Académique Documents

Professionnel Documents

Culture Documents

TOX Powerpackage-line-Q 10Q 201404 en

Transféré par

Purece EugenDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

TOX Powerpackage-line-Q 10Q 201404 en

Transféré par

Purece EugenDroits d'auteur :

Formats disponibles

TOX -Powerpackage line-Q

! The new preferred series !

Pneumatic press forces from 10300kN

ry time

e

v

i

l

e

d

Short

ricing

p

W

e

v

i

t

stroke

r

o

f

NE W Attrac

n

c pisto

i

t

E

e

n

g

a

N

W M itoring

E

ance

d

i

u

on

N

g

m

eal and

s

t

s

e

t

W La

ervals

t

y

n

g

i

E

o

l

e

c

o

n

N

techn

intena

a

m

d

W Extende

E

N

l i n e -

TOX-Powerpackage line-Q

The new preferred series

g

onitorin

troke m

s

r

o

y

f

log

on

echno

tic pist

ance t

Magne

id

u

W

g

d

ls

l an

NE

interva

est sea

nance

e

W Lat

t

in

a

E

m

N

ended

W Ext

E

N

Advantages of the TOX-Powerpackage line-Q:

The line-Q drives offer the known

advantages of the TOX-Powerpackage cylinders, which have proven their quality in applications all

over the world, with the additional

advantages of short delivery times

and even more attractive pricing.

+ We guarantee for 10 million

cycles within 12 months without

work-shift restrictions.

Proven TOX-Quality:

+Pure

+

pneumatic operation (no hydraulic unit required)

+Simple

+

controls same as for any

double acting pneumatic cylinder

+High

+

stroke frequencies

+High

+

resistance to wear due to few

moving parts

+Saves

+

tooling and reduces noise

levels due to low impact forces

during fast approach

+Defined

+

positive stop with damping

at bottom dead centre

+High

+

pressure connection is standard equipment (can be used for

sequential controls)

+Oil

+ level indicator (maintenance

friendly)

Advantages in detail:

The patented power bypass protects

the oil system from negative pressure,

which can be generated in applications such as punching, shearing,

etc. or high cycle speeds. The power

bypass is the basic requirement for

trouble-free operation of pneumo-hydraulic systems in such applications.

Damping gap

Bypass valve

Patented hydraulic end position

damping for the return stroke provides for quiet, tool saving operation.

The double supported working rod

ensures extremely precise guidance.

The absolute air/oil separation is a

prerequisite for trouble-free operation.

The ingenious double function of the

mechanical spring results in energy

savings. No air is used for the return

stroke of the intensifier piston, and the

automatic preload of the oil reservoir

allows for mounting the cylinder in any

position.

Accessories:

End position monitoring ZHU

All TOX-Powerpackages of the line-Q

are equipped with a special barrel

and a magnet on the working rod to

detect the position.

Sensors can be mounted on the

tie rods to monitor the cylinder rod

position. Please order the required

number of sensors (ZHS), mounting

brackets (ZMP) and cables (length)

separately. (See data sheet 10.00,

ZHU for the technical data on the

stroke monitor).

Oil pump ZP

It guarantees the optimum maintenance concept and extended maintenance intervals.

For easy, air-free refilling and reduction of the oil volume of the TOXPowerpackage line-Q. Clear body

and refill hose allow easy monitoring

of the oil level in the pump. Little

operator effort required. Capacity

0.30 liters.

Order no.: ZP 20.000

2

www.tox-en.com

10Q.201404.en

l i n e -

Function of the TOX-Powerpackage

Typical applications

Clinching,

TOX-Sheet metal

joining

Assembling,

Press-fitting,

Mounting

Inserting,

Fastener-Insertion

Riveting,

Crimping,

Flaring

The TOX-Powerpackage is a pneumatic operated cylinder with automatic activation of the hydraulic power

stroke.

The power stroke is automatically

triggered as soon as the working rod

(tool) meets a counterforce, at any

point of the total stroke.

