Académique Documents

Professionnel Documents

Culture Documents

CSF in A Dairy Market

Transféré par

m n gTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CSF in A Dairy Market

Transféré par

m n gDroits d'auteur :

Formats disponibles

Critical Success Factors

in a Competitive Dairy Market

MICHAEL BOEHLJE* and WILLIAM SCHIEK

*Department of Agricultural Economics, Purdue University,

1145 Krannert, West Lafayette, IN 47907-1145

Dairy Institute of California, 1127 11th Street, Suite 718, Sacramento 95814

ABSTRACT

Dramatic changes are occurring in production

agriculture, particularly in livestock production. In

this rapidly changing and increasingly competitive

environment, successful production units utilize and

embrace modern manufacturing concepts and principles to improve their competitive position and increase their efficiency and productivity. These concepts have not replaced the well-recognized concepts

of commodity production that were used in the past,

such as an emphasis on cost control through a combination of increased size, improved efficiency, and

adoption of the latest technology in all phases of the

production process. However, the traditional techniques of obtaining efficiency, reducing cost, and increasing margins are no longer sufficient to ensure

successful agricultural production. The manufacturing concepts discussed in this paper suggest additional strategies that are necessary for success in

modern agricultural production.

( Key words: industrialization, manufacturing, integrated systems, success factors)

Abbreviation key: r = recombinant.

INTRODUCTION

Production agriculture, particularly livestock

production, is experiencing dramatic change, much of

which is driven by the trends summarized in Figure 1

( 4 ) and in the literature (1, 2, 3, 4, 5, 6, 7, 8). In this

rapidly changing and increasingly competitive environment, successful production units utilize and

embrace modern manufacturing concepts and principles to improve their competitive position and increase efficiency and productivity. These concepts and

principles do not replace the well-recognized concepts

of commodity production that emphasize cost control

through increased size, improved efficiency, and adoption of the latest technology in all phases of the

Received July 15, 1996.

Accepted January 26, 1998.

1998 J Dairy Sci 81:17531761

production process. The manufacturing concepts discussed here suggest additional strategies that are

necessary for success in modern agricultural production.

RESULTS AND DISCUSSION

The Manufacturing Mentality

Food products versus commodities. The transition of agriculture from a commodity industry to one

of differentiated products, especially when combined

with a focus on the consumer and a manufacturing

approach to production, indicates a dramatic

paradigm shift in the industry ( 7 ) . Instead of producing a product and then trying to sell it, the current

strategy increasingly is to first ask consumers what

they want as attributes in food products and then

creating or manufacturing those attributes in the

products. Such an approach may require changes in

how the raw material is produced and in what is not

contained (i.e., chemical or other residues) as well as

what is contained. This manufacturing mentality has

become more predominant and has the potential to be

increasingly successful as more is learned about the

biological production process and as the capacity is

improved to control and manipulate that process

through genetics, nutrition, building and facility design, and health management programs.

With respect to the dairy industry, milk producers

will increasingly be called upon to produce milk of

varying composition for specific food uses. Obviously,

producers shipping to cheese plants will need to be

concerned about delivering milk with high casein contents. For producers shipping to ice cream plants, fat

may be the most important component, but, for those

shipping to fluid processing plants, delivering milk

with low bacterial counts may be paramount. The

overall theme is that producers must consider the

final market for the products made from the milk

they produce and make decisions on the farm with a

view toward that market.

Systemization and routinization. The predominant characteristics of the manufacturing

1753

1754

BOEHLJE AND SCHIEK

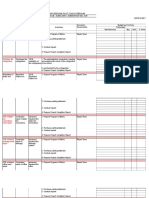

Internationalization

Greater Diversity

Greater reliance upon international trade and foreign comGreater diversity in farm size, volume, efficiency, enterprise

modity markets, substantial foreign sourcing of agriculture inspecialization, financial performance, managerial ability, and

puts, globalization of financial markets, and loss of United

production technology, which results in increased focus on marStates dominance in agriculture research and development.

ket segments and niches and more potential conflicts between

competing segments of agriculture.

The Restructuring of Farm and Agribusiness Firms

New Financing Options

Mergers and consolidations in input supply, production and

processing industries; restructuring of farm operations (e.g.,

downsizing, part-time farming, and owner-operators becoming

renters); increased contract production and greater vertical

integration of production processes; and more diversified marketing and financial strategies.

Increased use of alternatives to debt (leasing, for example) and

modified forms of debt such as adjustable term loans. Greater

involvement in US agriculture by international financial institutions.

Consumer-Driven Production

Strategic Planning

Consumers increasingly expect agricultural producers to meet

their preferences regarding taste, texture, color, nutritional

characteristics, and packaging and processing methods.

Increased long-term strategic planning. Mapping responses to a

wide variety of long-term future occurrences. Planning for alternative business scenarios.

New Technology

Environmental Importance

Further development and adoption of biotechnology and information technology. Ideas and innovation replacing strict reliance on mechanical technology and physical labor.

Heightened interest in sustainable agriculture as well as increased state and federal regulation in the areas of water quality and soil erosion. Incentives to encourage environmentally

sound farming practices.

Lower Production Costs

Changing Public Policies

Lower costs attributable to lower prices and greater efficiency

in the use of both purchased inputs (e.g., fertilizers and

chemicals) and contributed inputs (e.g., labor and facilities).

Present and future policy debate likely to influence agriculture

substantially; international trade policy; government standards

on food safety and quality; commodity price support policy;

animal rights and animal welfare issues; and environmental issues.

Figure 1. Megatrends affecting agriculture ( 4 ) .

process include a movement toward systems and routines. With increased understanding and ability to

control the biological production process, it becomes

increasingly possible to routinize, as tasks become

more programmable. Routines generally foster more

efficient use of facilities and personnel and require

less managerial oversight and lower overhead. Hourly

work schedules that identify specific tasks to be done

at specific times on specific days in the modern dairy

operation are examples of the systems and routines in

modern livestock production. In essence, agricultural

production is becoming more of a science and less of

an art.

In the dairy industry, there currently exist a handful of producers who have taken this view of their

dairy farming operations. For these operators, dairy

farming is a production system, not a craft or art

form. These farmers have replicated their operations

not just in their home region, but in other areas of the

country as well. This type of business organization

appears to be growing, particularly in parts of the

Southwest.

