and Allowable Stress :

| Int. Press |

From| To | + Liq. Hd

|

bar

|

|

Nominal | Total Corr|

Element |

Allowable |

Thickness | Allowance |

Diameter |

Stress(SE)|

mm

mm

mm

MPa

--------------------------------------------------------------------------Head|

18.097 |

8.0000 |

... |

610.00 |

115.15 |

Shell|

18.080 |

8.0000 |

... |

610.00 |

115.15 |

Body Flang|

18.000 |

8.0000 |

... |

593.60 |

137.90 |

Blind|

18.000 |

8.0000 |

... |

812.80 |

137.90 |

M.A.P. |

Minimum |

Required |

| New & Cold |

Thickness |

Thickness |

Element Required Thickness and MAWP :

Design |

From| To |

Pressure |

bar

M.A.W.P. |

Corroded

bar

bar

mm

mm

---------------------------------------------------------------------------Head|

18.0000 |

19.0593 |

19.1564 |

5.00000 |

4.72737 |

Shell|

18.0000 |

30.4379 |

30.5182 |

8.00000 |

4.75991 |

Body Flang|

18.0000 |

18.3984 |

18.9983 |

47.7520 |

No Calc |

Blind|

18.0000 |

18.3635 |

18.3635 |

68.0000 |

67.3228 |

18.283

18.363

Minimum

Note : The M.A.W.P is Governed by a Standard Flange !

Flange MAWP including Static Pressure: 18.283 = 18.398 - 0.115 bar

Internal Pressure Calculation Results :

ASME Code, Section VIII, Division 1, 2010, 2011a

Elliptical Head From 10 To 20 SA-240 316L at 50 C

28

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Internal Pressure Calculations :

Step:

5

1:01a Jan 11,2015

Head

Longitudinal

Joint:

Full Radiography per UW-11(a) Type 1

Circumferential Joint:

Full Radiography per UW-11(a) Type 1

Material UNS Number:

S31603

Required Thickness due to Internal Pressure [tr]:

= (P*Do*K)/(2*S*E+2*P*(K-0.1)) per Appendix 1-4 (c)

= (18.097*610.0000*1.000)/(2*115.15*1.00+2*18.097*(1.000-0.1))

= 4.7274 + 0.0000 = 4.7274 mm

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Less Operating Hydrostatic Head Pressure of 0.097 bar

= (2*S*E*t)/(K*Do-2*t*(K-0.1)) per Appendix 1-4 (c)

= (2*115.15*1.00*5.0000)/(1.000*610.0000-2*5.0000*(1.00-0.1))

= 19.156 - 0.097 = 19.059

bar

Maximum Allowable Pressure, New and Cold [MAPNC]:

= (2*S*E*t)/(K*Do-2*t*(K-0.1)) per Appendix 1-4 (c)

= (2*115.15*1.00*5.0000)/(1.000*610.0000-2*5.0000*(1.000-0.1))

= 19.156 bar

Actual stress at given pressure and thickness, corroded [Sact]:

= (P*(K*Do-2*t*(K-0.1)))/(2*E*t)

= (18.097*(1.000*610.0000-2*5.0000*(1.000-0.1)))/(2*1.00*5.0000)

= 108.779 MPa

Straight Flange Required Thickness:

= (P*Ro)/(S*E+0.4*P) + ca

per Appendix 1-1 (a)(1)

= (18.097*305.0000)/(115.15*1.00+0.4*18.097)+0.000

= 4.764 mm

29

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Internal Pressure Calculations :

Step:

5

1:01a Jan 11,2015

Straight Flange Maximum Allowable Working Pressure:

Less Operating Hydrostatic Head Pressure of 0.084 bar

= (S*E*t)/(Ro-0.4*t) per Appendix 1-1 (a)(1)

= (115.15 * 1.00 * 8.0000 )/(305.0000 - 0.4 * 8.0000 )

= 30.518 - 0.084 = 30.434

bar

Percent Elongation per UHA-44

(75*tnom/Rf)*(1-Rf/Ro)

5.715 %

Note: Please Check Requirements of Table UHA-44 for Elongation limits.

