Académique Documents

Professionnel Documents

Culture Documents

Technical Information: Series 20 Axial Piston Pumps

Transféré par

Heather MurphyDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Technical Information: Series 20 Axial Piston Pumps

Transféré par

Heather MurphyDroits d'auteur :

Formats disponibles

Series 20

Axial Piston Pumps

Technical

Information

Series 20 Axial Piston Pumps

Technical Information

General Description

INTRODUCTION

Sauer-Danfoss a world leader in hydraulic power systems has developed a family of axial

piston pumps.

DESCRIPTION

Sauer-Danfoss axial piston variable displacement pumps are of swash plate design with

variable flow capability suitable for hydrostatic transmissions with closed loop circuit.

Tilting the swash plate to the opposite side of the neutral or zero displacement position

reverses flow direction.

Sauer-Danfoss axial piston variable displacement pumps are well engineered and easy to

handle.

The full-length shaft with a highly efficient tapered roller bearing arrangement offers a

high loading capacity for external radical forces.

The hydro-mechanical servo displacement control maintains the selected swash plate

position and hence pumps displacement.

Upon release of the control handle, the swash plate automatically returns to zero

position and the flow reduces to zero.

High case pressures can be achieved without leakage even at the lowest temperatures

by using suitable shaft seals.

The servo valve arrangement offers the facility to incorporate function regulators and

remote control systems.

Axial piston units are designed for easy servicing. Complete dismantling and reassembly

can be carried out with standard hand tools, and all components or sub-assemblies are

replaceable.

Axial piston variable displacement pumps of the Sauer-Danfoss pattern are made by

licensed producers worldwide, providing consistent service and fully interchangeable

parts.

TYPICAL MARKETS

Industrial

Mining

Transit Mixer

Utility Vehicles

2003 Sauer-Danfoss. All rights reserved.

Sauer-Danfoss accepts no responsibility for possible errors in catalogs, brochures and other printed material.

Sauer-Danfoss reserves the right to alter its products without prior notice. This also applies to products

already ordered provided that such alterations arent in conflict with agreed specifications. All trademarks in

this material are properties of their respective owners. Sauer-Danfoss and the Sauer-Danfoss logotype are

trademarks of the Sauer-Danfoss Group.

Front cover illustrations: F005 104, F000 248, F000 150, F000 249

DKMH.PN.315.A1.02 520L0517

Series 20 Axial Piston Pumps

Technical Information

Contents

GENERAL DESCRIPTION

Introduction ..................................................................................................................................................... 2

Description ....................................................................................................................................................... 2

Typical markets ............................................................................................................................................... 2

SECTIONAL VIEW

Axial piston variable displacement pump............................................................................................. 4

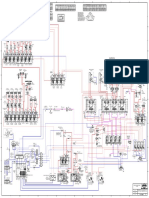

SYSTEM CIRCUIT

DESCRIPTION

Pump and motor circuit description ....................................................................................................... 5

Pump circuit schematic................................................................................................................................ 5

TECHNICAL

SPECIFICATION

Technical parameters.................................................................................................................................... 6

Design........................................................................................................................................................... 6

Type of mounting ..................................................................................................................................... 6

Pipe connections ...................................................................................................................................... 6

Direction of rotation ................................................................................................................................ 6

Installation position ................................................................................................................................. 6

External drain fluid loss .......................................................................................................................... 6

Hydraulic parameters.................................................................................................................................... 7

System pressure range, input p1 .......................................................................................................... 7

System pressure range, output p2 ....................................................................................................... 7

Case pressure ............................................................................................................................................. 7

Hydraulic fluid............................................................................................................................................ 7

Hydraulic fluid temperature range..................................................................................................... 7

Viscosity range........................................................................................................................................... 7

Filtration ....................................................................................................................................................... 7

Shaft load..................................................................................................................................................... 7

Determination of nominal pump size ............................................................................................... 8

Servo displacement control (linear response) ..................................................................................... 9

Pump flow direction ................................................................................................................................ 9

Reversing time .........................................................................................................................................10

Reset time..................................................................................................................................................11

Changing reversing and reset time..................................................................................................11

DIMENSIONS FRAME

SIZE 070 AND 089

Outline drawing, configuration PS, displacement control VML 1................................................12

Tapered shaft end ........................................................................................................................................15

Pump configuration AA 010, displacement control VML 1 ...........................................................15

DIMENSIONS FRAME

SIZE 334

Pump configuration PS, displacement control VML 1.....................................................................17

Pump configuration AA 010, displacement control VML 1 ...........................................................19

DKMH.PN.315.A1.02 520L0517

Series 20 Axial Piston Pumps

Technical Information

Sectional View

AXIAL PISTON VARIABLE DISPLACEMENT PUMP

Swash plate

Control handle

Servo valve (control valve)

Charge pump

Input shaft

Charge check valve

Shaft seal

Cylinder block assembly

DKMH.PN.315.A1.02 520L0517

Servo cylinder

P005 121E

Series 20 Axial Piston Pumps

Technical Information

System Circuit Description

PUMP AND MOTOR CIRCUIT DESCRIPTION

HEAT EXCHANGER BYPASS VALVE

RESERVOIR

VACUUM GAUGE

CONTROL

HANDLE

HEAT EXCHANGER

SERVO CONTROL CYLINDER

REVERSIBLE VARIABLE

DISPLACEMENT PUMP

SERVO

PRESSURE

RELIEF VALVES

PUMP SWASHPLATE

FIXED

DISPLACEMENT MOTOR

PURGE RELIEF VALVE

CHARGE PRESSURE

RELIEF VALVE

LOOP FLUSHING VALVE

INPUT SHAFT

MOTOR SWASHPLATE

SERVO CONTROL CYLINDER

WORKING LOOP (LOW PRESSURE)

WORKING LOOP (HIGH PRESSURE)

OUTPUT SHAFT

CONTROL FLUID

SUCTION LINE

CASE DRAIN FLUID

P000 027E

Above figure shows schematically the function of a hydrostatic transmission using an

axial piston variable displacement pump and a fixed displacement motor.

PUMP CIRCUIT

SCHEMATIC

M

4

vo

r

Se

B

L1

L2

7

S

6

Designation:

1

=

2

=

3

=

4

=

5

=

6

=

7

=

Variable displacement pump

Charge pump

Servo control valve

Charge check valve

Charge relief valve

Filter

Heat exchanger

Ports:

A, B

=

Main pressure ports

(working loop)

S

=

Suction port - charge pump

L1 , L2 =

Drain ports

M

=

Gauge port - charge pressure

P000 012

DKMH.PN.315.A1.02 520L0517

Series 20 Axial Piston Pumps

Technical Information

Technical Specification

TECHNICAL PARAMETERS

Design

Axial piston pump of swash plate design, with variable displacement.

Type of mounting

SAE four bolt flanges.

Pipe connections

Main pressure ports: SAE split flange

Remaining ports:

SAE O-ring boss

Direction of rotation

Clockwise or counterclockwise (viewing from the input shaft).

Installation position

Optional; pump housing must be always filled with hydraulic fluid.

External drain fluid loss

28

334

Typical values for 350 bar [5076 psi]

and 18 swashplate angle

24

20

5

4

3

2

1

0

External drain fluid loss (l/min)

(US gal/min)

16

12

089

8

070

0

0

1000

2000

3000

4000

Driveshaft speed n (min-1) (rpm)

P005 105E

DKMH.PN.315.A1.02 520L0517

Series 20 Axial Piston Pumps

Technical Information

Technical Specification

HYDRAULIC

PARAMETERS

System pressure range, input p1

Variable displacement pump:

Charge pressure nominal: 13 bar [189 psi] above case pressure

Charge pressure minimum: 8 bar [116 psi], intermittent only

Charge pump input pressure:

Min. allowable pressure, continuous

Min. allowable pressure, intermittent

=

=

0.75 bar [10.9 psi] absolute

0.50 bar [7.3 psi] absolute (for cold start)

Charge pump output pressure:

Max. operating pressure = 35 bar [508 psi] above case pressure

System pressure range, output p2

Pressure on port A or B: Max. operating pressure p = 420 bar [6092 psi]

Max. high pressure setting p = 460 bar1 [6672 psi]

1

only with POR-valve

Case pressure

Max. rated pressure =

Intermittent

=

2.5 bar [36.3 psi]

5.0 bar [72.5 psi]

Hydraulic fluid

Refer to Sauer-Danfoss publications Hydraulic Fluids and Lubricants and Experience with

Bio Fluids for biodegradable hydraulic fluids.

Hydraulic fluid temperature range

min = - 40 C [- 40 F]

max = 95 C [203 F]

Viscosity range

min = 7 mm2/s [49 SUS*]

max = 1000 mm2/s [4630 SUS*] (intermittent cold start)

Recommended viscosity range: 12 - 60 mm2/s [66 - 280 SUS*]

*SUS (Saybolt Universal Second)

Filtration

Required cleanliness level: ISO 4406 - 1999 Code 22/18/13 or better. Refer to SauerDanfoss publication Hydraulic Fluids and Lubricants and Design Guideline for Hydraulic

Fluid Cleanliness.

Shaft load

The pump will accept radial and axial loads on its shaft, the maximum capacity being

determined by direction and point of application of the load.

Please contact your Sauer-Danfoss representative.

DKMH.PN.315.A1.02 520L0517

Series 20 Axial Piston Pumps

Technical Information

Technical Specification

HYDRAULIC

PARAMETERS

(continued)

Technical data

Frame size

Max. displacement

cm

[in3]

Charge pump displacement

cm

[in3]

070

089

334

69.8

[4.26]

89.0

[5.43]

333.7

[20.36]

options

Minimum speed

min-1 (rpm)

Rated speed 1

min (rpm)

Mass moment of inertia of rotating group

(without charge pump)

3200

degree

12.30

[0.75]

2900

1900

18

kg m2 10-3

[lbf ft2 10-3]

12.34

[292.8]

17.77

[421.7]

161.40

[3830.0]

kg

[lb]

63

[139]

78

[172]

270

[595]

Weight

1

65.50

[4.00]

500

-1

Maximum swash plate angle

18.03

[1.10]

for higher speeds contact your SauerDanfoss reprezentative

Determination of nominal pump size

Unit:

Metric system:

Inch system

Pump

output

flow

Vg n v

Q =

1000

l/min

Vg n v

Q =

231

[gpm]

Input torque

Vg p

M =

20 m

Nm

Vg p

M =

2 m

[lbfin]

Input power

Vg n p

P =

600 000 t

kW

Vg n p

P =

396 000 t

[hp]

Efficiency characteristic curves available on request.

Vg = Pump displacement per revolution

n = Pump speed

p = Hydraulic pressure differential

p = pHD - pND

v = Pump volumetric efficiency

m = Pump mechanical efficiency

t = Pump total efficiency

pHD = High pressure

pND = Low pressure

DKMH.PN.315.A1.02 520L0517

cm3 [in3]

min-1 (rpm)

bar [psid]

bar

bar

[psid]

[psid]

Series 20 Axial Piston Pumps

Technical Information

Technical Specification

SERVO DISPLACEMENT

CONTROL

(LINEAR RESPONSE)

Regulated by the control handle on the servo valve, the swash plate can be infinitely

varied in both directions with the help of the servo system.

The pump displacement resulting from any control handle position can be established

using the figures on this page.

The angle of the control handle for stroke initiation and for the final position of the

stroke can vary from unit to unit within the range of the tolerance band.

The inter-relation of flow direction, rotation of the pump and the control handle

movement is shown below.

Pump flow direction

Flow direction changes with the direction of rotation and the control handle movement

(see above).

C

D

Null position

Maximum

displacement

Maximum displacement

Control handle

Serrated shaft

P000 013E

Movement of control

handle in direction

Pump rotation

Counterclockwise (L)

Clockwise (R)

Pressure port

OUT

Pressure port

IN

A

89.0

69.8

60

Vg [cm3]

40

25.7

20

15

23.5 20

60

[]

40

[]

80

Vg [cm3]

10

5 3 0.5

0.5 3 5

10

20 23.2

15

25.7

29.5

27 25

20

5 3 0.5

0.5 3 5

10

60

Vg [cm3]

80

25 27

20

29.5

[]

40

60

15

40

20

10

20

[]

20

15

Vg [cm3]

89.0

69.8

P000 016

SPV 2/070

P000 017

SPV 2/089

333.7

300

Vg [cm3]

250

200

150

100

[]

29.2 26.7

25

20

50

15

10

5 3 0.5

50

0.5 3 5

10

15

25 26.2

20

29.2

[]

100

150

200

250

300

Vg [cm3]

333.7

SPV 2/334

DKMH.PN.315.A1.02 520L0517

P000 021

Series 20 Axial Piston Pumps

Technical Information

Technical Specification

SERVO DISPLACEMENT

CONTROL

(LINEAR RESPONSE)

(continued)

Reversing time

Time for the directional change of the flow from Qmax , across zero to Qmax , depending

on the size of the control orifice fitted in the supply port to the servo valve (see below).

The values given assume movement of the control handle directly from one end position

to the other.

Adjustment time of handle: < minimum reserving time

Operating pressure:

p2 = 210 bar [3046 psi]

Speed:

n = 1450 min-1 (rpm)

System temperature:

50 C [122 F]

Viscosity:

35 mm2/s [164 SUS]

Frame size

Minimum reversing time (s)

without orifice

Maximum reversing time (s)

with orifice 0.66 in supply port

070

1.0

9.3

089

1.1

9.0

334

5.6

43.8

Schematic diagram of servo valve with alternative orifice positions

Orifices in the

pilot ports

Supply port with orifice

P000 056E

10

DKMH.PN.315.A1.02 520L0517

Series 20 Axial Piston Pumps

Technical Information

Technical Specification

SERVO DISPLACEMENT

CONTROL

(LINEAR RESPONSE)

(continued)

Reset time

Time for reducing the flow from either flow direction from Qmax to 0 releasing the

control handle.

Assuming no mechanical blockage of the control handles free return and assuming no

orifices in the pilot ports:

Operating pressure:

p2 = 210 bar [3046 psi]

System temperature:

50 C [122 F]

Viscosity:

35 mm2/s [164 SUS]

Frame size

Minimum reset time (s)

070

3.0

Pilot ports

089

334

Servo valve counter bored recesses for

orifice insert

5.4

Orifice in supply port

(see table on page 10)

P000 057E

Changing reversing and reset time

Inserting one orifice in each of the pilot ports can extend the reversing time. The reset

time will also be extended.

Inserting an orifice in one of the pilot ports only can extend the reversing time in one

flow direction. The reset time will be extended only for this flow direction.

DKMH.PN.315.A1.02 520L0517

11

Series 20 Axial Piston Pumps

Technical Information

Dimensions Frame Size 070 and 089 cm3

OUTLINE DRAWING,

CONFIGURATION

PS, DISPLACEMENT

CONTROL VML 1

View Z

*

**

Minimum and maximum angle , (see section

servo displacement control).

Shaft spline data: spline shaft with involute

spline, according to SAE handbook, 1963,

class 1, fillet root side fit.

D

Null position

*

Maximum

displacement

+0.3

- 0.2

Maximum

displacement

6.73 0.1

19

Control handle

R 50.8

R 25.4

Serrated shaft

P000 022E

Port "L1": Case drain port

(use highest port as outlet)

B

J

Gauge port - servo cylinder pressure

(both sides) 7/16-20 UNF-2B

SAE straight thread

O-ring boss

K

L

M

56

20

28.4

68.3

Port "S"

36.6

27.79

Counterclolcwise (L) Clolcwise (R)

rotation

rotation

57.15

M10

Charge pressure

relief valve

127 - 0.05

Coupling may not protrude

beyond 48 mm maximum

lenght of full spline

Port "B"

H

12.45 0.24

Approximate

centre of gravity

Shaft spline data:**

Pitch

=P

Pressure angle = 30

Number of teeth = R

Pitch

=S

E

D

C

A

P005 106E

12

DKMH.PN.315.A1.02 520L0517

Series 20 Axial Piston Pumps

Technical Information

Dimensions Frame Size 070 and 089 cm3

View Y

U

Case drain port

Gauge port servo cylinder

pressure

V

96

Port "S":

Suction port

(charge pump)

19

Port "L1":

Case drain port

Position of charge pump for

clockwise (R) rotation

Port "A"

OUTLINE DRAWING,

CONFIGURATION

PS, DISPLACEMENT

CONTROL VML 1

(continued)

Position of charge pump for

counterclockwise (L) rotation

Gauge port "M"

Port "L2":

Case drain port

Port "B"

Y

Port "B"

Y

Port "A"

U

Case drain port

P005 107E

Max. torque for charge pump inlet port (7/8 -14 UNF - 2B) is 22 - 28 Nm [195 - 248 lbfin].

Frame size

070

089

Port A and B

SAE flange, size 1

SAE split flange boss

5000 psi

4 threads

3/8-16 UNC-2B

18 deep

DKMH.PN.315.A1.02 520L0517

Port L1 and L2

Port S

7/8-14 UNF-2B

SAE straight thread

O-ring boss

Port M

7/16-20 UNF-2B

SAE straight thread

O-ring boss

13

Series 20 Axial Piston Pumps

Technical Information

Dimensions Frame Size 070 and 089 cm3

OUTLINE DRAWING, CONFIGURATION PS, DISPLACEMENT CONTROL VML 1 (continued)

View X (for SPV 2/070 only)

View X (for SPV 2/089 only)

Control handle shaft

spline data: 64/128 pitch,

64 diametral pitch acc.

to SAE handbook 1963

Outside diameter = 10.13 - 0.14

Number of teeth = 24

DD

EE

9.4 0.24

Control

handle

Z

CC

15

GG

78

Rotation

L

16

R

Z

62

FF

BB

AA

AA

Z

62

GG

1/4 - 20 UNC - 2A

CC

BB

FF

Control

handle

45

45

16

2

EE

9.4 0.24

1/4 - 20 UNC - 2A

Rotation

L

Control handle shaft

spline data: 64/128 pitch,

64 diametral pitch acc.

to SAE handbook 1963

Outside diameter = 10.13 - 0.14

Number of teeth = 24

DD

62

GG

GG

62

78

Approximate

centre of gravity

Approximate

centre of gravity

0.8

15 + 0.3

0.8

15 + 0.3

21

6

167

JJ

JJ

HH

HH

HH

HH

P005 108E

Dimensions

Frame

size

mm

[in]

mm

[in]

mm

[in]

mm

[in]

mm

[in]

mm

[in]

mm

[in]

mm

[in]

mm

[in]

mm

[in]

mm

[in]

mm

[in]

315

[12.402]

294

[11.575]

305

[12.008]

259

[10.197]

188

[7.402]

146

[5.748]

112

[4.409]

120

[4.724]

84

[3.307]

48

[1.890]

16

[0.630]

84

[3.307]

089

328

[12.913]

307

[12.087]

312

12.283]

271

[10.669]

195

[7.677]

140

[5.512]

118

[4.646]

129

[5.079]

91

[3.583]

49

[1.929]

17.5

[0.689]

98

[3.858]

mm

[in]

mm

[in]

mm

[in]

mm

[in]

mm

[in]

mm

[in]

mm

[in]

AA

mm

mm

BB

[in]

[in]

CC

mm

mm

DD

[in]

[in]

EE

mm

[in]

070

71.4

[2.811]

112.7

[4.437]

105

[4.134]

108

[4.252]

60.5

[2.382]

85.8

[3.378]

9.5

[0.374]

187.6

[7.386]

162

[6.378]

128.6

[5.063]

133

[5.236]

113

[4.449]

089

77.7

[3.059]

128.7

[5.067]

115

[4.528]

119

[4.685]

65

[2.559]

95.2

[3.748]

12.7

[0.500]

198.6

[7.819]

173

[6.811]

139.6

[5.496]

144

[5.669]

123

[4.843]

Frame

size

FF

mm

mm

mm

GG

HH

[in]

[in]

[in]

JJ

mm

[in]

A1

mm

[in]

Charge pump

cm3

[in]

12

[0.732]

18

[1.098]

Shaft spline

mm

[in]

mm

[in]

Bore diameter for

shaft coupling

mm

[in]

mm

[in]

070

126

[4.961]

123

[4.843]

130

[5.118]

194

[7.638]

372

[14.646]

381

[15.000]

34.50 - 0.17

[1.358 - 0.0067]

33.338

[1.313]

21

[0.827]

16/32

31.75 + 0.062

[1.250 + 0.0024]

089

140

[5.512]

134

[5.276]

148

[5.827]

194

[7.638]

358

[14.094]

394

[15.512]

37.68 - 0.17

[1.483 - 0.0067]

36.513

[1.438]

23

[0.906]

16/32

34.95 + 0.062

[1.376 + 0.0024]

Short version available on request. Please contact your local Sauer-Danfoss representative.

14

070

Frame

size

DKMH.PN.315.A1.02 520L0517

Series 20 Axial Piston Pumps

Technical Information

Dimensions Frame Size 070 and 089 cm3

57.9 max

TAPERED SHAFT END

Depth, keygroove: 5,7 + 0,1

Shaft, cone:

1 :8

32.5 0.7

22.4 0.7

26

31.75

Frame size 033-070 = 84

Frame size

089 = 98

Key A 9.525 x 9.525 x 31.75

1-20 UNEF-2B

Wrench size: 38

Coupling may not protrude beyond

81 mm maximum lenght of shaft

P000 006E

PUMP CONFIGURATION

AA 010, DISPLACEMENT

CONTROL VML 1

1

3

M

4

rv

Se

Control and charge

pressure port

Return from charge relief

valve to pump case

Designation:

1

=

Variable Displacement pump

3

=

Servo control valve

4

=

Charge check valve

7

=

Heat exchanger

Ports:

A, B =

B

L1

L1, L2 =

M

=

L2

Main pressure ports

(working loop)

Drain ports

Gauge port - charge pressure

P000 058E

DKMH.PN.315.A1.02 520L0517

15

Series 20 Axial Piston Pumps

Technical Information

Dimensions Frame Size 070 and 089 cm3

PUMP CONFIGURATION AA 010, DISPLACEMENT CONTROL VML 1 (continued)

29

Control and charge

pressure port R 3/4

34

B

Return from charge relief

valve to pump case R 3/4

A

P000 009E

Dimensions

16

Frame Size

A mm [in]

B mm [in]

Weight kg [lb]

070

339 [13.346]

316 [12.441]

63.5 [140]

089

352 [13.858]

329 [12.953]

78.5 [173]

DKMH.PN.315.A1.02 520L0517

Series 20 Axial Piston Pumps

Technical Information

Dimensions Frame Size 334 cm3

*

**

Minimum and maximum angle , (see section

servo displacement control).

Shaft spline data: spline shaft with involute

spline, according to SAE handbook, 1963,

class 1, fillet root side fit.

View Z

C

*

in.

26.7m

Maximum

displacement

Null position

*

26.7m

in.

Maximum

displacement

+0.3

- 0.2

6.73 0.1

19

Control handle

R 50.8

R 25.4

Serrated shaft

P000 026E

578

244

Port "L1": Case drain port

(use highest port as outlet)

208

Gauge port - servo cylinder pressure

(both sides) 7/16-20 UNF-2B

SAE straight thread

O-ring boss

Charge pressure

relief valve

198

77

25.5

Coupling may not protrude

beyond 48 mm maximum

lenght of full spline

30.2

2.12

58.7

79.4

M 16

64.66 - 0.16

114

36.5

177.8 - 0.05

PUMP CONFIGURATION

PS, DISPLACEMENT

CONTROL VML 1

30

Port "S":

Charge pump

suction port

40.5

15.6 0.24

Port "B"

86

246

Shaft spline data:**

Pitch

Pressure angle

Number of teeth

Pitch

= 63.500

= 30

= 27

= 16/32

Internal opening

for grooving

= 61.93 + 0.062

Approximate

centre of gravity

311

433

475

493

656

P005 115E

DKMH.PN.315.A1.02 520L0517

17

Series 20 Axial Piston Pumps

Technical Information

Dimensions Frame Size 334 cm3

PUMP CONFIGURATION PS, DISPLACEMENT CONTROL VML 1 (continued)

View Y

Gauge port servo cylinder

pressure

187.2

Case drain port

164

96

View X

174

153

Position of charge pump for

clockwise (R) rotation

9.4 0.24

Control handle

Control handle shaft

spline data: 64/128 pitch,

64 diametral pitch acc.

to SAE handbook 1963

Outside diameter = 10.13 - 0.14

Number of teeth = 24

1/4 - 20UNC - 2A

225

216

17.5

247

Port "A"

190.6

116

95.8

Rotation

L

249.6

Charge pump pressure

gauge port

7/16-20 UNF-2B

SAE straight thread

O - ring boss

45

170.2

Port "L1":

Case drain port

Gauge port "M"

50

216

116

17.5

Approximate

centre of gravity

Port "L2":

Case drain port

Port "B"

81

Port "S"

158.7

Port "B"

27.7 0.6

300

158.7

Port "A"

187.2

Case drain port

Position of charge pump for

counterclockwise (L) rotation

212

212

P005 111E

Frame size

334

18

Port A and B

SAE flange, size 1 1/2

SAE split flange boss

6000 psi

4 threads

5/8-11 UNC-2B

35 deep

Port L1 and L2

Port S

Port M

1 7/8-12 UNF-2B

SAE straight thread

O-ring boss

SAE flange, size 1 1/4

SAE split flange boss

3000 psi

4 threads

7/16-14 UNC-2B

28 deep

7/16-20 UNF-2B

SAE straight thread

O-ring boss

DKMH.PN.315.A1.02 520L0517

Series 20 Axial Piston Pumps

Technical Information

Dimensions Frame Size 334 cm3

PUMP CONFIGURATION

AA 010, DISPLACEMENT

CONTROL VML 1

1

3

M

4

o

rv

Se

Control and charge

pressure port

Return from charge relief

valve to pump case

Designation:

1

=

Variable Displacement pump

3

=

Servo control valve

4

=

Charge check valve

7

=

Heat exchanger

Ports:

A, B =

B

L1

S

=

L1, L2 =

M

=

L2

7

Main pressure ports

(working loop)

Suction port - charge pump

Drain ports

Gauge port - charge pressure

P000 058E

73

Return from charge relief

valve to pump case R 3/4

Control and charge

pressure port R 3/4

2

60

B

A

P000 010E

Dimensions

Frame size

A mm [in]

B mm [in]

C mm [in]

Weight kg [lb]

334

546 [21.496]

520 [20.472]

21 [0.827]

264.5 [583]

DKMH.PN.315.A1.02 520L0517

19

OUR PRODUCTS

Sauer-Danfoss Mobile Power and Control Systems

Market Leaders Worldwide

Hydrostatic transmissions

Hydraulic power steering

Sauer-Danfoss is a comprehensive supplier providing complete

systems to the global mobile market.

Electric power steering

Electrohydraulic power steering

Closed and open circuit axial piston

pumps and motors

Gear pumps and motors

Bent axis motors

Orbital motors

Transit mixer drives

Planetary compact gears

Proportional valves

Directional spool valves

Cartridge valves

Sauer-Danfoss serves markets such as agriculture, construction, road

building, material handling, municipal, forestry, turf care, and many

others.

We offer our customers optimum solutions for their needs and

develop new products and systems in close cooperation and

partnership with them.

Sauer-Danfoss specializes in integrating a full range of system

components to provide vehicle designers with the most advanced

total system design.

Sauer-Danfoss provides comprehensive worldwide service for its

products through an extensive network of Authorized Service

Centers strategically located in all parts of the world.

Hydraulic integrated circuits

Hydrostatic transaxles

Integrated systems

Fan drive systems

Electrohydraulics

Microcontrollers and software

Electric motors and inverters

Joysticks and control handles

Displays

Sensors

Sauer-Danfoss (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239-6000, Fax: +1 515 239 6618

Sauer-Danfoss (Neumnster) GmbH & Co. OHG

Postfach 2460, D-24531 Neumnster

Krokamp 35, D-24539 Neumnster, Germany

Phone: +49 4321 871-0, Fax: +49 4321 871 122

Sauer-Danfoss (Nordborg) A/S

DK-6430 Nordborg, Denmark

Phone: +45 7488 4444, Fax: +45 7488 4400

DKMH.PN.315.A1.02 520L0517

www.sauer-danfoss.com

Vous aimerez peut-être aussi

- Pneumatic and Hydraulic Components and Instruments in Automatic Control: Proceedings of the IFAC Symposium, Warsaw, Poland, 20-23 May 1980D'EverandPneumatic and Hydraulic Components and Instruments in Automatic Control: Proceedings of the IFAC Symposium, Warsaw, Poland, 20-23 May 1980H. J. LeskiewiczÉvaluation : 1 sur 5 étoiles1/5 (1)

- Danfoss Series 20 Axial Piston Pumps s20Document19 pagesDanfoss Series 20 Axial Piston Pumps s20lucas solon de souza costa100% (1)

- Gear Pumps Technical InformationDocument48 pagesGear Pumps Technical Informationalecandro_90100% (3)

- Installation and Service Manual Hydraulic Cab Tilt 3010003741 Rev 0BDocument22 pagesInstallation and Service Manual Hydraulic Cab Tilt 3010003741 Rev 0BMario PazPas encore d'évaluation

- Flow - Pressure Control in PumpsDocument13 pagesFlow - Pressure Control in PumpssurjitvarmaPas encore d'évaluation

- Hydraulic MotorDocument8 pagesHydraulic MotorDoral247Pas encore d'évaluation

- A10VSODocument40 pagesA10VSOJulio Carrero100% (1)

- Hydraulic OverviewDocument32 pagesHydraulic OverviewMACHINERY101GEAR100% (3)

- IP SA151 Pump User ManualDocument7 pagesIP SA151 Pump User ManualAleex ParradoPas encore d'évaluation

- Bomag Single Drum Rollers 40Document12 pagesBomag Single Drum Rollers 40Alex TanPas encore d'évaluation

- Advanced Hydraulics Don GillilandDocument17 pagesAdvanced Hydraulics Don GillilandYeahkevinrocksPas encore d'évaluation

- TR-500EX: Tadano LTDDocument6 pagesTR-500EX: Tadano LTDMuhammadFaridPas encore d'évaluation

- 45 Series K and L Frame Repair Manual (520L0632 REV A) (BLN-10196)Document28 pages45 Series K and L Frame Repair Manual (520L0632 REV A) (BLN-10196)Sasko Dimitrov100% (2)

- VP1 Service ParkerDocument16 pagesVP1 Service ParkerAdrian Alonso Bustos GonzalezPas encore d'évaluation

- 45 Series F Frame Service Manual (11005158 Rev AB Sept 2007)Document28 pages45 Series F Frame Service Manual (11005158 Rev AB Sept 2007)Sasko Dimitrov100% (2)

- CAT 4660 - G-TechnicalDocument72 pagesCAT 4660 - G-Technicaljhames limaPas encore d'évaluation

- Hydrostatic DriveDocument13 pagesHydrostatic DriveDhanraj PatilPas encore d'évaluation

- Hydroirma Catalog Gear PumpDocument104 pagesHydroirma Catalog Gear PumpEng-Mohammed Salem100% (1)

- SCC500D+Crawler+Crane 1Document2 pagesSCC500D+Crawler+Crane 1Mohamed RashedPas encore d'évaluation

- Testing and AdjustingDocument53 pagesTesting and AdjustingAlexandra Yupanqui sarmiento100% (1)

- Industrial Hydraulics TrainingDocument1 pageIndustrial Hydraulics TrainingDharma KusumahPas encore d'évaluation

- Cat Pump Part List 67dx39g1iDocument4 pagesCat Pump Part List 67dx39g1iJorge M M100% (1)

- Program Information Mobile Hydraulics, Mobile Electronics, GearsDocument27 pagesProgram Information Mobile Hydraulics, Mobile Electronics, GearsCem KoçakPas encore d'évaluation

- Powertrain Troubleshooting (Test and Adjust)Document11 pagesPowertrain Troubleshooting (Test and Adjust)Jean Jacques ouanda100% (1)

- Control Block EDC Modular Directional Valve Flow Sharing SystemDocument8 pagesControl Block EDC Modular Directional Valve Flow Sharing SystemthierrylindoPas encore d'évaluation

- Caterpillar Excabadora 246d Diagrama HydraDocument11 pagesCaterpillar Excabadora 246d Diagrama Hydrahitler morales gavidia100% (1)

- 320C Swing MotorDocument5 pages320C Swing Motormanu luvungaPas encore d'évaluation

- SAGA400 Side Housing Total Ass'Y CAT 330D: AP' CH' DR' Rev. No Date DescriptionDocument1 pageSAGA400 Side Housing Total Ass'Y CAT 330D: AP' CH' DR' Rev. No Date DescriptionDarwin SupòPas encore d'évaluation

- Sundstrand Series 42 Pump Technical Info PDFDocument52 pagesSundstrand Series 42 Pump Technical Info PDFAngelo AlmeidaPas encore d'évaluation

- Load-Independent Proportional Valve Type PVG 120: CatalogueDocument24 pagesLoad-Independent Proportional Valve Type PVG 120: CataloguemagzigioPas encore d'évaluation

- Curso PDFDocument185 pagesCurso PDFJose VidalPas encore d'évaluation

- Manual Eaton Hydraulic Systems Transit Mixers Concrete Applications Components Hydrostatic Gearbox Pumps Fluids PDFDocument24 pagesManual Eaton Hydraulic Systems Transit Mixers Concrete Applications Components Hydrostatic Gearbox Pumps Fluids PDFSabah100% (1)

- Piston Pump (Brake, Hydraulic Fan)Document7 pagesPiston Pump (Brake, Hydraulic Fan)EVER DAVID SAAVEDRA HUAYHUAPas encore d'évaluation

- Hydraulic Drive SystemDocument23 pagesHydraulic Drive Systemsitiajaar100% (1)

- Truck Frame and Suspension Repair ManualDocument5 pagesTruck Frame and Suspension Repair Manualsample namePas encore d'évaluation

- 45 Series F Frame Repair Manual (520L0821 Rev AA Nov 2006)Document28 pages45 Series F Frame Repair Manual (520L0821 Rev AA Nov 2006)Sasko Dimitrov100% (1)

- Hydraulic Rams Selection Design GuideDocument18 pagesHydraulic Rams Selection Design GuideDeepak SawantPas encore d'évaluation

- Atachment System 3.sis PDFDocument2 pagesAtachment System 3.sis PDFJuan GarciaPas encore d'évaluation

- Dozers: What Are These ? & What They Does ?Document118 pagesDozers: What Are These ? & What They Does ?harirambo100% (1)

- Cosechadora 522B Plano HYD 2016 SISDocument8 pagesCosechadora 522B Plano HYD 2016 SISFabrizio Jesús100% (1)

- Hyd PDFDocument90 pagesHyd PDFRamon CasillasPas encore d'évaluation

- Hydraulics Excavator PDFDocument16 pagesHydraulics Excavator PDFChandaKunda100% (1)

- Testeo TransmisionDocument31 pagesTesteo TransmisionmockshaPas encore d'évaluation

- 4 Pumps 95Document126 pages4 Pumps 95Rafael Santos100% (2)

- Load Sensing ControlDocument2 pagesLoad Sensing ControlMSc Kostic MilosPas encore d'évaluation

- Hydraulics Part 2Document28 pagesHydraulics Part 2MACHINERY101GEAR100% (1)

- Stihl sr420 Modification PDFDocument3 pagesStihl sr420 Modification PDFCvita Cvitić0% (1)

- HX225S HX225S: Engine STD Opt Hydraulic System STD Opt Safety STD OptDocument12 pagesHX225S HX225S: Engine STD Opt Hydraulic System STD Opt Safety STD OptAlekseyPas encore d'évaluation

- Hydrostatic Drive System: Creeper Valve Brake Master CylinderDocument27 pagesHydrostatic Drive System: Creeper Valve Brake Master CylinderGiancarlo Olivera Bejar100% (3)

- 330bl NFC AdjustDocument10 pages330bl NFC AdjustDaniel Rhasty-ghee AhmanorPas encore d'évaluation

- Blue Line Hydraulic Breakers: Product RangeDocument6 pagesBlue Line Hydraulic Breakers: Product RangeChandra prakash Jangid0% (1)

- Brochure bl61b bl71b t3 en 21 20024035 e PDFDocument24 pagesBrochure bl61b bl71b t3 en 21 20024035 e PDFCristian PatrașPas encore d'évaluation

- Bolts and Bolt TorqueDocument1 pageBolts and Bolt TorqueRichard ChuaPas encore d'évaluation

- Axial Piston Variable Pump A10V (S) O Series 31 AmericasDocument56 pagesAxial Piston Variable Pump A10V (S) O Series 31 AmericasFawzi AlzubairyPas encore d'évaluation

- Beginners' Guide To Car Suspension Types and Why They Matter - Autodeal PDFDocument8 pagesBeginners' Guide To Car Suspension Types and Why They Matter - Autodeal PDFChitoPas encore d'évaluation

- Hydromatik A7VODocument20 pagesHydromatik A7VOadelmomouraPas encore d'évaluation

- DanforDocument18 pagesDanforCristian Mena Hidalgo100% (1)

- Sauer Danfoss Serie 20Document36 pagesSauer Danfoss Serie 20CristianPas encore d'évaluation

- HYDROCONTROLoverview 2012Document178 pagesHYDROCONTROLoverview 2012Heather MurphyPas encore d'évaluation

- HYDROCONTROLoverview 2012Document178 pagesHYDROCONTROLoverview 2012Heather MurphyPas encore d'évaluation

- Bauer Motors PDFDocument30 pagesBauer Motors PDFeduardoraul0% (1)

- Alfa Laval Manual Model Mab 103 (+B)Document178 pagesAlfa Laval Manual Model Mab 103 (+B)Mery A. Dominguez100% (3)

- Salami Catalog vdm8 PDFDocument38 pagesSalami Catalog vdm8 PDFHeather Murphy0% (1)

- Alignment: Application and Installation GuideDocument28 pagesAlignment: Application and Installation GuideHeather MurphyPas encore d'évaluation

- Bauer Motors PDFDocument30 pagesBauer Motors PDFeduardoraul0% (1)

- Motor BauerDocument3 pagesMotor BauerHeather Murphy100% (1)

- Denison Gold Cup PDFDocument64 pagesDenison Gold Cup PDFOleg080100% (3)

- 1-Am 0009 - PV-PVTDocument36 pages1-Am 0009 - PV-PVTHeather MurphyPas encore d'évaluation

- 1-AM012-C - World CupDocument35 pages1-AM012-C - World CupHeather MurphyPas encore d'évaluation

- 1-AM012-C - World CupDocument35 pages1-AM012-C - World CupHeather MurphyPas encore d'évaluation

- Alfa-Laval Modelo MAB-103 - Manual de InstrucaoDocument163 pagesAlfa-Laval Modelo MAB-103 - Manual de Instrucaod750sport100% (1)

- HYDROCONTROLoverview 2012Document178 pagesHYDROCONTROLoverview 2012Heather MurphyPas encore d'évaluation

- Motor BauerDocument3 pagesMotor BauerHeather Murphy100% (1)

- Salami Catalog vdm8 PDFDocument38 pagesSalami Catalog vdm8 PDFHeather Murphy0% (1)

- Manual Cat C6.6Document253 pagesManual Cat C6.6Heather Murphy91% (23)

- Manual Cat C4.4Document487 pagesManual Cat C4.4Heather Murphy79% (14)

- AD12-Service ManualDocument66 pagesAD12-Service ManualHeather MurphyPas encore d'évaluation

- Alfa-Laval Modelo MAB-103 - Manual de InstrucaoDocument163 pagesAlfa-Laval Modelo MAB-103 - Manual de Instrucaod750sport100% (1)

- MAB103 Spare PartsDocument54 pagesMAB103 Spare Partsmanglares21100% (2)

- HYTEKDocument1 pageHYTEKHeather MurphyPas encore d'évaluation

- MAB103 Spare PartsDocument54 pagesMAB103 Spare Partsmanglares21100% (2)

- Alfa-Laval Modelo MAB-103 - Manual de InstrucaoDocument163 pagesAlfa-Laval Modelo MAB-103 - Manual de Instrucaod750sport100% (1)

- Deutz SBV6-8-9 M628Document669 pagesDeutz SBV6-8-9 M628cengiz kutukcu93% (29)

- 468-110 - Falk Torus Type WA10, WA11, WA21, Sizes 20-160,1020-1160 Couplings - Installation ManualDocument5 pages468-110 - Falk Torus Type WA10, WA11, WA21, Sizes 20-160,1020-1160 Couplings - Installation ManualHeather MurphyPas encore d'évaluation

- MAB103 Spare PartsDocument54 pagesMAB103 Spare Partsmanglares21100% (2)

- Alfa-Laval Modelo MAB-103 - Manual de InstrucaoDocument163 pagesAlfa-Laval Modelo MAB-103 - Manual de Instrucaod750sport100% (1)

- StaffaproductpverviewDocument71 pagesStaffaproductpverviewHeather Murphy100% (1)

- Bendix R-12P Pilot Relay Valve: DescriptionDocument8 pagesBendix R-12P Pilot Relay Valve: DescriptionSteven FryePas encore d'évaluation

- February 2023Document2 pagesFebruary 2023rohitchanakya76Pas encore d'évaluation

- EIM 7 - 8-Module 1Document24 pagesEIM 7 - 8-Module 1Donna Shane ReyesPas encore d'évaluation

- Coelmo 60 kVA PDT114TG3 PDFDocument2 pagesCoelmo 60 kVA PDT114TG3 PDFEmily BullockPas encore d'évaluation

- Foreword: Toyota Motor CorporationDocument11 pagesForeword: Toyota Motor CorporationAryo Wicaksono0% (2)

- Engine Nomenclature &performance ParametersDocument47 pagesEngine Nomenclature &performance Parametersahmed jemalPas encore d'évaluation

- Platina 125 SPCDocument67 pagesPlatina 125 SPCmuheetPas encore d'évaluation

- RMZ HVAC Services - BrochureDocument4 pagesRMZ HVAC Services - BrochurewaseemkhanmbaPas encore d'évaluation

- O&M Quality Dossier 9973604123Document93 pagesO&M Quality Dossier 9973604123Prajay ManePas encore d'évaluation

- Atlet Aergo ElectricDocument64 pagesAtlet Aergo Electricmalita.adrianPas encore d'évaluation

- Mechanics of Machines II: Lec. 1: Turning Moment Diagrams and FlywheelDocument20 pagesMechanics of Machines II: Lec. 1: Turning Moment Diagrams and FlywheelMustafa AhdithyPas encore d'évaluation

- C-10 & C-12 Industrial Engine BDLDocument18 pagesC-10 & C-12 Industrial Engine BDLblueseatxPas encore d'évaluation

- F125-3829 Hydraulic DiagramDocument3 pagesF125-3829 Hydraulic DiagramhacknotePas encore d'évaluation

- 10 Crane Tyre Crawler Check ListDocument1 page10 Crane Tyre Crawler Check Listjohn rajPas encore d'évaluation

- Diagrama CD PDFDocument9 pagesDiagrama CD PDFCarlos AranedaPas encore d'évaluation

- MTC-650 A: Marine Temperature CalibratorDocument8 pagesMTC-650 A: Marine Temperature CalibratorSof TalhacPas encore d'évaluation

- Operating Instructions: Radial Drill Press R32Document23 pagesOperating Instructions: Radial Drill Press R32Osama EidPas encore d'évaluation

- Parts Manual SL 2012Document118 pagesParts Manual SL 2012Aleks BubaevPas encore d'évaluation

- WL-80 FTCDocument5 pagesWL-80 FTCMr.Thawatchai hansuwanPas encore d'évaluation

- Krombach Strainers & GGCDocument35 pagesKrombach Strainers & GGCMeanRatPas encore d'évaluation

- Ekm QB Jan 2010 Apr 2016Document34 pagesEkm QB Jan 2010 Apr 2016Amit Kumar NarayanPas encore d'évaluation

- EG - DC Wire Harness Instructions 4.0Document32 pagesEG - DC Wire Harness Instructions 4.0Hybrid Racing89% (9)

- HC50 S e 067 W B 38 M B (T38)Document12 pagesHC50 S e 067 W B 38 M B (T38)Raphael Ruiz RamosPas encore d'évaluation

- Air Compressor Monthly Inspection ReportDocument1 pageAir Compressor Monthly Inspection ReportVigneshwaraPas encore d'évaluation

- Types: Positive Displacement PumpsDocument4 pagesTypes: Positive Displacement PumpsAnonymous hUxOtWChmIPas encore d'évaluation

- Hatz Repair ManualDocument174 pagesHatz Repair ManualGeert Vda92% (12)

- 621 State Street New Holland Agriculture Racine, Wisconsin 53404 866-639-4563 Option 1Document6 pages621 State Street New Holland Agriculture Racine, Wisconsin 53404 866-639-4563 Option 1Diego Alvarez AlvarezPas encore d'évaluation

- Brochure Makita 18v Cordless Impact WrenchDocument36 pagesBrochure Makita 18v Cordless Impact WrenchHidaayah Ngabas NoorPas encore d'évaluation

- Mechanisms PDFDocument56 pagesMechanisms PDFamk2009Pas encore d'évaluation

- SC3200 ServiceDocument246 pagesSC3200 ServiceАлексей100% (3)