Specialization. Modern production systems also

require specialization, not only with respect to busiJournal of Dairy Science Vol. 81, No. 6, 1998

ness venture and focus but also with respect to individual employee tasks or function. As more of the

output of the swine, dairy, beef, and poultry industries is being produced by larger scale, specialized

units, employees within these units are becoming

more specialized in their tasks or functions; for example, some are focused only on breeding, some on feeding, and some on health maintenance. This specialization of function of personnel as well as business focus

of the firm again is increasingly feasible because of

better understanding and control of the biological

process.

In some parts of the country, particularly Florida

and the western states, the raising of grain and concentrate feed, the growing of forages, and the raising

of replacement stock each have emerged as separate

business enterprises often with separate ownership.

Areas where this type of specialization has occurred

seem to be garnering a larger share of national

production while areas where traditional dairy farming combined with feed and heifer raising is practiced

are losing market share. In the future, specialization

could take on another dimension, as dairy farmers

cater to one business segment or another. For exam-

SYMPOSIUM: UNITED STATES DAIRY INDUSTRY

ple, some farms will concentrate on producing for and

selling to cheese plants exclusively, and others will

service only fluid processing plants. This type of

specialization is a natural outgrowth of the different

needs for raw products of the various customer

groups.

Scheduling and utilization. A further implication of the manufacturing paradigm in agricultural

production is increased emphasis on facility utilization, flow scheduling, and process control. In the past,

the variability associated with the lagged dynamics of

output response to current and expected prices and

the biological production processes has made facility

use, scheduling, and process control difficult if not

impossible. Many production units have in essence

maintained excess plant capacity as one means of

accommodating the uncertainty of the output of the

biological production process. But again, as a result of

the increased ability to predict and control that

process, facility use can be more accurately predicted

and controlled, and process control to improve efficiency and reduce cost is more applicable and useful

than in the past.

Of course, with respect to scheduling and utilization, the biggest problem in the dairy industry is the

seasonality of milk production. Adequate processing

capacity must be maintained to handle milk during

the peak part of the season, but plants are often idle

during autumn and winter months. This excess capacity adds substantial system costs, which are paid for

by dairy producers, processors, and ultimately consumers. As milk producers enter into coordinated arrangements with processors, it will be more likely

that financial incentives will exist for producers to

use all means possible to ensure continual, even

production throughout the year by staggering

freshening times and employing selective use of

recombinant ( r) bST. Pursuing a more level production pattern is costly to dairy producers, and current

arms-length marketing arrangements provide little or

no reward for such activities.

A Systems Approach

Systems process flow. The manufacturing mentality places increasing emphasis on the entire value

chain from raw materials supplier to end user. This

system focus, rather than stage or segment focus,

reduces the chances for suboptimization within a

stage or sector and for dead weight losses because

stages are not well matched in terms of product flow,

characteristics, quality, or other critical attributes.

Matching milk production capacity to processing

plant capacity is but one example in dairy production.

1755

Dead weight losses can be particularly large in biological production processes because many attributes

naturally vary widely because of variation in genetic

and other inputs as well as growing conditions. Thus,

the potential exists for a very high payoff if manufacturing processes can be used to reduce the dead

weight losses in the system.

Systems cost. Although cost control is critical in

any production system, a manufacturing approach

that is focused on end user products recognizes total

costs for production and distribution systems as being

more critical than the cost at each stage of the value

chain. And, as more resources are out-sourced, the

cost structure of the business changes, and a higher

proportion of the cost is variable. With this changing

proportion of fixed and variable cost, each stage becomes more responsive to the changing demands of

the end user and to competitive pressures. Because

the short-term costs that influence production adjustment decisions are variable, the smaller the proportion is of variable costs to total costs, the more prices

must decline before a firm reduces output. Consequently, firms with a high proportion of fixed costs

are quite lethargic in adjusting to changes in market

conditions, and conversely, firms with a higher

proportion of variable costs are more responsive to

changing market conditions.

In the US dairy industry, the contrast between

operations with high fixed costs and those with relatively low fixed costs can be illustrated by comparing

the milk production systems in place in the Midwest

and in the Southwest. Traditional dairy operations,

where feed and forage production is a large part of the

enterprise (the Midwest), have considerable capital

tied up in planting and harvesting equipment and, in

many cases, feed storage. The colder climate in the

Midwest also necessitates a greater investment in

buildings to shelter animals and equipment. Dairy

drylot operations in the Southwest have a larger

proportion of their total costs in purchased feed and

labor. Consequently, output in western and southwestern operations is more responsive to changing

market conditions.

Input packages. As the capacity increases to control and understand the biological process through

biotechnology and genetic engineering techniques,

producers will be more capable of developing optimal

input combinations that match nutritional and biological attributes to obtain the optimum quality and

characteristics of output. Livestock genetics are being

matched to feed ingredient genetics to obtain the

proper ration and nutrient contents to produce the

most efficient production system as well as specific

animal product attributes. In this situation, the

Journal of Dairy Science Vol. 81, No. 6, 1998

1756

BOEHLJE AND SCHIEK

strategy of the past, by which producers could buy

feed or nutritional inputs from one firm and genetic

material from a second, may become increasingly

difficult. In some cases, the producer will purchase

prespecified input packages that have been optimized

in biological and chemical characteristics; in other

cases, the producer will be instructed that certain

nutritional and genetic inputs respond better when

used together or that performance may be suboptimal

if used in other than the recommended combinations.

This strategy of matched inputs has the risk of

reduced flexibility and response if supplies of an input

decrease or prices increase.

Companies such as Monsanto, which markets a

form of rbST, may find it advantageous to bundle feed

additives, animal health products, and management

plans for herds and individual animals in order to

ensure optimal performance of their products.

Producers using this and similar technologies will

find it necessary to purchase the entire input bundle,

rather than putting together feeds and animal health

products from separate suppliers, in order to get the

kind of performance that justifies the investment in

the technology.

