Académique Documents

Professionnel Documents

Culture Documents

Codigos de Falla AC EXCABADORAS

Transféré par

Abdul Zapata EscobarCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Codigos de Falla AC EXCABADORAS

Transféré par

Abdul Zapata EscobarDroits d'auteur :

Formats disponibles

365C L Excavator ELC00001-UP (MACHINE) POWERED BY C-15 Engine(SEBP42...

Pgina 1 de 6

Cerrar SIS

Pantalla anterior

Producto: EXCAVATOR

Modelo: 365C EXCAVATOR ELC

Configuracin: 365C L Excavator ELC00001-UP (MACHINE) POWERED BY C-15 Engine

Pruebas y Ajustes

345C, 365C and 385C Excavators Air Conditioning and Heating

Nmero de medio -RENR7328-08

Fecha de publicacin -01/07/2009

Fecha de actualizacin -01/07/2009

i02250510

Air Conditioning System Troubleshooting

SMCS - 7320

Troubleshooting the System with the Manifold Gauge Set

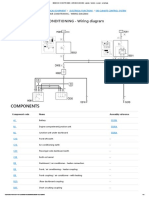

Illustration 1

g00862735

(1) Power switch

(2) Automatic temperature control switch

(3) Air conditioning override switch

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb... 27/02/2013

365C L Excavator ELC00001-UP (MACHINE) POWERED BY C-15 Engine(SEBP42... Pgina 2 de 6

(4) Temperature select switches

(5) Preset temperature display

(6) Fan speed switches

(7) Air outlet select switch

(8) Air inlet select switch

(9) Control panel

(10) Switch for defroster

The following conditions must exist in order to perform the checking procedures:

Engine ... Normal operating temperature

Door ... Open

Air inlet select switch (8) ... Recirculation

Temperature of air at inlet ... 30 to 35C (86 to 95F)

Fan speed switch (6) ... HI

Engine rpm ... 1500 rpm

Temperature select switch (4) ... MAX COOL

The following readings are correct under normal operating conditions.

Illustration 2

g00475933

(L) Low pressure side 0.15 to 0.25 MPa (22 to 36 psi)

(H) High pressure side 1.37 to 1.57 MPa (200 to 230 psi)

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb... 27/02/2013

365C L Excavator ELC00001-UP (MACHINE) POWERED BY C-15 Engine(SEBP42... Pgina 3 de 6

Problem

The system has an insufficient amount of refrigerant charge.

Symptoms

Pressure is low on the low side and the high side.

Bubbles continuously appear in the sight glass.

The cooling effect is poor.

Cause

A refrigerant leak exists. This leak causes the amount of refrigerant charge to be low.

Corrective Measures

1. Isolate the leak and repair the refrigerant leak.

2. Recharge the air conditioning system. Refer to the Testing and Adjusting, "Refrigerant System Charge" section for the proper procedure.

Problem

The system is overcharged with refrigerant. This causes poor cooling by the condenser.

Symptoms

Pressure is high on the low side and the high side.

Bubbles do not appear in the sight glass even when the system is operated slowly.

The cooling effect is poor.

Cause

The system is overcharged with refrigerant and the condenser is not cooling well.

Corrective Measures

1. Recover the refrigerant until the level is correct. Refer to the Specifications, "System Capacities

for Refrigerant" section for the proper amount of charge.

2. Clean the condenser.

3. Check the engine cooling fan.

Problem

Moisture is present in the refrigerant circuit.

Symptom

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb... 27/02/2013

365C L Excavator ELC00001-UP (MACHINE) POWERED BY C-15 Engine(SEBP42... Pgina 4 de 6

After a few minutes of use, the low pressure side gradually indicates negative pressure.

Cause

Moisture has entered the refrigerant circuit.

Corrective Measures

1. Replace the receiver-dryer. Refer to the Operation and Maintenance Manual, "Refrigerant

Receiver-Dryer - Replace" section for the proper procedure.

2. Evacuate the system. Refer to the Testing and Adjusting, "Refrigerant System - Evacuate"

section for the proper procedure.

3. Charge the system. Refer to the Testing and Adjusting, "Refrigerant System - Charge" section

for the proper procedure.

Problem

The compressor is supplying insufficient compression.

Symptoms

The manifold gauge set shows excessive high pressure on the low side.

The high pressure side measures pressure that is too low.

Pressure equalizes when the compressor is turned OFF.

Cause

The compressor is failing.

Corrective Measure

Check and repair the compressor.

Problem

The refrigerant does not circulate properly.

Symptoms

Negative pressure is indicated immediately on the low side when the system is completely

clogged.

Negative pressure is indicated gradually on the low side when the system is sometimes clogged.

Air temperature is different before clogging and after clogging.

Cause

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb... 27/02/2013

365C L Excavator ELC00001-UP (MACHINE) POWERED BY C-15 Engine(SEBP42... Pgina 5 de 6

Debris collects around the small holes of the expansion valve. It is also possible that moisture is

freezing around the expansion valve.

