Académique Documents

Professionnel Documents

Culture Documents

Technical Guide On Wood Biomass Pellets Production Final PDF

Transféré par

Milorad ZelenovicDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Technical Guide On Wood Biomass Pellets Production Final PDF

Transféré par

Milorad ZelenovicDroits d'auteur :

Formats disponibles

Anyang Gemco Energy Machinery Co., Ltd.

: Professional Biomass Pellet Machine

Anyang Gemco Energy Machinery Co., Ltd.

Free Technical Guide on Wood Pellet Production

Professional Wood Pellet Production Advice

The complete technical guide for free http://www.pelletmillequipment.com

P2

Anyang Gemco Energy Machinery Co., Ltd.: Professional Biomass Pellet Machine

emco specializes in

the m anufacturing of c ommercial a nd

residential f lat di e and r ing die p ellet m ills. We are de dicated to

providing the highest quality and most advanced pellet mills to our

customers. Gemco has over 10 years of experience in this field and our

engineers a re highly q ualified. Fr om s ales t o design t o installation, w e

have yo ur needs covered. C ustomers i n t he U SA, R ussia, and A frica

depend o n our mills e veryday t o g et t he jo b done r ight. O ur products

meet s everal European standards i ncluding CCC, I SO, etc. T he entire G

team welcomes you to become our business partner and friend.

The complete technical guide for free http://www.pelletmillequipment.com

P3

Anyang Gemco Energy Machinery Co., Ltd.: Professional Biomass Pellet Machine

Content

Intro: Why Choose Wood and Biomass Pellets? .................... 5

Price: .................................................................................. 5

Wide Material Source:....................................................... 6

Environmentally Friendly: ................................................ 7

Convenience: ..................................................................... 7

Part 1. How to Make Pellets? ................................................. 8

Pellet Plant ......................................................................... 8

Pellet Mill ........................................................................ 11

Part 2. Different Types of Pellet Mills .................................. 12

Part 3. How to Choose the Suppliers .................................... 15

Part 4. Free Consultation Service ......................................... 17

In this f ree t echnical guide, Gemco gives yo u a brief introduction on w ood

pellet production and how to choose the right pellet mill to meet your needs.

Gemco provides a free consultation service with 20 years study on pellet fuel

industry an d p ellet mill manufacturers. Gemco has p rofessional experiences

on pellet mill production.

The complete technical guide for free http://www.pelletmillequipment.com

P4

Anyang Gemco Energy Machinery Co., Ltd.: Professional Biomass Pellet Machine

Intro: Why Choose Wood and Biomass Pellets?

Four advantages of Wood and Biomass Pellets have led to rising popularity in

the wood pellet's market.

Price:

Wood an d bi omass pellet fuel, as an al ternative f or fossil f uels, has a m ore

competitive and s table pricing than does kerosene an d natural gas in many

countries. Supported by the green tax policy, wood pellet fuel is encouraged to

be used as a countermeasure against global warming, energy security and rise

of oil p rices. I t has pr oved t o h ave a good e ffect. As t he da ta shows in the

following table, you can understand this point very clearly.

Table 1: Below data shows the comparison on home heating fuels, the values shown are

international averages on 2011-1.

Application

Efficiency

Cost per

Million BTU

Item

Cost

Pellets

190USD/Ton

80%

14.48

Fuel Oil # 2

3.58USD/Gallon

78%

33.25

Electricity

0.12USD/KWH

100%

35.16

Natural Gas

1.39USD/Therm

78%

17.38

LP Gas / Propane

2.83USD/ Gallon

78%

39.72

Hardwood(Air dried )

200USD/Cord

60%

16.66

Coal

250USD/Ton

75%

10.89

The complete technical guide for free http://www.pelletmillequipment.com

P5

Anyang Gemco Energy Machinery Co., Ltd.: Professional Biomass Pellet Machine

Wide Material Source:

Wood and bi omass pellet fuel, has competitive and stable pricing, is clean

burning and pr oduces little pollution. The moisture content can b e ea sily

controlled d uring the pr oduction process. The r aw material s ources ar e very

wide, such as wood w aste (residual sawdust, wood shavings, wood peelings,

etc.), yard debris (grass, leaves, tree sticks, forsythia, wisteria, woody bushes,

etc.), farm waste ( corn c obs, c orn st alks, straw from p lants, etc.) and other

residues biomass waste. We can recycle energy from the above materials.

Traditional heating f uel and fossil fuels are expensive and c an easily cause

environmental pollution. Trees grow slowly and the moisture is hard to control,

which are not good for stoves & boilers, and the source is very limited.