Separation and Realignment

Separation of production stages. The old

paradigm in production agriculture has been to combine various stages of production within one firmfor

example, to combine in swine production the breeding, gestation, farrowing, nursery, growing, and

finishing activities in one firm at one location and,

furthermore, to integrate these activities with feed

production and processing. The new paradigm is geographic and stage separation of many of these stages

of production. In dairy production, milking is increasingly separated from production of replacement heifers, and feed production is separated from milking

and breeding activities. The advantages of this separation are not only economies of scale and specialization of both human and capital resources, but also

disease control and improved herd health. A further

dimension of this separation is in the ownership and

operation of the resources. More assets in production

agriculture are being out-sourced; for example, 41% of

the farm land today is owned by a nonoperator compared with 22% in 1945 ( 8 ) . Separation of the various stages of production does not necessarily imply

separate firms, although stage and geographic separation may facilitate separation of ownership as well.

Geographic and stage separation, in turn, frequently

implies larger scale and more specialized capital,

labor, and management resources at each individual

Journal of Dairy Science Vol. 81, No. 6, 1998

plant site or facility location. The implications of

separation on flexibility are unclear. More specialization in resource use decreases flexibility, but participation in only one stage may increase the options for

negotiating with other partners in other systems if

there are other systems in the market.

Partners and alliances. At the same time that

geographic and stage separation is occurring, various

forms of alliances are being formed. In the traditional

approach to agricultural production, an independent

producer purchases inputs and sells products through

various market mechanisms to other independent

businessmen. Increasingly, producers form various

types of partnerships with other resource suppliers to

expand volume with limited capital outlay. In

livestock production, this phenomenon is occurring

through contracting arrangements; a dairy operator

may own the milking facilities but contract the feed

production and replacement heifer growing phases. In

essence, the dairy producer leverages volume by investing his funds in only part of the total fixed assets

needed to produce milk while maintaining a high

degree of control of the other phases through the

specification of the growing conditions. The critical

dimension of such partnerships or alliances is that

more resources and services are out-sourced if that is

a less expensive technique for obtaining production

inputs, and more linkages up the value chain to the

end user are used to capture value in additional

stages of the chain ( 3 ) .

Negotiated Coordination

Open access markets. Production agriculture has

traditionally focused primarily on commodity

products with coordination through impersonal open

access markets. The increased specificity in requirements for raw materials combined with the potential

for producing specific attributes in those raw materials is transforming part of the agricultural market to

a differentiated product market rather than a commodity product market. The need for greater diversity, more exacting quality control, and flow control

will tax the ability of open access markets to coordinate production and processing effectively. Open

access markets increasingly encounter difficulty in

conveying full information concerning attributes

(e.g., quantity, quality, and timing) of a product and

characteristics (including services) of a transaction.

When open markets fail to achieve the needed coordination, other options, such as contracts, integration,

or joint ventures, will be used (5, 6).

Currently, processors have the ability to purchase

open market loads of raw or pasteurized milk from

SYMPOSIUM: UNITED STATES DAIRY INDUSTRY

cooperatives. There is no guarantee, however, that

this milk has the attributes desired by the processor,

which, in a world of generic commodities, would not

be an issue because the processor would have no other

option for obtaining the desired raw materials.

However, increasingly, not all milk is equal for a

given end use. As consumers and processors begin to

demand milk with special attributes, such as high

casein contents, extra low somatic cell counts, high

lactose contents, or from cows that have not been

treated with rbST, open markets increasingly are

woefully inadequate mechanisms. The options available to the processor are to develop its own shippers by

forming partnerships directly with selected milk

producers or with a dairy cooperative that will deliver

milk with the desired attributes. In either case, the

system requires more coordination than does the spot

market.

Information flow. Related to the difficulty of open

markets to convey proper information is the speed of

information flow and the rate of adoption with different coordination mechanisms. In general, negotiated

coordination results in more rapid transmission of

information among the various economic stages and,

consequently, enhanced ability of the system to adjust

to changing consumer demands, economic conditions,

or technological improvements. The ability of the

production and distribution system to be more responsive and to adjust rapidly to changing conditions is

increasingly important because of the increased rate

of change in economic and social systems worldwide.

The ability to respond quickly to economic changes

is critical to maintain profit margins and to extract

profits from innovation. Quick recognition of erroneous decisions, followed by appropriate adjustments

and corrections, are essential to survival and success.

Market coordination of systems characterized by biological lags cannot respond to changing conditions as

quickly as an integrated or contract coordinated system.

The response at one stage can be initiated only

after price signals the need for change, and the

change in quantity or quality is realized only after a

full production cycle. By their nature, negotiated coordination systems require more frequent and direct

communication between the decision makers at each

stage on a wider variety of product and service

characteristics than is typically possible with more

traditional open markets. Thus, the improved information flows and more rapid adoption and adjustment allow negotiated coordination systems to function more effectively in rapidly changing markets.

These arguments suggest that traditional open

commodity markets can function quite effectively and

1757

efficiently when specific attributes are not demanded,

when supplies are fully adequate and can be obtained

from various sources, and when information flow between the various stages is minimal. With deviation

from these conditionswhich is increasingly the case

with more specificity in raw materials, information

flows, and fewer potential sources of acceptable

suppliesvarious forms of negotiated coordination

systems become more effective and necessary for efficient functioning of the production and distribution

system.

In the dairy industry, coordinated systems are superior at directing high casein milk to cheese plants

where it is most useful. Coordination also is superior

at directing milk with low somatic cell counts to fluid

processing plants where it can be part of the process

of extending bottled milk shelf-life. Coordinated systems will also be better at identifying and addressing

problems created by antibiotic residues in milk and

will make adoption of HACCP (hazards analysis critical control point) systems more feasible.

Risk

Sources and strategies. Risk has been a

hallmark of the agricultural sector, and the industrialization of agriculture is both a result of the business

strategies to reduce risk and has implications for

future strategies to reduce risk. One risk is that of

prices of inputs or products. A common business

strategy is to reduce the risk of high input prices by

contracting for supplies. A related strategy is to contract product sales. Some firms reduce price risks by

vertically integrating into the input supply or product

distribution channels. These coordination methods attempt to reduce the impact of market fluctuations

that are part of the open market pricing system.

A second source of risk is related to quantity and

quality features. Food packaging and processing unit

costs have become very sensitive to operating at full

plant capacity; thus, flow scheduling is critical to

being cost competitive. Matching the physical capacity of various stages (for example, milk supplies with

processing plant capacity) is critical to the overall

efficiency of the system. This coordination may be

more difficult to attain in open markets. Furthermore, some food distribution channels may require

particular quality characteristics that may not be

available in predictable quantities in open markets.