Corrective Measures

1. Replace the receiver-dryer. Refer to the Operation and Maintenance Manual, "Refrigerant

Receiver-Dryer - Replace" section for the proper procedure.

2. Evacuate the system. Refer to the Testing and Adjusting, "Refrigerant System - Evacuate"

section for the proper procedure.

Problem

Air is present in the refrigerant circuit.

Symptoms

Pressure is high on both sides of the manifold gauge set.

The low pressure lines are not cold.

Bubbles appear at the sight glass.

Cause

The refrigerant circuit contains air.

Corrective Measures

1. Recover the refrigerant. Refer to the Testing and Adjusting, "Refrigerant Recovery" section for

the proper procedure.

2. Evacuate the system. Refer to the Testing and Adjusting, "Refrigerant System - Evacuate"

section for the proper procedure.

3. Charge the system. Refer to the Testing and Adjusting, "Refrigerant System - Charge" section

for the proper procedure.

Problem

The expansion valve is not opening properly.

Symptoms

Pressure is high on both sides of the manifold gauge set.

The low pressure lines are frosting.

Cause

The expansion valve is malfunctioning.

Corrective Measure

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb... 27/02/2013

365C L Excavator ELC00001-UP (MACHINE) POWERED BY C-15 Engine(SEBP42... Pgina 6 de 6

Make sure that the thermal tube is installed correctly.

Troubleshooting Abnormal Noises

Table 1

Troubleshooting Abnormal Noises

Component

Possible Cause

V-Belt

Tension is low. The belt is loose.

The bearing is worn or the bearing is damaged.

Magnetic clutch

Contact exists between the stator and the rotor.

Incorrect installation

Idle pulley

The bearings are worn or the bearings are damaged.

Foreign material is obstructing proper movement.

Blower motor

The blower is loose.

A mounting bolt is loose.

Valves are bad.

Compressor

The bearing is worn or the bearing is damaged.

Misalignment

Mounting clamps are loose or installed incorrectly.

Refrigerant lines

Incorrect gap for safety

Copyright 1993 - 2013 Caterpillar Inc.

Wed Feb 27 16:57:44 EST 2013

Todos los derechos reservados.

Red privada para licenciados del SIS.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb... 27/02/2013

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Parts Manual Hydraulic Breaker: Document No.: AA099-0012 Revision Date: 2010-06-25Document28 pagesParts Manual Hydraulic Breaker: Document No.: AA099-0012 Revision Date: 2010-06-25Abdul Zapata EscobarPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Manual Parts 966H - Vol 1 PDFDocument738 pagesManual Parts 966H - Vol 1 PDFvalentineusebio86% (29)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Martillo hb3600 Atlas CopcoDocument44 pagesMartillo hb3600 Atlas CopcoAbdul Zapata Escobar100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Manual de Partes Vibrocompatador Ingersold Rand SD100 PDFDocument358 pagesManual de Partes Vibrocompatador Ingersold Rand SD100 PDFAbdul Zapata Escobar100% (9)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Manual de Partes TL642 PDFDocument402 pagesManual de Partes TL642 PDFAbdul Zapata EscobarPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- CAT Service Manuals TL642 TL943Document197 pagesCAT Service Manuals TL642 TL943Shivanan Singh100% (7)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Partes Compresor Sullair 550rh, 600hh, 700hh, 750hDocument104 pagesPartes Compresor Sullair 550rh, 600hh, 700hh, 750hAbdul Zapata Escobar67% (3)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Parts Manual Hydraulic Breaker: Document No.: AA099-0012 Revision Date: 2010-06-25Document28 pagesParts Manual Hydraulic Breaker: Document No.: AA099-0012 Revision Date: 2010-06-25Abdul Zapata EscobarPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Rodamientos TimkenDocument44 pagesRodamientos TimkenAbdul Zapata EscobarPas encore d'évaluation

- Ingersoll Rand AC185D Operators ManualDocument70 pagesIngersoll Rand AC185D Operators ManualYuswintoroPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Operacion y Partes Compresores SullairDocument67 pagesOperacion y Partes Compresores SullairAbdul Zapata EscobarPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Ingersolrand Portable Diesel Compressor PartsDocument163 pagesIngersolrand Portable Diesel Compressor PartsTeo Deustch100% (6)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Parts Manual Hydraulic Breaker: Document No.: AA099-0012 Revision Date: 2010-06-25Document28 pagesParts Manual Hydraulic Breaker: Document No.: AA099-0012 Revision Date: 2010-06-25Abdul Zapata EscobarPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- AA099-0006 Parts EHB20 100625Document26 pagesAA099-0006 Parts EHB20 100625Abdul Zapata EscobarPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Catalogo de Peças EHB40Document26 pagesCatalogo de Peças EHB40andré GuilhermePas encore d'évaluation

- Correas Cat..EquivalenciasDocument8 pagesCorreas Cat..EquivalenciasAbdul Zapata Escobar100% (6)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Correas Cat..EquivalenciasDocument8 pagesCorreas Cat..EquivalenciasAbdul Zapata Escobar100% (6)