The complete technical guide for free http://www.pelletmillequipment.com

P6

Anyang Gemco Energy Machinery Co., Ltd.: Professional Biomass Pellet Machine

Environmentally Friendly:

Carbon-neutral is t he gr een i mage and advantage of w ood an d

biomass pellet fuel. Burned pellet fuel only liberates CO2 which is

stored during t he lifetime o f pl ant, and i s harmless t o t he

environment. B urned fossil f uels will free extra CO2 into

atmosphere which have b een stored for ov er a m illion y ears, accelerating

global warming.

Convenience:

Pellets ar e p roduced with uniform moisture

content, shape, size, and density, matching the

needs f rom the automated c ombustion

systems of stoves and boilers. It also takes up

less space in storage than other biomass fuels

because they have higher energy c ontent by

weight ( roughly 7,750 B tu p er pound at s ix

percent moisture content).

The complete technical guide for free http://www.pelletmillequipment.com

P7

Anyang Gemco Energy Machinery Co., Ltd.: Professional Biomass Pellet Machine

Part 1. How to Make Pellets?

First, y ou should h ave an idea of your target production capacity, budget and

application purpose. This i nformation w ill h elp y ou decide w hich pellet m ill i s

right for y ou. If your t arget c apacity is b eyond 500Kg p er hour or you desire

mass commercial pr oduction, you need t o build a pellet p lant. I f your t arget

capacity is less than the previous data and/or only for household use, a pellet

mill is your best choice.

The production processes between pellet production plants and pellet mills are

different in m aterial preparation, ad justments t o the m achinery, de tailed

equipment to use, etc.

Pellet Plant

The pr oduction process can g enerally be divided into 9 sections, as y ou can

see below.

1. Reduce the size of raw material into appropriate particles.

In this section, t he raw m aterial needs to be c rushed. You c an c hoose the

hammer m ill, chipper or w ood waste s hredder in accordance with your r aw

material.

Based on our comparison t ests for different p ellet mill and c ommon wood &

biomass materials, the p ellet p roduced f rom c rushed raw m aterial has b etter

and more consistent quality than those produced from rough raw materials.

You will f ind more i nformation on different r aw materials size r eduction

in our complete guide: http://www.pelletmillequipment.com

2. Dry the size-reduced material to meet required moisture content.

The moisture content of the pellet will straightly affect the p ellet qu ality of the

burning efficiency and the clean burning (no smoke).

According t o our y ears of study and consultation experiences, t he g eneral

requirement to moisture content of wood & biomass materials is from 10% to

15%. By choosing and controlling on right moisture content, you can cut down

your cost on energy consumption. In this section, a rotary drum dryer is a good

The complete technical guide for free http://www.pelletmillequipment.com

P8

Anyang Gemco Energy Machinery Co., Ltd.: Professional Biomass Pellet Machine

option.

3. Mix t he dr ied m aterial with t he b inder, lu bricants or ot her needed

material.

Due to the different characteristics of various raw materials, the pellet quality is

unequal. To improve the pellet quality or maximize the production capacity, you

can add a binder (a kind of glue, e.g., vegetable oil or rapeseed cake) to help

the lignin-lacked material to compress into pellets much easier. But please test

and analyze the binder-added p ellets, t he ash r ate and the clean b urning

performance may change accordingly.

4. Conditioning process to the mixed material.

By adding dry s team i nto the mixed m aterial can heat and s often the lignin.

This helps t he mixed material become compressed into final pellets much

easier, and maintains a consistent quality of the mixed material which ensures

the consistent quality of pellets. Its final purpose is to increase the production

capacity.

Please note: steam conditioning process is ONLY used in some LARGE pellet

mills, if y our m ill is a small plant, this process is not necessary, you c an skip

this section.

5. Pellet compression process.

This pr ocess usually adopts the ring die p ellet m ill, al so known as r ound d ie

pellet mill. Actually, this is the most important part in making pellets. We

have a

detail description o n t his process in the complete

guide: http://www.pelletmillequipment.com

6. Cool the final pellets to room temperature.

The f resh final pellets a re v ery h ot with ex tra moisture which needs t o be

released. The unreleased heat and moisture usually makes the pellets soft, so

their s hape is n ot f ormed. T o r each t he q uality r equirements on s urface

hardness and m oisture content, the cooling process becomes an important

part, and a counter-flow cooler is usually adopted.

The complete technical guide for free http://www.pelletmillequipment.com

P9

Anyang Gemco Energy Machinery Co., Ltd.: Professional Biomass Pellet Machine

7. Screen the cooled pellets.

To remove the fines or dusts from materials that failed in compression process

and from some broken pellets, a vibrating screen will be very helpful.

