Académique Documents

Professionnel Documents

Culture Documents

Mech Syllabus 2013 14

Transféré par

netraCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mech Syllabus 2013 14

Transféré par

netraDroits d'auteur :

Formats disponibles

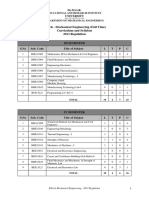

B.V.

Bhoomaraddi College of Engineering & Technology, Hubli 31

3.6 Course Syllabi

Semester: I

Course

Code

MAC103

PHC102

CVC103

MEC105

EEC105

HSC109

MEL101

PHL102

Course Syllabi

Course Title Categ Total No. Of contact Hours Credits

Marks

ory Leture Tutor Pract Self Total

CIE SEE Total

(L)

ial ical Study Hour

(T) (P) (S)

s

Calculus

BS

4

0

0

0

50

4

50 50 100

Engineering

BS

4

0

0

0

50

4

50 50 100

Physics

Engineering

ES

4

0

0

0

50

4

50 50 100

Mechanics

Elements of

Mechanical

ES

4

0

0

0

50

4

50 50 100

Engineering

Basic

Electrical

ES

4

0

0

0

50

4

50 50 100

Engineering

Social

HSS

2

0

0

0

20

3

50 50 100

Innovation

Workshop

ES

0

0

1.5

0

30

3

50 50 100

Practice

Engineering

BS

0

0

1.5

0

30

3

50 50 100

Physics Lab

Total

22

0

3

0

25

Semester: II

Course

Code

MAC104

CHC102

CSC103

MEC110

Course Syllabi

Course Title Categ Total No. Of contact Hours Credits

Marks

ory Leture Tutor Pract Self Total

CIE SEE Total

(L)

ial ical Study Hour

(T) (P) (S)

s

Differential

50 50 100

Equations &

BS

4

0

0

0

50

4

Vector

Calculus

Engineering

50 50 100

BS

4

0

0

0

50

4

Chemistry

Programming

50 50 100

Fundamentals ES

4

0

0

0

50

4

with C

Computer50 50 100

Aided

ES

2

0

2

0

40

4

Engineering

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 1

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

Course

Code

ECC105

HSC105

CSL107

CHL104

Course Syllabi

Course Title Categ Total No. Of contact Hours Credits

Marks

ory Leture Tutor Pract Self Total

CIE SEE Total

(L)

ial ical Study Hour

(T) (P) (S)

s

Drawing

Basic

50 50 100

ES

4

0

0

0

50

4

Electronics

Professional

0

30

50 50 100

Communicatio HSS

2

0

0

2

n

C

50 50 100

Programming ES

0

0

1.5

0

40

1.5

Lab

Engineering

50 50 100

BS

0

0

1.5

0

40

1.5

Chemistry Lab

Total

20

0

5

0

25

Semester: III

Course

Code

Course Title

MAC209 Statistics and Integral

Transforms

MEC209 Basic

Thermodynamics

MEC202 Mechanics of

Materials

MEC204 Manufacturing

Processes

MEC206 Material Science

MEC211 Engineering Design

MEL205 Material Science Lab

MEL207 Engineering Design

Lab

HSC204 Management Theory

& Practice

Course Syllabi

Cate Total No. Of contact Hours Cred

Marks

gory Letu Tuto Pract Self Total its CIE SEE Total

re rial ical Stud Hour

(L) (T) (P) y (S) s

BS5

ES9

PSC

PSC

PSC

ES

ES

ES

HSS

Total

50

50

100

50

50

100

50

50

100

50

50

100

4

2

0

0

1

0

0

0

1

0

0

0

4

2

2

4

3

1

50

50

50

50

50

50

100

100

100

50

50

100

50

50

100

24

30

27

Semester: IV

Course

Code

Course Title

Mechanical Engineering (UG)

Course Syllabi

Cate Total No. Of contact Hours Cred

Marks

gory Letu Tuto Pract Self Total its CIE SEE Total

re rial ical Stud Hour

Self Assessment Report

Page No.: 2

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

Numerical Methods

MAC213 and Partial Differential

Equations

MEC203 Fluid Mechanics

MEC210 Energy Conversion I

MEC207 Theory of Machine I

Theory of Metal

MEC208

cutting

Energy Conversion I

MEL204

Lab

Metal Forming &

MEL206

Metal Cutting Lab

Kinematics Simulation

MEL208

Lab

Accounting &

HSC205

Financial Management

(L)

(T)

(P)

y (S)

BS

50

50

100

PSC

PSC

PSC

4

4

4

0

0

0

0

0

0

0

0

0

4

4

4

4

4

4

50

50

50

50

50

50

100

100

100

PSC

50

50

100

ES

50

50

100

ES

50

50

100

ES

50

50

100

HSS

50

50

100

Total

22

28

25

Semester: V

Course

Code

MEC

301

MEC

302

MEC

303

MEC

304

MEC

313

MEE

301

Course Title

Course Syllabi

Cate Total No. Of contact Hours Cred

Marks

gory Letu Tuto Pract Self Total its CIE SEE Total

re rial ical Stud Hour

(L) (T) (P) y (S) s

Machine Design I

50

50

100

50

50

100

50

50

100

50

50

100

50

50

100

PSE

50

50

100

PRJ

50

50

100

80

20

100

ES

80

20

100

ES

80

20

100

22

32

28

PSC

Energy Conversion - II

PSC

Metrology &

Instrumentation

PSC

Theory of Machine - II

PSC

Automatic Control

Systems

PSC

Theory of Elasticity

I C Engine

MEE

302

MEP 301 Mini Project-I

MEL

Energy conversion II

301

Lab

MEL

Metrology &

302

Instrumentation Lab

MEL

Machine Shop Lab

303

ES

Total

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 3

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

Semester: VI

Course

Code

MEC

310

MEC

311

MEC

314

MEC

315

Course Title

Heat & Mass Transfer

PSC

50

50

100

Machine Design - II

PSC

50

50

100

Mechatronics

PSC

50

50

100

PSC

50

50

100

PSC

50

50

100

PSE

50

50

100

PRJ

50

50

100

ES

80

20

100

ES

80

20

100

Total

19

26

24

Automation in

Manufacturing

Professional Aptitude

HSC 301

& Logical Reasoning

MEE

Gas Dynamics

303

MEE

305

Course Syllabi

Cate Total No. Of contact Hours Cred

Marks

gory Letu Tuto Pract Self Total its CIE SEE Total

re rial ical Stud Hour

(L) (T) (P) y (S) s

FEM

MEP 302 Mini Project-II

MEL

Heat Transfer Lab

307

MEL

Automation Lab

308

Semester: VII

Course

Code

MEC

409

MEC

408

HSC 401

MEE

409

MEE

410

MEE

401

MEE

413

MEO

402

Course Title

Operations Research

Design of Thermal

Systems

CIPE/EVS

Course Syllabi

Cate Total No. Of contact Hours Cred

Marks

gory Letu Tuto Pract Self Total its CIE SEE Total

re rial ical Stud Hour

(L) (T) (P) y (S) s

PSC

50

50

100

PSC

50

50

100

HSC

50

50

100

PSE

50

50

100

PSE

50

50

100

OE

50

50

100

Composite Materials

Power Plant

Engineering

CFD

Mechanical Vibration

Non Conventional

Energy Systems

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 4

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

MEO

MEMS

403

MEP 401 Project Work

MEL

Design Lab

403

MEL

Computer Integrated

404

Manufacturing Lab

PRJ

50

50

100

ES

80

20

100

ES

80

20

100

19

26

24

Total

Semester: VIII

Course

Code

MEC

404

MEE

406

MEE

407

MEE

411

MEE

412

MEO

405

Course Title

Course Syllabi

Cate Total No. Of contact Hours Cred

Marks

gory Letu Tuto Pract Self Total its CIE SEE Total

re rial ical Stud Hour

(L) (T) (P) y (S) s

Manufacturing System

PSC

Engineering

Automotive

Engineering

PSE

Fracture Mechanics

50

50

100

50

50

100

OE

50

50

100

OE

50

50

100

PRJ

10

10

10

50

50

100

NTM

Organizational

Behaviour

Nanotechnology

Design of Aircraft

MEO

Structures

404

MEP 402 Project Work

Total

Mechanical Engineering (UG)

12

10

Self Assessment Report

22

22

Page No.: 5

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

Semester: I / II

Course Content

Course Code :

Course Title

:

Teaching Hours :

MAC213

Calculus

50

L-T-P-S: 4-0-0-0

CIE: 50

SEE: 50

Course Outcomes

1. Obtain the higher order derivatives using the orocess of successive differentiation

2. Apply Taylors and Maclarins series to express any differentiable function in power

series.

