Académique Documents

Professionnel Documents

Culture Documents

94camry-Engine Removal & Installation

Transféré par

Trey OwenTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

94camry-Engine Removal & Installation

Transféré par

Trey OwenDroits d'auteur :

Formats disponibles

1994 Toyota Camry LE

2.2L 4-CYL - VIN [S] 1994 ENGINES Toyota 2.2L 4-Cylinder

ENGINE

NOTE:

Remove engine and transaxle as an assembly.

Removal

1. Release fuel pressure. See FUEL PRESSURE RELEASE under REMOVAL & INSTALLATION.

Remove hood, battery and battery tray. Drain cooling system and engine oil.

2. Disconnect control cables at throttle body. Remove air intake duct with air cleaner assembly and air

cleaner case. Remove cruise control actuator (if equipped). Remove radiator.

3. Disconnect electrical connections at relay box, located near driver's side front corner of engine

compartment. Disconnect electrical connections at ignitor and noise filter on driver's side front fender.

4. Disconnect necessary electrical connections, coolant hose, vacuum hoses and fuel lines. Remove A/C

compressor (if equipped) and power steering pump with hoses attached and secure aside.

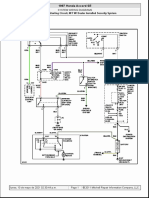

5. Remove lower instrument panel cover and glove box. Disconnect connectors at Engine Control Module

(ECM) and remaining engine wiring connectors. See Fig. 9 . Remove nuts from firewall and pull engine

wiring out through firewall.

Fig. 9: Identifying ECM & Engine Wiring Connectors

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

TxMechs

Monday, January 28, 2013 10:24:05

10:23:56 AM

(512) 945-2757

Page 1

2005 Mitchell Repair Information Company, LLC.

1994 Toyota Camry LE

2.2L 4-CYL - VIN [S] 1994 ENGINES Toyota 2.2L 4-Cylinder

6. Raise and support vehicle. Remove lower engine covers. On M/T models, remove clutch release cylinder

with hose attached and secure aside. Remove starter. On A/T models, disconnect oil cooler lines at

transaxle.

7. Disconnect control cables and electrical connections at transaxle. Disconnect front exhaust pipe from

front catalytic converter on exhaust manifold.

8. Remove front wheels. Remove cotter pin and retainer from end of axle shaft. Loosen axle shaft nut while

applying the brakes. Remove axle shaft nut.

9. Remove inner fenderwell aprons for access to axle shaft. Drain transaxle fluid. Remove nut and separate

tie rod from steering knuckle.

10. Disconnect stabilizer bar link from lower control arm. Remove ball joint-to-lower control arm bolts/nuts.

Cover axle shaft boots with shop towel.

11. Using soft-faced hammer, tap axle shaft from hub assembly. Pull steering knuckle outward and separate

axle shaft from hub assembly.

12. To remove left (driver's side) axle shaft, pry between transaxle case and axle shaft until axle shaft

disengages from transaxle. See Fig. 10 .

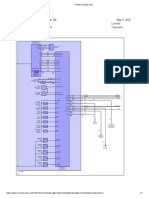

13. To remove right (passenger's side) axle shaft, remove axle shaft bearing bolt. See Fig. 11 . Remove snap

ring from axle shaft bearing retainer. See Fig. 11 . Pull right axle shaft from transaxle.

14. Support engine with hoist. Disconnect engine and transaxle mounts. Lift engine and transaxle from

vehicle.

Fig. 10: Removing Left Axle Shafts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

TxMechs

Monday, January 28, 2013 10:23:56 AM

(512) 945-2757

Page 2

2005 Mitchell Repair Information Company, LLC.

1994 Toyota Camry LE

2.2L 4-CYL - VIN [S] 1994 ENGINES Toyota 2.2L 4-Cylinder

Fig. 11: Removing Right Axle Shafts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Installation

1. To install, reverse removal procedure. Tighten bolts/nuts to specification. See TORQUE

SPECIFICATIONS.

2. When installing control rod and bracket on strut tower and right (timing belt side) engine mount, tighten

bolts to specification in sequence. See Fig. 12 .

3. Before installing axle shafts, install NEW snap ring on end of left axle shaft. Coat axle shaft seals in

transaxle with grease. Coat axle shaft splines and sliding surfaces with gear oil. Position snap ring on end

of left axle shaft with opening facing downward.

4. Install left axle shaft by lightly tapping axle shaft into transaxle. Ensure left axle shaft will move inward

and outward approximately .079-.120" (2.00-3.00 mm) and cannot be pulled from transaxle.

5. When installing right axle shaft, install NEW snap ring and NEW axle shaft bearing bolt. Tighten axle

shaft bearing bolt to specification. See TORQUE SPECIFICATIONS.

6. To install remaining components, reverse removal procedure. Use NEW gasket and NEW nuts when

installing front exhaust pipe on catalytic converter. Tighten bolts/nuts to specification. See TORQUE

SPECIFICATIONS. Adjust fluid levels and control cables.

