Académique Documents

Professionnel Documents

Culture Documents

Durability of Lime Stabilized Earth Blocks

Transféré par

Uche IwuTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Durability of Lime Stabilized Earth Blocks

Transféré par

Uche IwuDroits d'auteur :

Formats disponibles

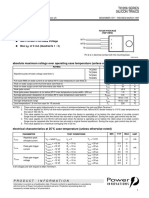

African Journal of Basic & Applied Sciences 5 (2): 102-106, 2013

ISSN 2079-2034

IDOSI Publications, 2013

DOI: 10.5829/idosi.ajbas.2013.5.2.1130

Appropriate Design and Construction of Earth Buildings:

Contesting Issues of Protection Against Cost

C. Egenti, J.M. Khatib and D. Oloke

School of Technology, University of Wolverhampton,

Wulfruna Street, Wolverhampton, WV1 1LY, United Kingdom

Abstract: Stabilisation and adequate overhang are construction and architectural design requirements for

unbaked earth walls for protective purposes. Adequate stabilisation is cost intensive; so is adequate overhang

in the context of modern Architecture. The paper analysed the cost implications of the protective requirements

of an unbaked earth walls with the intention of assessing its viability in the context of the existing earth

technology. The factor of adequacy in stabilisation was determined by experimental research in a case study

of Auchi, in Edo State of Nigeria. The research question was: Is the intended low construction cost of earth wall

achievable within the framework of the existing design and construction requirements. The paper revealed that

the overall cost of earth building in the modern context may not be cheaper than the sand-cement block building

with simple roofs. A Composite Compressed Earth Block (CCEB) is proposed for further scientific analysis and

study. This paper is part of an on-going research on the development of earth construction for improved

utilization in urban areas.

Key words: Adobe % Cost % Compressed Earth % Durability % Rammed Earth % Sustainability

INTRODUCTION

A communal effort led and arranged by

Architect Diebedo Francis Kere and group of friends to

build a school from locally sourced material [3]. The

concept of high steel roof trusses on reinforced concrete

beam was the architects way of introducing protective

overhang in modern architectural context. The walls and

piers of the school were made of compressed earth blocks

which were stabilised with small amount of cement. The

open roof structure is, however, susceptible to wind

damage in tropical environment and with the cement

stabilised wall, it constitute a high cost element of the

building.

Another example is the Arrillhjere Demostration

House in Alice Spring, Australia [3]. Built of handmade

mud bricks from the red soil found on site and stabilized

with bitumen for water resistance of wall. The roof is of

steel structure with appreciable overhang. The roof is

gabble and structurally separated from the walls,

supported by a metal frame.

In the above cases as most modern earth buildings,

walls were given limited stabilization probably due to cost

of adequately durable stabilization. Further protection was

given by the roofs of elaborate steel or concrete structure

Loam has to be sheltered against rain and

frost, especially in its wet state. Earth walls can be

protected by roof overhangs, cement, lime or bitumen

stabilisation, damp proof courses, appropriate surface

coatings etc. [1]. The impact of the micro-climate on the

building envelope is a major concern in earth

construction.

Heathcote

[2] explained that the

mechanism causing removal of material from the surface

of earth walls is the release of the kinetic energy

associated with raindrops impacting on the surface.

Erosion is further intensified when the earth wall surface

absorbs moisture thereby weakening the binding strength

of clay.

The design of earth building has to give due

consideration to these requirements for good practise.

It is therefore a common feature of modern earth buildings

to see considerable overhangs. An appreciable overhang

requires adequate structural support which if given a

modern architectural approach could be cost involving.

Typical example is the Primary School in Gando, Burkina

Faso [3].

Corresponding Author:

C. Egenti, School of Technology, University of Wolverhampton, Wulfruna Street,

Wolverhampton, WV1 1LY, United Kingdom.

102

African J. Basic & Appl. Sci., 5 (2): 102-106, 2013

the micro climate of tropical rain forest. It goes further to

investigate if such percentage stabilization is

economically practicable. This investigation is expected

to assist further research on the development of

compressed earth for increased utilization in tropical

urban environment.