3. Apply concept of derivate in binding of curves, extreme values function of several

variables.

4. Apply partial differentiation for the function of several variables.

5. Draw an approximate shape of the given curves.

6. Evaluate integrals using reduction formulas and beta and gamma functions

7. Apply multiple integral techniques in evaluating area of plane and volume of solid region.

Course Content

UNIT I

1. Differential Calculus

Determination of nth derivatives of standard functions, Leibnitzs theorem (no

proof), Polar curves Angle between the radius vector and the tangent pedal

Equation of polar curves only. Radius of curvature Cartesian, parametric, polar

and pedal forms. Maxima and Minima for function of two variables. Lagranges 20 hours

method of undetermined multipliers Partial differentiation: Eulers Theorem,

Total differentiation, Differentiation of Composite and implicit function,

Jacobians Errors and approximation, Differentiation under integral signconstant and variable limits using Leibnitz rule-examples.

UNIT II

2. Indeterminate forms and series expansion

Maclaurins series expansions and Taylors Theorem for a function of single

variable, Indeterminate forms LHospitals rule,

05 hours

3. Integral Calculus

n

Reduction Formulae for the integration of sin (x) , cos (x) , sin (x).cos (x) and

evaluation of these integrals with standard limits problems, Tracing of standard 15 hours

curves in Cartesian form, parametric form and Polar form, Derivatives of arc

length, Applications to find length, area, Volume and surface area (Cartesian,

parametric and polar curves).

UNIT III

4. Multiple Integrals

Multiple Integrals - Evaluation by change of order of integration change of

variables and applications to area and volume. Beta and gamma functions.

Text Books:

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 6

10 hours

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

1. Grewal B S, Higher Engineering Mathematics, 38ed, Khanna Publication, New Delhi,

2001

2. Bali and Iyengar, A text book of Engineering Mathematics, 6ed, Laxmi

Publications(p) Ltd, New Delhi,2003.

References:

1. Peter V. ONeil, Advanced Engineering Mathematics, 5ed, Thomson Publisher.2003.

Evaluation Scheme:

Course Unitization for Minor Exams and Semester End Examination

1. The questions for minor examination will be chosen approximately in line with the

hourly weightage of that chapters in that Unit.

2. The SEE will have the weightage as follows.

Scheme of CIE:

Assessment

Minor Exam I (Unit I)

Minor Exam II (Unit II)

Assignment/Quiz

Total

Weightage in Marks

20

20

10

50

Unit

Chapters

Differential Calculus

Indeterminate forms and

series expansion

Integral Calculus

Multiple Integrals

II

III

Course Code :

Course Title

:

Teaching Hours :

Teaching No of Questions in SEE

Hours

1M

2 M 5 M 10 M

20

05

4

6 out

10

5

out

of 8

of 5

15

10

Course Content

PHC102

Engineering Physics

50

Total M

100

Convert

ed for 50

L-T-P-S: 4-0-0-0

CIE: 50

SEE: 50

Course Outcomes

1. Present the necessity of the quantum mechanics to overcome the failure of classical

theories.

2. Describe the dual nature of the matter, group concept, and probabilistic nature of

measurement and desctirisation of energy levels.

3. Interpret the electrical and thermal conductivities in leals in terms of quantum free

electron theory in comparison with classical free electron theory with their respective

limitations.

4. Differentiate the properties of lasers with ordinary light and to explain the conditions

to obtain the laser actions.

5. Explain how, the different types of lasers are obtained and use the same for different

industrial applications

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 7

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

6. Give an account of the theory of propagation of light through optical fibers and their

applications

7. List the different crystals structures on the basis of lattice parameters and to calculate

the miller indices, packing fraction and coordination number for cubic structures.

8. Classify the different types of electrics and magnetic material on the basis of their

properties

9. Differentiate the various properties and electron density distribution at nano scale in

comparison with bulk materials.

10. Explain the applications of ultra sonic in non destructive testing methods.

UNIT I

Photonics:

a) Lasers:

Over view of Lasers and applications, characteristics, basic principles: stimulated

absorption, spontaneous emission and stimulated emission. Einstein co-efficients, 7 Hrs

expression for energy density. Population inversion and metastable state. High

energy lasers and their applications: CO2 laser, Lasers in cutting, drilling and

welding. Low energy lasers and their applications: Semiconductor laser, LIDAR and

Holography. Problems.

b)Optical fibers:

Propagation mechanism, Numerical aperture, Types of optical fibers, Attenuation. 3 Hrs

Applications in communication and sensors. Advantage of optical fiber

communication over conventional methods. Problems.

Crystal Structure and X-ray Diffraction:

Introduction: lattice, space lattice, basis vectors and crystal structures. Bravais

lattice, Unit cell, lattice parameter, Crystal systems. Direction and planes in a 6 Hrs

crystal. Miller Indices. Equation for the

interplanar spacing. Co-ordination

number. Atomic packing factor. Structures of NaCl and

diamond. Braggs law,

Braggs X-ray spectrometer, determination of crystal structure. Problems.

Dielectrics:

Overview of Dielectrics and their applications. Some important dielectric materials.

Polarisation under DC and AC fields, Different Polarisation mechanisms. Internal 4 Hrs

fields in solids and liquids, Clausius- Mossotti equation. Ferroelectric and

Piezoelectric materials and their application in brief. Problems.

UNIT II

Quantum Physics:

Black body radiation, Photoelectric effect, and Compton Effect (qualitative),

descritisation of energy. de-Broglies hypothesis of matter waves, Wave nature of

particle. Phase velocity, group velocity relation between group velocity and particle

velocity. Expression for de-Broglies wavelength. Verification of wave nature of 10 Hrs

particle by Davission and Germer Experiment. Heisenbergs Uncertainty principle:

statement, physical significance, and application to show that a free electron do not

exists in the nucleus and its implications. One dimensional time independent

Schrdinger wave equation. Wave function and its significance, normalization.

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 8

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

Eigen function Eigen value. Application of Schrdinger wave equation: 1) Particle

in 1-D potential well of infinite height 2) The case of free particle. Problems.

Conductivity in Solids:

Classical theory, advantages and draw backs, Mean free path, mean collision time,

drift velocity, relaxation time. Expression for electrical conductivity and thermal

conductivity in metals, Wediemann-Franz law, temperature dependence of electrical

resistivity, Matthiessens rule. Quantum theory: Distribution of electrons as per 10 Hrs

quantum free electron theory, Fermi-Dirac distribution, Fermi energy, temperature

dependence of Fermi factor and qualitative treatment of density of states.

Conduction in Semiconductors: Electrical conductivity of semiconductor, concept of

effective mass, carrier concentration and Fermi energy in intrinsic and extrinsic

semiconductors.

UNIT III

Magnetic materials and Ultrasonics:

Soft and Hard magnetic materials, properties and applications. Magnetic storage

device.

05 Hrs

Ultrasonics:

Introduction, principles, attenuation and measurement of wavelength,

compressibility using ultrasonic interferometer. Applications: NDT using pulse echo

method for the detection of flaw.

Nanoscience and Nanotechnology:

Length scales, variation of physical properties from bulk to thin films to

nanomaterials, confinement of electron energy states (LDOS) in 0-D, 1-D, 2-D, and

05 Hrs

3-D systems(qualitative treatment), surface, size, shape and assembly effects.