TxMechs

Monday, January 28, 2013 10:23:56 AM

(512) 945-2757

Page 3

2005 Mitchell Repair Information Company, LLC.

1994 Toyota Camry LE

2.2L 4-CYL - VIN [S] 1994 ENGINES Toyota 2.2L 4-Cylinder

Fig. 12: Control Rod & Bracket Bolt Installation Sequence

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NOTE:

Remove engine and transaxle as an assembly.

OIL PAN

Removal

1. Disconnect negative battery cable. Raise and support vehicle. Remove lower engine covers. Drain engine

oil. Remove front exhaust pipe located below oil pan.

2. Remove catalytic converter braces, catalytic converter, cushion, retainer and gasket to access oil pan (if

necessary). See Fig. 13 .

3. Remove stiffener plate at rear of oil pan (if equipped). Remove dipstick. Remove bolts/nuts and oil pan.

Installation

1. Ensure sealing surfaces are clean. Apply bead of sealant at center of oil pan sealing surface, between

bolt/nut holes and on inside of bolt/nut holes.

2. Install oil pan. Install and tighten bolts/nuts to specification. See TORQUE SPECIFICATIONS. To install

remaining components, reverse removal procedure.

3. Use NEW nuts when installing exhaust pipe on catalytic converter. Use NEW gasket when installing

catalytic converter (if removed). Fill crankcase with oil.

TxMechs

Monday, January 28, 2013 10:23:56 AM

(512) 945-2757

Page 4

2005 Mitchell Repair Information Company, LLC.

1994 Toyota Camry LE

2.2L 4-CYL - VIN [S] 1994 ENGINES Toyota 2.2L 4-Cylinder

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

Application

A/C Compressor Bolt

Alternator Bracket Bolt

Axle Shaft Bearing Bolt

Axle Shaft Nut

Ft. Lbs. (N.m)

20 (27)

31 (42)

24 (33)

217 (294)

36 (49)

Balance Shaft Assembly-To-Cylinder Block Bolt (1)

Ball Joint-To-Lower Control Arm Bolt/Nut

Camshaft Bearing Cap Bolt (2)

Camshaft Sprocket Bolt

Catalytic Converter Brace Bolt/Nut

Catalytic Converter-To-Exhaust Manifold Bolt/Nut

Connecting Rod Nut

Step 1

Step 2

Coolant Outlet Bolt

Crankshaft Pulley Bolt

Cylinder Head Bolt (3)

Step 1

Step 2

EGR Valve

Bolt

94 (127)

14 (19)

40 (54)

31 (42)

21 (29)

18 (24)

Additional 90 Degrees

11 (15)

80 (109)

36 (49)

Additional 90 Degrees

(4)

Union Nut

Engine Hanger Bolt

Engine Mounts & Brackets

Control Rod Bracket-To-Right (Timing Belt Side) Engine Mount Bracket

Bolt (5)

Control Rod-To-Strut Tower Bolt

Front (Exhaust Manifold Side) Engine Mount-To-Cylinder Block Bolt

Front (Exhaust Manifold Side) Engine Mount-To-Frame Bolt

Rear (Intake Manifold Side) Engine Mount-To-Cylinder Block Bolt

Rear (Intake Manifold Side) Engine Mount Insulator-To-Frame Nut

Right (Timing Belt Side) Engine Mount Bracket-To-Cylinder Block Bolt

Transaxle Mount-To-Transaxle Bolt

Exhaust Manifold Nut

Flywheel/Drive Plate Bolt

A/T

M/T

TxMechs

Monday, January 28, 2013 10:23:56 AM

43 (58)

18 (24)

47 (64)

47 (64)

57 (77)

59 (80)

47 (64)

49 (66)

38 (52)

47 (64)

36 (49)

61 (83)

65 (88)

(512) 945-2757

Page 5

2005 Mitchell Repair Information Company, LLC.

1994 Toyota Camry LE

2.2L 4-CYL - VIN [S] 1994 ENGINES Toyota 2.2L 4-Cylinder

Front Exhaust Pipe-To-Catalytic Converter Nut

Front Exhaust Pipe-To-Exhaust Pipe Bolt/Nut

Fuel Line-To-Fuel Filter Union Bolt

Fuel Pulsation Damper

Intake Manifold Bolt/Nut

Intake Manifold Brace Bolt

12-mm Bolt

14-mm Bolt

Knock Sensor

Main Bearing Cap Bolt (6)

No. 1 Idler Pulley Bolt

No. 2 Idler Pulley Bolt

Oil Cooler Relief Valve-To-Cylinder Block

Oil Pump Sprocket Nut

Power Steering Pump Bracket Bolt

Power Steering Pump-To-Bracket Bolt

Spark Plug

Stabilizer Bar Link-To-Lower Control Arm Nut

Stiffener Plate Bolt

Throttle Body Bolt

Tie Rod Nut

Valve Cover Nut

Wheel Lug Nut

46 (62)