The coordination that is needed to ensure both quality and quantity for efficient operations can be

achieved through contracts, ownership of more than

one stage, joint ventures, or similar arrangements in

the food production and distribution chain.

Journal of Dairy Science Vol. 81, No. 6, 1998

1758

BOEHLJE AND SCHIEK

With respect to attributes such as protein content

and bacteria content (somatic cells), regulated pricing structures can be adapted to give economic signals

to appropriate parties, but regulation is slow to

respond to changing market conditions. Third-party

relationships can also present problems. For example,

dairy cooperatives often have difficulty delivering

milk with specific attributes because members who

produce milk that does not have these attributes are

hesitant to support economic rewards to producers

who do produce such milk.

A third source or type of risk in the food chain that

has become more serious in recent years is that of the

safety and health risk in food production. This risk

has two dimensions, the health risk from food-borne

disease and the risk for pollution of water, air, and

land resources during the food production processes.

These risks can result in significant direct costs and

liability exposure, not only for the responsible firm in

the food chain, but also for firms that supply related

inputs and purchase products from the responsible

firm, such as in the case of strict (joint and severable) environmental liability related to chemical use.

Thus, system coordination to reduce or control these

risks may be in part a response to the broad sweep of

laws pertaining to product and environmental liabilities.

With respect to food-borne disease, the structural

changes in the industry are making these problems

easier to identify and solve. For example, if an ice

cream manufacturer detects an antibiotic residue in

its product, the problem will be easier to trace and

solve if the manufacturer has contracts directly with

four large dairy farms for milk supply than if it

purchases from a cooperative that commingles milk

from 6000 producers. With respect to environmental

risk, the increased scale of dairy farming has increased the likelihood of groundwater contamination

from runoff because of higher concentrations of

animals in small spaces, but these larger enterprises

are probably more able to manage waste from the

dairy operation, as well as to invest in the necessary

equipment to handle and process dairy waste. Large

dairy farms have even greater advantages in managing these problems to the extent that they receive

assistance in quality control and waste management

from their partners in food processing.

Relationship risk. The expanding use of contractual and other forms of negotiation-based linkages

between the various stages of the agricultural production and distribution system, and the decline in impersonal market-based transactions, will result in

price risk being replaced by relationship or contracJournal of Dairy Science Vol. 81, No. 6, 1998

tual risk for many agribusiness firms. At a minimum,

the shift from impersonal open markets to

negotiation-based closed markets will have an impact

upon the organizations that use the risk allocation

system offered by the futures and commodities exchanges and, possibly, the product that is traded in

those exchanges. Alternatively, the volume of activity

may be changed to make exchanges less efficient and

effective in risk allocation. This shift may eliminate

the usefulness of exchanges completely, as is the case

for the production of fruits, vegetables, and poultry.

Niche markets. The food and industrial use markets for agricultural commodities are increasingly

characterized as segmented or niche markets that can

appear and disappear rapidly. This phenomenon of

market volatility (i.e., markets developing and then

disappearing literally within weeks or months) does

not characterize the generic commodity markets. For

many agribusiness firms that are in the food processing and distribution business, the risk of changing

consumer preferences or a food safety scare may be a

much more critical and important risk to manage

than price or availability of raw materials. One reason for a contractual arrangement to obtain raw

materials is to reduce risks from price, availability,

and food safety from chemicals while simultaneously

obtaining the attributes needed in the final product

from the specific attribute raw material. This technique for strategically managing exposure to multiple

risks is likely to become increasingly important in the

industrialized agriculture of the future at the expense

of using futures exchanges to manage the single

dimension of price risk exposure.

In the dairy industry, organic dairy products and

products made with milk from cows that were not

treated with rbST are examples of niche markets.

Although these markets may not appear and then

disappear overnight, their size and relative importance may wax and wane as information regarding

the benefits of consuming organic or natural foods

appears in the media.

The Role of Information

An increasing role. Although numerous forces

and drivers contribute to the structural changes that

are occurring in agriculture, information and

knowledge are significant. As in other industries

characterized by negotiated or personal linkages,

those individuals with unique and accurate information and knowledge have increasing power and control in the agricultural production system. With

power and control comes the capacity to garner profits

from and transfer risk to others with less power, as

SYMPOSIUM: UNITED STATES DAIRY INDUSTRY

well as to influence the rate of technological and

institutional changes in the industry.

The role of knowledge and information in obtaining

control, increasing profits, and transferring risk in

the agricultural sector is increasing for two fundamental reasons. First, the manufacture of food and

industrial products has become an increasingly

sophisticated and complex business, especially when

contrasted with commodity production as in the past.

Because of this increased complexity, those individuals who have more knowledge and information about

the detailed processes and about how to combine

those processes in a total system (i.e., the value chain

approach) will have a comparative advantage. The

second development is the dramatic growth in

knowledge of the chemical, biological, and physical

processes involved in agricultural production. This

vast expansion in knowledge and understanding

means that those who can sort through that

knowledge and put it to work in a practical context

have a further comparative advantage. Thus, the role

of knowledge and information in achieving success in

the agricultural industry is more important today

than ever before.

Technology has developed and is continuing to develop in the dairy industry whereby it is possible to

fractionate milk into its constituent components. At

the same time, food and industrial uses are developing for these components, thereby increasing the demand for milk with high levels of one or another of

these constituents. Examples include casein in

cheese, lactose for use in processed foods, and serum

(noncasein) milk proteins that can be used to fortify

a variety of foods. One of the difficulties in developing

a system that transmits signals to producers in a way

that rewards those who produce milk with high

specific component content is the ability to measure

the components in the milk coming off the farm. New

methods that use infrared measuring devices are

making it easier to measure components in raw milk.

Thus, technology and the information made available

through the use of that technology are driving the

flow of information back to producers that will allow

them to make changes in management and herd

genetics to favor the production of one component or

another.

Access to information. The logical question, then,

for individuals in the manufacturing chain for food

and industrial products is how to obtain access to

knowledge and information. Historically, particularly

for the independent producers in the farm sector,

knowledge and information have been obtained from

public sources and from sources such as genetics and

chemical companies, feed companies, machinery and

1759

equipment manufacturers, packers, and processors.