Example: Carbon nanotubes, characterization: Scanning Tunneling Microscope

(STM) (qualitative).

Text Books:

1 Solid State Physics

Pub(2006)

2 A Text book of Engg. Physics

& Co

3 Elementary Solid State Physics

4 Electronic Devices and Circuits

(2002)

References:

1. Lasers and Non Linear Optics

2. Lasers Principles, Types and

Applications

3. Concepts of Modern Physics

Edition.

4. Modern Physics

5. Introduction to Solid State Physics

6. Fundamentals Of Physics

Mechanical Engineering (UG)

S.O. Pillai, 5thedition, New Age International

M.N.Avadhanulu & P.G.Kshirasagar., S.Chand

M A Omar, Addison-Wesley Publishers

J. Millmann & C.C. Halkias,Tata McGraw Hill

B.B. Laud, Wiley Eastern Ltd

K R Nambiar, New Age International

Arthur Beiser, 6th edition, Tata McGraw-Hill

Kenneth S Krane, John Wiley & sons

C. Kittel.

Resnick and Halliday,extended 3rd edition, John

Wiley & Sons

Self Assessment Report

Page No.: 9

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

7. Introduction to solids

8. Solid State Physics

9. Physics for Engineers

L. V. Azaroff

A. J. Dekkar

M.R. Shriniwasan New Age International.

Evaluation Scheme:

Course Unitization for Minor Exams and Semester End Examination

1. The questions for minor examination will be chosen approximately in line with the

hourly weightage of that chapters in that Unit.

2. The SEE will have the weightage as follows.

Scheme of CIE:

Assessment

Minor Exam I

(Unit- I)

Minor Exam II

(Unit-II)

Assignment/Quiz

Total

Weightage in Marks

20

20

10

50

Unit Chapters

II

III

Photonics

Crystal Structure and X-ray

Diffraction

Dielectrics

Quantum Physics

Conductivity in Solids

Magnetic materials and

Ultrasonics

Nanoscience and Nanotechnology

Mechanical Engineering (UG)

No of Questions in SEE

Teaching

1

2

5

10 M Total

Hours

M

M

M

10

06

04

10

10

05

10

4

out

of

5

6 out

of 8

05

Self Assessment Report

Page No.: 10

100

Converted

for 50

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

Course Code :

Course Title

:

Teaching Hours :

Course Content

CVC103

Engineering Mechanics

50

L-T-P-S: 4-0-0-0

CIE: 50

SEE: 50

Course Outcomes

1. Explain the basic principles upon which the study of engineering Mechanics is based.

2. Explain the effect of force systems acting on a particle or body.

3. Demonstrate the ability to use the basics of mathematics, physics and engineering

mechanics in solving simple problems of day today life.

4. Locate the position of centroid of a plane and also to find moment of inertia of a plane

about a given axis.

5. Calculate various parameters related to motion of a body (force, velocity, distance and

time) using work - energy and impulse- momentum principles

Course Content

UNIT I

Coplanar concurrent force system Introduction to Engineering Mechanics:

Basic idealizations Particle, Continuum, Body, Rigid body Deformable body,

Definition of force and its elements; Laws of Mechanics Parallelogram law of 03hrs

forces, Principle of transmissibility, Law of Superposition, Newtons laws of

motion. Classification of force systems

Resultant of coplanar concurrent force system :

Definitions Resultant, composition & Resolution of a force, Equilibrium, 04 hrs

Equilibrant, Formulae for resultant of forces and resolution of a force. Numerical

problems on resultant of forces.

Equilibrium of coplanar concurrent force system:

Conditions of equilibrium, Action & Reaction, Free body diagram, Lamis

05 hrs

theorem. Numerical problems on equilibrium of forces.

Coplanar non-concurrent force system

Resultant of a force system: Moment, moment of a force, couple, moment of a

couple, Characteristics of couple, Equivalent force-couple system, Numerical 05 hrs

problems on moment of forces and couples, on equivalent force-couple system.

Varignons principle of moments, Resultant of coplanar- non-concurrent force

systems and numerical problems.

Equilibrium of a force system

Conditions of equilibrium, types of support and loading for a statically determinate

05 hrs

beam, Reactions at support connections, Numerical problems on equilibrium of

force systems and support reactions for a statically determinate beam.

UNIT II

Static Friction

Introduction, types of friction, definition, limiting friction, coefficient of friction, 08 hrs

laws of Coulomb friction, angle of friction and angle of repose, cone of friction.

Wedge and belt friction theory. Derivation of belt friction formula. Numerical

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 11

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

problems on, impending motion on horizontal and inclined planes (including

connected bodies); wedge friction; Ladder friction and Belt friction

Centroid and Moment of Inertia of Plane Figures Centroid

Introduction, Definition, Methods of determining the centroid, axis of reference, axis

of symmetry, Locating the centroid of simple plane figures (triangle, semicircle, 05 hrs

quadrant of a circle and sector of a circle etc,.) using method of integration,

Numerical problems on Centroid of simple built up sections.

Moment of Inertia

Introduction, Definition, Method of determining the MI, Section Modulus, Radius of

gyration, perpendicular and Parallel axis theorems, Polar MI, MI of simple plane 05 hrs

figures (triangle, rectangle, semicircle, circle etc,.) using method of integration,

Numerical problems on MI of simple built up sections.

UNIT III

1. Kinetics of a particleWork, Power, Energy

Introduction Kinematics and Kinetics, Definitions work, power and energy.

Work done by a force (constant, gravitational and spring forces) in rectilinear 06 hrs

motion. Numerical problems, Kinetic energy of a particle, principle of work and

energy.

Impulse and Momentum

04 hrs

Introduction, Definitions, principle of Impulse and Momentum, conservation of

Momentum.Numerical problems.

Text Books:

1. Beer, F.P. and Johnston, R., Mechanics for Engineers: Statics, McGraw Hill Company,

New York, 1988.

2. Bhavikatti, S.S.& Rajasshekarappa K.G., Engineering Mechanics, 3Ed., New Age Int.

Pub. Pvt. Ltd., New Delhi, 2008.

3. Kumar, K.L., Engineering Mechanics, Tata McGraw Hill Publishing Company, New

Delhi, 2000.

References:

1. Jagadeesh, T.R. and Jayaram, Elements of Civil Engineering, Sapna Book House,

Bangalore, 2006.

2. Ramamrutham, S., Engineering Mechanics, Dhanpat Rai Publishing Co., New Delhi,

1997.

3. Singer, F.L., Engineering Mechanics, Harper Collins, 1994

4. Timoshenko, S.P. and Young, D.H., Engineering Mechanics, McGraw Hill Publishing

Company, New York, 1940.

Evaluation Scheme:

Course Unitization for Minor Exams and Semester End Examination

1. The questions for minor examination will be chosen approximately in line with the

hourly weightage of that chapters in that Unit.

2. The SEE will have the weightage as follows.

Scheme of CIE:

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 12

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

Assessment

Weightage in Marks

Minor Exam I (Unit-I)

20

Minor Exam II (Unit-II)

20

Assignment

10

Total

50

No of Questions in SEE

Teaching

1

2

5

10

Total

Hours

M

M

M

M

M

Unit Chapters

II

III

Coplanar concurrent force system

12

Coplanar non-concurrent force

system

Static Friction

10

Centroid and Moment of Inertia of

Plane Figures

10

Kinetics of a particleWork, Power,

Energy

06

Impulse and Momentum

04

08

10

100

4

6

out out Converted

of 5 of 8 for 50

Course Content

Course Code :

Course Title

:

Teaching Hours :

MEC105

Elements of Mechanical Engineering

50

L-T-P-S: 4-0-0-0

CIE: 50

SEE: 50

Course Outcomes

1. Explain the need, benefits and applications of various renewable energy sources.

2. Differentiate between reciprocating and rotary prime movers.

3. Classify turbines, IC engines and describe their principle of working.

4. Identify the characteristics of successful product development which leads to an economic

success of any manufacturing firm believing strongly that identification of the needs of

customers and quickly create products that meet these needs and can be produced at low

cost is a product development problem not solely marketing problem,nor is it solely design

problem or a manufacturing problem.