41 (56)

21 (29)

25 (34)

14 (19)

16 (22)

31 (42)

27 (37)

43 (58)

31 (42)

31 (42)

58 (79)

21 (29)

32 (43)

32 (43)

13 (18)

29 (39)

27 (37)

14 (19)

36 (49)

17 (23)

76 (103)

INCH Lbs. (N.m)

78 (8.8)

115 (13.0)

69 (7.8)

69 (7.8)

48 (5.4)

78 (8.8)

48 (5.4)

82 (9.3)

82 (9.3)

82 (9.3)

82 (9.3)

Coolant By-Pass Pipe-To-Water Pump Nut

Fuel Delivery Pipe Bolt

No. 3 Timing Belt Cover Bolt

Oil Cooler-To-Cylinder Block Nut

Oil Pan Bolt/Nut

Oil Pump Body Cover Bolt

Oil Pump Pick-Up Tube Bolt/Nut

Oil Pump-To-Cylinder Block Bolt

Rear Plate-To-Cylinder Block Bolt

Rear Seal Housing Bolt

Water Pump-To-Cylinder Block Bolt (7)

Water Pump-To-Water Pump Cover Bolt

(1) Tighten bolts to specification in sequence. See Fig. 32 .

82 (9.3)

(2) Tighten

bolts to specification in sequence. See Fig. 24 and Fig. 25 .

(3) Tighten

bolts to specification in sequence. See Fig. 14 .

TxMechs

Monday, January 28, 2013 10:23:56 AM

(512) 945-2757

Page 6

2005 Mitchell Repair Information Company, LLC.

1994 Toyota Camry LE

2.2L 4-CYL - VIN [S] 1994 ENGINES Toyota 2.2L 4-Cylinder

(4) Tighten

bolt 115 INCH lbs. (13.0 N.m).

(5) Tighten

bolts to specification in sequence. See Fig. 12 .

(6) Tighten

bolts to specification in sequence. See Fig. 45 .

(7) Tighten

bolts to specification in sequence. See Fig. 35 .

ENGINE SPECIFICATIONS

GENERAL ENGINE SPECIFICATIONS

GENERAL SPECIFICATIONS

Application

Displacement

Bore

Stroke

Compression Ratio

Fuel System

Horsepower @ RPM

California Models

All Others

Torque Ft. Lbs. @ RPM

Specification

134 Cu. In. (2.2L)

3.43" (87.1 mm)

3.58" (90.9 mm)

9.5:1

MFI Or SFI

125 @ 5400

130 @ 5400

145 @ 4400

CRANKSHAFT, MAIN & CONNECTING ROD BEARINGS SPECS

CRANKSHAFT, MAIN & CONNECTING ROD BEARINGS SPECS

Application

Crankshaft

End Play

Standard

Wear Limit

Maximum Runout

Main Bearings

Journal Diameter (1)

Size Mark "0"

Size Mark "1"

Size Mark "2"

Journal Out-Of-Round

Journal Taper

TxMechs

Monday, January 28, 2013 10:23:56 AM

In. (mm)

.0008-.0087 (.020-.220)

.0118 (.300)

.0024 (.060)

2.1653-2.1655 (54.99855.003)

2.1651-2.1653 (54.99354.998)

2.1649-2.1651 (54.98854.993)

.0008 (.020)

.0008 (.020)

(512) 945-2757

Page 7

2005 Mitchell Repair Information Company, LLC.

1994 Toyota Camry LE

2.2L 4-CYL - VIN [S] 1994 ENGINES Toyota 2.2L 4-Cylinder

Oil Clearance

Standard Crankshaft Journal

No. 3 Journal

Standard

.0010-.0017 (.025-.044)

Wear Limit

.0031 (.080)

All Other Journals

Standard

.0006-.0013 (.015-.034)

Wear Limit

.0031 (.080)

.010" (.25 mm) Undersize Crankshaft Journal

No. 3 Journal

Standard

.0011-.0026 (.027-.067)

Wear Limit

.0031 (.080)

All Other Journals

Standard

.0007-.0023 (.019-.059)

Wear Limit

.0031 (.080)

Connecting Rod Bearings

Journal Diameter

2.0466-2.0472 (51.985-52.000)

Journal Out-Of-Round

.0008 (.020)

Journal Taper

.0008 (.020)

Oil Clearance

Standard Crankshaft Journal

Standard

.0009-.0022 (.024-.055)

Wear Limit

.0031 (.080)

.010" (.25 mm) Undersize Crankshaft Journal

Standard

.0009-.0027 (.024-.069)

Wear Limit

.0031 (.080)

(1) Main bearing journal diameter is determined by size mark stamped on crankshaft. See Fig. 46 .