8. Pack and store the screened pellets.

Because the w ood pellet w ill not enter i nto the fuel process immediately, in

order to keep the wood pellet as dry as p ossible, to avoid the influence f rom

water or dampness, the packing process is necessary. To reduce your cost on

labor source, a pellet packing machine is recommended, you can c hoose a

semi-auto or a completely auto one in accordance to your needs.

9. Common transportation machineries in pellet plants.

Among the above s ections, the m aterials and t he p ellets n eed to b e

transported b etween different equipments. T o improve t he pr oduction

efficiency, you can use different machines as mentioned below:

Piping system is an infrastructure conveyor corridor in a p ellet plant s ite, it is

very p opular among the above s ections, s uch as b etween r aw material inlet

and hammer mills. A considerate design can lower your energy consumption.

The belt conveyor is another common transportation machine. It can be used

in for raw material inlet transportation, etc. It is a great solution to reduce your

labor cost.

The screw conveyor is another choice for material transportation. Because of

its light weight, low cost, and is easy to control.

The b ucket elevator is g enerally us ed for final pellet transportation in the final

stage to prevent damages.

Please note, the sequence of the sections and the choosing of the machines

may change in accordance with different material.

The complete technical guide for free http://www.pelletmillequipment.com

P10

Anyang Gemco Energy Machinery Co., Ltd.: Professional Biomass Pellet Machine

Pellet Mill

Compared with t he p ellet pl ant, t he pr oduction pr ocess of pellet m ill is m uch

simpler. It can generally be divided into 5 sections, as you can see below:

1. Reduce the size of raw material into appropriate particles.

2. Dry the size- reduced material to reach required moisture content.

The above two sections are still necessary. Please read the information at the

same parts in pellet plant.

Please note, for a pellet mill, a rotary drum dryer is not necessary. You can us e

sunshine to dry your raw material or choose a hot air dryer instead.

3. Pellet compression process.

For this process usually adopts flat die pellet mill.

4. Cool the final pellets to room temperature.

You can put the final pellets in the open air to release heat and moisture. There

is no need for any machine.

5. Pack and store the cooler pellets. A packing machine is still needed.

To S ection 4 and 5, p lease r ead t he information at t he s ame p arts i n p ellet

plant.

Due to the environmental protect requirement and the increasing price of

traditional fuel; the wood p ellet h eating i s b ecoming a t rend. M aking

pellets by a pellet m ill i s attractive to most f amilies. In t his case, w e

devote m uch more w ords a bout pellet m ill a nd pe llet production in our

complete g uide in or der t o give you r eaders a better

understanding: http://www.pelletmillequipment.com

The complete technical guide for free http://www.pelletmillequipment.com

P11

Anyang Gemco Energy Machinery Co., Ltd.: Professional Biomass Pellet Machine

Part 2. Different Types of Pellet Mills

In Part 1, we mentioned two different pellet mills, flat die pellet mill and ring die

pellet mill.

1. Ring Die Pellet Mill

also known as round die pellet mill. The ring die

pellet mill has even wear between roller and die. The consumable cost is lower

and the efficient energy s aving is b etter; th e ring di e p ellet m ill and its die &

rollers ar e m uch bi gger, h eavier and m ore expensive t han f lat d ie pellet mill

(causing daily maintenance, and adjustments is quite different f rom flat die

pellet mill). The above two reasons are why ring die pellet mill is preferred for

mass commercial production.

The complete technical guide for free http://www.pelletmillequipment.com

P12

Anyang Gemco Energy Machinery Co., Ltd.: Professional Biomass Pellet Machine

Open the shell and you can see the ring die and rollers.

2. Flat Die P ellet mi ll

is be tter f or s mall production c apacity and/or

residential use. It has the following advantages:

compact structure makes it small in size and lightweight;

portable roller an d die are c heaper, easier t o c lear and faster to

change than these on a ring die pellet mill;

Because of i ts design and structure, you c an monitor the pe lleting

process directly b y w atching the p elleting chamber. This will help you

solve y our p roduction t rouble qu ickly. T his i s why you c an t ry some

indeterminate material as raw m aterials to m ake p ellets, w hich m ake

your available sources greater.

Generally t here ar e t wo different designs o f flat die p ellet mill. O ne i s w ith a

rotating die and another is with a rotating roller.