5. Define a product development process as the sequence of steps or activities, which an

enterprise employs to conceive,design,and commercialise a product and practice this with

real time product development examples.

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 13

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

6. State the necessity of product planning process which takes place before a product

development project is formally approved,before substantial resources are applied,and

before the larger development team is formed and further compare and contrast the theory

with practice by taking real time examples.

7. Identify various manufacturing processes available to produce the products as per

customer requirements.

8. Explain the importance of quality control concepts in maintaining the quality of the

product.

UNIT I

1. Energy Sources:

Forms, Sources and Classification of energy sources Non .Renewable energy

sources: Coal, Oil and Natural Gas, R/P Ratio of Conventional Energy Sources,

Renewable energy sources Solar energy, Wind energy, Tidal energy, Hydel

energy, Ocean thermal energy and Geothermal energy. Utilization of energy with

simple block diagrams

2.Turbines:

Steam turbines: Classification of steam turbines , Principle of operation of

Impulse and reaction turbine. Velocity, Pressure and Velocity & Pressure

Compounding of Steam Turbines.

Gas turbines Classification, Working principles and Operations of Open cycle

and Closed cycle gas turbines.

Water turbines Classification, Principles and operations of Pelton wheel,

Francis turbine and Kaplan turbine.

3.Internal Combustion Engines:

Classification, I.C. Engines parts, 2/4 Stroke Petrol and 4-stroke diesel engines.

P-V diagrams of Otto and Diesel cycles. Simple problems on indicated power,

brake power, indicated thermal efficiency, brake thermal efficiency, mechanical

efficiency and specific fuel consumption.

UNIT II

08Hours

06 Hours

06 Hours

4.Introduction to Product Development

Characteristics of Product Development, Who designs & develops products?,

Duration and Cost of development, Challenges of product development,

Morphology of Design

5.Product planning and process and 5 steps

02 Hours

3Hour

03 Hours

6. Identify the customer needs. 5 steps

7.Technology and Sustainable Development:

Sustainable development and well being, History, definition and understanding

of sustainability and sustainable development, Presentation of general case

studies explaining how certain human practices have over the years become

unsustainable, Indictors of sustainable development, why engineering for

sustainable development, Sustainability issues in Engineering and innovation.

8. Product specifications: What are specifications, when they are established

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 14

08 Hours

01 Hours

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

02 Hours

9.Concept generation : 5 steps

UNIT III

Design and Documentation

02 Hours

Prototype basics & types

02 Hours

Overview of Manufacturing processes

04 Hours

Quality Control

02 Hours

Text Books:

1. Gopalkrishna K.R. A Text Book of Elements of Mechanical Engineering , Subhash

Publishers, Bangalore.

References:

1. S.Trymbaka Murthy, A text Book of Elements of Mechanical Engineering ,

I.K.International Publishing House Pvt .Ltd., Bangalore

2. El. Wakil, Power Plant Engineering , Tata McGraw Hill

3. G.D.Rai,, Non Conventional Sources of Energy Khanna Publishers,2B,NathMarket,Nai Sarak,Delhi-110006

4. SKH Chowdhary, AKH Chowdhary, Nirjhar Roy, The Elements of Workshop

Technology - Vol I & II , 11th edition 2001, Media Promotors and Publishers,

5. Geoffrey Boothroyd, Winston A Knight, ,Fundamentals of Machining and Machining

Tools- CRS Press Book, Taylor and Franicis Group, 270,Madison Avenue, New

York

6. Dieter, Engineering Design-, McGraw-Hill

7. Course material developed by Department of Mechanical Engineering

8. Product Design and Development Karl T Ulrich and Steven D Eppinger

Evaluation Scheme:

Course Unitization for Minor Exams and Semester End Examination

1. The questions for minor examination will be chosen approximately in line with the

hourly weightage of that chapters in that Unit.

2. The SEE will have the weightage as follows.

Scheme of CIE:

Assessment

Weightage in Marks

Minor Exam I (Unit- I)

20

Minor Exam II (Unit-II)

20

Assignment/Quiz

05

Chapter End Quizes

05

Total

50

Unit Chapters

Mechanical Engineering (UG)

Teaching No of Questions in SEE

Self Assessment Report

Page No.: 15

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

Hours

II

III

Energy Sources

08

Turbines

06

Internal Combustion Engines

06

Introduction to Product Development

02

Product planning and process

04

Identify the customer needs

03

Technology and Sustainable

Development

08

Product specifications

01

Concept generation

02

Design and Documentation

02

Prototype basics & types

02

Overview of Manufacturing

processes

04

Quality Control

02

Mechanical Engineering (UG)

1

M

10

Self Assessment Report

2

M

5

M

10

M

Total

6

out

of 8

100

4

out

of 5

Page No.: 16

Converted

for 50

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

Course Code :

Course Title

:

Teaching Hours :

Course Content

EEC105

Basic Electrical Engineering

50

L-T-P-S: 4-0-0-0

CIE: 50

SEE: 50

Course Outcomes

1. Analyze electric and magnetic circuits (3a/H)

2. Explain the significance of power factor and choose the appropriate load for

maximum power efficiency

3. (3b/M, 3c/L)

4. Distinguish between different DC motors and choose a particular motor for a definite

application (3c/H)

5. Recognize the application of transformer in transmission and distribution of electrical

energy (3i/H)

6. Outline the importance of energy conservation and explain the various non

conventional energy sources (3j/H)

UNIT I

1.D.C. Circuits

Network Analysis by Maxwells circulating currents, constant current generator,and 4 Hrs

Node voltage method of analysis.

2. Simple Magnetic Circuits

4 hrs

Introduction to magnetic circuits mmf, permeability, reluctance, comparison of

electric & magnetic circuits, series magnetic circuits.

3.Single phase A.C Circuits

Introduction AC circuits and theory of generation of sinusoidal alternating voltage.

Concept of average and effective (RMS) values, Form Factor, Peak Factor of

sinusoidally varying Voltage & Current. Average and effective values of A.C. 12hrs

Alternating current, voltage and power in resistive ,inductive and capacitive circuits

,R-L series, R-C series, RLC series Circuit, Measurement of energy in single phase

AC circuit, energy meter.

UNIT II

4.Three Phase Systems

6 hrs

Disadvantages of the single phase systems and generation of three phase e.m.f.s,

Star and Delta connections of three phase windings, Voltage and currents in a star

and delta connected systems, Power in a three phase systems with balanced load,

Measurement of active power & power factor by means of two wattmeters, necessity

of ear thing.

5.D.C Machines

Working principle of D.C machine as Generator and as a Motor. Constructional

features of D.C machine, EMF equation of generator, dc shunt generator and simple 8 hrs

problems on it. Back EMF and torque equation of motor and simple problems on the

same. DC shunt motor and DC series motor Characteristics of D.C motors, and their

applications. Necessity of starter, three point starter.

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 17

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

6. Transformers

Introduction to Transformer, construction of single phase core and shell type 6 hrs

Transformer. Principle of operation, EMF equation and power losses, efficiency,

definition of voltage regulation.

UNIT III

7. Three Phase Induction Motors

Introduction to Induction motor and constructional features, Concept of rotating 5 hrs

magnetic field and principle of operation. Problems on Slip calculation. Applications

of Squirrel cage and Slip ring motors. Necessity of starters: qualitative study of stardelta starter

8.Photovoltaic & Wind Energy Systems

Typical Power ratings of electrical energy appliances, Solar PV systems and its

components, Solar PV module ratings & cost, Battery ratings & Inverter ratings & 5 hrs

cost, Maximum Power point tracking , Solar PV Lantern, Stand Alone PV

System, Wind Energy Wind flow, Power in the wind, types of wind turbines,

components of a wind turbine.