Coining,

Marking,

Stamping

Punching,

Piercing

Retracted position

Fast

approach

Air operated fast approach

Start of

power stroke

Resistance activates

power stroke independent

of travel position

(Example application: Clinching)

Power

stroke

Return stroke

Pneumatic hydraulic power stroke

Controls

It is operated like a pneumatic cylinder

and has the press force of a hydraulic

cylinder. All that is needed is a standard 4/2 or 5/2 way pneumatic valve

such as used with a normal double acting pneumatic cylinder. The included

sequence valve controls automatically

the changeover from fast approach to

power stroke whenever the working

rod meets an opposing force during

the fast approach.

Investment

The TOX-Powerpackage is up to

20% less expensive than hydraulic,

pneumatic or toggle systems for

comparable technical requirements.

Energy consumption

The TOX-Powerpackage provides

up to 90% energy savings compared

to pneumatic or hydraulic systems.

Energy is used only when needed,

namely for the power stroke, barely

any for the fast approach and return

stroke.

Pressing,

Compressing,

Bending

Fast approach the main control

valve (a) is switched. The working

piston (1) extends at high speed until

it meets resistance at any point of the

stroke. This resistance causes the

changeover of the included power

stroke sequence valve (d).

The changeover time can be adjusted

via the included throttle valve. With

the throttle closed, no power stroke

occurs.

Clamping,

Tensioning,

Peening

Power stroke the intensifier plunger

(3) passes the high pressure seal and

compresses the oil in the working

area (5) up to 400bar. This oil pressure

acts on the back of the working rod (1)

and generates the power stroke.

Return stroke switching the main

control valve (a) again results in switching of the power stroke valve (d)

and venting of chamber (e). The working piston (1) and the intensifier piston (2) return to their initial position.

Scope of delivery

Compression spring

Supplied by

the customer

Performance

The TOX-Powerpackage behaves

like a pneumatic cylinder in its operation and cycle speeds. Despite its

compact dimensions, it delivers the

hard work and high forces associated with hydraulic systems, however,

without the need for an expensive hydraulic unit. The TOX-Powerpackage

provides a clean, quiet and reliable

operation.

Environment

The TOX-Powerpackage provides

an extremely low noise level due to

the hydraulic end position damping

in the return stroke. In addition, a

low exhaust noise and reduced air

consumption. No oil disposal or oil

contamination from leakage, no generation of noise such as produced by a

constantly running hydraulic pump.

10Q.201404.en

www.tox-en.com

l i n e -

TOX-Powerpackage line-Q type S

at 6bar 10 300kN

Return

stroke

Rckhub

4

C

Q-SS12 - S

Q-S

15 30

Fast approach stroke

Eilhub

G

M

Order no.

total

stroke

type

Q-S 001.030.100.

Q-S 002.030.100.

Q-S 004.030.100.

Q-S 008.030.100.

Q-S 015.030.100.

Q-S 030.030.100.

included

power

stroke

22

12

12

12

12

12

fast

approach

force

N

1400

1400

1700

3200

4500

6600

max.

press

force

kN

11.6

16.5

39.9

76.4

130.4

283.9

return

stroke

force

N

A

B

1450

70 738

1450

70 738

1900

85 821

3250 110 941

5350 135 978

9150 170 1207

*IV: integrated sequence valve

C

D

E

Ff7 G

6xM8x12 54 G1/4 40 9

6xM8x12 54 G1/4 40 9

6xM8x15 64 G3/8 50 10

6xM10x16 88 G1/2 70 9

6xM16x25 100 G1/2 75 15

6xM20x30 132 G3/4 100 17

H

20

20

30

45

50

56

K

26.0

26.0

28.5

35.0

36.0

47.0

L

M16x1.5

M16x1.5

M22x2

M30x2

M30x2

M39x2

M

15

15

20

25

25

35

N

17

17

24

36

41

50

O

104

104

124

165

175

232**

R

13.0

13.0

14.0

15.0

17.5

20.0

S

166.0

166.0

175.0

183.0

184.5

236.0

** Series with external sequence valve approach/power stroke

Vg6

18

26

26

W * IV

x

7

x

7

x

7

x

Dimensions in mm

TOX-Powerpackage line-Q type K

at 6bar 10 150kN

Fast approach stroke

Order no.