In general, independent producers have obtained

knowledge and information from external sources in

much the same fashion as they have contracted physical and financial resources and inputs. In contrast,

ownership or contract-coordinated production and distribution systems receive knowledge and information

from a combination of internal and external sources.

Many of these firms or alliances of firms have an

internal research and development staff to enhance

the knowledge and information base. The knowledge

obtained is proprietary and not shared outside the

firm or alliance; it is a source of strategic competitive

advantage.

Integrated systems. The research and development activities in coordinated systems are more focused on the efficiency and effectiveness of the total

system than on individual components of that system

and are focused on integration of areas (e.g., nutrition, genetics, building and equipment design, health

and disease control programs, and marketing

strategy) than on these areas or topics separately. In

addition to more effective research and development,

such alliances or integrated firms have the capacity to

implement technological breakthroughs more rapidly

over a larger volume of output to obtain larger profits

as an innovator. In the case of a defective new technology, ownership or contract-coordinated systems

generally have more monitoring and control procedures in place and can consequently detect deteriorating performance earlier and make adjustments more

quickly than is possible with a system with impersonal market coordination.

With respect to the previous example of milk fractionation and milk component marketing, it is likely

that some particular combination of technologies and

management practices will be necessary to obtain

optimal product and component yields from raw milk.

For an individual processor and its milk suppliers,

there is obviously an advantage to retaining information about the methods used to optimize milk component delivery as privileged. Benefits in terms of

higher profits on the sale of components will accrue to

the participants in this coordinated system, and those

firms that are not privy to this information will not be

as successful. Again, this arrangement introduces an

element of risk if one of the raw milk producers

breaks its relationships with the food processor and

begins supplying a competing firm, thereby transferring the knowledge and information that had previously been privileged.

As knowledge and information become more important as sources of strategic competitive advantage,

those who have access to the knowledge and informaJournal of Dairy Science Vol. 81, No. 6, 1998

1760

BOEHLJE AND SCHIEK

tion will be more successful than those who do not.

Given the declining public sector funding for research

and development and for the dissemination of

knowledge and information, the expanded capacity of

integrated systems to generate proprietary knowledge

and technology and to adapt it rapidly enables the

participants in that system to capture and create

innovator profits while simultaneously increasing

control and reducing risk. This ability provides a

formidable advantage to this coordinated production

system over the system of independent stages and

decision making.

This discussion of integrated systems would appear

to contradict our earlier discussion about the need for

specialization and separation of business enterprises.

However, these two strategies are not mutually exclusive. It is possible for a firm to integrate or coordinate

some activities (if the benefits are there) while outsourcing other activities for which there is little or no

benefit to integration.

Value of information. As information has become

increasingly context specific and decision focused, it

has become more valuable. And, as information becomes more valuable, the incentive increases for the

private sector to provide that information and capture

some of that value. Consequently, the growth in the

private sector of data gathering and information service firms is not surprising given the growing value of

information.

This increased value of information and the expanding role of the private sector in providing it

increases the importance of the issue of the

proprietary nature of and access to data and information. With the increasing value of information and its

use as a strategic competitive advantage, data and

information are less freely exchanged, and the issue

of ownership becomes critical. For example, with

respect to site-specific information about soil characteristics, who owns itthe grower who paid for it, or

the service company that gathered it? Can a grower

obtain this information from one company, such as a

fertilizer or chemical dealer, and then provide it to a

competitor who might have a lower price on fertilizer

or chemical products? Does it make a difference if the

grower pays for the service, how much is paid, or

whether the information service is provided as part of

a bundled package with the product? If coordinated

production systems have the potential to obtain superior information, how can a producer who is not

part of that system obtain access to similar information to remain competitive? Does a producer need to

become part of the system to obtain access to the

latest information needed to stay competitive?

Journal of Dairy Science Vol. 81, No. 6, 1998

Public policy. In a broader context, the public

policy issues of intellectual property rights and the

role of the public sector in making information a

public good that is broadly available to all potential

users become critical (1, 2). The debate about intellectual property rights has historically focused

more on research and development and new innovations that are protectable under patent or copyright

law. Particularly in agriculture, the public sector has

played a major role in the research and development

activity and thus provided broad access to new technology and ideas. In this context, part of the public

purpose was developing and disseminating new ideas

in a sufficiently broad fashion so that a wide spectrum of users benefited and so that individual firms

could not restrict access to the new idea or capture

the value associated with it. The role of the public

sector was that of leveling the playing field, so that

all participants had the same access to new ideas and

information.

As increasingly more of the research and development and, thus, more of the new ideas come from

private sector firms, and, as more of the information

dissemination system becomes privatized, individual

firms have more potential to capture value at the

expense of end users. Those firms have the potential

to restrict access to new ideas and information to

particular users, thus favoring some producers and

excluding others from the ideas, technology, or information necessary for them to be competitive. The

concepts of intellectual property rights, including patent and copyright law as applied to agriculture, were

developed in an era of domestic markets and national

firms; a relatively large public sector system for

research, development, and information dissemination; and a limited role of information as a critical

resource. These concepts should be reevaluated in the

current context of global markets and multinational

business firms; the shrinking role of the public sector

in research and development and disseminating information; and the increasing importance of information

compared with other resources as a source of strategic

competitive advantage.

CONCLUSIONS

The structural changes that are expected to occur

within the agricultural sector over the next decade

will be profound. These changes will include both

technological and institutional innovations. Production agriculture has readily accepted technological

innovations; for example, farmers have generally

been eager to try new hybrids, new chemicals, new

tillage practices, new feeding regimens, and new

SYMPOSIUM: UNITED STATES DAIRY INDUSTRY

equipment. Institutional innovations or new ways of

doing business have met with more resistance, possibly because they change relationships and frequently

substitute interdependence for independence in the

decision-making process. But the economic benefits of

the combined technological and institutional innovations will likely result in a rapid movement of the

livestock sectors followed by grain sectors to an industrial model of production and distribution.

REFERENCES

1 Anonymous. 1994. The industrialization of agriculture: policy,

research, and education needs. A symposium. Counc. Food,

Agric., Res. Econ. Washington, DC.

2 Barkema, A., and M. Cook. 1993. The changing pork industry: a

1761

dilemma for public policy. Econ. Rev. (Fed. Reserve Bank Kansas City, second quarter):4965.