Text Books:

1. Hughes , Electrical & Electronic Technology, 8th edition, Pearson Education

2. Chetan Singh Solanki, Renewable Energy Technologies, PHI Pvt. Ltd.

References:

1. V.N. Mittle and Arvind Mittal , Basic Electrical Engineering, 2nd edition, Tata

McGraw Hill

2. B.L. Theraja, Electrical Technology, First Multicolour edition 2005, Reprint 2006, S.

Chand & Company Ltd., New Delhi.

Evaluation Scheme:

Course Unitization for Minor Exams and Semester End Examination

1. The questions for minor examination will be chosen approximately in line with the

hourly weightage of that chapters in that Unit.

2. The SEE will have the weightage as follows.

Scheme of CIE

Assessment

Weightage in Marks

Minor Exam I (Unit-I)

20

Minor Exam II (Unit-II)

20

Two objective types before minor I and II 10

Total

Unit Chapters

Mechanical Engineering (UG)

50

Teaching No of Questions in SEE

Hours

1

2

5

10 Total

Self Assessment Report

Page No.: 18

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

II

III

D.C. Circuits

04

Simple Magnetic Circuits

04

Single phase A.C Circuits

12

Three Phase Systems

06

D.C Machines

08

Transformers

06

Three Phase Induction Motors

05

Photovoltaic & Wind Energy

Systems

05

10

6

out

of

8

100

4

out

of

5

Converted

for 50

Course Content

Course Code :

Course Title

:

Teaching Hours :

HSC109

Social Innovation

50

L-T-P-S: 2-0-0-0

CIE: 50

SEE: 50

Course Outcomes

1. Develop an awareness of key social issues facing the local community and indentify

areas ripe for innovation.

2. Acquire the requisite skills to tackle social issues through innovative and sustainable

solutions.

3. Design new services/products that can improve the quality of life of individuals and

communities in local areas.

4. Build communication, analytical thinking and decision making skills to become more

effective and creative leaders.

5. Enhance knowledge of IT applications to be more competitive in a globalizing

economy.

Course Content

Module: Knowledge and Tools

Topics 1 to 10

Course overview and Introduction to Social Innovation & Global Perspectives,

Social Innovation and Leader ship, Identifying local issues and Idea generation,

Issues based problem solving Tree, creating effective Project proposals, SWOT

analysis, Engineering & Social Innovation (Part I & Part II),

exploring Stake holder analysis, Innovative fund raising and budgeting

20 hrs

Module: Development

Topics 11 to 18

Critical issue awareness (Grama Shikshna) Critical issue awareness (HIV), RTI

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 19

16 hrs

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

(session I & II), Innovative resource management, Calculated risk management,

Group presentations (Part I) Course Review and Group Presentation (Part II)

Site Visits

Topics 19 to 21

6 hrs

Akshaya Patra, Agastya Foundation, Smarthanam

Sessions Run Parallely

Topics 22 to 23

4 hrs

IT skills for aspiring entrepreneurs (Part I & Part II)

References:

Suggested sites to reference:

1. www.ashoka.org

2. http://www.fastcompany.com/social/2008/index.html

3. http://www.mindtools.com/brainstm.html

4. http://foundationcenter.org/getstarted/tutorials/prop_budgt/pbb_prep.html

5. http://www.brainstorming.co.uk/toolbox/brainstormingtoolbox.html

6. http://www.startupnation.com/pages/contact/elevator_pitch.asp

7. http://www.youtube.com/watch?v=Tq0tan49rmc

Evaluation Scheme:

Scheme of CIE:

Assessment

Weightage in Marks

Minor Exam I (Unit-I)

20

Minor Exam II (Unit-II)

20

Assignment/Quiz

05

Unit End Quizzes(Unit-I and II)

05

Total

50

Scheme for Semester End Examination (SEE)

Written Assignments 25%

Social Innovator Spotlight (T) 5%

Fact Sheet & Blog (I) 5%

Peer Evaluation #1 (I) 2%

Peer Evaluation #2 (I) 3%

Media Release & Activity Marketing Flyer (T) 5%

Field Visit Report (I) 5%

Project Implementation & Presentation 25%

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 20

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

Problem Tree & Project Proposal #1 (T) 5%

Project #1 Presentation (T) 5%

Problem Tree #2 (T)- 5%

Project Proposal #2 (T) 5%

Final Examination 50%

Project 2 Presentation (T) 25%

Written Exam (I) 25%

Course Code :

Course Title

:

Teaching Hours :

Course Content

Workshop Practice

MEL101

50

L-T-P-S: 0-0-1.5-0

CIE: 50

SEE: 50

Course Outcomes

1. Explain working of equipment used for workshop practice and the safety precautions

2. Demonstrate ability to read drawings and carry out operations such as filing, drilling,

sawing, punching, welding and sheet metal operations.

3. Explain the working of demonstrated machine tools

Course Content

UNIT - 1

Introduction to Engineering Practices Lab and workshop, and

Safety precautions in Workshop.

3 hrs.

Introduction to Fitting: Fitting Tools, Fitting Operations,

Introduction to Welding: Welding tools, Welding Operations, Types of welding,

Practice sessions for fitting.

3 hrs.

V Joint

3 hrs.

T Joint

3 hrs.

UNIT 2

Practice sessions for Welding.

3 hrs.

Lap Joint

3 hrs.

Butt Joint

3 hrs.

Sheet Metal: Tools and Operations.

3 hrs.

UNIT 3

Demonstration: Carpentry: Tools and Operations

3 hrs.

Demonstration: Lathe Machine and Milling Machine

3 hrs.

Demonstration: Grinding Machine and Shaping Machine

3 hrs.

Evaluation Scheme:

Experiments are evaluated continuously for CIE (Attendance + Practice + viva + Journal

submission)

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 21

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

One experiment is to be conducted for SEE (Selected demonstration + Viva)

Assessment

Weightage in Marks

CIE

50

SEE

50

Total

100

References:

1. The Elements of Workshop Technology -, Vol 1 & 2, S.K.H. Choudhury,

A.K.H.Choudhury, Nirjhar Roy, 11th edition, 2001, Media Promoters and Publishers,

Mumbai.

2. Shop Theory By Anderson (Tata McGraw Hill)

Course Code :

Course Title

:

Teaching Hours :

Course Content

PHL102

Engineering Physics Lab

50

L-T-P-S: 0-0-1.5-0

CIE: 50

SEE: 50

Course Outcomes

1

2

3

4

Realize theoretical concepts through experiments conducted

Co-relate the gap between theoreticalfundamentals and practical.

Get hands on experience to use different measuring instruments.

Calculate possible errors in estimation of a given parameters.

UNIT I

Measurement of wavelength of Laser using diffraction grating

3 hrs

Characteristics of Optical Fiber

Determination of Plancks Constant using the principle of photoelectric effect

Verification of Stefans T4 law and estimation of errors

UNIT II

Temperature dependence of resistivity of metal and Fermi energy.

Ultrasonic interferometer

Study of B-H curve of ferromagnetic materials.

Electrical Resistivity of Semiconductor by Four probe method

UNIT III

Measurement of Dielectric Constant

Identification of electrical passive componets.

3 hrs

3 hrs

3 hrs

3 hrs

3 hrs

3 hrs

3 hrs

3 hrs

3 hrs

Materials and Resources Required:

1. Books/References: Laboratory manual in applied Physics by H. Satyaseelan. 2001.

2. Lab Manual: Literature of experiments prepared by department of physics

Evaluation Scheme:

Assessment

Weightage in Marks

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 22

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

CIE

50

SEE

50

Total

100

Course Code :

Course Title

:

Teaching Hours :

Course Content

MAC104

Differential Equations and Vector calculus

50

L-T-P-S: 4-0-0-0

CIE: 50

SEE: 50

Course Outcomes

1 Solve linear differential equations with constant coefficients

2 Solve linear differential equations with variable coefficients using series

approximations

3 Solve application problems related electrical circuits, population growth, simple

harmonic motions etc.