SA-240 316L, Min Metal Temp without impact per UHA-51: -196 C

Cylindrical Shell From 20 To 30 SA-240 316L at 50 C

Shell

Longitudinal

Joint:

Full Radiography per UW-11(a) Type 1

Circumferential Joint:

Full Radiography per UW-11(a) Type 1

Material UNS Number:

S31603

Required Thickness due to Internal Pressure [tr]:

= (P*Ro) / (S*E+0.4*P) per Appendix 1-1 (a)(1)

= (18.080*305.0000)/(115.15*1.00+0.4*18.080)

= 4.7599 + 0.0000 = 4.7599 mm

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Less Operating Hydrostatic Head Pressure of 0.080 bar

= (S*E*t)/(Ro-0.4*t) per Appendix 1-1 (a)(1)

= (115.15*1.00*8.0000)/(305.0000-0.4*8.0000)

= 30.518 - 0.080 = 30.438

bar

Maximum Allowable Pressure, New and Cold [MAPNC]:

30

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Internal Pressure Calculations :

Step:

5

1:01a Jan 11,2015

= (S*E*t)/(Ro-0.4*t) per Appendix 1-1 (a)(1)

= (115.15*1.00*8.0000)/(305.0000-0.4*8.0000)

= 30.518 bar

Actual stress at given pressure and thickness, corroded [Sact]:

= (P*(Ro-0.4*t))/(E*t)

= (18.080*((305.0000-0.4*8.0000))/(1.00*8.0000)

= 68.218 MPa

Percent Elongation per UHA-44

(50*tnom/Rf)*(1-Rf/Ro)

1.329 %

Note: Please Check Requirements of Table UHA-44 for Elongation limits.

SA-240 316L, Min Metal Temp without impact per UHA-51: -196 C

Hydrostatic Test Pressure Results:

Pressure per UG99b

= 1.3 * M.A.W.P. * Sa/S

23.768

bar

Pressure per UG99b[34] = 1.3 * Design Pres * Sa/S

23.400

bar

Pressure per UG99c

= 1.3 * M.A.P. - Head(Hyd)

23.754

bar

Pressure per UG100

= 1.1 * M.A.W.P. * Sa/S

20.112

bar

Pressure per PED

= 1.43 * MAWP

26.145

bar

Horizontal Test performed per: UG-99c

Please note that Nozzle, Shell, Head, Flange, etc MAWPs are all considered

when determining the hydrotest pressure for those test types that are based

on the MAWP of the vessel.

Stresses on Elements due to Test Pressure:

From To

Stress

Allowable

Ratio

Pressure

---------------------------------------------------------------------Head

143.1

155.1

0.923

31

23.81

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Internal Pressure Calculations :

Step:

5

1:01a Jan 11,2015

Shell

89.8

155.1

0.579

23.81

----------------------------------------------------------------------

Elements Suitable for Internal Pressure.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

32

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------External Pressure Calculations :

Step:

6

1:01a Jan 11,2015

External Pressure Calculation Results :

ASME Code, Section VIII, Division 1, 2010, 2011a

Elliptical Head From 10 to 20 Ext. Chart: HA-4 at 50 C

Head

Elastic Modulus from Chart: HA-4 at 50 C

: 0.192E+06 MPa

Results for Maximum Allowable External Pressure (MAEP):

Tca

OD

D/t

Factor A

5.000

610.00

122.00

0.0011384

65.13

EMAP = B/(K0*D/t) = 65.1257/(0.9000 *122.0000 ) = 5.9304 bar

Results for Required Thickness (Tca):

Tca

OD

D/t

Factor A

1.613

610.00

378.29

0.0003672

35.22

EMAP = B/(K0*D/t) = 35.2184/(0.9000 *378.2888 ) = 1.0343 bar

Check the requirements of UG-33(a)(1) using P = 1.67 * External Design

pressure for this head.

Material UNS Number:

S31603

Required Thickness due to Internal Pressure [tr]:

= (P*Do*K)/(2*S*E+2*P*(K-0.1)) per Appendix 1-4 (c)

= (1.727*610.0000*1.000)/(2*115.15*1.00+2*1.727*(1.000-0.1))

= 0.4569 + 0.0000 = 0.4569 mm

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

= ((2*S*E*t)/(K*Do-2*t*(K-0.1)))/1.67

per Appendix 1-4 (c)

33

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------External Pressure Calculations :

Step:

6

1:01a Jan 11,2015

= ((2*115.15*1.00*5.0000)/(1.000*610.0000-2*5.0000*(1.00-0.1)))/1.67

= 11.471 bar

Maximum Allowable External Pressure [MAEP]:

= min( MAEP, MAWP )

= min( 5.93 , 11.4709 )

= 5.930 bar

Thickness requirements per UG-33(a)(1) do not govern the required

thickness of this head.