CONNECTING RODS SPECIFICATIONS

CONNECTING RODS SPECIFICATIONS

Application

Bore Diameter

Pin Bore

Maximum Bend

Maximum Twist

Side Play

Standard

Wear Limit

In. (mm)

.8663-.8668 (22.005-22.017)

.002 Per 3.94 (.05 Per 100.1)

.0059 Per 3.94 (.150 Per 100.1)

.0063-.0123 (.160-.312)

.0138 (.350)

PISTONS, PINS & RINGS SPECIFICATIONS

TxMechs

Monday, January 28, 2013 10:23:56 AM

(512) 945-2757

Page 8

2005 Mitchell Repair Information Company, LLC.

1994 Toyota Camry LE

2.2L 4-CYL - VIN [S] 1994 ENGINES Toyota 2.2L 4-Cylinder

PISTONS, PINS & RINGS SPECIFICATIONS

Application

Pistons

Clearance

Standard

Wear Limit

In. (mm)

.0055-.0063 (.140-.160)

.0071 (.180)

Diameter (1)

Size Mark "1"

Size Mark "2"

Size Mark "3"

Pins

Diameter

Piston Fit

3.4193-3.4197 (86.850-86.860)

3.4197-3.4201 (86.860-86.870)

3.4201-3.4205 (86.870-86.880)

.8660-.8665 (21.997-22.009)

(2)

Rod Fit

Standard

.0002-.0004 (.005-.011)

Wear Limit

.0020 (.050)

Rings

No. 1

End Gap

Standard

.0106-.0197 (.270-.500)

Wear Limit

.0433 (1.100)

Side Clearance

.0016-.0031 (.040-.080)

No. 2

End Gap

Standard

.0138-.0236 (.350-.600)

Wear Limit

.0472 (1.200)

Side Clearance

.0012-.0028 (.030-.070)

No. 3 (Oil)

End Gap

Standard

.0079-.0217 (.200-.550)

Wear Limit

.0453 (1.150)

(1) Piston diameter is determined by size mark stamped on top of piston. See Fig. 41 .

(2) With

piston temperature at 140F (60C), piston pin should slide through piston with thumb pressure.

CYLINDER BLOCK SPECIFICATIONS

CYLINDER BLOCK SPECIFICATIONS

Application

In. (mm)

(1)

Cylinder Bore

Size Mark "1"

3.4252-3.4256 (87.000-87.010)

TxMechs

Monday, January 28, 2013 10:23:56 AM

(512) 945-2757

Page 9

2005 Mitchell Repair Information Company, LLC.

1994 Toyota Camry LE

2.2L 4-CYL - VIN [S] 1994 ENGINES Toyota 2.2L 4-Cylinder

Size Mark "2"

3.4256-3.4260 (87.010-87.020)

Size Mark "3"

3.4260-3.4264 (87.020-87.030)

Maximum Deck Warpage

.002 (.05)

Main Bearing Bore I.D. (2)

Size Mark "1"

2.3326-2.3239 (59.020-59.026)

Size Mark "2"

2.3239-2.3241 (59.026-59.032)

Size Mark "3"

2.3241-2.3243 (59.032-59.038)

(1) Cylinder bore diameter is determined by size mark on cylinder block deck surface. See Fig. 42 .

Maximum bore diameter is 3.4342" (87.230 mm).

(2) Main bearing bore I.D. is determined by main bearing bore size mark on cylinder block. See Fig. 46 .

VALVES & VALVE SPRINGS SPECIFICATIONS

VALVES & VALVE SPRINGS SPECIFICATIONS

Application

Intake Valves

Face Angle

Minimum Margin

Minimum Refinish Length

Stem Diameter

Exhaust Valves

Face Angle

Minimum Margin

Minimum Refinish Length

Stem Diameter

Specification

44.5

.020" (.50 mm)

3.823" (97.10 mm)

.2350-.2356" (5.9705.985 mm)

44.5

.020" (.50 mm)

3.858" (98.00 mm)

.2348-.2354" (5.9655.980 mm)

Valve Springs

Free Length

1.6520-1.6531" (41.9641.99 mm)

.079" (2.00 mm)

Lbs. @ In. (kg @ mm)

37-43 @ 1.366 (16.719.5 @ 34.70)

Out-Of-Square Limit

Pressure

CYLINDER HEAD SPECIFICATIONS

CYLINDER HEAD SPECIFICATIONS

Application

Maximum Warpage

Cylinder Block Surface

Specification

.002" (.05 mm)

TxMechs

Monday, January 28, 2013 10:23:56 AM

(512) 945-2757

Page 10

2005 Mitchell Repair Information Company, LLC.

1994 Toyota Camry LE

2.2L 4-CYL - VIN [S] 1994 ENGINES Toyota 2.2L 4-Cylinder

Intake & Exhaust Manifold Surface

Valve Seats

Intake Valve

Seat Angle

Seat Width

Exhaust Valve

Seat Angle

Seat Width

Valve Guides

Intake Valve

Valve Guide Cylinder Head Bore I.D.