- Excavadora 336DL CAT Manual de Partes PDFDocument1 179 pagesExcavadora 336DL CAT Manual de Partes PDFJuan Paco100% (7)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Heat Pumps With Puron® Refrigerant Single Speed, Two-Speed: User'S Information ManualDocument8 pagesHeat Pumps With Puron® Refrigerant Single Speed, Two-Speed: User'S Information ManualJulie SavoiePas encore d'évaluation

- Field Installed UPM Rev3-RelDocument28 pagesField Installed UPM Rev3-RelMichaelRotnitskyPas encore d'évaluation

- Conservation Energy OpportunitiesDocument23 pagesConservation Energy OpportunitiesGeorgette RepuntePas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- CS-C24BKP Cu-C24bkp5Document79 pagesCS-C24BKP Cu-C24bkp5Dũng LêPas encore d'évaluation

- Course Description: Module Title: Course CDCS: Certified Data Centre Specialist Duration: 3 DaysDocument5 pagesCourse Description: Module Title: Course CDCS: Certified Data Centre Specialist Duration: 3 DaysRoberto CarrascoPas encore d'évaluation

- Toshiba Wac+05k 12k User+Manual 2021+ (Ing Esp Preview07) + +Bt+ModuleDocument64 pagesToshiba Wac+05k 12k User+Manual 2021+ (Ing Esp Preview07) + +Bt+ModuleJorgePas encore d'évaluation

- Performance Characteristics of An Air-Cooled Condenser Under Ambient ConditionsDocument6 pagesPerformance Characteristics of An Air-Cooled Condenser Under Ambient Conditionstarun_aseriPas encore d'évaluation

- FreewattDocument40 pagesFreewattTMOSteelPas encore d'évaluation

- Saes K 101Document4 pagesSaes K 101mika cabello100% (1)

- Solar Dwelling Design ConceptsDocument145 pagesSolar Dwelling Design ConceptsMoreMoseySpeed100% (3)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Final Final Year Project ReportDocument53 pagesFinal Final Year Project Reportsehaj02843% (7)

- Dryers: Dry Air Dryers For Plastic ResinDocument16 pagesDryers: Dry Air Dryers For Plastic ResinSaravanavel CPas encore d'évaluation

- Hpac - 201301Document69 pagesHpac - 201301Antonio LebrunPas encore d'évaluation

- J293-A4 Fancontrol ModuleDocument1 pageJ293-A4 Fancontrol ModuleYadi Vhoobe100% (1)

- G Tower ReportDocument22 pagesG Tower ReportElaine Bong50% (2)

- Compendium 2005 Ee PS PDFDocument175 pagesCompendium 2005 Ee PS PDFSuryakant KumarPas encore d'évaluation

- E6020 Air Conditioning - Wiring Diagram - Lancia - Ypsilon - Elearn - 4cardataDocument2 pagesE6020 Air Conditioning - Wiring Diagram - Lancia - Ypsilon - Elearn - 4cardataAnonymous TqVS8FdPas encore d'évaluation

- Nissan Y61 - Heater and Air ConditionerDocument128 pagesNissan Y61 - Heater and Air ConditionerblumngPas encore d'évaluation

- Env107l Lab Report 02Document7 pagesEnv107l Lab Report 02SunjiyaPas encore d'évaluation

- PAC12L ManualDocument22 pagesPAC12L ManualThameePas encore d'évaluation

- Catalogue RAC Mitsubishi ElectricDocument10 pagesCatalogue RAC Mitsubishi ElectricYizhar Bechamel MestokoPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Vapor Cycle Air Conditioning System TR-134 SMDocument33 pagesVapor Cycle Air Conditioning System TR-134 SMDavid BondPas encore d'évaluation

- Ebook 1 Humidity TheoryDocument28 pagesEbook 1 Humidity Theoryangel plazolaPas encore d'évaluation

- Manual ENG Coolius A30 22102-V20177rev03.bDocument38 pagesManual ENG Coolius A30 22102-V20177rev03.bThabo NgidiPas encore d'évaluation

- Ed. - Michael Kauffeld .... - Handbook On Ice Slurries - Fundamentals and Engineering PDFDocument364 pagesEd. - Michael Kauffeld .... - Handbook On Ice Slurries - Fundamentals and Engineering PDFBhawandeep Sharma100% (1)

- Pub HandbookDocument40 pagesPub HandbookZaw Moe KhinePas encore d'évaluation

- Ab 12Document199 pagesAb 12PauloPas encore d'évaluation

- Ae 2420ZK 301 A0Document1 pageAe 2420ZK 301 A0Adam NabawiPas encore d'évaluation

- LCMCDocument80 pagesLCMCYanilda SolorzanoPas encore d'évaluation

- JCB - 9831-3150-4-OM-EN-previewDocument21 pagesJCB - 9831-3150-4-OM-EN-previewxaheha5170Pas encore d'évaluation

- Practical Reservoir Engineering and CharacterizationD'EverandPractical Reservoir Engineering and CharacterizationÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Well Integrity for Workovers and RecompletionsD'EverandWell Integrity for Workovers and RecompletionsÉvaluation : 5 sur 5 étoiles5/5 (3)