The first type has a stationary roller with a rotating die. During the wood pellets

making pr ocess, t he d ie is r otating and t he r ollers are stationary. T he

mechanical action of the second type is completely different from the previous

one, it h as a stationary die w ith a rotating roller, w hen i t is w orking t he di e is

stationary but the rollers are rotating

The complete technical guide for free http://www.pelletmillequipment.com

P13

Anyang Gemco Energy Machinery Co., Ltd.: Professional Biomass Pellet Machine

A typical flat die pellet mill

The complete technical guide for free http://www.pelletmillequipment.com

P14

Anyang Gemco Energy Machinery Co., Ltd.: Professional Biomass Pellet Machine

Part 3. How to Choose the Suppliers

The easiest and best way to get a lower price, better service and support is to

locate a suitable manufacturer who can match your requirements and needs.

By g etting our consultation s ervice and s uggestions, some clients found that

their supplier can not give them satisfactory price, better service and support.

Firstly because their supplier are agents or intermediaries, secondly because

they need t o r e-sell the p ellet mill b y add ing t heir ow n profit, thirdly because

they do not know the machine in details, and lastly because they do not have

experiences in pellet production and can not give you after-sale service! So do

you still want to buy a pellet mill on eB ay or from agents?

Here is free ad vice for you to l ocate your ow n manufacturer, if you wish to go

directly to the suppliers or manufacturers. The best way is to identify an agent

or manufacturer through a few strategic questions:

ask for the latest photos or videos of the workshop, assembly line for pellet

mill manufacturing and of customers visits.

ask to visit t he f actory in pe rson, only manufacturers w ill b e able t o

accommodate your request.

ask some professional questions w hich require t o be replied to within a

limited time, only manufacturers can give a complete answer and analysis

to your questions by the support from their technical team.

Market Analysis

Gemco is a company with years of biomass fuel marketing analysis, both in the

technological and manufacturing fields. Pellet fuel technology has seen a rapid

growth i n r ecent years. After gathering data from r ecent surveys, w e h ave

found that there are some companies leading the way in advanced technology.

Below, we have pr ovided a list of m ost i nfluential t echnology providers in t he

world:

The complete technical guide for free http://www.pelletmillequipment.com

P15

Anyang Gemco Energy Machinery Co., Ltd.: Professional Biomass Pellet Machine

Bhler, Germany

Buhlers line uses steam and water to condition the cut straw just before pellet

mill it helps t o increase the lifetime of dies and rolls and also saves the

energy. Moreover, the plant in Co- penhagen uses a shredding device that is

able to shred and cut the straw bales of every kind (round, small and big cube

bales) and is n ot s ensitive to t he moisture c ontent. E ven when this c rusher

technology is rather expensive and energy intense, it still can be an important

advan- tage to secure the planned production quantity.

Reference s ite: B uehler pelletizing t echnology was used in the l argest s traw

pelletizing pl ant of E urope i n K oge, D enmark. W ith an original c apacity of

100.000 t ons p er year i t c urrently produces 60.000 t ons of s traw pellets p .a.

The plant p artly us es t echnology f rom other s uppliers. I t had s evere s tarting

problems pa rticularly in t he t ransport of t he material be tween the di fferent

steps of the production process.

California Pelletizing Machines (CPM), California

This technology is widely used for wood pellet production in Central and

Eastern Europe. The technology requires comparatively high operation costs.

Reference site: The straw pellets plant with a yearly capacity of 3,5 tons per

hour in Jelcz- Laskowice, Poland was constructed with CPM technology. Until

today t he p lant has s evere t echnology problems. These difficulties partly are

caused through wrong strategic decisions of the investor.

GEMCO, China

This Chinese m anufacturer h as decades y ears o f ex perience o f p ellet m ill

research and manufacture. They have their own patents of design and

pelletizing devices, die and roller. Such as MZSP Series, which has been sold

to many countries of the world.

8mt/h pelletizing line with drying system costs 528 000 USD FOB Tianjin J.

Amandus Kahl Pelletizing, Germany

Amandus Kahl is known as a very solid and high quality technology.

The complete technical guide for free http://www.pelletmillequipment.com

P16

Anyang Gemco Energy Machinery Co., Ltd.: Professional Biomass Pellet Machine

Reference site: One pelletizing plant in Poland in Grudziadz was equipped with

Kahl t echnology. T he plant s tarted operation in S eptember 08. At t he time of

this analysis, the plant was still in the start-up phase, in which the utilization of

low-quality raw m aterials resulted in low pl ant p erformance. As onl y this d ata

was available, the Kahl technology was not further considered in this analysis.

Today, after optimization of the raw material management by the operator, the

plant reaches the required capacity and product quality.

Gama Pardubice, Czech Republic

This Czech p elletizing l ines producer o ffers production l ines w ith capacities

between 2. 6 an d 3.6 mt/h to very low prices. The c ompany f ounded in 19 94

has supplied several straw pelletizing plants in Czech Republic.