Standard Valve Guide

.003" (.08 mm)

45

.039-.055" (1.00-1.40 mm)

45

.039-.055" (1.00-1.40 mm)

.4331-.4341" (11.000-11.027

mm)

.4350-.4361" (11.050-11.077

mm)

.2366-.2374" (6.010-6.030 mm)

Oversize Valve Guide

Valve Guide I.D.

Valve Stem-To-Guide Oil Clearance

Standard

Wear Limit

Exhaust Valve

Valve Guide Cylinder Head Bore I.D.

Standard Valve Guide

.0010-.0024" (.025-.060 mm)

.0031" (.080 mm)

.4331-.4341" (11.000-11.027

mm)

Oversize Valve Guide

.2366-.2374" (6.010-6.030 mm)

Oversize Valve Guide

Valve Guide I.D.

Valve Stem-To-Guide Oil Clearance

Standard

Wear Limit

.0012-.0026" (.030-.065 mm)

.0039" (.100 mm)

CAMSHAFT SPECIFICATIONS

CAMSHAFT SPECIFICATIONS

Application

End Play

Intake Camshaft

Standard

Wear Limit

Exhaust Camshaft

Standard

Wear Limit

Gear Backlash

In. (mm)

.0018-.0039 (.045-.100)

.0047 (.120)

.0012-.0033 (.030-.085)

.0039 (.100)

TxMechs

Monday, January 28, 2013 10:23:56 AM

(512) 945-2757

Page 11

2005 Mitchell Repair Information Company, LLC.

1994 Toyota Camry LE

2.2L 4-CYL - VIN [S] 1994 ENGINES Toyota 2.2L 4-Cylinder

Standard

Wear Limit

Journal Diameter

Journal Runout

Lobe Height

Intake Camshaft

Standard

.0008-.0079 (.020-.200)

.0118 (.300)

1.0614-1.0620 (26.959-26.975)

.0016 (.040)

1.6539-1.6579 (42.01042.110)

1.6496 (41.900)

Wear Limit

Exhaust Camshaft

Standard

1.5772-1.5811 (40.06040.160)

1.5728 (39.950)

Wear Limit

Oil Clearance

Standard

Wear Limit

.0010-.0024 (.025-.062)

.0039 (.100)

VALVE LIFTERS SPECIFICATIONS

VALVE LIFTERS SPECIFICATIONS

Application

Bore Diameter

Lifter Diameter

Oil Clearance

Standard

Wear Limit

In. (mm)

1.2205-1.2212 (31.000-31.018)

1.2191-1.2195 (30.966-30.976)

.0009-.0020 (.024-.052)

.0028 (.070)

TxMechs

Monday, January 28, 2013 10:23:56 AM

(512) 945-2757

Page 12

2005 Mitchell Repair Information Company, LLC.

Vous aimerez peut-être aussi

- Presion de Compresion Toyota Tacoma 2005 2RZDocument2 pagesPresion de Compresion Toyota Tacoma 2005 2RZGustavo GamezPas encore d'évaluation

- 1991 Toyota Corolla 1.6 Diagrama de MotorDocument4 pages1991 Toyota Corolla 1.6 Diagrama de Motormario alfredo castro escobar100% (2)

- Si Nissan Sentra 03-05 - Curso 1a ParteDocument14 pagesSi Nissan Sentra 03-05 - Curso 1a PartePablo ChilinganoPas encore d'évaluation

- 2GR-FE Engine CKP Sensor CodesDocument7 pages2GR-FE Engine CKP Sensor CodesYdelkadiasmela Dominguezmorel100% (1)

- Despiece Clasico WhirlpoolDocument15 pagesDespiece Clasico Whirlpoolhenry ramirezPas encore d'évaluation

- The Wayback Machine archive of an AE86 forum post about a 4AGE to 7AGE engine conversionDocument4 pagesThe Wayback Machine archive of an AE86 forum post about a 4AGE to 7AGE engine conversionDanno NPas encore d'évaluation

- 071 RelaysDocument36 pages071 RelaysMicael FigueiraPas encore d'évaluation

- P1449 Fallos de La Batería Del Civic Híbrido.Document4 pagesP1449 Fallos de La Batería Del Civic Híbrido.Norman Valle SáenzPas encore d'évaluation

- Captiva 2008 Out Speed Sensor ReemplacementDocument3 pagesCaptiva 2008 Out Speed Sensor ReemplacementJose Luis Velasquez RomeroPas encore d'évaluation

- 2015 Chevrolet Trax 1.8 2h0 Especificaciones de MotorDocument13 pages2015 Chevrolet Trax 1.8 2h0 Especificaciones de MotorGerardo Cessa SolisPas encore d'évaluation

- 1991 Toyota TercelDocument2 pages1991 Toyota Tercelfrancisco Alba100% (1)

- MTX-L PlusDocument14 pagesMTX-L Plusjuanlasserre9444Pas encore d'évaluation

- DongFeng RICH-ZD25TCI-PINOUTDocument3 pagesDongFeng RICH-ZD25TCI-PINOUTEduardo Antonio Barria OjedaPas encore d'évaluation

