Académique Documents

Professionnel Documents

Culture Documents

92

Transféré par

adamzlametCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

92

Transféré par

adamzlametDroits d'auteur :

Formats disponibles

FAILURE ANALYSIS OF HIGH-PERFORMANCE SURFACES USED FOR TRANSVERSAL STABILITY

OF SHIPS (BILGE KEELS)

1, a

Hugo Rodrigues, 1, b, 3 Rui F. Martins, 2, c L. Leal das Neves, 2, d Paulo Silva

1

Faculdade de Cincias e Tecnologia, Universidade Nova de Lisboa

UNIDEMI, Departamento de Engenharia Mecnica e Industrial

Campus de Caparica, 2829-516 Caparica, Portugal

Email:a hugo_rodrigues@live.com.pt, b rfspm@fct.unl.pt

2

Portuguese Navy, Directorate of Ships, Studies Department

Naval Base of Lisbon, 2800-001 Alfeite, Portugal

Email: c leal.neves@marinha.pt , d pires.silva@marinha.pt

ICEMS/IST, Av. Rovisco Pais, 1, 1049-001 Lisbon - Portugal

ABSTRACT

During a scheduled maintenance program of a ship, several cracks were detected in the internal structure of bilge keels,

as well as on the connection of these to the hull. The cracks encountered compromised the watertight integrity of the

hull and, in the long run, could jeopardize its integrity.

This paper presents a failure analysis of the structural damages detected, in order to identify the causes of failure and

propose improvements that could avoid them. Several stress concentration areas were identified, which coincided with

the critical areas where there have been found the structural failures. It was confirmed the reinforcements (stiffeners)

influence in the increased levels of stress in the welded joints of the bilge keels to the hull.

Alternative design geometries for the bilge keel internal structure are presented as well as it is shown that the

application of brackets or a bulb flat on the connection of the bilge keels to the hull can reduce the high level of tensile

stresses that are induced in the structure.

The fatigue analysis according to the Germanischer Lloyd Classification Society is applied to the new structural

internal geometry and is presented on this paper.

KEY WORDS: Bilge Keels, Structural Failures, Failure Analysis, Improved Design Arrangement, Finite Element

Analysis.

1. INTRODUCTION

The hydrodynamic resistance of a ship to roll motion

can be increased through passive and/or active

stabilizers. Encased in the passive roll stabilizers are the

bilge keels under study, which, in addition to attenuate

the roll motion, present a low manufacturing cost,

compared with the cost associated with the manufacture

of active stability systems.

condition, possesses good weldability and low harden

effect after welding, due to the low probability of

martensitic transformation during cooling [2].

In essence, bilge keels are hull appendices, applied

approximately at half length of the ship, on both sides

of the hull, which transform the vessels motion kinetic

energy into fluid motion, especially under the form of

vortex shedding [1]. Their efficiency depends on their

location, size and shape [1]. The bilge keels studied and

presented in this article have a triangular, or V,

arrangement as shown in Figure 1.

The bilge keel in study is built in D36 steel,

characterized by the chemical composition and

mechanical properties referred in Table 1 and 2 [2],

respectively. The steel, furnished in the normalized

Figure 1. Cross section view of the bilge keel with a

V arrangement studied. Examples of cracks detected.

.Table 1. Chemical composition of D36 naval steel

grade type [2].

C [%]

Si[%]

Mn [%]

P [%]

S [%]

Al [%]

0.18

0.5

0.7

0.035

0.035

0.02

Table 2. Mechanical Properties of D36 naval steel

grade type used in the bilge keels manufacture [2].

Yield Strength

[MPa]

Tensile Strength

[MPa]

Elongation [%]

355

490-620

21

The connection to the hull is performed through a

doubler plate (Figure 2), where a full welding

penetration without any intermittent fillet welds is

imposed. The doubler plate connection to the hull is

often encountered in marine structures, not only due to

its easiness in production, because it provides a faster

and easier way to perform the alignment of the bilge

keel over the hull structure, but also represents an

excellent configuration to avoid multi-axial stress states

at the connection to the hull [1].

watertightness and the separation of the welded

connection/joint between the two plates that define the

external surface used for the transversal stability of

ships (Fig.1).

2.4. Structural Failures Location

Both the cracks in the bilge keel internal reinforcements

and the cracks at the plating edge occurred along the

entire length of the bilge keel.