MATERIAL AND METHODS

Plate 1: Primary School, Gando, Burkina Faso, 2001 [3].

The materials used for this experiment were mainly

soil and cement. Clay serves as the binder (physical) of

silt, sand and gravel, just as cement (chemical) binds the

concrete. Clay is soluble in water; its physical properties

change with increase in moisture.

Two samples of earth in Etsako West Local

Government Areas in Edo State of Nigeria were selected

for this experiment: Aviele laterite soil (TYPE 1) and the

soil of Ubiane (TYPE 2). The choice of the two different

soils was to investigate, first the percentage of

stabilization that is durable and second, if the required

percentage of stabilization changes with the composition

of soil. A particle size distribution analysis and atterberg

limit tests were conducted on the two soil samples.

Bricks of different percentages of stabilisation were

moulded with a simple hydraulic press and a uniform

pressure. Samples were cured for 7 days and air dried till

the 14th day, before drying to constant mass in a

ventilated oven. The dry weights before the simulated rain

test were recorded against the dry weight after test.

Plate 2: Arrillhjere Demonstration House 1997. [3]

capable of sustaining a reasonable cantilever; or simpler

structures with isolated piers, columns or posts to

support roof overhangs.

The planning of an adequate roof overhang to

protect earth wall in Africa is very challenging. The micro

climate of heavy driving rainfall in most parts of the

continent and the low level of infrastructural development

like irregular supply of electricity make such planning

difficult. The Architect goes through the arduous task of

balancing between creating internal spaces of adequate

natural lighting and ventilation while avoiding an

exposure of the external walls. Architects efforts at such

planning always end up in a compromise of exposing few

external walls. The planning becomes almost impossible

when it comes to storey buildings which are most

desirable in Africa for the factor of security, increased

air-flow and social class factor.

This paper aimed at assessing the implications of

constructing a truly durable earth building, economically,

in a contemporary urban environment.

The

achievement of durability and modernity in a low cost

housing setting may reverse the present trend of low

utilization of unbaked earth in construction of building in

most urban environment. The paper investigates through

an experimental investigation, the amount of stabilization

that is required to produce an adequately durable

stabilised compressed earth wall, which is exposable to

Durability

Assessment:

Appropriate

durability

assessment has been a subject of many research

works [4-6]. Most laboratory assessment methods for

durability of earth wall are inconsistent with their field

performance. A proper simulation of rainfall by drip test

from a height of not less than two metres may give a

better result [7]. In this work durability was assessed by

subjecting the sample blocks of varying percentages of

stabilisation to a laboratory simulation of the rain in

tropical rain forest. Jets of water released with pressure

from a height of 3 metres impacted on samples at vertical

angle of 15 degrees for a period of 6 hours. The dry

weight of eroded component was plotted against

percentage of stabilisation.

RESULTS AND DISCUSSION

Soil Type 1 - Aviele Laterite Soil: Soil Type 1 is a laterite

soil and the particle size distribution and atterberg limit

tests results were as shown in Figures 1 and 2.

103

African J. Basic & Appl. Sci., 5 (2): 102-106, 2013

Fig. 1: Particle size distribution chart for Aviele laterite soil (Type 1).

Fig. 2: Liquid and Plastic Limit of Aviele laterite soil (Type 1).

Fig. 3: Particle size distribution of Ubiane soil (Type 2).

104

African J. Basic & Appl. Sci., 5 (2): 102-106, 2013

on the composition of the Soil. Cement is more suitable for

a soil with a higher percentage of sand, while lime is more

appropriate with a clayey soil as it reacts, though slowly,

with clay to form a stable pozzolanic material [4]. However

the considerable amount of water required for lime and

bitumen in process of production may restrict their use to

adobe blocks and not compressed earth blocks that

requires small amount of water for good compression [4].

The availability of these binders could also be a factor for

a choice in local application. There have been

recommendations, in the literature, that 5 per cent to 8 per

cent cement is required for the satisfactory performance of

compressed earth walls [10].