3 Barry, P. J., S. T. Sonka, and K. Lajili. 1992. Vertical coordination, financial structure, and the changing theory of the firm.

Am. J. Agric. Econ. 74:1219.

4 Boehlje, M. 1991. Megatrends impacting agriculture. Staff

Paper. Pages 120. Dep. Agric. Appl. Econ., Univ. Minnesota,

St. Paul.

5 Mahoney, J. T. 1992. The choice of organizational form: vertical financial ownership versus other methods of vertical integration, Strategic Manag. J. 13:559584.

6 Martin, L., R. Westgren, L. Schrader, L. Cousineau, N. LeRoch,

R. Paguaga, and V. Amanor-Boadu. 1993. Alternative business

linkages: the case of the poultry industry. Working Paper

10-93, George Morris Ctr. Food Ind. Res. Group, Guelph, ON,

Canada.

7 Urban, T. 1991. Agricultural industrialization: its inevitable.

Choices (fourth quarter):46.

8 United States Department of Agriculture. 19451995. Farm

Real Estate Developments. Selected issues. US Govt. Printing

Office, Washington, DC.

Journal of Dairy Science Vol. 81, No. 6, 1998

Vous aimerez peut-être aussi

- Pennsylvania CasebookDocument194 pagesPennsylvania CasebookLeandroSouza1750% (2)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Iffco-Tokio General Insurance Co - LTD: Servicing OfficeDocument3 pagesIffco-Tokio General Insurance Co - LTD: Servicing Officevijay_sudha50% (2)

- 2009 ART Smallholder Dairy DevelopmentHEIFER040609Document4 pages2009 ART Smallholder Dairy DevelopmentHEIFER040609TauseefAhmadPas encore d'évaluation

- Four Functions of Agribusiness ManagementDocument3 pagesFour Functions of Agribusiness ManagementLeigh Lyn100% (1)

- Major factors contributing to agricultural productivity gains in Asia and implications for the futureDocument13 pagesMajor factors contributing to agricultural productivity gains in Asia and implications for the futureNinaPas encore d'évaluation

- CVP Analysis ProjectDocument63 pagesCVP Analysis ProjectMBA Sec APas encore d'évaluation

- Managing the World's Largest Industry - AgribusinessDocument11 pagesManaging the World's Largest Industry - AgribusinessMitchPas encore d'évaluation

- Eco DairyDocument16 pagesEco DairyNilamdeen Mohamed ZamilPas encore d'évaluation

- Farm Animal Welfare: The Business Case For Action: October 2011Document8 pagesFarm Animal Welfare: The Business Case For Action: October 2011Errorlevel 88Pas encore d'évaluation

- 2 Chapter TwoDocument11 pages2 Chapter TwoWondmageneUrgessaPas encore d'évaluation

- BS Assignment 1Document5 pagesBS Assignment 1Ambika Sharma100% (1)

- Module 3 - Food Product DevelopmentDocument15 pagesModule 3 - Food Product Developmentrbtlch1nPas encore d'évaluation

- MDA Msu Feedlot Feasability 184592 7 PDFDocument61 pagesMDA Msu Feedlot Feasability 184592 7 PDFEd ZPas encore d'évaluation

- EconomicsDocument15 pagesEconomicsNinaPas encore d'évaluation

- Clapp 2021 Growing Corporate ConcentrationDocument5 pagesClapp 2021 Growing Corporate ConcentrationAndrés GarcíaPas encore d'évaluation

- Agriculture Value ChainDocument5 pagesAgriculture Value ChainCalvince OmondiPas encore d'évaluation

- Desai - Tirupati AbstractDocument2 pagesDesai - Tirupati Abstractdesai1959Pas encore d'évaluation

- Howard - 2009 - Visualizing Consolidation in The Global Seed Industry. 1996-2008Document22 pagesHoward - 2009 - Visualizing Consolidation in The Global Seed Industry. 1996-2008heisengellPas encore d'évaluation

- Processed Food Industry PakistanDocument6 pagesProcessed Food Industry PakistanSyed Moazzam Abbas0% (1)

- Farm Management TipsDocument31 pagesFarm Management TipsAjeet ThounaojamPas encore d'évaluation

- Bhavika Dalvi Roll - No 8Document25 pagesBhavika Dalvi Roll - No 8Bhavika DalviPas encore d'évaluation

- Engaging The Private SectorDocument62 pagesEngaging The Private SectorHengleenaPas encore d'évaluation

- Supply Chain Management and Challenges FacingDocument11 pagesSupply Chain Management and Challenges FacingRano JoyPas encore d'évaluation

- Robust Supply Chain A Key Parameter For The Success of The Dairy IndustryDocument2 pagesRobust Supply Chain A Key Parameter For The Success of The Dairy IndustrytorqtechPas encore d'évaluation

- REVIEW of AGRICULTURE - Efficient Agricultural MarketingDocument8 pagesREVIEW of AGRICULTURE - Efficient Agricultural MarketingkarankhatiPas encore d'évaluation

- Diversification in SugaracaneDocument12 pagesDiversification in SugaracanedonbosskissPas encore d'évaluation

- Case 2.4 - Asher Farms IncDocument7 pagesCase 2.4 - Asher Farms IncStarbucksPestle0% (1)

- Farming as a Business Opportunities and ChallengesDocument6 pagesFarming as a Business Opportunities and ChallengesKimberly Rose NarcisoPas encore d'évaluation

- Mle e PDFDocument92 pagesMle e PDFSabyasachi pradhanPas encore d'évaluation

- Agriculture-Industry Interface: Value Added Farm ProductsDocument9 pagesAgriculture-Industry Interface: Value Added Farm ProductsAnanda PreethiPas encore d'évaluation

- Food Product Innovation: A Background PaperDocument35 pagesFood Product Innovation: A Background PaperDinesh DinuPas encore d'évaluation

- Module 3 - Food Product DevelopmentDocument16 pagesModule 3 - Food Product Developmentrbtlch1n88% (8)

- FS Doc 6Document55 pagesFS Doc 6BARILLO ERYKAPas encore d'évaluation

- Individual AssignmentDocument5 pagesIndividual AssignmentWenzile GumedePas encore d'évaluation