The remaining cracks (Figure 3, points marked) were

located in the middle plane of the internal

reinforcements of the hull (bulkheads /frames) and, in

some cases, also in the alignment with the middle plane

of the bilge keel internal reinforcements (Figure 3).

Figure 3. External overview of the bilge keel. Recorded

location of cracks (marked points).

3. DESIGN LOAD, PBK

Figure 2. Doubler connection detail of the bilge keel to

the hull.

In case of an accident or catastrophic failure, the bilge

keel will partly, or entirely, detach from the ship's hull

structure without causing structural damages that could

compromise the hull plating water tightness.

While one can often adequately predict heave, pitch,

sway, yaw and even surge, roll motions of a ship are

still remarkably difficult to predict, since roll is the

motion that is very dependent upon viscous effects of

the fluid on the surfaces used for transversal stability of

a ship [3]. Nevertheless, design principles from the

Germanischer Lloyd Classification Society were used

[4], in order to determine the maximum load applied on

the bilge keels, PBK (fig.4) (1)

2. FAILURE REGISTER

2.1. Cracks in the Bilge Keel Connection to Hull

Several cracks were detected by visual and dye

penetrant inspection up to 150mm long, mainly in the

welded connection between the bilge keel plating and

the doubler plate (Fig.1), but also in much smaller

number and size, on the doubler connection to the

ships hull plating.

2.2. Fractures in the Internal Structure of Bilge Keel

After a close inspection at the internal structure of the

bilge keel, multiple fractures, originated from fatigue

cracks, were recorded. These occurred at the

intersection between the longitudinal and transverse

reinforcements of the bilge keels, leading to the

complete separation of the link between them (Fig.1).

2.3. Fractures in the Bilge Keels Plating Edge

At the bilge keels plating edge multiple fractures were

recorded, resulting in the loss of the bilge keel

.

Figure 4. Design load, uniformly distributed across the

bilge keel span.

Equation 1 is valid for ships with a length L between

50m and 200 m, measured in the corresponding

waterline and for bilge keels located between 0.4L and

0.6L.

PBK =

52000 d

(L + 240 )1.1

fdyn kN / m 2

(1)

Where, d, represents the density fluid value, involving

the bilge keels (of 1.025, for saltwater at 25C), L the

distance measured from bow to stern, on the waterline

(109m, for the case in study), and

fdyn the

partial

safety factor representative of permanent and cyclic

loads acting on the undamaged structure in normal

operational conditions (considered a value of 2).

Accordingly, a design load ( PBK ) of approximately

170kPa, was calculated.

When submitted to an uniaxial tensile test, some

mechanical properties of the D36 steel used in the bilge

keel construction (Table 1 and 2) are characterised by

its true StressStrain curve, as shown in Figure 7 [5].

The calculated coefficient and exponent of the

Ramberg-Osgood Law, K and n, were 879.2 MPa and

0.1634, respectively, and the stress-strain curve was

considered in the definition of the FE material model.

Since the waterline length of the ship, where the bilge

keels under study are installed, is 109m, the domain of

validity for the design load is satisfied; regarding the

second parameter on the range of validity of the

equation, between 0.4L and 0.6L, the design load is

only valid for approximately 70% of the length of the

bilge keels under study, as shown in Figure 5. Although

the region where the application of the design load is

valid does not include the entire length of the bilge keel,

it covers some of the registered structural failures (Fig.

5), not invalidating the calculated value of the design

load and its implementation in subsequent studies.

Figure 7. True Stress-Strain curve for the D36 naval

steel [5].

Figure 5. Valid domain for the design load, overlapped

with the location of the recorded cracks.

The regions identified as hot spots were numbered

(Figure 8), having been registered their corresponding

Von Mises stress values (Table 3).

4. BILGE KEEL GEOMETRY MODELING AND

ANALYSIS BY FINITE ELEMENT METHOD

(FEM)

4.1. Nonlinear FEM Analysis of a Bilge Keel Section

A bilge keel section with 200 mm long was modeled, in

order to perform an analysis of the induced stress and

deflection on the structure due to the design load. The

model shown in Figure 6 includes the internal structural

arrangement of the bilge keel and a hull section of

400x500mm length with a 3m curvature radius.

The three-dimensional model was uniformly loaded

with 170kPa in the upper face of the bilge keel plating,

corresponding to the design load (PBK). The edges of the

hull were fixed, in order to simulate the boundary

conditions present in the real structure (Figure 6).