inclutotal ded

type

stroke power

stroke

Q-K 001.030.100. 24

Q-K 001.030.200. 52

Q-K 002.030.100. 15

Q-K 002.030.200. 34

Q-K 004.030.100. 05

Q-K 004.030.200. 13

Q-K 008.030.100. 08

Q-K 008.030.200. 18

Q-K 015.030.200. 12

max.

press

force

kN

11.8

11.8

16.3

16.3

48.6

48.6

67.4

67.4

140.4

3

5

fast

appr- return

oach stroke

force force

N

N

A

1400 1500 70

1400 1450 70

1400 1500 70

1400 1450 70

1700 1950 85

1700 1900 85

3200 3300 110

3200 3250 110

4500 5350 135

*IV: integrated sequence valve

A2

85

85

85

85

110

110

135

135

170

A2

7

3

1

2

3

4

5

6

7

Control throttle X

High pressure connection

Oil filling nipple

Sequence valve approach/power stroke

Bleed plate

Oil level indicator

Bleed screw

B

371

571

371

571

397

597

426

626

650

C

D

6xM8x12 54

6xM8x12 54

6xM8x12 54

6xM8x12 54

6xM8x15 64

6xM8x15 64

6xM10x16 88

6xM10x16 88

6xM16x25 100

E

G1/4

G1/4

G1/4

G1/4

G3/8

G3/8

G1/2

G1/2

G1/2

K 8 - K 30

K 50

A

D

N

A

D

N

Ff7

40

40

40

40

50

50

70

70

75

G H

9 20

9 20

9 20

9 20

10 30

10 30

9A 45

2

9 45

O

15 50

K

26.0

26.0

26.0

26.0

28.5

28.5

35.0

35.0

36.0

L

M16x1.5

M16x1.5

M16x1.5

M16x1.5

M22x2

M22x2

M30x2

M30x2

M30x2

Power stroke

Total stroke

6bar series

Press force category

Version S/K

line-Q

A

D

M

15

15

15

15

20

20

25

25

25

** Series with external sequence valve approach/power stroke

N

17

17

17

17

24

24

36

36

41

O

P

117 160

117 160

117 160

117 160

165 200

165 200

177A2 250

O

177 250

232** 315

R

13.0

13.0

13.0

13.0

14.0

14.0

15.0

15.0

17.5

S

166.0

266.0

166.0

266.0

175.0

275.0

183.0

283.0

284.5

U Vg6

8

8

8

8

10 18

10 18

12 26

12 26

16 26

7

7

7

7

7

X *IV

98.5

244.5 x

98.5

244.5 x

86.5

204.5 x

93.5

229.5 x

185.5

Dimensions in mm

TOX PRESSOTECHNIK GmbH & Co. KG Riedstrasse 4 D-88250 Weingarten Tel. +49(0)751/5007-0

Fax +49(0)751/5 23 91 E-Mail: info@tox-de.com www.tox-en.com

Subject to technical modifications.

Eilhub

How to order:

Q-S 8.30.100.12

Q-K 1K 1 Q-K

- K 1515

L

F

V

H

M K

G

W

G

Rckhub

Return stroke

S

R

S

E R

E

10Q.201404.en

M K

Vous aimerez peut-être aussi

- Operating Manual: TOX Ware ServerDocument46 pagesOperating Manual: TOX Ware ServerWarlley CastroPas encore d'évaluation

- TOX PowerpackageDocument98 pagesTOX PowerpackageArmando RCPas encore d'évaluation

- GMN HF Spindles For Auto Tool Change PDFDocument45 pagesGMN HF Spindles For Auto Tool Change PDFsergioduartePas encore d'évaluation

- Centroid Cnc10 PLCMANDocument91 pagesCentroid Cnc10 PLCMANClaudio GiacomelliPas encore d'évaluation

- CNC Programming Examples Guide for S3000-S4000 SeriesDocument128 pagesCNC Programming Examples Guide for S3000-S4000 SeriesSQuestPas encore d'évaluation