Cylindrical Shell From 20 to 30 Ext. Chart: HA-4 at 50 C

Shell

Elastic Modulus from Chart: HA-4 at 50 C

: 0.192E+06 MPa

Results for Maximum Allowable External Pressure (MAEP):

Tca

OD

SLEN

D/t

L/D

Factor A

8.000

610.00

2297.00

76.25

3.7656

0.0004912

47.12

EMAP = (4*B)/(3*(D/t)) = (4*47.1178 )/(3*76.2500 ) = 8.2380 bar

Results for Required Thickness (Tca):

Tca

OD

SLEN

D/t

L/D

Factor A

3.448

610.00

2297.00

176.90

3.7656

0.0001431

13.72

EMAP = (4*B)/(3*(D/t)) = (4*13.7243 )/(3*176.9043 ) = 1.0343 bar

Results for Maximum Stiffened Length (Slen):

Tca

OD

SLEN

D/t

L/D

Factor A

8.000

610.00

66104.80

76.25

50.0000

0.0001932

18.54

EMAP = (4*B)/(3*(D/t)) = (4*18.5364 )/(3*76.2500 ) = 3.2409 bar

External Pressure Calculations

34

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------External Pressure Calculations :

Step:

6

1:01a Jan 11,2015

Section |

From| To |

Length |

mm

Outside |

Corroded |

Diameter | Thickness |

mm

mm

Factor

Factor |

MPa

|

|

--------------------------------------------------------------------------10|

20|

No Calc |

610.000 |

5.00000 |

0.0011384 |

65.1257 |

20|

30|

2297.00 |

610.000 |

8.00000 | 0.00049120 |

47.1178 |

30|

40|

No Calc |

... |

47.7520 |

No Calc |

No Calc |

40|

50|

No Calc |

... |

68.0000 |

No Calc |

No Calc |

External Pressure Calculations

From| To |

|

External |

External

Actual T. | Required T.|Des. Press. |

M.A.W.P.

bar

mm

External |

mm

External

bar

---------------------------------------------------------------10|

20|

5.00000 |

1.61252 |

1.03420 |

5.93044 |

20|

30|

8.00000 |

3.44819 |

1.03420 |

8.23798 |

30|

40|

47.7520 |

No Calc |

1.03420 |

No Calc |

40|

50|

68.0000 |

37.6682 |

1.03420 |

No Calc |

Minimum

5.930

External Pressure Calculations

| Actual Len.| Allow. Len.| Ring Inertia | Ring Inertia |

From| To | Bet. Stiff.| Bet. Stiff.|

|

mm

mm

Required |

mm**4

Available |

mm**4

------------------------------------------------------------------10|

20|

No Calc |

No Calc |

No Calc |

No Calc |

20|

30|

2297.00 |

66104.8 |

No Calc |

No Calc |

30|

40|

No Calc |

No Calc |

No Calc |

No Calc |

40|

50|

No Calc |

No Calc |

No Calc |

No Calc |

35

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------External Pressure Calculations :

Step:

6

1:01a Jan 11,2015

Elements Suitable for External Pressure.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

36

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Element and Detail Weights :

Step:

7

1:01a Jan 11,2015

Element and Detail Weights

Element |

Element |

From| To | Metal Wgt. | ID

|

kgm

Corroded |

Volume |Metal Wgt. |

m

kgm

Corroded | Extra due

ID Volume | Misc %

m

kgm

|

|

|

--------------------------------------------------------------------------10|

20|

33.0736 |

0.039026 |

33.0736 |

0.039026 |

1.65368 |

20|

30|

268.288 |

0.61226 |

268.288 |

0.61226 |

13.4144 |

30|

40|

127.648 |

0.042183 |

127.648 |

0.042183 |

6.38241 |

40|

50|

283.228 |

... |

283.228 |

... |

14.1614 |

--------------------------------------------------------------------------Total

712

0.69

712

0.69

Weight of Details

From|Type|

|

Weight of |

X Offset, | Y Offset, |

Detail | Dtl. Cent. |Dtl. Cent. | Description

kgm

mm

mm

------------------------------------------------10|Liqd|

35.5072 |

... |

-75.0000 |

LIQUID

10|Nozl|

5.56748 |

... |

-150.000 |

N3

20|Liqd|

226.965 |

... |

450.000 |

LIQUID

20|Nozl|

8.73081 |

322.400 |

1187.00 |

N1

20|Nozl|

7.18497 |

322.400 |

1812.00 |

N5

20|Nozl|

7.18497 |

322.400 |

162.000 |

N6

20|Nozl|

7.18497 |

322.400 |

1812.00 |

K1

20|Nozl|

8.15833 |

341.450 |

962.000 |

K2A

20|Nozl|

8.15833 |

341.450 |

162.000 |

K2B

20|Nozl|

8.15833 |

341.450 |

712.000 |

K3A

20|Nozl|

8.15833 |

341.450 |

162.000 |

K3B

20|Nozl|

7.18497 |

322.400 |

1002.00 |

K4A

20|Nozl|

7.18497 |

322.400 |

162.000 |

K4B

37

35

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Element and Detail Weights :

Step:

7

1:01a Jan 11,2015

20|Nozl|

8.15833 |

341.450 |

962.000 |

K5A

20|Nozl|

8.15833 |

341.450 |

512.000 |

K5B

20|Nozl|

19.8200 |

354.150 |

162.000 |

HH

20|Lugs|

32.1232 |

... |

1924.00 |

LUG

20|Wght|

100.000 |

... |

2100.00 |

MIST ELIMINATOR

40|Nozl|

7.18497 |

... |

2460.00 |

N2

40|Nozl|

6.61229 |

... |

2460.00 |

N4

Total Weight of Each Detail Type

Total Weight of Liquid

262.5

Total Weight of Nozzles

132.8

Total Weight of Lugs

32.1

Total Weight of Weights

100.0

--------------------------------------------------------------Sum of the Detail Weights

527.4 kgm

Weight Summation

Fabricated

Shop Test

Shipping

Erected

Empty

Operating

-----------------------------------------------------------------------------747.8

912.8

747.8

912.8

747.8

912.8

...

693.0

...

...

...

262.5

132.8

...

132.8

...

...

...

32.1

...

32.1

...

...

...

...

...

...

...

...

100.0

...

...

...

...

...

...

...

...

...

...

132.8

...

...

...

...

...

32.1

...

-----------------------------------------------------------------------------912.8

1605.8

912.8

912.8

38

912.8

1275.2 kgm

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Element and Detail Weights :

Step:

7

1:01a Jan 11,2015

Miscellaneous Weight Percent: 5.0 %

Note that the above value for the miscellaneous weight percent has

been applied to the shells/heads/flange/tubesheets/tubes etc. in the

weight calculations for metallic components.

Note: The shipping total has been modified because some items have

been specified as being installed in the shop.

Weight Summary

Fabricated Wt.

- Bare Weight W/O Removable Internals

912.8 kgm

Shop Test Wt.

- Fabricated Weight + Water ( Full )

1605.8 kgm

Shipping Wt.

- Fab. Wt + Rem. Intls.+ Shipping App.

912.8 kgm

Erected

- Fab. Wt + Rem. Intls.+ Insul. (etc)

912.8 kgm

Ope. Wt. no Liq - Fab. Wt + Intls. + Details + Wghts.

912.8 kgm

Wt.

Operating Wt.

- Empty Wt + Operating Liq. Uncorroded

1275.2 kgm

Field Test Wt.

- Empty Weight + Water (Full)

1605.8 kgm

Mass of the Upper 1/3 of the Vertical Vessel

636.4 kgm

Outside Surface Areas of Elements

Surface

From| To |

Area

mm

---------------------------10|

20|

484863. |

20|

30|

4.233E+06 |

30|

40|

582175. |

40|

50|

692506. |

----------------------------Total

5992808.500 mm

39

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Element and Detail Weights :

Step:

7

1:01a Jan 11,2015

Element and Detail Weights

| To |

From| To |

|

Total Ele.| Total. Ele.|Total. Ele.|

Empty Wgt.|

kgm

Total Dtl.| Oper. Wgt. |

Oper. Wgt.|Hydro. Wgt.| Offset Mom.| No Liquid

kgm

kgm

N-m

kgm

|

|

--------------------------------------------------------------------------10|

20|

40.2947 |

75.8019 |

79.2965 |

... |

40.2947 |

20|Lugs|

316.782 |

578.916 |

807.345 |

299.889 |

396.954 |

Lugs|

30|

78.3459 |

143.176 |

199.671 |

74.1678 |

98.1739 |

30|

40|

134.031 |

134.031 |

176.188 |

... |

134.031 |

40|

50|

311.187 |

311.187 |

311.187 |

... |

311.187 |

Cumulative Vessel Weight

| Cumulative Ope | Cumulative | Cumulative

From| To | Wgt. No Liquid | Oper. Wgt. | Hydro. Wgt. |

|

kgm

kgm

kgm

------------------------------------------------------10|

20|

... |

... |

... |

20|Lugs|

-40.2947 |

-75.8019 |

-79.2965 |

Lugs|

30|

543.391 |

588.394 |

687.045 |

30|

40|

445.217 |

445.217 |

487.375 |

40|

50|

311.187 |

311.187 |

311.187 |

Note: The cumulative operating weights no liquid in the column above

are the cumulative operating weights minus the operating liquid

weight minus any weights absent in the empty condition.

Cumulative Vessel Moment

| Cumulative | Cumulative |Cumulative |

From| To | Empty Mom. | Oper. Mom. |Hydro. Mom.|

40

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Element and Detail Weights :

Step:

7

1:01a Jan 11,2015

N-m

N-m

N-m

------------------------------------------------10|

20|

... |

... |

... |

20|Lugs|

299.889 |

299.889 |

299.889 |

Lugs|

30|

74.1678 |

74.1678 |

74.1678 |

30|

40|

... |

... |

... |

40|

50|

... |

... |

... |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

41

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Nozzle Flange MAWP :

Step:

8

1:01a Jan 11,2015

Nozzle Flange MAWP Results :

Nozzle

----- Flange Rating

Description

Operating

bar

Ambient

Temperature

bar

Class

Grade|Group

---------------------------------------------------------------------------N3

18.4

19.0

50

150

GR 2.2

N1

96.2

99.3

50

600

GR 2.2

N5

18.4

19.0

50

150

GR 2.2

N6

18.4

19.0

50

150

GR 2.2

K1

18.4

19.0

50

150

GR 2.2

K2A

18.4

19.0

50

150

GR 2.2

K2B

18.4

19.0

50

150

GR 2.2

K3A

18.4

19.0

50

150

GR 2.2

K3B

18.4

19.0

50

150

GR 2.2

K4A

18.4

19.0

50

150

GR 2.2

K4B

18.4

19.0

50

150

GR 2.2

K5A

18.4

19.0

50

150

GR 2.2

K5B

18.4

19.0

50

150

GR 2.2

HH

18.4

19.0

50

150

GR 2.2

N2

18.4

19.0

50

150

GR 2.2

N4

18.4

19.0

50

150

GR 2.2

---------------------------------------------------------------------------Minimum Rating

18.4

19.0

bar

Note: ANSI Ratings are per ANSI/ASME B16.5 2009 Metric Edition

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

42

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Natural Frequency Calculation :

Step:

9

1:01a Jan 11,2015

The Natural Frequencies for the vessel have been computed iteratively

by solving a system of matrices. These matrices describe the mass

and the stiffness of the vessel. This is the generalized eigenvalue/

eigenvector problem and is referenced in some mathematical texts.

The Natural Frequency for the Vessel (Empty.) is 81.2720 Hz.

The Natural Frequency for the Vessel (Ope...) is 64.8727 Hz.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

43

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Wind Load Calculation :

Step:

10

1:01a Jan 11,2015

Note: Using the User Defined Wind Profile ...

Wind Vibration Calculations

This evaluation is based on work by Kanti Mahajan and Ed Zorilla

Nomenclature

Cf

- Correction factor for natural frequency

- Average internal diameter of vessel mm

Df

- Damping Factor < 0.75 Unstable,

Dr

- Average internal diameter of top half of vessel mm

f

f1

L

> 0.95 Stable

- Natural frequency of vibration (Hertz)

- Natural frequency of bare vessel based on a unit value of (D/L)(104)

- Total height of structure mm

Lc

- Total length of conical section(s) of vessel mm

tb

- Uncorroded plate thickness at bottom of vessel mm

V30 - Design Wind Speed provided by user km/hr

Vc

- Critical wind velocity km/hr

Vw

- Maximum wind speed at top of structure km/hr

- Total corroded weight of structure N

Ws

- Cor. vessel weight excl. weight of parts which do not effect stiff. N

- Maximum amplitude of vibration at top of vessel mm

Dl

- Logarithmic decrement ( taken as 0.03 for Welded Structures )

Vp

- Vib. Chance, <= 0.314E-05 (High); 0.314E-05 < 0.393E-05 (Probable)

P30 - wind pressure 30 feet above the base

Check other Conditions and Basic Assumptions:

#1 - Total Cone Length / Total Length < 0.5

0.000/2467.400 = 0.000

44

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Wind Load Calculation :

Step:

10

1:01a Jan 11,2015

#2 - ( D / L ) * 104 < 8.0 (English Units)

- ( 2.02/8.10 ) * 104 = 307.689 [Geometry Violation]

Compute the vibration possibility. If Vp > 0.393E-05 no chance. [Vp]:

= W / ( L * Dr)

= 12504/( 2467.40 * 606.011 )

= 0.13800E-04

Since Vp is > 0.393E-05 no further vibration analysis is required !

Wind Loads on Masses/Equipment/Piping

ID

Wind Area

mm

Elevation

mm

Pressure

Force

kPa

------------------------------------------------------------------------MIST ELIMINAT

0.00

2138.00

0.75

0.00

The Natural Frequency for the Vessel (Ope...) is 64.8727 Hz.

Wind Load Calculation

Wind

Wind |

Wind |

Wind

Element |

From| To |

Height

Diameter |

Area |

Pressure

Wind Load |

kPa

mm

mm

mm

--------------------------------------------------------------------------10|

20|

109.385 |

732.000 |

116927. |

0.75000 |

87.6934 |

20|

30|

1292.50 |

732.000 | 1.617E+06 |

0.75000 |

1212.71 |

30|

40|

2473.20 |

712.320 |

108558. |

0.75000 |

81.4163 |

40|

50|

2583.40 |

975.360 |

66324.5 |

0.75000 |

49.7422 |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

45

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Earthquake Load Calculation :

Step:

11

1:01a Jan 11,2015

Earthquake Loading Specified in G's

Horizontal Acceleration factor

(GX)

0.500

Horizontal Acceleration factor

(GZ)

0.500

Vertical

(GY)

-2.000

Acceleration factor

The Natural Frequency for the Vessel (Ope...) is 64.8727 Hz.

Earthquake Load Calculation

| Earthquake | Earthquake |

From| To |

|

Element |

Height |

Weight | Ope

mm

Load |

N

Element |

Emp Load |

N

-------------------------------------------------------------10|

20|

19.0000 |

743.314 |

525.602 |

279.399 |

20|Lugs|

1809.00 |

5676.85 |

4014.14 |

2196.53 |

Lugs|

30|

2028.00 |

1403.99 |

992.769 |

543.242 |

30|

40|

2323.20 |

1314.30 |

929.353 |

929.353 |

40|

50|

2433.40 |

3051.49 |

2157.73 |

2157.73 |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

46

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Wind/Earthquake Shear, Bending :

Step:

12

1:01a Jan 11,2015

The following table is for the Operating Case.

Wind/Earthquake Shear, Bending

| Distance to| Cumulative |Earthquake |

From| To |

|

Wind | Earthquake |

Support| Wind Shear |

Shear |

Bending |

Bending |

mm

N-m

N-m

--------------------------------------------------------------------------10|

20|

1854.61 |

... |

... |

... |

... |

20|Lugs|

885.500 |

87.6934 |

525.602 |

4.00173 |

23.9849 |

Lugs|

30|

219.000 |

459.308 |

4605.46 |

895.018 |

2467.76 |

30|

40|

514.200 |

131.158 |

3087.09 |

15.4821 |

473.210 |

40|

50|

624.400 |

49.7422 |

2157.73 |

1.69193 |

73.3929 |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

47

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Wind Deflection :

Step:

13

1:01a Jan 11,2015

Wind Deflection Calculations:

The following table is for the Operating Case.

Wind Deflection

| Cumulative |

Centroid | Elem. End | Elem. Ang. |

From| To | Wind Shear | Deflection |Deflection |

|

mm

mm

Rotation

|

|

-------------------------------------------------------------10|

20|

20|Lugs|

... | 0.00030324 |0.00060651 |

... |

87.6934 |

-0.011117 |

... |

... |

Lugs|

30|

459.308 |

-0.011573 |-0.0080331 |

-0.00002 |

30|

40|

131.158 | -0.0067998 |-0.0055664 |

-0.00002 |

40|

50|

49.7422 | -0.0050160 |-0.0044657 |

-0.00002 |

Critical Wind Velocity for Tower Vibration

1st Crit. |

2nd Crit. |

From| To | Wind Speed | Wind Speed |

|

km/hr

km/hr

------------------------------------10|

20|

852.459 |

5327.87 |

20|

30|

852.459 |

5327.87 |

30|

40|

829.541 |

5184.63 |

40|

50|

1135.87 |

7099.17 |

Allowable deflection at the Tower Top (Ope)(

Allowable deflection : 12.337

6.000"/100ft. Criteria)

Actual Deflection : 0.001 mm

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

48

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Longitudinal Stress Constants :

Step:

14

1:01a Jan 11,2015

Longitudinal Stress Constants

| Metal Area | Metal Area |New & Cold |

From| To | New & Cold |

|

mm

Corroded

Corroded |Sect. Mod. | Sect. Mod. |

mm

mm

mm

-------------------------------------------------------------10|

20|

9503.34 |

9503.34 | 1.426E+06 |

1.426E+06 |

20|

30|

15129.9 |

15129.9 | 2.248E+06 |

2.248E+06 |

30|

40|

15129.9 |

15129.9 | 2.248E+06 |

2.248E+06 |

40|

50|

15129.9 |

15129.9 | 2.248E+06 |

2.248E+06 |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

49

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Longitudinal Allowable Stresses :

Step:

15

1:01a Jan 11,2015

Longitudinal Allowable Stresses

| Hydrotest

| Compressive | Compressive |

From| To |

Tensile

MPa

Tensile

MPa

| Hydrotest

MPa

MPa

------------------------------------------------------------------10|

20|

138.176 |

186.165 |

-88.0035 |

-90.1732 |

20|Lugs|

138.176 |

186.165 |

-95.5055 |

-97.8688 |

Lugs|

30|

138.176 |

186.165 |

-95.5055 |

-97.8688 |

30|

40|

165.480 |

223.398 |

-104.311 |

-105.116 |

40|

50|

165.480 |

223.398 |

-104.311 |

-105.116 |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

50

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Longitudinal Stresses Due to . . .

Step:

16

1:01a Jan 11,2015

Longitudinal Stress Report

Note: Longitudinal Operating and Empty Stresses are computed in the

corroded condition. Stresses due to loads in the hydrostatic test

cases have been computed in the new and cold condition.

Longitudinal Stresses Due to . . .

| Long. Str. | Long. Str. |Long. Str. |

From| To | Int. Pres. | Ext. Pres. |Hyd. Pres. |

|

MPa

MPa

MPa

------------------------------------------------10|

20|

53.6478 |

-3.18083 |

70.7962 |

20|

30|

33.0573 |

-1.99793 |

43.6240 |

30|

40|

... |

... |

... |

40|

50|

... |

... |

... |

Longitudinal Stresses Due to . . .

| Wght. Str. | Wght. Str. |Wght. Str. | Wght. Str. | Wght. Str. |

From| To |

|

Empty

MPa

| Operating

|Hydrotest

MPa

MPa

Emp. Mom. |

MPa

Opr. Mom. |

MPa

--------------------------------------------------------------------------10|

20|

... |

... |

... |

... |

... |

20|Lugs|

0.026118 |

0.049133 |

... |

0.13338 |

0.13338 |

Lugs|

30|

-0.35221 |

-0.23427 |

... |

0.032988 |

0.032988 |

30|

40|

-0.28858 |

-0.28858 |

... |

... |

... |

40|

50|

-0.20170 |

-0.20170 |

... |

... |

... |

Longitudinal Stresses Due to . . .

| Wght. Str. | Bend. Str. |Bend. Str. | Bend. Str. | Bend. Str. |

51

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Longitudinal Stresses Due to . . .