Durability in modern context should not be how long

the earth wall stands without falling but also how well the

integrity of the original texture of exposed surfaces lasts

with little or no deterioration.

The result

of the durability tests of

compressed earth blocks produced from soil types 1 and

2 (Aviele and Ubiane) are shown in Figure 5. The

percentage of cement stabilisation was plotted against the

percentage or erosion.

Soil Type 1 with less clay content became very

durable at 8 per cent stabilization. Soil Type 2 with higher

clay content became adequately durable with 12 per cent

stabilization.

Fig. 4: Liquid and Plastic Limits of Ubiane soil (Type 2).

Cost Analysis: A fairly modest single-storey dwelling

needs around 120 tonnes to 150 tonnes of soil to build the

external and some internal walls [11]. A physical

measurement and calculation on a building site shows

that an area of one square metre (1 m2) of a 300mm thick

compressed earth wall requires 0.686 m3 of dry pulverised

earth when a compressive pressure of 15 N/mm2 is

applied. This was deduced from a compressed earth brick

mould of uncompressed volume of 0.0024m3 which

produces a compressed brick of 0.00105 m3 and a mass of

1.9 Kg.

The required cement for 8 per cent stabilisation

was calculated as follows: One square metre (1m2)

area of 300mm thick wall has a compressed or

brick volume of 0.3m3 which requires 0.686 m3 of

dry pulverised

earth,

based

on a measured

relationship.

Fig. 5: Percentage of erosion of stabilised Compressed

Earth blocks made from Aviele laterite soil

(Type 1) and Ubiane soil (Type 2)

The Aviele laterite soil is cohesive and gravelly with

Liquid limit of 33 and plastic limit of 18. The Plasticity

index is 15.

Soil Type 2-Ubiane: The relevant properties of Soil

type 2 were determined from the particle size distribution

and atterberg limit tests as shown in Figures 3 and 4.

The Ubiane soil has high clay content.

The Ubiane soil is more clayey and with

Liquid limit of 35 and plastic limit of 21. The Plasticity

index is 14.

Stabilisation: The weather resistant ability of earth walls

is greatly improved when stabilised and compressed [8, 9].

The addition of cement, lime or bitumen to earth before

compression changes the characteristic of earth from its

unstable state of strength and volume with changing

moisture conditions to a more suitable building material.

The suitability of the above materials may be dependent

Weight of required dry pulverised earth for 1m2 of wall

=

0.686 1900

= 543Kg

0.0024

Required cement for 8% stabilisation: 543 x 0.08 = 43.5 Kg

105

African J. Basic & Appl. Sci., 5 (2): 102-106, 2013

Comparison with Sand-Cement Blocks in Nigeria:

A 50kg bag of cement produces 25 units of

450x225x225mm hollow blocks which is capable of

covering 2.5 m2 of wall excluding plaster. This places the

cost of cement for 8 per cent stabilization of earth higher

than production of sand-cement blocks.

The above assessment was based solely on the

quantity of cement required. Other cost elements like the

cost of sand for sand-cement blocks may compare

favourably with the labour cost of digging and

pulverising earth.

Though the self-help factor of earth construction

works in rural communities where all hands come on deck

to assist in a housing project, it is hardly workable in

urban environment where neighbours are busy and will

not want to get muddy or dirty in assistance.

A Composite Compressed Earth Block (CCEB) is

proposed for adequate stabilisation with less overall cost

of wall and elimination of overhang. The development of

the composite compressed earth block by scientific study,

test and analysis of performance is a subject of an ongoing research.

REFERENCES

1.

Minke, G., 2000. Earth Construction Handbook,

United Kingdom: WIT Press Southampton,

2. Heathcote, K.A., 1995. Durability of earth wall

buildings. Construction and Building Material,

9(3): 185-89.

3. Real, R., 2010. Earth Architecture, New York:

Princeton Architectural Press.

4. Rigassi, V., 1985. Compressed earth blocks: Manual

of

production-Volume

1.

Deutsches

Entwicklungstechnologien Zentrum fur - GATE

in: Deutsche Gesellschaft fur Technische

Zusammenarbe it (GTZ) GmbH in coordination with

BASIN.