Reference site: Under investigation

Andritz

Andritz does not have any reference sites of straw pelletizing. Right now they

just starting with it some investors are interested in creating one in England

and the other one may rise in Poland In Splno Krajeskie the plant will be

owned by Mr. Romuald Haabuda Romico company.

To b e honest, if you are a wealthy f amily, then the G erman t echnology is n o

doubt the b est choice. However, if you ar e l ooking to reduce your energy bill,

then the price should b e y our top priority t o consider. Since not all p ellet mills

are c reated equally, you n eed t o c hoose wisely. P ellet m ills f rom China are

priced lower than the others and have equal or better performance. Therefore,

if you w ant a qu ality m achine at a l ower price, I w ould enc ourage you to bu y

from a Chinese manufacturer.

Part 4. Free Consultation Service

We un derstand in this s ection we g ive you more questions than answers on

how to c hoose t he necessary equipments. I ts normal, thats w hy w e offer a

free c onsultation s ervice exclusively f or anyone who h as p ossession of this

guide. The help is free, available five days a week our technical research team.

The most common question y ou m ay have w ill concern w hether or not it i s

possible to make pellets with your specific material. Please contact our friendly

The complete technical guide for free http://www.pelletmillequipment.com

P17

Anyang Gemco Energy Machinery Co., Ltd.: Professional Biomass Pellet Machine

customer service info@pelletmillequipment.com

Order our complete guide to know everything about making pellets!

Wondering? Hesitating?

Opportunity not to be missed!

You can send us an email: info@pelletmillequipment.com for links or you

can visit our website, click the below access to

our complete professional guide for free

http://www.pelletmillequipment.com

The complete technical guide for free http://www.pelletmillequipment.com

P18

Vous aimerez peut-être aussi

- Wood Pellet ProductionDocument20 pagesWood Pellet ProductionDjordjePetkovicPas encore d'évaluation

- Technical Guide On Wood& Biomass Pellets ProductionDocument20 pagesTechnical Guide On Wood& Biomass Pellets ProductionLeal Cindy100% (1)

- Biomass Pelleting PDFDocument6 pagesBiomass Pelleting PDFbanapte59100% (1)

- Biomass Pelleting: Together, We Make A DifferenceDocument8 pagesBiomass Pelleting: Together, We Make A DifferenceELAPas encore d'évaluation

- Biomass Pelletization Process PDFDocument14 pagesBiomass Pelletization Process PDFmos3ad2006Pas encore d'évaluation

- Wood Ring Die Pellet Mill PDFDocument5 pagesWood Ring Die Pellet Mill PDFpelletsmillmachineryPas encore d'évaluation

- Biomass Briquette MFG Machine CatalogueDocument6 pagesBiomass Briquette MFG Machine CatalogueHemanth Kumar RamachandranPas encore d'évaluation

- Complete Guide On Wood Pellet Production PDFDocument62 pagesComplete Guide On Wood Pellet Production PDFkhouchaymi100% (2)

- The Beginners Guide To Making PelletsDocument11 pagesThe Beginners Guide To Making PelletsDesPas encore d'évaluation

- Briquette Plant: Email: Mobile: +234 806 5893 646Document9 pagesBriquette Plant: Email: Mobile: +234 806 5893 646Paul ItorPas encore d'évaluation

- Charcoal Briquette MachineDocument5 pagesCharcoal Briquette Machinepelletsmillmachinery100% (1)

- Complete Project of Biomass Briquetting MachineDocument23 pagesComplete Project of Biomass Briquetting MachineDeepi17100% (2)

- Biomass for Energy, Environment, Agriculture and IndustryD'EverandBiomass for Energy, Environment, Agriculture and IndustryPas encore d'évaluation

- Pellet-Business-Plan PDFDocument74 pagesPellet-Business-Plan PDFSuratman Blanck Mandho100% (2)

- Wood Pellet in FinlandDocument85 pagesWood Pellet in FinlandJoao Minho100% (1)

- Business Case Biomass Fuel PelletDocument18 pagesBusiness Case Biomass Fuel Pelletagbuc11100% (2)

- Business PlanDocument34 pagesBusiness PlanSuratman Blanck MandhoPas encore d'évaluation

- Board Paper Presentation (Palm-Based Biomass Pellet)Document20 pagesBoard Paper Presentation (Palm-Based Biomass Pellet)Jenny Yap100% (1)

- Wood Pellet CostsDocument8 pagesWood Pellet CostsSeptian HardiPas encore d'évaluation

- Pellet HandbookDocument86 pagesPellet Handbookkiki_dPas encore d'évaluation

- BIOMASSDocument22 pagesBIOMASSPRATIK RUPNAR100% (1)

- News Brazil Biomass Project InvestmentsDocument126 pagesNews Brazil Biomass Project Investmentsmar4478100% (1)

- Wood PelletDocument18 pagesWood Pelletb40wapr100% (1)

- Small Biomass Pellet PlanDocument4 pagesSmall Biomass Pellet PlanHendi HendriansyahPas encore d'évaluation

- Wood Pellet Heat GuidebookDocument26 pagesWood Pellet Heat GuidebookSudhakar GanjikuntaPas encore d'évaluation

- Wood Pellet Production and Market Structure in Serbia PDFDocument49 pagesWood Pellet Production and Market Structure in Serbia PDFNizar GarzounPas encore d'évaluation

- BRIQUETTE Cement - ProductionDocument77 pagesBRIQUETTE Cement - Productionashbak2006#zikir#scribd#2009Pas encore d'évaluation

- How To Use Pellet Binders During Making Pellets Processing CorrectlyDocument6 pagesHow To Use Pellet Binders During Making Pellets Processing CorrectlyM Syifaut TamamPas encore d'évaluation

- Life Cycle Assessment of Wood Pellet: Siyu ChenDocument82 pagesLife Cycle Assessment of Wood Pellet: Siyu Chentopollillo24Pas encore d'évaluation

- Wood Pellet Final Report CM Nov07Document40 pagesWood Pellet Final Report CM Nov07muji7Pas encore d'évaluation

- Global Wood Pellet Fuel Market Research Report 2017Document2 pagesGlobal Wood Pellet Fuel Market Research Report 2017Eric Bendic0% (1)

- FAO - Industrial Charcoal ProductionDocument33 pagesFAO - Industrial Charcoal ProductionFabiano de Souza0% (1)

- Lillooet Pellet Business PlanDocument74 pagesLillooet Pellet Business Planlovedorik100% (1)

- Charcoal Making ProcessDocument41 pagesCharcoal Making ProcessRolando Jr100% (1)

- Biomass Boiler DesignDocument23 pagesBiomass Boiler DesignMatias Mancilla100% (1)

- 9 BPUA12 Olaf Naehrig KAHLDocument68 pages9 BPUA12 Olaf Naehrig KAHLGladiador EdinsonPas encore d'évaluation

- Briquette Proposal PlanDocument20 pagesBriquette Proposal PlanCyprian AendePas encore d'évaluation

- Biomass BriquettingDocument48 pagesBiomass Briquettinggdanon100% (2)

- Project Report FinalDocument24 pagesProject Report FinalmujeebPas encore d'évaluation

- Biomass Pelletising Critical AnalysisDocument54 pagesBiomass Pelletising Critical Analysissunitbhaumik100% (1)

- What Is PyrolysisDocument3 pagesWhat Is PyrolysisHazim Calixto LimmayogPas encore d'évaluation

- FB Biomass Pelleting en DataDocument8 pagesFB Biomass Pelleting en Datasarah ahmedPas encore d'évaluation

- Business Plan BiodieselDocument8 pagesBusiness Plan BiodieselManas KelaskarPas encore d'évaluation

- Astec Wood Pellet PlantsDocument7 pagesAstec Wood Pellet Plantsb40waprPas encore d'évaluation

- The Significance of Pelletization Operating ConditionsDocument17 pagesThe Significance of Pelletization Operating ConditionsAzaelBermudesTorresPas encore d'évaluation

- Argus BiomassDocument14 pagesArgus BiomassVijendranArumugamPas encore d'évaluation

- Pellet Mill HandbookDocument21 pagesPellet Mill HandbookBorko Cicovic100% (2)

- Charcoal Production From Alternative Feedstocks - NL Agency 2013Document77 pagesCharcoal Production From Alternative Feedstocks - NL Agency 2013TuiVuelaPas encore d'évaluation

- BM11 - 2008-08-08 Deloitte Pellet Cost StudyDocument70 pagesBM11 - 2008-08-08 Deloitte Pellet Cost Studym0k123_11264014067% (3)

- News Brazil Biomass Wood Chips InvestmentsDocument126 pagesNews Brazil Biomass Wood Chips Investmentsmar4478100% (3)

- Biomass BriquettesDocument41 pagesBiomass BriquettesPamarthi Dhruva100% (4)

- Palm Oil Mill EffluentDocument3 pagesPalm Oil Mill EffluentChrisna Saputra Archlord100% (2)