- Sistema de Lubricación VW Passat 1.8LDocument6 pagesSistema de Lubricación VW Passat 1.8LOsvaldoMarianoPas encore d'évaluation

- M.I.L. On DTC p1349 - Vvti Actuator T-Eg009-03Document4 pagesM.I.L. On DTC p1349 - Vvti Actuator T-Eg009-03Omar Aguilar100% (1)

- Circuit Diagram For CityStar 3Document105 pagesCircuit Diagram For CityStar 3Jezuz ZarmientoPas encore d'évaluation

- 1990 Ranger To 1988 TC Wiring PinoutDocument4 pages1990 Ranger To 1988 TC Wiring PinoutNenita GtzPas encore d'évaluation

- Manual Vivant TacumaDocument76 pagesManual Vivant TacumaLuis Alberto Martinez Tinoco100% (1)

- Diagrama Electrico Audi A4 2008 3.2Document4 pagesDiagrama Electrico Audi A4 2008 3.2Juan AndresPas encore d'évaluation

- HYUNDAI SANTA FE 2002 - Schemat ElektrycznyDocument60 pagesHYUNDAI SANTA FE 2002 - Schemat Elektrycznylukasz.mietlowskiPas encore d'évaluation

- Understanding the LE-Jetronic Fuel Injection and Electronic Ignition SystemsDocument32 pagesUnderstanding the LE-Jetronic Fuel Injection and Electronic Ignition SystemsLivio CaramanPas encore d'évaluation

- Sony+XM 504Z+Car+Power+AmplifDocument18 pagesSony+XM 504Z+Car+Power+AmplifB.r. ArturoPas encore d'évaluation

- System Wiring DiagramsDocument87 pagesSystem Wiring Diagramshcastens3989100% (1)

- R61Document32 pagesR61Gti MotorsPas encore d'évaluation

- ECM-641A Camshaft Control, Exhaust. Faulty Signal, B5254T2: Diagnostic Trouble Code (DTC) InformationDocument4 pagesECM-641A Camshaft Control, Exhaust. Faulty Signal, B5254T2: Diagnostic Trouble Code (DTC) Informationapek1Pas encore d'évaluation

- CHEVROLET (DAEWOO) Lacetti (J200) 1.8 16V F18D3: Timing Belt: Removal/installationDocument7 pagesCHEVROLET (DAEWOO) Lacetti (J200) 1.8 16V F18D3: Timing Belt: Removal/installationJuan Jesus FernandesPas encore d'évaluation

- Section T Part 2 3l80 THM 400 t19 To t24-6044 PDFDocument47 pagesSection T Part 2 3l80 THM 400 t19 To t24-6044 PDFcampollano14Pas encore d'évaluation

- CVVT System CVVT SystemDocument15 pagesCVVT System CVVT SystemSubbu Kannappan SrinivasanPas encore d'évaluation

- 1983 Volkswagen Vanagon GL Diagramas - PDF Versión 1Document4 pages1983 Volkswagen Vanagon GL Diagramas - PDF Versión 1FranciscoPas encore d'évaluation

- Suzuki Grand Vitara 1999Document2 pagesSuzuki Grand Vitara 1999Olga PlohotnichenkoPas encore d'évaluation

- Autohelm 6000 Power Pilot Installation and Operating Handbook PDFDocument18 pagesAutohelm 6000 Power Pilot Installation and Operating Handbook PDFМилен НанковPas encore d'évaluation

- Ags 200Document2 pagesAgs 200dsimovicPas encore d'évaluation

- ID517f784b6-1996 Ford Explorer Engine ManualDocument2 pagesID517f784b6-1996 Ford Explorer Engine ManualBruce Mcleans Island0% (1)

- 1kz Te Banda de MotorDocument5 pages1kz Te Banda de MotorTaller Energy EnergyPas encore d'évaluation

- Atos Fuel SDocument133 pagesAtos Fuel Singenieriaelectronic100% (1)

- TDI Injection and Glow Plug System 2.0LDocument79 pagesTDI Injection and Glow Plug System 2.0LFailCucPas encore d'évaluation

- Pin Data FiatDocument3 pagesPin Data FiatCarlos ArquerosPas encore d'évaluation

- Diagram 1 Brake Pedal Positio..Document1 pageDiagram 1 Brake Pedal Positio..carlos garduño garciaPas encore d'évaluation

- Bujias Champion 2010 PDFDocument82 pagesBujias Champion 2010 PDFwilly036650% (2)

- Diagrama de Arranque HondaDocument1 pageDiagrama de Arranque HondaJose NuñezPas encore d'évaluation

- 4 Ataxle PDFDocument22 pages4 Ataxle PDFAnonymous XTkln6H100% (1)

- Diagramas Prelude H22A1Document53 pagesDiagramas Prelude H22A1Rodríguez AndrésPas encore d'évaluation