5. Walker, P., 1996. Specifications for stabilised pressed

earth blocks. Masonry Int., 10(1): 1-6.

6. Guettala, A., A. Abibsi and H. Houari, 2006.

Durability study of stabilised earth concrete under

both laboratory and climatic conditions exposure.

Construction and Building Materials, 20: 119-127.

7. Ogunye, F.O. and H. Boussabaine, 2002. Diagnosis of

assessment methods for weatherability of stabilised

compressed soil blocks. Construction and Building

Materials, 16: 163-172.

8. May, G.W., 1984. Standard Engineering for earth

buildings. In: McHenry PG, editor. Adobe and

rammed earth buildings. NewYork: John Wiley and

Sons.

9. Smith, R.G., 1987. Webb DJT. Small scale manufacture

of stabilised soil blocks. Geneva: ILO Publications.

10. Venkatarama, R.B.V. and K.S. Jagadish, 1987. Spray

erosion studies on pressed soil blocks. Build

Environ, 22(2): 135-40.

11. Keefe, L., 2005. Earth Building. New York: Taylor &

Francis Group.

Durability at a Lower Cost: Following the issues relating

to adequacy and durability of earth walls and the

corresponding cost implications, the concept of a

Composite Compressed Earth Block (CCEB) may be worth

the efforts of further research work. The Composite

Compressed Earth Masonry Unit is an earth block of two

layers of different percentages of stabilisation. The inner

layer/core shall constitutes of about 60 per cent of the

blocks volume shall be of less stabilised earth and the

outer layer/shell, which constitutes about 40 per cent of

block is of highly stabilised earth - all compressed

mechanically into a single solid block.

The concept was evolved with the intention of giving

adequate stabilisation to the exposed part of compressed

earth block with less overall cost of wall.

CONCLUSIONS

These results indicate that different soils may require

different percentages of stabilization which may go as

high as 12 per cent before adequate durability can be

achieved. Buildings are expected to function at a high

level of quality and reliability and all materials and

components in the building envelope are required to

perform their functions and maintain their integrity with

minimum maintenance.

Efforts towards achieving a durable earth wall in the

context of modern architecture are usually expensive.

Inadequate stabilisation is commonly inevitable, as the

cost of adequate stabilisation of the entire masonry unit

is high. The complementary overhang is a major cost

element which makes the low cost factor associated with

earth wall, contestable.

106

Vous aimerez peut-être aussi

- Design of Pile FoundationsDocument186 pagesDesign of Pile Foundationsroborocks100% (1)

- Design of Pile FoundationsDocument186 pagesDesign of Pile Foundationsroborocks100% (1)

- Optimizing Asphalt Mix DesignsDocument16 pagesOptimizing Asphalt Mix DesignsUche IwuPas encore d'évaluation

- Drainage LevelsDocument2 pagesDrainage LevelsUche IwuPas encore d'évaluation

- Civil Engineering - Bridge Design ManualDocument937 pagesCivil Engineering - Bridge Design ManualDeepali ChausalkarPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Mechanical SealDocument64 pagesMechanical SealKhoh Kai ShengPas encore d'évaluation

- 04 Nowy-Styl-Group Price-List Office-Furniture EXP-CZ-SK en BNOS-RG E06 2018Document420 pages04 Nowy-Styl-Group Price-List Office-Furniture EXP-CZ-SK en BNOS-RG E06 2018Marin IonutPas encore d'évaluation

- Fire Watch Training PDFDocument41 pagesFire Watch Training PDFHamdi Rafiek83% (23)

- Performance Comparative Analysis of Monocrystalline and Polycrystalline Single Diode Solar Panel Models Using The Five Parameters MethodDocument6 pagesPerformance Comparative Analysis of Monocrystalline and Polycrystalline Single Diode Solar Panel Models Using The Five Parameters MethodAlif Mu'tashimPas encore d'évaluation

- Corrosion of Cast Aluminum Alloys in Engine Coolants Under Heat-Rejecting ConditionsDocument4 pagesCorrosion of Cast Aluminum Alloys in Engine Coolants Under Heat-Rejecting ConditionsInsumos GygPas encore d'évaluation