- USAID - Briquetting Feasibility Study SudanDocument95 pagesUSAID - Briquetting Feasibility Study Sudansrachoprdoch100% (3)

- Waste Wood As A Biomass Fuel: WWW - Defra.gov - UkDocument42 pagesWaste Wood As A Biomass Fuel: WWW - Defra.gov - UkMoh ArifPas encore d'évaluation

- EU Pellet HandbookDocument86 pagesEU Pellet HandbookTran Xuan DamPas encore d'évaluation

- PMF5E4 Flat Die Pelletizer MachineDocument5 pagesPMF5E4 Flat Die Pelletizer MachineAlabalaPas encore d'évaluation

- Ecp 101Document12 pagesEcp 101onejako12Pas encore d'évaluation

- Fabrication of Pellet Making MachineDocument3 pagesFabrication of Pellet Making MachineInternational Journal of Innovations in Engineering and SciencePas encore d'évaluation

- Business Plan F.projectDocument24 pagesBusiness Plan F.projectzetseatPas encore d'évaluation

- How To Buy A Quality Pellet MillDocument11 pagesHow To Buy A Quality Pellet MillandreibotezanPas encore d'évaluation

- 7.7 Weld-On Noses and Nose RebuildsDocument14 pages7.7 Weld-On Noses and Nose RebuildsMilorad ZelenovicPas encore d'évaluation

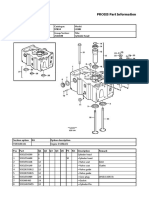

- PROSIS Part Information: 17.2.2023 EQ154 97834 L330EDocument2 pagesPROSIS Part Information: 17.2.2023 EQ154 97834 L330EMilorad ZelenovicPas encore d'évaluation

- Bager New Holand E50Document559 pagesBager New Holand E50Milorad ZelenovicPas encore d'évaluation

- Delco 39MT Sheet 5 23Document2 pagesDelco 39MT Sheet 5 23Milorad ZelenovicPas encore d'évaluation

- PROSIS Part InformationDocument2 pagesPROSIS Part InformationMilorad ZelenovicPas encore d'évaluation

- PROSIS Part Information: Date: Image Id: Catalogue: ModelDocument1 pagePROSIS Part Information: Date: Image Id: Catalogue: ModelMilorad ZelenovicPas encore d'évaluation

- PROSIS Part Information: 17.2.2023 EJ167 97834 L330EDocument2 pagesPROSIS Part Information: 17.2.2023 EJ167 97834 L330EMilorad ZelenovicPas encore d'évaluation

- Service Training Malaga 345C/365C/385C Hydraulic Excavators: Francis Apr 05Document5 pagesService Training Malaga 345C/365C/385C Hydraulic Excavators: Francis Apr 05Milorad Zelenovic100% (1)

- SM 48Document691 pagesSM 48Milorad ZelenovicPas encore d'évaluation

- 1992/04/01 Systems Operation (SENR2625-01)Document63 pages1992/04/01 Systems Operation (SENR2625-01)Milorad ZelenovicPas encore d'évaluation

- Libro de Oro KOMATSU PDFDocument154 pagesLibro de Oro KOMATSU PDFErwinParis100% (5)

- Torque Converter Stall TestDocument3 pagesTorque Converter Stall TestMilorad ZelenovicPas encore d'évaluation

- VW Golf 6 Fuel Supply System Diesel Engines EngDocument65 pagesVW Golf 6 Fuel Supply System Diesel Engines EngMilorad ZelenovicPas encore d'évaluation

- Service Training Malaga 345C/365C & 385C Hydraulic ExcavatorsDocument14 pagesService Training Malaga 345C/365C & 385C Hydraulic ExcavatorsMilorad Zelenovic100% (1)

- Service Training Malaga 345C/365C/385C Hydraulic Excavators: Francis Apr 05Document19 pagesService Training Malaga 345C/365C/385C Hydraulic Excavators: Francis Apr 05Milorad ZelenovicPas encore d'évaluation

- Technical Supplement: Alternators and Starters Cross ReferenceDocument20 pagesTechnical Supplement: Alternators and Starters Cross ReferenceMilorad ZelenovicPas encore d'évaluation

- Acert Technology For Off-Highway C15 Engines: Caterpillar ConfidentialDocument62 pagesAcert Technology For Off-Highway C15 Engines: Caterpillar ConfidentialMilorad ZelenovicPas encore d'évaluation

- Catalogoholset PDFDocument331 pagesCatalogoholset PDFMilorad Zelenovic100% (1)

- Fuel Supply Pump L H PumpDocument2 pagesFuel Supply Pump L H PumpMilorad ZelenovicPas encore d'évaluation

- Fuel Supply Pump Inner Parts PDFDocument2 pagesFuel Supply Pump Inner Parts PDFMilorad ZelenovicPas encore d'évaluation

- Fuel Supply Pump Inner Parts PDFDocument2 pagesFuel Supply Pump Inner Parts PDFMilorad ZelenovicPas encore d'évaluation

- Beechcraft Heritage MuseumDocument16 pagesBeechcraft Heritage MuseumCAP History LibraryPas encore d'évaluation

- Domus Ventilation Guide 2019Document96 pagesDomus Ventilation Guide 2019Regie CayasPas encore d'évaluation

- Lexmark-E 321 Service ManualDocument184 pagesLexmark-E 321 Service ManualRemysPas encore d'évaluation

- ALV List and ALV GridDocument6 pagesALV List and ALV Gridlavi2Pas encore d'évaluation

- Omni PageDocument98 pagesOmni Pageterracotta2014Pas encore d'évaluation

- Udhe 2.standardsDocument1 pageUdhe 2.standardsom dhamnikarPas encore d'évaluation

- SE440BX-2 Motherboard: Technical Product SpecificationDocument90 pagesSE440BX-2 Motherboard: Technical Product SpecificationEvelio MorenoPas encore d'évaluation

- Mike and KeyDocument25 pagesMike and KeyddscribePas encore d'évaluation

- Void Acoustics 2017 BrochureDocument28 pagesVoid Acoustics 2017 BrochureCraig ConnollyPas encore d'évaluation

- KEDA Quotation of 2 3 4 Inch Mini Gold DredgerDocument3 pagesKEDA Quotation of 2 3 4 Inch Mini Gold DredgerShane CapstickPas encore d'évaluation

- Bomba Submersa FE - Petro STPDocument6 pagesBomba Submersa FE - Petro STProbsonlagambaPas encore d'évaluation

- ' ' Shail Ahmad: Privet of India Acres N Inches List of ClientDocument3 pages' ' Shail Ahmad: Privet of India Acres N Inches List of Clientapi-243316402Pas encore d'évaluation

- BE Spec Flash EconomizerDocument4 pagesBE Spec Flash Economizeronkarrathee100% (1)

- 300B Parallel SET AmplifierDocument8 pages300B Parallel SET Amplifierandree wPas encore d'évaluation

- A Project Report On DMRCDocument22 pagesA Project Report On DMRCRahul Mehrotra100% (1)

- Advantages of Group Decision MakingDocument1 pageAdvantages of Group Decision MakingYasmeen ShamsiPas encore d'évaluation

- 000 139 PDFDocument17 pages000 139 PDFtareqcccccPas encore d'évaluation

- Promt MidjourneyDocument2 pagesPromt MidjourneyMarcelo PaixaoPas encore d'évaluation

- PPG en-US P162.OutputDocument4 pagesPPG en-US P162.OutputChemical EngineerPas encore d'évaluation

- Center Pivot Cable / Wire Raintec Span Cable Raintec Motor DropDocument1 pageCenter Pivot Cable / Wire Raintec Span Cable Raintec Motor Drophicham boutouchePas encore d'évaluation

- Microsoft Word - CHALLAN DHSK - 5th - Sem - Challan - 22-23Document1 pageMicrosoft Word - CHALLAN DHSK - 5th - Sem - Challan - 22-23YoUnG PrINCePas encore d'évaluation

- MARINO WORLD MAGAZINE July-August IssueDocument52 pagesMARINO WORLD MAGAZINE July-August IssueNhal LopezPas encore d'évaluation

- NetflixDocument16 pagesNetflixGianluca VenturiPas encore d'évaluation

- Life-Saving Rules: Tool Box Talk SeriesDocument86 pagesLife-Saving Rules: Tool Box Talk SeriesSalahBouzianePas encore d'évaluation

- Digital Data, Digital SignalDocument8 pagesDigital Data, Digital SignalBastomi Adi NugrohoPas encore d'évaluation

- Unreal Tournament CheatDocument3 pagesUnreal Tournament CheatDante SpardaPas encore d'évaluation

- Sample Acceptable Use Policy From Southern Regional High SchoolDocument4 pagesSample Acceptable Use Policy From Southern Regional High Schoolapi-356000194Pas encore d'évaluation

- LAB3Document5 pagesLAB3Kaishavi UmrethwalaPas encore d'évaluation

- CMP Tutorial PDFDocument83 pagesCMP Tutorial PDFMax HaroutunianPas encore d'évaluation

- Wwii Aircraft Vol 2Document50 pagesWwii Aircraft Vol 2Virág Árpád100% (5)