- Installation of Bridge Cutter P31 Machine GuideDocument25 pagesInstallation of Bridge Cutter P31 Machine GuideHữu Dũng NguyễnPas encore d'évaluation

- Fisher 3661Document36 pagesFisher 3661HYDRAULICGURU100% (1)

- Ultrasonic Thickness Gauge ManualDocument13 pagesUltrasonic Thickness Gauge ManualMark K50% (2)

- DX Operators Book (04!12!10)Document80 pagesDX Operators Book (04!12!10)IsmaelPas encore d'évaluation

- Manual PRC PRI7000 V1.7.2.0 WPDocument173 pagesManual PRC PRI7000 V1.7.2.0 WPChristian AldrinPas encore d'évaluation

- CJT CONN BroschureDocument756 pagesCJT CONN BroschureOzanPas encore d'évaluation

- DWG ST 418-20 - Sockolets - WeldoletDocument11 pagesDWG ST 418-20 - Sockolets - WeldoletLis RincónPas encore d'évaluation

- Haas Service Manual ArchiveDocument340 pagesHaas Service Manual ArchiveJos Miranda100% (1)

- SKK Gearmotor MFG500 Series A Series CataloqDocument128 pagesSKK Gearmotor MFG500 Series A Series Cataloqyb7knv100% (2)

- AIRWAVE King Series - Kitchen ESPDocument12 pagesAIRWAVE King Series - Kitchen ESPMason LeePas encore d'évaluation

- SimMan Tut 01 BackstepDocument20 pagesSimMan Tut 01 BackstepVenkata VasanthaPas encore d'évaluation

- Industrial Theodolites & Total Stations Brochure en PDFDocument8 pagesIndustrial Theodolites & Total Stations Brochure en PDFGiora RozmarinPas encore d'évaluation

- SENTRON LV36 Complete English 2014Document284 pagesSENTRON LV36 Complete English 2014charlonPas encore d'évaluation

- Tescom Technical Training - Pressure Regulators Explained - Ver1.1Document19 pagesTescom Technical Training - Pressure Regulators Explained - Ver1.1Amod DeshpandePas encore d'évaluation

- Digital Photo Professional 4.9 Instruction Manual Win EN PDFDocument162 pagesDigital Photo Professional 4.9 Instruction Manual Win EN PDFbubimir13Pas encore d'évaluation

- Omron CJ2 Auxiliar Area MemoryDocument38 pagesOmron CJ2 Auxiliar Area MemoryAline Oliveira FotografaPas encore d'évaluation

- Manual Tool Change Electrospindles Increase Machine EfficiencyDocument5 pagesManual Tool Change Electrospindles Increase Machine EfficiencyM. MUBASHARPas encore d'évaluation

- Cyclone 5.8 PDFDocument492 pagesCyclone 5.8 PDFவி.சுரேஷ் குமார்Pas encore d'évaluation

- Tox PressotechnikDocument23 pagesTox PressotechnikCristobal Espinoza FloresPas encore d'évaluation

- UTStudio3 User Guide 2013-07-30Document77 pagesUTStudio3 User Guide 2013-07-30Ramakrishnan AmbiSubbiahPas encore d'évaluation

- 07387102Document455 pages07387102IvanPas encore d'évaluation

- CNC Programming Functions GuideDocument68 pagesCNC Programming Functions GuideJon Morales100% (1)

- Ace Tut 02 Turbulent BackstepDocument22 pagesAce Tut 02 Turbulent BackstepHilario de JesusPas encore d'évaluation

- H-1000-5021-06-B (E)Document53 pagesH-1000-5021-06-B (E)marioPas encore d'évaluation

- Yamaha Rx-A3030 PDFDocument225 pagesYamaha Rx-A3030 PDFboroda2410Pas encore d'évaluation

- Tracker Pilot Reference Manual V2.1.0en - 4Document195 pagesTracker Pilot Reference Manual V2.1.0en - 4Sea Man MktPas encore d'évaluation

- TESCOMDocument654 pagesTESCOMmechanikyPas encore d'évaluation

- Resistance Welding: Resistance Welding Is A Pressure Welding Technique Using HighDocument32 pagesResistance Welding: Resistance Welding Is A Pressure Welding Technique Using HighPratik ThakerPas encore d'évaluation

- PGF310 XGF315XDocument164 pagesPGF310 XGF315Xkishore_bulli6666100% (1)

- Countersink Tool Downward - WZ19enDocument10 pagesCountersink Tool Downward - WZ19enBebe Ionuț AnițaPas encore d'évaluation

- Welding Symbol Reference ChartDocument2 pagesWelding Symbol Reference ChartAamer MohammedPas encore d'évaluation

- 20 INV SPL. 2.50 MOD 20 PA 22F01113 HB IND. 55x50x MM (PART - ModelDocument1 page20 INV SPL. 2.50 MOD 20 PA 22F01113 HB IND. 55x50x MM (PART - Modelhb IndustriesPas encore d'évaluation

- The Art of Bending - Press Brake Tooling Solutions For Every Challenge - by Jeff Paulson - Marketing Manager - Wilson Tool InternationalDocument1 pageThe Art of Bending - Press Brake Tooling Solutions For Every Challenge - by Jeff Paulson - Marketing Manager - Wilson Tool InternationalSM TECH SRLPas encore d'évaluation

- Siemens CU240B 2 CU240E 2 ManualDocument364 pagesSiemens CU240B 2 CU240E 2 Manualangelboy_20Pas encore d'évaluation

- RCEG-12 Assembly Drawings and SchematicsDocument121 pagesRCEG-12 Assembly Drawings and SchematicsEnrique Martinez RojasPas encore d'évaluation

- 1-Piece Instrumentation, 40G and 40 Series: Part NoDocument2 pages1-Piece Instrumentation, 40G and 40 Series: Part Nozidanejason8Pas encore d'évaluation

- GSK980TD CNC User ManualDocument408 pagesGSK980TD CNC User Manualmfmejiab0% (1)

- Joh. Heinr. Bornemann GMBH Postfach 1162, D-31676 Obernkirchen Phone: +49 5724 390-0 Fax +49 5724 390 290Document6 pagesJoh. Heinr. Bornemann GMBH Postfach 1162, D-31676 Obernkirchen Phone: +49 5724 390-0 Fax +49 5724 390 290vuthanhPas encore d'évaluation

- AMO Incremental Length Encoder CatalogDocument56 pagesAMO Incremental Length Encoder CatalogElectromatePas encore d'évaluation

- Plextor Plexwriter 820 ManualDocument88 pagesPlextor Plexwriter 820 Manualvegaskink100% (1)

- Tin Plate India Ltd Research Report AnalysisDocument8 pagesTin Plate India Ltd Research Report AnalysisPriyank PatelPas encore d'évaluation

- NEMA and IEC standard motor dimensionsDocument2 pagesNEMA and IEC standard motor dimensionsVijay Raghavan0% (1)

- Plugin 6zb5411 0cb02 0ba0Document10 pagesPlugin 6zb5411 0cb02 0ba0Teguh PrasetyoPas encore d'évaluation

- QuikCal 190 Quick StartDocument12 pagesQuikCal 190 Quick StartsuberecPas encore d'évaluation

- AbsoluteEncoders MCD SSI Datasheet DataContentDocument10 pagesAbsoluteEncoders MCD SSI Datasheet DataContent77sn1321Pas encore d'évaluation

- Catalog GCEDocument107 pagesCatalog GCEpablobobadilla1990Pas encore d'évaluation

- 28.GOMA Pump T-8000 CatalougeDocument2 pages28.GOMA Pump T-8000 Catalougeramesh babuPas encore d'évaluation

- Tube-Mac Metric CatalogeDocument279 pagesTube-Mac Metric CatalogeTheAnonymousLugia100% (2)

- Numerical Analysis - I. Jacques and C. Judd PDFDocument109 pagesNumerical Analysis - I. Jacques and C. Judd PDFMaria AquisePas encore d'évaluation

- Parts list for industrial gearbox assemblyDocument4 pagesParts list for industrial gearbox assemblyrestu yanuar salamPas encore d'évaluation

- CNV 03 BDocument4 pagesCNV 03 BMaitry ShahPas encore d'évaluation

- Wenzel Technical Data Sheet LH 1210 1512 Premium SelectDocument4 pagesWenzel Technical Data Sheet LH 1210 1512 Premium SelectBoris 'Junior' BorisovPas encore d'évaluation

- F162X Digital Arc Voltage Controller ManualDocument64 pagesF162X Digital Arc Voltage Controller ManualPandegaPas encore d'évaluation

- Hermetically Sealed Pumps Ensure Refrigerant Safety and EfficiencyDocument24 pagesHermetically Sealed Pumps Ensure Refrigerant Safety and EfficiencyWaseem HassanPas encore d'évaluation

- ArmstrongDocument6 pagesArmstrongJorge Herrera100% (1)

- The Law of CommunicationDocument3 pagesThe Law of CommunicationPurece EugenPas encore d'évaluation

- 17 Indisputable Laws of Teamwork - Getabstract PDFDocument5 pages17 Indisputable Laws of Teamwork - Getabstract PDFGILBER100% (1)

- Past Tense Simple & ContinuousDocument2 pagesPast Tense Simple & ContinuousAlexandru Ionut MihaiPas encore d'évaluation

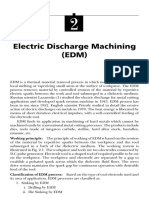

- Fundamentals: WEDM Dielectric BasicsDocument7 pagesFundamentals: WEDM Dielectric BasicsPurece EugenPas encore d'évaluation

- Camping trip cut short by rainDocument2 pagesCamping trip cut short by rainIulia IliePas encore d'évaluation

- EDM Wirecut Working PrincipleDocument22 pagesEDM Wirecut Working Principlemunjivramana_6611003Pas encore d'évaluation

- Pronume Si Adjective PosesiveDocument1 pagePronume Si Adjective PosesiveivlonelyPas encore d'évaluation

- Verbe NeregulateDocument8 pagesVerbe NeregulateAlexandra ComanPas encore d'évaluation

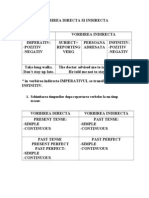

- Vorbirea Directa Si Indirecta - EnglezaDocument5 pagesVorbirea Directa Si Indirecta - EnglezaTrnu AndreiPas encore d'évaluation

- Present Tense Simple & ContinuousDocument1 pagePresent Tense Simple & ContinuousAna-Maria Nedelcu GiosanuPas encore d'évaluation

- Arburg Hydraulic Allrounders 680472 en GBDocument16 pagesArburg Hydraulic Allrounders 680472 en GBPurece EugenPas encore d'évaluation

- Curs de EnglezaDocument5 pagesCurs de EnglezaNeagu MarianPas encore d'évaluation

- Work NCDocument124 pagesWork NCPurece EugenPas encore d'évaluation

- Update Training Guide Worknc v23 2015-02Document98 pagesUpdate Training Guide Worknc v23 2015-02Purece Eugen100% (1)

- Development of Table Top Ultrasonic Assisted Sinking Micro Electrical Discharge Machining Set UpDocument19 pagesDevelopment of Table Top Ultrasonic Assisted Sinking Micro Electrical Discharge Machining Set UpPurece EugenPas encore d'évaluation

- Books INTRODUCTION PDFDocument137 pagesBooks INTRODUCTION PDFshahadPas encore d'évaluation

- Development of Table Top Ultrasonic Assisted Sinking Micro Electrical Discharge Machining Set UpDocument19 pagesDevelopment of Table Top Ultrasonic Assisted Sinking Micro Electrical Discharge Machining Set UpPurece EugenPas encore d'évaluation

- Roger Dawson - To Win in Negotiations Learn How To Taper ConcessionsDocument3 pagesRoger Dawson - To Win in Negotiations Learn How To Taper ConcessionsPurece EugenPas encore d'évaluation

- Die Sinking - Power For ProductionDocument19 pagesDie Sinking - Power For ProductionPurece EugenPas encore d'évaluation

- Electrical DischargeDocument3 pagesElectrical DischargeRipper JackPas encore d'évaluation

- h26IX PDFDocument74 pagesh26IX PDFschwerzerspanerPas encore d'évaluation

- 81 Sample ChapterDocument10 pages81 Sample ChapterPurece EugenPas encore d'évaluation

- Nomenclature Chemical PDFDocument1 pageNomenclature Chemical PDFPurece EugenPas encore d'évaluation

- Mechanical and Metal Trades HandbookDocument432 pagesMechanical and Metal Trades HandbookPurece EugenPas encore d'évaluation

- # Fundamentals and Applications of Ultrasonic WavesDocument1 page# Fundamentals and Applications of Ultrasonic WavesDoroteea TeoibasPas encore d'évaluation

- PM DesignTip EssentialsDocument20 pagesPM DesignTip EssentialsPurece EugenPas encore d'évaluation

- Catia BookDocument232 pagesCatia BookFlorin Manea100% (8)

- Product Design Mold DesignDocument19 pagesProduct Design Mold Designajithp_kvr100% (1)

- Chapter 14 - Axonometric ProjectionDocument38 pagesChapter 14 - Axonometric ProjectionPurece EugenPas encore d'évaluation

- Icmeas 2017: Local Advisory CommitteeDocument3 pagesIcmeas 2017: Local Advisory CommitteeZawad AbedinPas encore d'évaluation

- KrisEnergy LTD - Appendix D - Volume2Document194 pagesKrisEnergy LTD - Appendix D - Volume2Invest StockPas encore d'évaluation

- Roads and Road TransportDocument34 pagesRoads and Road TransportNimmy Fredrick100% (1)

- Chimney Sizing Chart For Fireplaces: 100 50 30 20 15 10 8 Flue Area, inDocument1 pageChimney Sizing Chart For Fireplaces: 100 50 30 20 15 10 8 Flue Area, inBen ZithaPas encore d'évaluation

- SMART BRO Data Pro Plans App FormDocument2 pagesSMART BRO Data Pro Plans App FormCatherine TominPas encore d'évaluation

- Bartec Headed Bars Qualification File and References 2017.09.08Document35 pagesBartec Headed Bars Qualification File and References 2017.09.08Andres Hermoso MeijidePas encore d'évaluation

- ATFMDocument4 pagesATFMYuranan LimpananvadeePas encore d'évaluation

- Cylinders FullDocument110 pagesCylinders FulltnvishPas encore d'évaluation

- Oracle Complex PO RetainageDocument19 pagesOracle Complex PO RetainageabiyeasamenewPas encore d'évaluation

- Exercise - Quality ToolsDocument10 pagesExercise - Quality ToolsĐức TrungPas encore d'évaluation

- Licence Fees For Satellite Services, Networks and Terminals in The Cept October 2001Document64 pagesLicence Fees For Satellite Services, Networks and Terminals in The Cept October 2001Anonymous 3Vgw3v2ZcHPas encore d'évaluation

- Jerbi ResumeDocument6 pagesJerbi ResumeLeah Nadine QuimzonPas encore d'évaluation

- Kitz Gate ValveDocument28 pagesKitz Gate ValvemohamedfirozPas encore d'évaluation

- TechTopics58 - E-Rated Vs R Rated FusesDocument2 pagesTechTopics58 - E-Rated Vs R Rated FusesBigBaby JulianPas encore d'évaluation

- Project Title: Simple Cafe Billing System: Rajokari Institute of TechnologyDocument8 pagesProject Title: Simple Cafe Billing System: Rajokari Institute of TechnologyVinodPas encore d'évaluation

- ISA RP60.3 Human Engineering For Control CentersDocument22 pagesISA RP60.3 Human Engineering For Control CentersDaniel Arrieta DarrásPas encore d'évaluation

- Alcatel Extension CodesDocument2 pagesAlcatel Extension Codesranma_ptPas encore d'évaluation

- Tata Teleservices - Case StudyDocument5 pagesTata Teleservices - Case Studyram_m2000Pas encore d'évaluation

- SOA Suite 10g Developer GuideDocument47 pagesSOA Suite 10g Developer GuideTusharPas encore d'évaluation

- Pgdca LevelDocument82 pagesPgdca Levelbetu8137Pas encore d'évaluation

- Sanitary Napkin Vending MachineDocument11 pagesSanitary Napkin Vending Machineshobanraj1995Pas encore d'évaluation

- 01.hazards of Trapped Pressure & Vacuum-38Document2 pages01.hazards of Trapped Pressure & Vacuum-38rahulPas encore d'évaluation

- FAST Project Phase 2 Submission UpdatesDocument91 pagesFAST Project Phase 2 Submission UpdatesEzon AguilaPas encore d'évaluation

- Actual4Test: Actual4test - Actual Test Exam Dumps-Pass For IT ExamsDocument4 pagesActual4Test: Actual4test - Actual Test Exam Dumps-Pass For IT ExamsLovis NKPas encore d'évaluation

- Authorization Objects: Bi SecurityDocument3 pagesAuthorization Objects: Bi SecurityDheeraj ReddyPas encore d'évaluation

- 1 - SAP BPC NW 10.0 Script Logic Implementation Guide V18Document84 pages1 - SAP BPC NW 10.0 Script Logic Implementation Guide V18Angel Ammulu100% (1)

- 2014 Brochure EN FERMENTECDocument18 pages2014 Brochure EN FERMENTECP RAJAVELUPas encore d'évaluation

- Tata Steel Corporate PresentationDocument49 pagesTata Steel Corporate Presentationjyoti mahajanPas encore d'évaluation

- Support Dept Cost Allocation - 3 Allocation MethodsDocument6 pagesSupport Dept Cost Allocation - 3 Allocation MethodsSophie PearsonPas encore d'évaluation

- (Type The Document Title) : Acquisition of Jaguar & Land Rover by Tata MotorsDocument46 pages(Type The Document Title) : Acquisition of Jaguar & Land Rover by Tata Motorsravneet050% (2)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionD'EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionÉvaluation : 4.5 sur 5 étoiles4.5/5 (542)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersD'Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersÉvaluation : 5 sur 5 étoiles5/5 (1)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsD'EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsÉvaluation : 4 sur 5 étoiles4/5 (1)

- 8051 Microcontroller: An Applications Based IntroductionD'Everand8051 Microcontroller: An Applications Based IntroductionÉvaluation : 5 sur 5 étoiles5/5 (6)

- Introduction to Petroleum Process SafetyD'EverandIntroduction to Petroleum Process SafetyÉvaluation : 3 sur 5 étoiles3/5 (2)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsD'EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsPas encore d'évaluation

- Guidelines for Implementing Process Safety ManagementD'EverandGuidelines for Implementing Process Safety ManagementPas encore d'évaluation

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesD'EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026D'EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Évaluation : 5 sur 5 étoiles5/5 (1)

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeD'EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromePas encore d'évaluation

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionD'EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionÉvaluation : 4 sur 5 étoiles4/5 (331)

- Guidelines for Auditing Process Safety Management SystemsD'EverandGuidelines for Auditing Process Safety Management SystemsPas encore d'évaluation

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemD'EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemPas encore d'évaluation

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationD'EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationPas encore d'évaluation

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsD'EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsÉvaluation : 5 sur 5 étoiles5/5 (2)

- Introduction to Power System ProtectionD'EverandIntroduction to Power System ProtectionPas encore d'évaluation

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesD'EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Understanding Automotive Electronics: An Engineering PerspectiveD'EverandUnderstanding Automotive Electronics: An Engineering PerspectiveÉvaluation : 3.5 sur 5 étoiles3.5/5 (16)

- The Rare Metals War: the dark side of clean energy and digital technologiesD'EverandThe Rare Metals War: the dark side of clean energy and digital technologiesÉvaluation : 5 sur 5 étoiles5/5 (2)

- Ramblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowD'EverandRamblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowPas encore d'évaluation

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)D'EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Évaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Build Your Own Electric Vehicle, Third EditionD'EverandBuild Your Own Electric Vehicle, Third EditionÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Current Interruption Transients CalculationD'EverandCurrent Interruption Transients CalculationÉvaluation : 4 sur 5 étoiles4/5 (1)