- MAB Till MidDocument102 pagesMAB Till MidMalik UsamaPas encore d'évaluation

- Research Paper On Agricultural Marketing in IndiaDocument5 pagesResearch Paper On Agricultural Marketing in IndiaqtbghsbndPas encore d'évaluation

- The Vegetable Seed Industry - Where Is It Heading?: By: Philip W. Ashcraft Director Verdant Partners LLC November 6, 2009Document4 pagesThe Vegetable Seed Industry - Where Is It Heading?: By: Philip W. Ashcraft Director Verdant Partners LLC November 6, 2009nmjklPas encore d'évaluation

- Making Food Safety A Mass Movement-Challenges Before The Developing CountriesDocument5 pagesMaking Food Safety A Mass Movement-Challenges Before The Developing CountriesRamachandra RajuPas encore d'évaluation

- Foodprocessingindustry 170603054137Document18 pagesFoodprocessingindustry 170603054137Satyendra DhakrePas encore d'évaluation

- Chapter 4 - Forecasting Demand: BackgroundDocument5 pagesChapter 4 - Forecasting Demand: BackgroundJeetender MishraPas encore d'évaluation

- Module II ABE Dynamics Cases - KVR-ENRDocument130 pagesModule II ABE Dynamics Cases - KVR-ENRHarikrishna HKPas encore d'évaluation

- Basics of financial record keeping for cow herd profitabilityDocument8 pagesBasics of financial record keeping for cow herd profitabilityJorge Ortiz RamosPas encore d'évaluation

- Accenture AgribusinessDocument16 pagesAccenture AgribusinessVipul Vikram Singh100% (1)

- Factor Affecting Seed MarketingDocument9 pagesFactor Affecting Seed Marketingkanavkhajuria401Pas encore d'évaluation

- Conclusion EcoDocument2 pagesConclusion EcoTanishq KambojPas encore d'évaluation

- Adoption Process, p95Document244 pagesAdoption Process, p95ZahraPas encore d'évaluation

- Q1Module 1Week1ExplanationDocument13 pagesQ1Module 1Week1ExplanationDesiree ManriquePas encore d'évaluation

- Chapter 1 - The Business of AgribusinessDocument42 pagesChapter 1 - The Business of AgribusinessMalik UsamaPas encore d'évaluation

- 2021 Book TheInnovationRevolutionInAgricDocument244 pages2021 Book TheInnovationRevolutionInAgricLeonardo RamirezPas encore d'évaluation

- Concept Note - 2023conferenceDocument4 pagesConcept Note - 2023conferencedheeraj12bhuPas encore d'évaluation

- Ice - CreamDocument72 pagesIce - CreamAshish Sheth100% (1)

- Emerging Trends in AgricultureDocument3 pagesEmerging Trends in AgriculturePrasad GowdPas encore d'évaluation

- Chapter 9Document23 pagesChapter 9husnainPas encore d'évaluation

- Agricultural Systems: David J. Spielman, Adam KennedyDocument12 pagesAgricultural Systems: David J. Spielman, Adam KennedyMahesh PaudyalPas encore d'évaluation

- Agriculture Faculties - Strategies For Addressing The Crises June 2022Document21 pagesAgriculture Faculties - Strategies For Addressing The Crises June 2022Thavam RatnaPas encore d'évaluation

- AGRI RETAILING GROWTH IN INDIADocument11 pagesAGRI RETAILING GROWTH IN INDIAShivaPas encore d'évaluation

- Consumer Behaviour and Brand Preference of Ready-to-Eat Food ProductsDocument73 pagesConsumer Behaviour and Brand Preference of Ready-to-Eat Food ProductsApeksha100% (1)

- Chapter 12Document14 pagesChapter 12husnainPas encore d'évaluation

- Farm Management - With Information on the Business, Marketing and Economics of Running a FarmD'EverandFarm Management - With Information on the Business, Marketing and Economics of Running a FarmPas encore d'évaluation

- Agribusiness Management in Sustainable Agricultural EnterprisesD'EverandAgribusiness Management in Sustainable Agricultural EnterprisesPas encore d'évaluation

- Post-Harvest Loss Management : Reducing Food Waste in DistributionD'EverandPost-Harvest Loss Management : Reducing Food Waste in DistributionPas encore d'évaluation

- The Chicken Millionaire's Handbook: What It Takes To Earn A Good Fortune From Chicken FarmingD'EverandThe Chicken Millionaire's Handbook: What It Takes To Earn A Good Fortune From Chicken FarmingPas encore d'évaluation

- Taxi Industry Australia - Trends 2016Document2 pagesTaxi Industry Australia - Trends 2016m n gPas encore d'évaluation

- Columbia 2007 PDFDocument47 pagesColumbia 2007 PDFAjeje BrazorfPas encore d'évaluation

- Chocolate Cake - GF - VDocument1 pageChocolate Cake - GF - Vm n gPas encore d'évaluation

- No Butter Vegan Millet CookiesDocument1 pageNo Butter Vegan Millet Cookiesm n gPas encore d'évaluation

- Case Book 1 2016 82613245 82613245Document60 pagesCase Book 1 2016 82613245 82613245m n gPas encore d'évaluation

- Darden 2009 PDFDocument82 pagesDarden 2009 PDFm n gPas encore d'évaluation

- Vegan Semolina CakeDocument2 pagesVegan Semolina Cakem n gPas encore d'évaluation

- Case Prep 101 2016 82613325 82613325Document20 pagesCase Prep 101 2016 82613325 82613325m n gPas encore d'évaluation

- Carrot CakeDocument1 pageCarrot Cakem n gPas encore d'évaluation

- Case Interview Prep GuideDocument2 pagesCase Interview Prep GuideAmit AshishPas encore d'évaluation

- Consulting Club Interview GuideDocument105 pagesConsulting Club Interview GuideSamuel LeePas encore d'évaluation

- Case Prep 201 92144242 92144242Document24 pagesCase Prep 201 92144242 92144242m n gPas encore d'évaluation

- Dteten PE HedgefundsDocument81 pagesDteten PE Hedgefundsm n gPas encore d'évaluation

- Books To ReadDocument10 pagesBooks To Readm n gPas encore d'évaluation

- Buckwheat CAKE Gluten-FreeDocument2 pagesBuckwheat CAKE Gluten-Freem n gPas encore d'évaluation