Figure 8. Bilge keel hot spots location.

Table 3. Maximum Von Mises stress values located in

the hot spots for the nonlinear Finite Element Analysis

(FEA) performed.

Total of

Nodes

Total of

elements

50680

24702

Hot

Hot

Hot

Hot

Hot

Spot 1 Spot 2 Spot 3 Spot 4 Spot 5

229

MPa

317

MPa

336

MPa

364

MPa

359

MPa

The data presented in Table 3 shows high levels of

stress concentration located in the hot spots, inducing

local plastic deformations, but also yield strength safety

factors close to one, which leads to the nucleation and

propagation of low-cyclic fatigue cracks.

Figure 6. Three-dimensional model of the bilge keel

section modeled, which includes the internal structural

arrangement, the finite element mesh, the design load

and the boundary conditions.

With reference to the yield strength value of the

structural steel in which the bilge keel is made of

(355MPa), the hot spots numbers 4 and 5 entered the

plastic regime, concurring with the location of the

register structural failures (Figure 1).

4.2. Study of the Influence of the Hull Reinforcements

Alignment with the Internal Structure of the Bilge Keel

Having been identified as hot spot 1, the stress

concentration at the bilge keel to the hull connection

(Figure 8), and having been detected a pattern in the

location of the structural failures, namely the

registration of cracks in the alignment of the hull

internal reinforcements, an analysis of the position

influence of the bulkhead/frames in the induced stress

values in the connection between the bilge keel and the

hull was carried out.

As shown in Figure 9, it was found that the presence of

the hulls internal reinforcements (bulkheads or frames)

resulted in an increase of the maximum stress value

present in the connection between the bilge keel and the

hull, since the maximum induced stress of 230 MPa

increased to approximately 260 MPa (+13%). In

addition, there was also a maximum stress concentration

in the region closest to the alignment of the

reinforcements.

details is the application of a steel bulb with 15mm in

diameter in the bilge keel plating edge (Figure 10).

Table 4. Alternative internal geometries

Reference

Geometry

nr: 1

Geometry

nr: 2

Geometry

nr: 3

Geometry

nr: 4

Geometry

nr: 5

Figure 9. Influence of the alignment between the bilge

keel and the hull transversal reinforcement.

5. ALTERNATIVE GEOMETRIES

Taking into account the results from the FEM analyses,

new geometries were designed and analysed in order to

propose a viable substitute for the bilge keel internal

structure and its connection to the hull.

Geometry

nr: 6

Description

Illustration

Model containing only

one solid and continuous

transversal stiffener.

Model containing one

transversal and

longitudinal stiffener,

with smooth cuts in the

intersection between

them.

Model containing only

one transversal stiffener

with two sections, with

soft cut contours.

Model containing one

transversal and

longitudinal stiffener,

with smooth cuts in the

intersection between

them and with two

sections with soft cut

contours

Model containing only

one transversal stiffener,

with multiple circular

cuts sections and stress

concentration reliever

holes.

Model containing one

transversal and

longitudinal stiffener,

with smooth cuts in the

intersection between

them, and with multiple

circular cuts sections

and stress concentration

relievers holes.

Detail A

5.1. New Internal Bilge Keel Geometry

With the objective of maintaining unchanged, as much

as possible, the hydrodynamic characteristics of the

bilge keel, in particular those related to its energy

dissipation and drag coefficient, only the internal

geometry of the bilge keel was redesigned, maintaining

the thicknesses of the components, so that the rigidity of

the structure was kept unchanged. The new developed

internal geometries are shown in Table 4.

Several details were included in the new internal

arrangements in order to minimize the stress

concentrations (Figure 9) and, concomitantly, facilitate

its production. An example representative of these

Figure 10. Stress concentration relievers.

All the tridimensional models of the new bilge keel

internal arrangements were uniformly loaded with

170kPa, corresponding to the design load. Also the

same boundary conditions as shown in Fig.6 were

applied, in order to compare the results with those

obtained for the current model.

Table 5 presents a summary of the results obtained from

the FEA, pointing out the main features of the new

geometries regarding the maximum Von Mises stresses

induced in the structure, the number of existing hot

spots, the maximum deflection value obtained and the

mass of the new bilge keels internal geometries

developed.

the bilge keel connection (Figure 11b). A twodimensional FEA was performed simulating the doubler

plate discontinuity and the presence of the brackets

(Figure 12) or the bulb flat. Accordingly with Figure 12

and with the data presented in Table 6, both proposed

solutions could be considered to reduce the stresses

induced in the doubler plate connection to the ships

hull, ensuring the water tightness of the hull.