- Manual ServicioDocument105 pagesManual ServicioISC Jaime Hernandez VelasquezPas encore d'évaluation

- Starter Chevrolet S10Document22 pagesStarter Chevrolet S10Maxi SardiPas encore d'évaluation

- Adaptronic Blacktop Installation NotesDocument6 pagesAdaptronic Blacktop Installation NotesRayz GsrPas encore d'évaluation

- K2900 Spec Sheet 0408Document2 pagesK2900 Spec Sheet 0408Alejandro Burgos100% (2)

- 1985 Honda Accord SE-i - Diagramas ElectricosDocument15 pages1985 Honda Accord SE-i - Diagramas ElectricosRodrigo López100% (1)

- Formula Renault 1.6 NEC JuniorDocument13 pagesFormula Renault 1.6 NEC JuniorRick LangedijkPas encore d'évaluation

- 08 V6 Ticking 08-017Document3 pages08 V6 Ticking 08-017Tuomas KoskinenPas encore d'évaluation

- Toyota-Tacoma 1998 EN US Diagrama Electrico 511b5d6952Document44 pagesToyota-Tacoma 1998 EN US Diagrama Electrico 511b5d6952matesaquic999Pas encore d'évaluation

- Actyon A0 A06005Document10 pagesActyon A0 A06005Arimbi GembiekPas encore d'évaluation

- MC 10162044 0001Document5 pagesMC 10162044 0001Daniel rodriguez alayoPas encore d'évaluation

- Dmax 2.4 Diagrama PDFDocument2 pagesDmax 2.4 Diagrama PDFPatricio Edgar Gualli Calagullin100% (1)

- Bulletin ToyotaDocument3 pagesBulletin Toyotamario100% (1)

- Toyota Tercel 1986Document885 pagesToyota Tercel 1986yorgo7002Pas encore d'évaluation

- Flasher and General Relays PDFDocument28 pagesFlasher and General Relays PDFfrank mutalePas encore d'évaluation

- Transmision Diagrama Electrico PathfinderDocument1 pageTransmision Diagrama Electrico PathfinderJORGE RUZ100% (1)

- Clutch: 1988 Toyota CelicaDocument6 pagesClutch: 1988 Toyota CelicaToua YajPas encore d'évaluation

- Electrical: 1. This Is The Problem 2. It Occurs As FollowsDocument1 pageElectrical: 1. This Is The Problem 2. It Occurs As FollowsTrey OwenPas encore d'évaluation

- Heat of ExtractionDocument1 pageHeat of ExtractionTrey OwenPas encore d'évaluation

- Noise, Vibration or Harshness: 1. This Is The Problem 2. It Occurs As FollowsDocument1 pageNoise, Vibration or Harshness: 1. This Is The Problem 2. It Occurs As FollowsTrey OwenPas encore d'évaluation

- Auto Trans dIAGNOSTIC SheetDocument1 pageAuto Trans dIAGNOSTIC SheetTrey OwenPas encore d'évaluation

- Chrysler J2534 Calibration GuideDocument443 pagesChrysler J2534 Calibration GuideTrey OwenPas encore d'évaluation

- Used Car Test Drive Used Car ChecklistDocument2 pagesUsed Car Test Drive Used Car ChecklistDoral247Pas encore d'évaluation

- Excel Style77086524 Car Inspection ChecklistDocument5 pagesExcel Style77086524 Car Inspection ChecklistTrey OwenPas encore d'évaluation

- Auto Trans dIAGNOSTIC SheetDocument1 pageAuto Trans dIAGNOSTIC SheetTrey OwenPas encore d'évaluation

- Inspection Checklist: City of Cleveland Heights Division of Inspectional Services 216-291-5900Document2 pagesInspection Checklist: City of Cleveland Heights Division of Inspectional Services 216-291-5900Trey OwenPas encore d'évaluation

- 3 - Troubleshooting - Web - 01 PDFDocument39 pages3 - Troubleshooting - Web - 01 PDFDavid VargasPas encore d'évaluation

- Auto Trans dIAGNOSTIC SheetDocument1 pageAuto Trans dIAGNOSTIC SheetTrey OwenPas encore d'évaluation

- 130 UDocument2 pages130 UTrey OwenPas encore d'évaluation

- 4L60E Overhaul ManualDocument185 pages4L60E Overhaul Manualanon_89043510089% (55)

- Modem SetupDocument39 pagesModem Setupasl421Pas encore d'évaluation

- DFSEvolution User Manual ENGDocument28 pagesDFSEvolution User Manual ENGEbe AdagbasaPas encore d'évaluation

- S60 Cylinder Kit Failure Analysis MethodDocument10 pagesS60 Cylinder Kit Failure Analysis MethodKepler452bPas encore d'évaluation

- D9B380, EU4SCR - EU5SCR - Eng - 01 - 647928Document2 pagesD9B380, EU4SCR - EU5SCR - Eng - 01 - 647928Hussain ShahPas encore d'évaluation