- Swot Wolf Earthwolf MCDDocument12 pagesSwot Wolf Earthwolf MCDm n gPas encore d'évaluation

- GMAT NotesDocument5 pagesGMAT Notesm n gPas encore d'évaluation

- Austrian CheesecakeDocument1 pageAustrian Cheesecakem n gPas encore d'évaluation

- ChocolatepuddingDocument1 pageChocolatepuddingm n gPas encore d'évaluation

- Marketing & Enhancing Competitiveness: ReformsDocument16 pagesMarketing & Enhancing Competitiveness: Reformsm n gPas encore d'évaluation

- Advertising Summer08 StuDocument13 pagesAdvertising Summer08 Stum n gPas encore d'évaluation

- CFA StudyScheduleDocument5 pagesCFA StudySchedulem n gPas encore d'évaluation

- Financialaccounting Horngren SolutionsDocument2 pagesFinancialaccounting Horngren Solutionsm n gPas encore d'évaluation

- Indian Food Procession Industry Report 270608Document28 pagesIndian Food Procession Industry Report 270608workosaurPas encore d'évaluation

- Note On Leveraged Buyouts Case #5-0004Document23 pagesNote On Leveraged Buyouts Case #5-0004vikhyatraiPas encore d'évaluation

- Mcdonalds US Vs ThailandDocument28 pagesMcdonalds US Vs Thailandpraveenbt17Pas encore d'évaluation

- KPMG RA - TelecomDocument50 pagesKPMG RA - Telecomm n g0% (1)

- Factors That Shape The Company's Strategy: (I) Internal Environment FactorsDocument6 pagesFactors That Shape The Company's Strategy: (I) Internal Environment Factorsmba departmentPas encore d'évaluation

- Union BankDocument7 pagesUnion BankChoice MyPas encore d'évaluation

- A Review of Journal/Article Title: Introducing The Hoshin Kanri Strategic Management System in Manufacturing Sme'SDocument2 pagesA Review of Journal/Article Title: Introducing The Hoshin Kanri Strategic Management System in Manufacturing Sme'SAlmas Pratama IndrastiPas encore d'évaluation

- Chanakya Neeti on ManagementDocument19 pagesChanakya Neeti on ManagementShivamPas encore d'évaluation

- Project Proposal: ESC472 - Electrical and Computer Capstone Design Division of Engineering ScienceDocument19 pagesProject Proposal: ESC472 - Electrical and Computer Capstone Design Division of Engineering Scienceapi-140137201Pas encore d'évaluation

- Capital Reduction MergedDocument33 pagesCapital Reduction MergedWhalienPas encore d'évaluation

- North America Equity ResearchDocument8 pagesNorth America Equity ResearchshamashmPas encore d'évaluation

- HP DeskJet Printer Supply Chain IssuesDocument26 pagesHP DeskJet Printer Supply Chain IssuesKaren VillafuertePas encore d'évaluation

- QSB InformationDocument4 pagesQSB InformationAtul KasarPas encore d'évaluation

- Purchase Order: Pt. Prastiwahyu Tunas EngineeringDocument1 pagePurchase Order: Pt. Prastiwahyu Tunas EngineeringBowoPas encore d'évaluation

- GreytHR - Features & ScreenshotsDocument22 pagesGreytHR - Features & ScreenshotsVishal DavePas encore d'évaluation

- Fractions Decimals and Percentages Word ProblemsDocument4 pagesFractions Decimals and Percentages Word ProblemsMary Jane V. RamonesPas encore d'évaluation

- Review MODULE - MATHEMATICS (Algebra-Worded Problems) : Number Problems Age ProblemDocument1 pageReview MODULE - MATHEMATICS (Algebra-Worded Problems) : Number Problems Age ProblemYeddaMIlaganPas encore d'évaluation

- Aarthi Mba Project FinalDocument20 pagesAarthi Mba Project FinalBnaren NarenPas encore d'évaluation

- Alk2-Brief Bible History - MachenDocument80 pagesAlk2-Brief Bible History - Machenanthonius70Pas encore d'évaluation

- Service Catalog Template DocDocument3 pagesService Catalog Template DocBabul BhattPas encore d'évaluation

- Norkis Distributors v. CA (CD-Asia)Document4 pagesNorkis Distributors v. CA (CD-Asia)Pia GPas encore d'évaluation

- Presentacion Evolucion Excelencia Operacional - Paul Brackett - ABBDocument40 pagesPresentacion Evolucion Excelencia Operacional - Paul Brackett - ABBHERMAN JR.Pas encore d'évaluation

- You Exec - Sales Process FreeDocument13 pagesYou Exec - Sales Process FreeMariana Dominguez AlvesPas encore d'évaluation

- Alkhabeer ANNUAL REPORT 2018 EnglishDocument62 pagesAlkhabeer ANNUAL REPORT 2018 EnglishedgarmerchanPas encore d'évaluation

- Hotels 2020 - Responding To Tomorrow's Customer and The Evolution of TechnologyDocument12 pagesHotels 2020 - Responding To Tomorrow's Customer and The Evolution of TechnologyHetalMehtaPas encore d'évaluation

- Sample Resume - SAP ABAPDocument12 pagesSample Resume - SAP ABAPnehra72Pas encore d'évaluation

- Starting Small Family BusinessDocument4 pagesStarting Small Family BusinessMJ BenedictoPas encore d'évaluation

- Customer Service ExcellenceDocument19 pagesCustomer Service ExcellenceAnh ThưPas encore d'évaluation

- Centum Rakon India CSR Report FY 2020-21Document14 pagesCentum Rakon India CSR Report FY 2020-21Prashant YadavPas encore d'évaluation

- AIP WFP 2019 Final Drps RegularDocument113 pagesAIP WFP 2019 Final Drps RegularJervilhanahtherese Canonigo Alferez-NamitPas encore d'évaluation

- Crs Report For Congress: Worldcom: The Accounting ScandalDocument6 pagesCrs Report For Congress: Worldcom: The Accounting ScandalMarc Eric RedondoPas encore d'évaluation

- Cheyne Capital ManagementDocument2 pagesCheyne Capital ManagementCheyne CapitalPas encore d'évaluation

- JollibeeDocument5 pagesJollibeeDaphane Kate AureadaPas encore d'évaluation