4 Find gradient, divergence and curl of given point functions

5 Express Cartesian coordinate system into orthogonal curvilinear system

6 Evaluate line, surface and volume integrals using integral theorems of vector calculus

UNIT I

1. Ordinary differential Equations

Introduction, Solutions of first order & first degree equations- variables

separable-Homogeneous and Non -Homogenous, Linear and Bernoullis

equations, Exact equations and reducible to exact form, Orthogonal trajectories of

Cartesian and polar forms. Linear differential equations of second and higher

20 hours

order with constant coefficients by the method of variation of parameters. Linear

differential equations of second and higher order with variable coefficients:

Cauchys homogeneous linear equation and Legendres linear differential

equations - solutions of initial and boundary value problems. Series solution of

Differential equations-validity of series solution.

UNIT II

2. Applications of differential equations: Newtons law of cooling, population

growth, Electrical circuits, motion of a boat across a stream, Simple harmonic

05 hours

motion. Spring mass system (damped).

3. Vector differentiation

Vector point functions, Velocity, Acceleration, Gradient of a scalar function,

Divergence of vector function, Curl of vector function, Laplacian, Solenoidal and 15 hours

Irrotational vectors and their properties. Orthogonal curvilinear coordinatesCylindrical polar coordinates, Spherical polar coordinates.

UNIT III

4. Vector integration

05 hours

Line integral, surface integral and volume integrals-examples

Integral theorems: Greens theorems, Gauss-divergence, Stokes theorem with

05 hours

simple problems.

Text Books:

1. Grewal B S, Higher Engineering Mathematics, 38ed, Khanna Publication, New

Delhi, 2001

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 23

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

2. Bali and Iyengar, A text book of Engineering Mathematics, 6ed, Laxmi

Publications(p) Ltd, New Delhi, 2003.

References:

1. Kreyszig, E., Advanced Engineering Mathematics, 8ed, John Wiley & sons, 2002.

2. Simmons G F and Krantz S G, Differential Equations, TATA McGraw-Hill, 2007.

3. Denniss G Zill and Michael R Cullen, Advanced Engineering Mathematics, 3ed,

Narosa Publishing House, 2009.

Evaluation Scheme:

Course Unitization for Minor Exams and Semester End Examination

1. The questions for minor examination will be chosen approximately in line with the

hourly weightage of that chapters in that Unit.

2. The SEE will have the weightage as follows.

Scheme of CIE:

Assessment

Minor Exam I (Unit-I)

Minor Exam II (Unit-II)

Assignment/Quiz

Total

Unit Chapters

I

II

III

Differential Calculus

Indeterminate forms and

series expansion

Integral Calculus

Multiple Integrals

Weightage in

Marks

20

20

10

50

No of Questions in SEE

Teaching

1M

2 5

10 M

Hours

M M

20

4

05

out 6 out of

10

5

of 8

15

5

10

Total

M

100

Converted

for 50

Course Content

Course Code :

Course Title

:

Teaching Hours :

CHC102

Engineering Chemistry

50

L-T-P-S: 4-0-0-0

CIE: 50

SEE: 50

Course Outcomes

1 Determine the calorific value of a fuel and explain the various techniques involved in

assessing the quality of the fuel.

2 Describe the concepts of electrode potential and standard electrode potential and

calculate the emf of a cell.

3 Describe the construction, working and applications of primary batteries, secondary

batteries, reserve batteries and fuel cells.

4 Explain the tendency of fast depletion of fossil - fuels and identify bio-fuels as a

perennial source of energy.

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 24

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

5 Describe the manufacture of solar grade silicon for PV cells.

6 Explain the mechanism of corrosion and discuss the various methods of

corrosion control.

7 Explain the basic terms involved in polymer chemistry and outline the synthesis,

properties and applications of different polymers.

8 Outline the desirable applications of conducting polymers in batteries, circuit boards,

sensors and fuel cells.

9 List out various natural sources of water and describe the techniques involved in

purification of water.

10 Explain the mechanism of lubrication of lubricants and analyze their specific usage in

engineering fields.

Course Content

UNIT I

Chapter 1:Chemical Energy Systems:

Energy; Fuels definition, classification; Calorific value definition, Gross and

Net calorific values, Units (S.I). Experimental determination of calorific value

of solid and liquid fuels by Bomb calorimeter. Numerical problems on Bomb 7 hrs.

calorimeter. Petroleum cracking Fluidized catalytic cracking. Reforming of

Petrol. Knocking Petrol and Diesel knocking.

Octane number, Cetane

number. Prevention of knocking anti knocking agents unleaded petrol.

Chapter 2:Electrochemical Energy systems & Electrical storage systems:

Single electrode potential definition, standard electrode potential definition.

Derivation of Nernst equation. Galvanic cell definition, classification

primary, secondary and concentration cells. Energetics of cell reactions.

Numerical problems on electrode potential, EMF and concentration cells.

Types of electrodes and their applications.

7 hrs

Batteries basic principle components of a battery; classification of batteries

primary, secondary and reserve batteries. Battery characteristics. Construction,

working and applications of Li-MnO2 battery (Primary),

Pb-acid and Zn air batteries (secondary)

battery).

and Li-V2O5 battery (Reserve

Chapter 3: New and Renewable Energy Sources

Biofuels power alcohol, biodiesel, synthetic petrol Fischer Tropsch method,

hydrogen as a source of energy. Solar energy manufacture of solar grade

silicon by diffusion technique, properties and application of silicon in PV cells. 6 hrs.

Fuel cells types of fuel cells solid polymer electrolyte fuel cells and solid

oxide fuel cells. Construction and working of H2 O2 and Methanol

O2 fuel cells.

UNIT II

Chapter 4: Corrosion Science and Metal Finishing

7 hrs.

Definition, electrochemical theory of corrosion. Types of corrosion

differential aeration, differential metal and stress corrosion. Factors affecting

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 25

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

rate of corrosion, measurement of corrosion rate. Control of corrosion

Inorganic coating anodizing and phosphating, Metal coating galvanization

and tinning, Anodic protection method and cathodic protection impressed

current method.

Metal finishing Technological importance. Electroplating significance of

polarization, decomposition

potential and overvoltage. Electroplating of

copper. Electroless plating meaning,

advantages over electroplating,

electrolessplating of copper and PCB preparation.

5 Chapter 5: High Polymers

Polymers-introduction, definitions of basic terms involved, classification based

on the different parameters based on chain structure, chain components,

intermolecular forces and thermal behavior. Types of polymerizations - addition

and condensation with examples.

Mechanism of addition polymerization taking Ethylene as an example. Number

average and weight average molecular weight, molecular weight determination

of a polymer by viscometer. Glass transition temperature and its significance.

Techniques of polymerization emulsion polymerisation. Synthesis, properties

and applications of PMMA, Polyurethane. Elastsomers meaning, advantages

of synthetic rubber over natural rubber. Synthesis, properties and applications of

Neoprene and Butyl rubber. Adhesives meaning, preparation, properties and

applications of Epoxy resins.

Chapter 6: Conducting Polymers and Membranes

Conducting Polymers: Introduction, mechanism of conduction in

Polyacetylene. Structures of conducting polymers Polyaniline (PA),

Polypyrrole (PPY), and Polythiophene (PTH). Applications of conducting

polymers in batteries, circuit board, sensors, electrochromic displays and fuel

cells.

6 hrs.

Membranes: Introduction, types of membranes, polymer selection for

development of membranes, modification of membranes- cross linking,

grafting, blending, copolymerization, hybrid networking. Preparation of

Polyvinyl alcohol. Applications of membranes in Reverse osmosis,

Electrodiolysis and Pervaporation.

UNIT III

Chapter 7: Water Technology

Natural sources of water impurities in water. Water analysis Determination

of Total Hardness (EDTA method) numerical problems; Determination of 5 hrs.

Flouride by SPADNS Method and Nitrate by Phenol disulphonic acid

method.Sewage Biological Oxygen Demand, Chemical Oxygen Demand

definition, experimental determination. Numerical problems on BOD and COD.