Step:

16

1:01a Jan 11,2015

From| To |

|

Hyd. Mom. | Oper. Wind |Oper. Equ. | Hyd. Wind

MPa

MPa

MPa

MPa

|

|

Hyd. Equ. |

MPa

--------------------------------------------------------------------------10|

20|

... |

... |

... |

... |

... |

20|Lugs|

... |

0.0017799 |

0.010668 |

... |

... |

Lugs|

30|

... |

0.39809 |

1.09761 |

... |

... |

30|

40|

... |

0.0068861 |

0.21047 |

... |

... |

40|

50|

... | 0.00075253 |

0.032644 |

... |

... |

Longitudinal Stresses Due to . . .

| Long. Str. | Long. Str. |Long. Str. | EarthQuake |

From| To | Vortex Ope.| Vortex Emp.|Vortex Tst.|

|

MPa

MPa

MPa

Empty |

MPa

-------------------------------------------------------------10|

20|

... |

... |

... |

... |

20|Lugs|

... |

... |

... |

0.0056709 |

Lugs|

30|

... |

... |

... |

0.22624 |

30|

40|

... |

... |

... |

0.21047 |

40|

50|

... |

... |

... |

0.032644 |

Longitudinal Stresses Due to . . .

| Long. Str. | Long. Str. |

From| To | Y Forces W | Y ForceS S |

|

MPa

MPa

------------------------------------10|

20|

... |

0.15645 |

20|Lugs|

... |

0.84874 |

Lugs|

30|

... |

-0.76276 |

30|

40|

... |

-0.57716 |

40|

50|

... |

-0.40341 |

52

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Longitudinal Stresses Due to . . .

Step:

16

1:01a Jan 11,2015

Long. Stresses due to User Forces and Moments

|Wind For/Mom| Eqk For/Mom|Wnd For/Mom| Eqk For/Mom|

From| To | Corroded

|

MPa

| Corroded

MPa

No Corr. |

MPa

No Corr. |

MPa

-------------------------------------------------------------10|

20|

... |

... |

... |

... |

20|Lugs|

... |

... |

... |

... |

Lugs|

30|

... |

... |

... |

... |

30|

40|

... |

... |

... |

... |

40|

50|

... |

... |

... |

... |

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2013

53

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Stress due to Combined Loads :

Step:

17

1:01a Jan 11,2015

Stress Combination Load Cases for Vertical Vessels:

Load Case Definition Key

IP = Longitudinal Stress due to Internal

Pressure

EP = Longitudinal Stress due to External

Pressure

HP = Longitudinal Stress due to Hydrotest Pressure

NP = No Pressure

EW = Longitudinal Stress due to Weight (No Liquid)

OW = Longitudinal Stress due to Weight (Operating)

HW = Longitudinal Stress due to Weight (Hydrotest)

WI = Bending Stress due to Wind Moment (Operating)

EQ = Bending Stress due to Earthquake Moment (Operating)

EE = Bending Stress due to Earthquake Moment (Empty)

HI = Bending Stress due to Wind Moment (Hydrotest)

HE = Bending Stress due to Earthquake Moment (Hydrotest)

WE = Bending Stress due to Wind Moment (Empty) (no CA)

WF = Bending Stress due to Wind Moment (Filled) (no CA)

CW = Longitudinal Stress due to Weight (Empty) (no CA)

VO = Bending Stress due to Vortex Shedding Loads ( Ope )

VE = Bending Stress due to Vortex Shedding Loads ( Emp )

VF = Bending Stress due to Vortex Shedding Loads ( Test No CA. )

FW = Axial Stress due to Vertical Forces for the Wind Case

FS = Axial Stress due to Vertical Forces for the Seismic Case

BW = Bending Stress due to Lat. Forces for the Wind Case, Corroded

BS = Bending Stress due to Lat. Forces for the Seismic Case, Corroded

BN = Bending Stress due to Lat. Forces for the Wind Case, UnCorroded

BU = Bending Stress due to Lat. Forces for the Seismic Case, UnCorroded

General Notes:

Case types HI and HE are in the Un-Corroded condition.

54

PV Elite 2013 Licensee: MSET ENGINEERING SDN BHD

FileName : V-6011

---------------------------------------Stress due to Combined Loads :

Step:

17

1:01a Jan 11,2015

Case types WE, WF, and CW are in the Un-Corroded condition.