- Ascon Design Department: Comparision Based On Value Engineered OptionDocument5 pagesAscon Design Department: Comparision Based On Value Engineered OptionAhmadPas encore d'évaluation

- Lab Report EnviroDocument19 pagesLab Report EnviroThinesh BoltPas encore d'évaluation

- HYDRAZINEDocument19 pagesHYDRAZINEDamla Taykoz100% (2)

- Repair and RehabilitationDocument115 pagesRepair and RehabilitationBala Subramanian0% (1)

- Astm A-6 PDFDocument1 pageAstm A-6 PDFFrank Berrios GarcesPas encore d'évaluation

- 3M - VHB - Structural Glazing Tapes Technical GuideDocument32 pages3M - VHB - Structural Glazing Tapes Technical GuideMahadeva PrasadPas encore d'évaluation

- August 2022 Report For Dennis T MuzilaDocument11 pagesAugust 2022 Report For Dennis T MuzilaDennis MuzilaPas encore d'évaluation

- Lecture 3 Coagulation and FlocculationDocument53 pagesLecture 3 Coagulation and FlocculationAbo-Khaled Mohammed100% (1)

- Patent Review On "Biodiesel Production Process": April 2011Document16 pagesPatent Review On "Biodiesel Production Process": April 2011Anton AlgrinovPas encore d'évaluation

- Mahaa One RMC: Er - Nanthakumar Boomi Textile MillsDocument19 pagesMahaa One RMC: Er - Nanthakumar Boomi Textile MillsMAHAA ONE RMC RAMASAMY MPas encore d'évaluation

- Brick Industry Project - Production and Operation ManagementDocument16 pagesBrick Industry Project - Production and Operation ManagementSundar Pro RiderPas encore d'évaluation

- BCA Booklet Content Drywall Internal Partition Sept 2013Document72 pagesBCA Booklet Content Drywall Internal Partition Sept 2013Carl XhingPas encore d'évaluation

- Reaction Mechanisms 1 MSDocument9 pagesReaction Mechanisms 1 MSBeatrice MoyoPas encore d'évaluation

- Slurry Shield AdditivesDocument8 pagesSlurry Shield AdditivesfabiodbdbPas encore d'évaluation

- WWW Visionalloys Com Stainless Steel Fasteners HTMLDocument4 pagesWWW Visionalloys Com Stainless Steel Fasteners HTMLNikhil JainPas encore d'évaluation

- Green Composites: An OverviewDocument11 pagesGreen Composites: An OverviewAyushPas encore d'évaluation

- Mechanical Engineering-Steam Boilers, Engines, Nozzles and Turbines Important MCQ PDFDocument28 pagesMechanical Engineering-Steam Boilers, Engines, Nozzles and Turbines Important MCQ PDFRobert Michael CorpusPas encore d'évaluation

- Mro Products and Oem Adhesives Catalog 2021Document44 pagesMro Products and Oem Adhesives Catalog 2021piyush1124Pas encore d'évaluation

- Astm A500Document5 pagesAstm A500Pierre Papeen67% (3)

- Sand ManufacturingDocument5 pagesSand ManufacturingJournalNX - a Multidisciplinary Peer Reviewed JournalPas encore d'évaluation

- Civil Engineering MCQDocument19 pagesCivil Engineering MCQSuhail RazaPas encore d'évaluation

- Thermax Absortion ChillersDocument28 pagesThermax Absortion ChillersFrancisco Alexander Navas Torres100% (5)

- Kingspan Logstor Handling and Installation Manual User Installation Guide en EurDocument290 pagesKingspan Logstor Handling and Installation Manual User Installation Guide en Eurvalentin.gomez-valadesPas encore d'évaluation

- Tic206 Series Silicon TriacsDocument6 pagesTic206 Series Silicon TriacsIgorCostaCorreiaPas encore d'évaluation

- Soal QafcoDocument3 pagesSoal QafcoRatu CeliaPas encore d'évaluation