Chapter 8: Engineering Materials

Lubricants: Introduction - Definition, mechanism of lubrication, Classification

- Solid lubricants, semi solid lubricants and liquid lubricants; properties, 5 hrs.

additives, significance and applications.

Liquid crystals: Introduction; classification thermo tropic and lyotropic with

examples. Molecular ordering in liquid crystals Nematic, Chiral nematic

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 26

hrs.

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

(Cholesteric), Smectic and Columnar phases.; Applications of liquid crystals.

Text Books:

i) Dara. S. S, A text Book of Engineering Chemistry, 11th edition, 2nd reprint, S. Chand &

Co. Ltd., New Delhi, 2009.

ii) Jain P.C and Jain M, A text Book of Engineering Chemistry, 16th edition, Dhanapatrai

Publications, New Delhi, 2006.

References:

i)

ii)

iii)

iv)

v)

vi)

vii)

viii)

ix)

Sharma B.K., Engineering Chemistry, Krishna Prakashan media Pvt. Ltd., Meerut,

1999.

Puri B. R., Sharma L.R. and Pathania M. S., Principles of Physical Chemistry, 33rd

Edition, S Nagin Chand & Co.,1992.

Fontana M G, Corrosion Engineering, Mc Graw Hill Publications, 1986.

Billmeyer F W, Text Book of Polymer Science, John Wiley & Sons, 1994.

Winston Ho W. S. and Kamalesh K. Sirkar, Membrane Hand Book, Kluwer

Academic

Publishers, 2001.

Gowariker V.R, Viswanatan N.V, Sreedhar J. Polymer Science, New Age

International (P) ltd., 2007

Purohit S.S, Biotechnology fundamentals and applications, Agrobias, Jodhapur, 1st

edition 2001.

Davis Fred J, Harood C M, Moody C J, Polymer Chemistry, The Practical Approach

in Chemistry, Oxford University Press.

Chilton J. A and Goosey M. T., Special Polymers for Electronics & Optoelectronics,

Edited by Chapman & Hall London SE18HN, Madras, First Edition, 1995.

Evaluation Scheme:

Course Unitization for Minor Exams and Semester End Examination

1. The questions for minor examination will be chosen approximately in line with the

hourly weightage of that chapters in that Unit.

2. The SEE will have the weightage as follows.

Scheme of CIE:

Assessment

Weightage in Marks

Minor Exam I (Unit-I)

20

Minor Exam II (Unit-II)

20

Assignment/Quiz

10

Total

50

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 27

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

Teaching No of Questions in SEE

Hours

1 M 2 M 5 M 10 M Total M

Unit Chapters

II

III

Chemical Energy Systems

07

Electrochemical Energy

Systems & Storage of

Electrochemical Energy

07

New and Renewable Energy

Sources

06

Corrosion Science and Metal

Finishing

07

High Polymers

07

Conducting Polymers and

Membranes

06

Water Technology

05

Engineering Materials

05

Mechanical Engineering (UG)

10

Self Assessment Report

4

out

of 5

6 out

of 8

Page No.: 28

100

Converted

for 50

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

Course Code :

Course Title

:

Teaching Hours :

Course Content

CSC103

Programming Fundamentals with C

50

L-T-P-S: 4-0-0-0

CIE: 50

SEE: 50

Course Outcomes

1 Explain the process of problem solving using computer.

2 Design an algorithmic solution for a given problem.

3 Write a maintainable C program for a given algorithm and implement the same.

4 Interpret a given C program.

5 Debug a given C program

Course Content

UNIT I

1.

Introduction to Computer Problem Solving and Fundamental

Algorithms

Introduction, The problem-solving Aspect, Top-down Design, Implementation of

7 Hours

Algorithms, Algorithm Notations, Flowcharts, Exchanging the Values of Two

Variables, Counting, Summation of a Set of Numbers, Factorial Computation, Sine

Function Computation, Generation of the Fibonacci Sequence, Reversing the

Digits of an Integer..

2.

Factoring Methods and Array Techniques

Finding the Square Root of a Number, The Smallest Divisor of an Integer, The

Greatest Common Divisor of Two Integers, Generating Prime Numbers, Array

Order Reversal, Array Counting or Histogrammig, Finding the Maximum Number

in a Set, Removal of Duplicates from an Ordered Array.

3.

7 Hours

Sorting, Searching and Text Processing

Sorting by Selection, Sorting by Exchange, Linear Search, Binary Search, Text

Line Length Adjustment, Left and Right Justification of Text.

6 Hours

UNIT II

4.

Functions

Designing Structured Programs, Functions in C, User Defined Functions, InterFunction Communication, Standard Functions, Scope, Recursion

5.

Arrays

Concepts, Using Arrays in C, Arrays in Inter-Function Communication, OneDimensional Arrays, Two-Dimensional Arrays

6.

7 Hours

7 Hours

Pointers

Introduction, Pointers for Inter-Function Communication, Pointers to Pointers,

Compatibility, Lvalue and Rvalue, Arrays and Pointers

UNIT III

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 29

6 Hours

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

7.

Pointer Applications and Strings

Passing an Array to a Function, Arrays of Pointers, C Strings, String Input/Output

Functions, Arrays of Strings, String Manipulation Functions

8.

5 Hours

Enumerated, Structure and Union Types

The Type Definition(typedef), Enumerated Types, Structure, Unions

5 Hours

Text Books:

1. Balaguruswamy, E. Programming in ANSI C, 3ed., Tata McGraw Hill, 2004.

References:

1. Campus Connect, Infosys Foundation Program, Vol. 1, 2006

2. Gottfried, B.S., Programming with C, 2ed., Tata McGraw Hill , 2006

3. Kernighan, B.W. and Ritchie, D.M., The C Programming Language, 2ed. Prentice

Hall of India, 2004.

Evaluation Scheme:

Scheme of CIE:

Assessment

Weightage in Marks

Minor Exam I (Unit I)

20

Minor Exam II (Unit II)

20

Assignment/Quiz

05

Unit End Quizzes(Unit-I and

II)

05

Total

50

Course Unitization for Minor Exams and Semester End Examination

No of Questions in SEE

Teaching

1

2

5

10 Total

Hours

M M M M

M

Unit Chapters

II

Introduction to Computer Problem

Solving and Fundamental Algorithms

Factoring Methods and Array

Techniques

Sorting, Searching and Text

Processing

Functions

Arrays

Pointers

Mechanical Engineering (UG)

Self Assessment Report

10

4

out

of

5

6

out

of

8

Page No.: 30

100

Converted

for 50

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

III

Pointer Applications and Strings

Enumerated, Structure and Union

Types

Course Code :

Course Title

:

Teaching Hours :

Course Content

MEC110

Computer Aided Engineering Drawing

50

L-T-P-S: 4-0-0-0

CIE: 50

SEE: 50

Course Outcomes

1 Orthographic projections of points, lines and solids and sectional views of simple

solids such as prisms, pyramids, cylinders and cones using First Angel Method of

Projection

2 Development of lateral surfaces of solids, truncated solids, frustums and transition

pieces

3 Orthographic projections of simple solids and their combinations and to convert them

into isometric projections/views

4 Convert pictorial views into orthographic projections with or without section and

finally transform his vision of a product into orthographic views

UNIT I

1. Introduction to Computer Aided Sketching:

Introduction, Engineering Drawing, Computer screen, layout of the software,

standard tool bar/menus and description of most commonly used tool bars,

navigational tools. Co-ordinate systems. Creation of 2D/3D environment.

Selection of drawing size and scale. Commands and creation of Lines, Co- 12 Hours

ordinate points, axes, poly-lines, square, rectangle, polygons, splines, circles,

ellipse, text, move, copy, off-set, mirror, rotate, trim, extend, break, chamfer,

fillet, curves, constraints viz. tangency, parallelism, inclination and

perpendicularity. Dimensioning, line conventions.