- Prevent Crankcase Explosions on Ships with Oil Mist DetectorsDocument40 pagesPrevent Crankcase Explosions on Ships with Oil Mist DetectorsrajishrrrPas encore d'évaluation

- OIL PUMP (Bus) MERCEDESDocument3 pagesOIL PUMP (Bus) MERCEDESKarthickPas encore d'évaluation

- Piaggio X9 250evo Workshop ManualDocument262 pagesPiaggio X9 250evo Workshop Manuallynhaven171% (7)

- Volvo Penta Aquamatic80 HandbookDocument49 pagesVolvo Penta Aquamatic80 HandbookautobritaiPas encore d'évaluation

- Mtu Diesel Engine MS150068 - 01eDocument287 pagesMtu Diesel Engine MS150068 - 01eM Nuraga Lazuardy Ramadhan100% (1)

- Spare Parts Catalogue: BV 200 (U.S.A.)Document64 pagesSpare Parts Catalogue: BV 200 (U.S.A.)Enrique LopezPas encore d'évaluation

- MaxxForce DT, 9, 10 Diesel Engine Workshop Repair & Service Manual - SAMPLE PDFDocument20 pagesMaxxForce DT, 9, 10 Diesel Engine Workshop Repair & Service Manual - SAMPLE PDFAnonymous Px2Uyn38% (34)

- SSP 420 2.0L TDI Engine With Common Rail Injection SystemDocument64 pagesSSP 420 2.0L TDI Engine With Common Rail Injection SystemVictor Andres BombinPas encore d'évaluation

- Operating Instruction 6L 4860Document284 pagesOperating Instruction 6L 4860Wagner GuimarãesPas encore d'évaluation

- Deutz Bf8m 1015 CP PDFDocument6 pagesDeutz Bf8m 1015 CP PDFAgus Rasid75% (4)

- MBJ1-Up, MBL1-UpDocument104 pagesMBJ1-Up, MBL1-UpthermodynevialPas encore d'évaluation

- Yamaha Jupiter MX T135 Service ManualDocument349 pagesYamaha Jupiter MX T135 Service Manualhwahyd80% (5)

- Compresor Aire RespirableDocument32 pagesCompresor Aire RespirableJorge Cruz PoolPas encore d'évaluation

- Porsche 993 Workshop ManualsDocument1 481 pagesPorsche 993 Workshop ManualsAnonymous HyecU1cl386% (22)

- 2003 Yamaha WR450F Partscatalog PDFDocument62 pages2003 Yamaha WR450F Partscatalog PDFPACHYYNPas encore d'évaluation

- 9-Kinroad XT250GK Sahara 250cc Owners ManualDocument48 pages9-Kinroad XT250GK Sahara 250cc Owners Manualoakstr76% (17)

- Crankcase Explosion Casualty Investigation British ValourDocument23 pagesCrankcase Explosion Casualty Investigation British Valoursevero97100% (1)

- Libherr Engine Operation ManualDocument91 pagesLibherr Engine Operation Manualali100% (2)

- Manual Partes s570 NuevoDocument578 pagesManual Partes s570 Nuevodario arias100% (1)

- Conjunto pedal arranque / Kickstart set motor engineDocument34 pagesConjunto pedal arranque / Kickstart set motor engineIñaki PerezPas encore d'évaluation

- TonyduramaxDocument173 pagesTonyduramaxAndres Contreras93% (15)

- BOOST™ Users Guide GeneralDocument2 pagesBOOST™ Users Guide GeneralBrian HenriquePas encore d'évaluation

- McCulloch chainsaw service manualDocument5 pagesMcCulloch chainsaw service manualRobert RoosePas encore d'évaluation

- 91 Introduction To Internal Combustion EnginesDocument35 pages91 Introduction To Internal Combustion Enginesraghu.entrepreneurPas encore d'évaluation

- 3600 ME A&I Control System - Lekm8468Document32 pages3600 ME A&I Control System - Lekm8468Kuswanto MarinePas encore d'évaluation

- Man 470 45Document164 pagesMan 470 45Tansu MavunacıPas encore d'évaluation

- Chevrolet Malibu 2013Document266 pagesChevrolet Malibu 2013Jesús Hurtado67% (3)

- Benz Motor PDFDocument65 pagesBenz Motor PDFclcasal100% (2)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksD'EverandArizona, Utah & New Mexico: A Guide to the State & National ParksÉvaluation : 4 sur 5 étoiles4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoD'EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoÉvaluation : 5 sur 5 étoiles5/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptD'EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Bahamas a Taste of the Islands ExcerptD'EverandThe Bahamas a Taste of the Islands ExcerptÉvaluation : 4 sur 5 étoiles4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksD'EverandNew York & New Jersey: A Guide to the State & National ParksPas encore d'évaluation

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensD'EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensPas encore d'évaluation