Table 5. Results obtained from the FEA of the new

internal bilge keel geometries.

Mass Nr.of hot

(kg)

spots

Maximum

Deflection

(mm)

Von Mises

Stress

(MPa)

3.8

364 MPa

Current Geometry

41,34

Geometry 1

39,44

249 MPa

Geometry 2

40,90

255 MPa

Geometry 3

37,77

246 MPa

3.3

Geometry 4

39,27

260 MPa

Geometry 5

37,84

230 MPa

Geometry 6

39,33

248 MPa

The analysis showed a significant reduction in the stress

level (a minimum reduction of 28% and a maximum

reduction of 37%). Of all the analysed geometries,

geometry number 5 presents the best alternative to the

existing geometry, because its definitely the geometry

that showed the lowest level of maximum induced

stress, 230MPa, together with the smallest number of

hot spots and a lower mass. Notwithstanding,

alternative geometries which include longitudinal

reinforcements, namely geometries number 6, 2 and 4

(Table 4), in this order, should be considered in case

bilge keel longitudinal strength needs to be enhanced.

These solutions also revealed a lower maximum

induced stress than the current geometry (Table 5).

5.2. Improved Design to Reduce the Stress in the Bilge

Keel Connection to the Hull

Having been registered several cracks in the bilge keel

connection to the hull, two alternative solutions have

been designed, so as to reduce the maximum induced

stress value to the connections under study (Figure 11),

in order to eliminate the structural failures found.

Figure 12. Two-dimensional FEA of the bilge keel

connection to the brackets

Table 6. Stresses present in the bilge keel upper plating,

with the implementation of brackets and bulb flat.

Stress in

Point 3

[MPa]

Stress in

Point 4

[MPa]

149

29

50,6

154

4,8

3,9

134

29,7

27,3

Stress in

Point 1

[MPa]

Stress in

Point 2

[MPa]

Current model

157

Application of brackets

155

Application of bulb plate

122

6. FATIGUE ANALYSIS

A fatigue strength assessment of the redesigned doubler

plate connection to the ships hull (Figure 13) has been

made assuming the inexistence of the doubler plate and

in accordance with the fatigue design curves included in

Germanischer Lloyd Rules [4], which state that for

structures submitted to cyclic loads resulting from

waves or engines [4] and for infinite life, eq.2 must be

fulfilled.

(2)

Rc f n fa Fdyn

where Rc is the corrected fatigue strength reference

value, fn is the correction factor considering the

allowable number of load cycles and the type of

spectrum applied and (fa.Fdyn) is the stress range due

to the dynamic loads applied in the assessed structure.

a)

b)

Figure 11. Cross section view of the bilge keel

connection to the hull with

a) brackets. b) bulb flat

The proposed solutions consisted in the application of

brackets inside the hull (Figure 11a), or a bulb flat along

Figure 13. Simplification of bilge keel to the hull

connection with internal stiffeners (bulb flat).

The S-N curves (Figure 14) for the welded detail

represented in Figure 13, relative to two standard

classes of Spectra A and B [4], were corrected through

the application of a factor, fn, [4], where Spectrum A

represents the denominated straight-line spectrum,

which is a typical stress range spectrum of seawayinduced stress ranges [4] and Spectrum B represents a

parabolic spectrum, which represents a Normal function

density of probability type of stress range. The fatigue

curves presented in Figure 14 are representative of the

fatigue resistance of medium/high strength structural

steels used in shipbuilding [4].

stress level induced by the presence of the bilge keel

transversal reinforcement only.

Once known the maximum stress value present at the

cruciform joint (155 MPa, Table 6) it was assumed a

local stress of 170 MPa (Figure 14) due to the weld toe

stress concentration factor (Figure 13) for the stress

variation present in structure due to dynamic loads,

(fa.Fdyn). The fatigue life prediction can be observed in

Figure 14. For the spectra B or A, which reflect the

service conditions of the ship, the estimated lifetime is

approximately 16 years and infinite lifetime,

respectively. The cycle conversion was carried out once

known that 5x107 fatigue life cycles in a class A

spectrum, is equivalent to a lifetime of 25 years with

230 days per year of service at sea [4].

In order to propose a new solution capable of

preventing the structural failures identified in the

internal bilge keel structure, six alternatives geometries

to the internal structure of bilge keel were designed and

analysed, maintaining unchanged the hydrodynamic

characteristics of the bilge keel. The best solution found

(geometry nr.5, Table 4) contains 3 hot spots regions

and a maximum Von Mises stress of 230MPa,

corresponding to a reduction of 37% in the stress

induced levels when compared to the current geometry.

Notwithstanding alternative geometries which include

longitudinal reinforcements, namely geometries number

6, 2 and 4 (Table 4), in this order, should be considered

in case bilge keel longitudinal strength needs to be

enhanced. These solutions also revealed a lower

maximum induced stress than the current geometry

(Table 5).

A 2D FEA performed to the doubler plate and the bilge

keel, and between the doubler plate and the hull allowed

to determine the maximum Von Mises stress present in

the welded joint due to the stress concentration

introduced by the welded detail, fact which is in

accordance with the failure observed. The application of

brackets or a bulb flat allowed to reduce the maximum

stress induced to 155MPa between the doubler plate and

the bilge keel.

Finally, a fatigue life assessment analysis to the bilge

keel welded connection to the hull resulted in an infinite

lifetime for a Spectrum A type. Adopting a more

conservative approach, the fatigue lifetime for a class B

spectrum estimated a fatigue lifetime of 16 years.

REFERENCES

Figure 14. Fatigue life prediction for spectra A and B

7. CONCLUSIONS

This paper refers to an analysis performed to the

structural failures found in bilge keels, with the

objective of presenting structural solutions to solve

them.

It was confirmed, through the analyses carried out by

FEM that the location of the internal failures in the bilge

keels coincides with high stress concentration regions.

It was verified the existence of stress levels close to the

material yield strength and, consequently, some areas

were identified where local plasticity can occur.

The alignment between the bilge keels internal

structure and the hull transversal reinforcements results

in an increased and more concentrated stress level along

the hull-bilge keel connection, when compared to the

[1] ON THE STRUCTURAL DESIGN OF BILGE

KEELS. Mateus, Antnio F. Hamburg, Germany :

2006. 25th International Conference on Offshore

Mechanics and Arctic Enginneering.

[2] Det Norske Veritas, Offshore Standard DNV-OSB101, Metallic Materials, April 2009.

[3] Grant, David James. Full Scale Investigation of

Bilge Keel Effectiveness at Forward Speed. April

28, 2008.

[4] Lloyd, Germanischer. Rules for Classification and

Construction, III Naval Ship Tecnology. :

Germanischer Lloyd, 2004.

[5] Zhang, Guihua. Development of Numerical

Approaches to Predict Ductile and Cleavage

Fracture of Structural Materials. University of

Akron, December 2007.

Vous aimerez peut-être aussi

- Absen Meeting ProjectDocument1 pageAbsen Meeting ProjectadamzlametPas encore d'évaluation

- Setting Up Webmail For Microsoft Outlook Express: Windows 2000/XpDocument3 pagesSetting Up Webmail For Microsoft Outlook Express: Windows 2000/XpadamzlametPas encore d'évaluation

- Weld SchedulesDocument7 pagesWeld SchedulesadamzlametPas encore d'évaluation

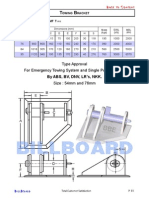

- Type Approval For Emergency Towing System and Single Point MooringDocument1 pageType Approval For Emergency Towing System and Single Point MooringadamzlametPas encore d'évaluation

- Rumus Crash StopDocument3 pagesRumus Crash StopadamzlametPas encore d'évaluation

- Callnames (Parte 1 de 4) - ByGOALDocument76 pagesCallnames (Parte 1 de 4) - ByGOALadamzlametPas encore d'évaluation

- Load Index ChartDocument2 pagesLoad Index ChartadamzlametPas encore d'évaluation

- Navigation Lamp Wiring: by James W. HebertDocument2 pagesNavigation Lamp Wiring: by James W. HebertadamzlametPas encore d'évaluation

- How To Uninstall NetCut Defender - Uninstall NetCut CompletelyDocument1 pageHow To Uninstall NetCut Defender - Uninstall NetCut CompletelyadamzlametPas encore d'évaluation

- Yanmar 6AYM WET Datasheet 3Document2 pagesYanmar 6AYM WET Datasheet 3adamzlamet33% (3)

- 074 The Helideck ManualDocument50 pages074 The Helideck Manualadamzlamet100% (2)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Ship Construction IonsDocument25 pagesShip Construction Ionsanon-49038083% (6)

- I. Hull Construction: This Section Will Cover The Following Main PointsDocument5 pagesI. Hull Construction: This Section Will Cover The Following Main Pointscaramara2462Pas encore d'évaluation

- (Vol A), 2015 Guidance For FRP and Wooden Fishing Vessel Up To 24 M, 2015Document139 pages(Vol A), 2015 Guidance For FRP and Wooden Fishing Vessel Up To 24 M, 2015Dandy Adrianto0% (1)

- FirebossDocument146 pagesFirebossMark Evan SalutinPas encore d'évaluation

- MARL022 Demonstrate Basic Knowledge of Ship Construction: Release: 1Document8 pagesMARL022 Demonstrate Basic Knowledge of Ship Construction: Release: 1mas_munir7174Pas encore d'évaluation

- ORC VPP Documentation 2011Document79 pagesORC VPP Documentation 2011Михаил ТихоновPas encore d'évaluation

- RES6-EnG Rules For Pleasure Yachts Part B 2018Document274 pagesRES6-EnG Rules For Pleasure Yachts Part B 2018Baris AkgülPas encore d'évaluation

- Bottom ConstructionDocument8 pagesBottom ConstructionarmanimamsPas encore d'évaluation

- First Mate of A FGDocument18 pagesFirst Mate of A FGSandipanBiswasPas encore d'évaluation

- BTM Basic ShiphandlingDocument24 pagesBTM Basic ShiphandlingMirza AKPas encore d'évaluation

- 14 KeelDocument5 pages14 KeelbswalimbePas encore d'évaluation

- 10 Structural Members of A ShipDocument5 pages10 Structural Members of A ShipJOSHUA DURADOPas encore d'évaluation

- Parts of The ShipDocument22 pagesParts of The ShipSherwin CabangPas encore d'évaluation

- Choosing HullDocument16 pagesChoosing Hullnyaungzin100% (1)

- Boat Operation Manual Issue 1 21022012Document184 pagesBoat Operation Manual Issue 1 21022012nick77maxPas encore d'évaluation

- 65M Construction Vessel SpecDocument98 pages65M Construction Vessel Specronny-su100% (1)

- Ship ConDocument7 pagesShip ConThusitha DalpathaduPas encore d'évaluation

- Sea Keeping of Motor YachtsDocument9 pagesSea Keeping of Motor YachtsManoj KumarPas encore d'évaluation

- Dynamic Behavior and Operational Limits of Stabiliser FinsDocument9 pagesDynamic Behavior and Operational Limits of Stabiliser FinsEd CallahanPas encore d'évaluation

- Open 5.70 Class RulesDocument9 pagesOpen 5.70 Class RulesOpen Sailing, IncPas encore d'évaluation

- Training in HSLDocument18 pagesTraining in HSLG Sri SoumyaPas encore d'évaluation

- Kf-Svnvsv-Mp-Spe-0009-000 A09 - Technical Specification For Jotun PaintsDocument46 pagesKf-Svnvsv-Mp-Spe-0009-000 A09 - Technical Specification For Jotun PaintsMehman NasibovPas encore d'évaluation

- Maritime DictionaryDocument192 pagesMaritime DictionarymetallourgosPas encore d'évaluation

- Fredyn PDFDocument2 pagesFredyn PDFSarath Babu SPas encore d'évaluation

- Ship StabilityDocument31 pagesShip Stabilitymsk5in75% (4)

- Final Scantling CalculationDocument15 pagesFinal Scantling CalculationAnonymous SiA1p78SUPas encore d'évaluation

- GSK Part 1 Oct 2010 - Compressed - PPT Auto Saved)Document88 pagesGSK Part 1 Oct 2010 - Compressed - PPT Auto Saved)Agbor Joseph100% (1)

- Study of Design Methodology of Sail Vessels: Slt. Dushyant Kumawat 43418 - ADocument30 pagesStudy of Design Methodology of Sail Vessels: Slt. Dushyant Kumawat 43418 - ADushyant KumawatPas encore d'évaluation

- SeakeepingDocument5 pagesSeakeepingPallavi YempadaPas encore d'évaluation

- Basic Ship Structure DefinitionsDocument23 pagesBasic Ship Structure Definitionsancamardelli100% (1)