2. Orthographic Projections :

Principles of projections, VP. H.P and Profile Planes. Projection of points and 06 Hours

straight lines in first quadrant

3.Projections of Solids (First Angle Projection Only) :

Introduction, Definitions Projections of right regular tetrahedron, hexahedron 06Hours

(cube), prisms, pyramids, cylinders and cones and their frustum in simple

positions : axis perpendicular to either HP or VP

4.Development of Lateral Surfaces :

Sections of Solids in simple position and Development of lateral surfaces of 15 Hours

above solids, their frustums and truncations and transition pieces.

UNIT II

5.Isometric view :

15 Hours

Introduction, Isometric projections and views of simple solids, Isometric view of

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 31

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

combination of solids

UNIT III

6.Conversion of Isometric views in to orthographic projections:

Conversion of pictorial views into orthographic projections of simple machine

parts with and without section .

18 Hours

Text Books:

1. Engineering Drawing - N.D. Bhatt & V.M. Panchal, 48th edition, 2005-Charotar

Publishing House, Gujarat.

2. Engineering Graphics - K.R. Gopalakrishna, 32nd edition, 2000- Subash Publishers

Bangalore.

References:

1 Fundamentals of Engineering Drawing with an Introduction to Interactive Computer

Graphics for Design and Production-Luzadder Warren J., Duff John M., Eastern

Economy Edition, 2005-Prentice-Hall of India Pvt. Ltd., New Delhi.

Conducting classes

Classes may be conducted in two slots/ week of 3 hours each (Instruction 1 hr. +Sketching &

Practice ( 2 hr.)

Evaluation Scheme:

Scheme of CIE:

Assessment

Weightage in Marks

Minor Exam I (Unit-I)

15

Minor Exam II (Unit-II)

15

Assignment

20

Unit End Quizzes(Unit-I and II)

---

Total

50

Course Unitization for Minor Exams and Semester End Examination

No of Questions in

Teaching

Minor

Minor

Hours

Exam 1

Exam 2

Unit Chapters

No of

Questions

in SEE

Projections of Solids (First Angle

Projection Only)

06

--

--

Development of Lateral Surfaces

15

--

II

Isometric view

15

--

III

Conversion of Isometric views in to

18

--

--

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 32

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

orthographic projections

Course Content

Course Code :

Course Title

:

Teaching Hours :

ECC105

Basic Electronics

50

L-T-P-S: 4-0-0-0

CIE: 50

SEE: 50

Course Outcomes

1 Apply the Boolean algebra to design and simplify various logical expressions.

2 Explain the basic principles of communication system and study their related

applications in telegraphy,telephony and superheterodyne receiver.

3 Design circuit to perform signal operations,such as signal addition,integration using

operational amplifier,which are used in consumer and industrial electronics.

4 Describe the functionality of the cathode ray oscilloscope that is used as a measuring

instrument.

5 Analyze the characterstics of semiconductor devices and their applications in

rectifiers,amplifiers and oscillators.

UNIT I

1.

Semiconductor Diode and its Applications

Qualitative analysis of PN junction, PN junction diode, characteristics and

parameters, diode approximations, temperature dependence of PN

characteristics. half wave rectifier, full wave rectifier (centre tap and bridge),

capacitor filter and its approximate analysis, numerical examples as applicable.

Zener diode and its applications

10 Hours

2.

Transistor BJT, transistor voltages and currents, amplification,

transistor configurations CB, CE, CC. DC load line and numerical.

3.

Transistor Biasing methods

05 Hours

Need for biasing, different biasing techniques (base bias, collector bias and

voltage divider bias) and their comparisons. Thermal stability of biasing

circuits.

UNIT II

05 Hours

4. Application of transistors

Amplifiers: Cascading, RC coupled amplifier (single and two stage) and its

frequency response. Oscillators: Barkhausen criterion, RC phase shift

Oscillator, Principle of oscillation (Tank circuit), Crystal oscillator.

05 Hours

5. Digital Logic

Decimal, Binary, Octal and Hexadecimal number systems, Conversions,

Addition and subtraction in different number systems. Logic gates: AND, OR,

12 Hours

NOT, NAND, NOR, Ex-OR, Ex-NOR, Boolean algebra: Theorems and

postulates, DeMorgans Theorems, simplification of logical expressions, Design

of Half Adder and Full Adder, Parallel Adder using full adders.

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 33

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

6. Cathode Ray Oscilloscope

Block diagram of PRO, block diagram of CRT, Measurement of amplitude,

frequency and phase of a given signal

UNIT III

7. Operational Amplifier

Ideal op-amp characteristics, op-amp applications: Comparator, Inverting

amplifier, Non inverting amplifier, Voltage follower, Integration,

Differentiation, Adder, Subtractor, and numerical as applicable.

05 Hours

8. Communication Systems.

Basic block diagram of communication system, Need for modulation, Different

modulation techniques: AM, FM, their comparison and numerical as applicable.

Super heterodyne receivers.

05 Hours

Text Books:

1 DEVID a Bell, ELECTRONICS DEVICES AND CIRCUITS, phi new Delhi, 2004

2 K.A.KRISHNAMURTHY AND M.R Raghuveer, Electrical, Electronics and

Computer Engineering for Scientist and Engineers, Second Edition New age

International Publications, Wiley Eastern,2001

References:

1.

2.

3.

4.

5.

6.

A.P Malvino, Electronics Principles Sixth edition Tata McGraw Hill, 1999

George Kennedy, Electronics Communication System Fourth Editions Tata

McGraw Hill, 2000

Morris Mano, Digital logic and computer design 21st Indian print prentice Hall

India 2000

Floyd, Digital Fundamentals Third Edition prentice Hall India 2001

Boylestead Nashelsky, Electronics devices and circuits theory Sixth Edition

prentice Hall India 2000.

Ramakant Gayekawad Operational Amplifiers and applications Third Edition,

prentice Hall India 2000.

Evaluation Scheme:

Course Unitization for Minor Exams and Semester End Examination

1. The questions for minor examination will be chosen approximately in line with the

hourly weightage of that chapters in that Unit.

2. The SEE will have the weightage as follows

Scheme of CIE:

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 34

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

Assessment

Weightage in Marks

Minor Exam I (Unit- I)

20

Minor Exam II (Unit- II)

20

Assignment/Quiz

--

Unit End Quizzes(Unit-I and II)

10

Total

50

Uni

t

No of Questions in SEE

Teaching

1

2

5

10 M Total M

Hours

M M M

II

III

Chapters

Semiconductor Diode and its

Applications

10

Transistor

Transistor Biasing methods

Application of transistors

Digital Logic

10

Cathode Ray Oscilloscope

Operational Amplifier

Communication Systems.

10

4

out

of

5

6 out

of 8

100

Convert

ed for 50

Course Content

Course Code :

Course Title

:

Teaching Hours :

HSC105

Professional Communication

50

L-T-P-S: 4-0-0-0

CIE: 50

SEE: 50

Course Outcomes

1 Implement the unique techniques that are imparted for continuous upgrading of the

language.

2 Gain self confidence,associate with high-use domain in English communication and

asses themselves through continuous monitoring to attain linguistic refinement.

3 Express authentic sentences and expression with proper stress,intonation and pause in

accordance with various situations.

4 Use rephrased forms and indiredt speech appropriately in oral presentation as well as

in effective formal writing like project reports,abstracts,formal letters etc.

5 Give presentation on any topic of their interest by gathering information from various

sources of knowledge and attempt an analysis of other students presentations and

indentify the areas of improvement.

6 Work as a team with proper interaction and present their view points on a given issue.

Mechanical Engineering (UG)

Self Assessment Report

Page No.: 35

B.V.Bhoomaraddi College of Engineering & Technology, Hubli 31

Course Content

UNIT I

1. Linguistic data installation:

Introduction, Authenticity of corpus, Explanation of template mix-ups & error

detection.

2. Grammar & Rephrasing:

Part I: Necessity of grammar, Tense paradigms: Format and Install, Structural

practices with examples.

3. Bouncing Practice:

Definition and types of bouncing and its practice with examples.

UNIT II

4. Rephrasing Practice: