Académique Documents

Professionnel Documents

Culture Documents

Loctite 222MS™: Technical Data Sheet

Transféré par

babshuagTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Loctite 222MS™: Technical Data Sheet

Transféré par

babshuagDroits d'auteur :

Formats disponibles

Technical Data Sheet

LOCTITE 222MS

October-2009

TYPICAL PROPERTIES OF UNCURED MATERIAL

Specific Gravity @ 25 C

Flash Point - See MSDS

Viscosity, Brookfield - RVF, 25 C, mPas (cP):

Spindle 3, speed 2 rpm, Helipath

Spindle 3, speed 20 rpm, Helipath

Lubricity, ASTM D5648, K value, ASTM D 5648, %:

3/8 x 16 steel GR 2 nuts & GR 5 bolts

1.05

5,000LMS

800 to 1,600LMS

-10 to +10LMS

(In critical applications, it is necessary to determine the K

values independently. Henkel corporation makes no warranty of

specific performance on any individual fastener):

at

e

di

ch

ro

m

ee

nc

St

25

0

1min

Zi

50

el

s

as

Br

te

ss

es

inl

a

St

5min10min 30min 1h

3h 6h

24h

Cure Time

72h

Cure Speed vs. Bond Gap

The rate of cure will depend on the bondline gap. Gaps in

threaded fasteners depends on thread type, quality and size.

The following graph shows shear strength developed with time

on steel pins and collars at different controlled gaps and tested

according to ISO 10123.

100

75

50

m

0.

15

NSF International

Registered to NSF Category P1 for use as a sealant where

there is no possibilty of food contact in and around food

processing areas. Note: This is a regional approval. Please

contact your local Technical Service Center for more

information and clarification.

75

5m

ASTM D5363

Each lot of adhesive produced in North America is tested to

the general requirements defined in paragraphs 5.1.1 and

5.1.2 and to the Detail Requirements defined in section 5.2.

100

0.0

Mil-S-46163A

LOCTITE 222MS is tested to the lot requirements of Military

Specification Mil-S-46163A.

Cure Speed vs. Substrate

The rate of cure will depend on the substrate used. The graph

below shows the breakaway strength developed with time on

M10 steel nuts and bolts compared to different materials and

tested according to ISO 10964.

% of Full Strength on Steel

LOCTITE 222MS is designed for the locking and sealing of

threaded fasteners which require easy disassembly with

standard hand tools. The product cures when confined in the

absence of air between close fitting metal surfaces and

prevents loosening and leakage from shock and vibration.

Particularly suitable for applications such as adjustment of

set screws, small diameter or long engagement length

fasteners, where easy disassembly is required without

shearing the screw. The thixotropic nature of LOCTITE

222MS reduces the migration of liquid product after

application to the substrate.

TYPICAL CURING PERFORMANCE

% of Full Strength on Steel

PRODUCT DESCRIPTION

LOCTITE 222MS provides

the following product

characteristics:

Technology

Acrylic

Chemical Type

Dimethacrylate ester

Appearance (uncured) Purple liquidLMS

Fluorescence

Positive under UV lightLMS

Components

One component - requires no mixing

Viscosity

Low, thixotropic

Cure

Anaerobic

Secondary Cure

Activator

Application

Threadlocking

Strength

Low

2

0.

25

0

1min

5min10min 30min 1h

3h 6h

Cure Time

24h

72h

TDS LOCTITE 222MS, October-2009

3/8 x 16 steel nuts (grade

2) and bolts (grade 5)

3/8 x 24 cadmium nuts and bolts

50

3/8 x 24 zinc nuts and bolts

5min10min 30min 1h

3h 6h

24h

Cure Time

72h

Cure Speed vs. Activator

Where cure speed is unacceptably long, or large gaps are

present, applying activator to the surface will improve cure

speed. The graph below shows the breakaway strength

developed with time on M10 zinc dichromate steel nuts and

bolts using Activator 7471 and 7649 and tested according

to ISO 10964.

2.8 to 9.0LMS

(25 to 80)

1.1 to 4.5LMS

(10 to 40)

1.1 to 4.5LMS

(10 to 40)

Nm

(lb.in.)

Nm

(lb.in.)

Nm

(lb.in.)

Nm

(lb.in.)

1 to 6

(9 to 50)

1.1 to 5.6LMS

(10 to 50)

0.5 to 2.8LMS

(4 to 25)

0.5 to 2.8LMS

(4 to 25)

100

No activator

75

50

r7

ato

25

tiv

Ac

74

After 1 hour @ 22 C

Breakaway Torque, ISO 10964:

3/8 x 16 steel nuts (grade

2) and bolts (grade 5)

Nm

(lb.in.)

1.1 to 9.0LMS

(10 to 80)

Prevail Torque, ISO 10964:

3/8 x 16 steel nuts (grade

2) and bolts (grade 5)

Nm

(lb.in.)

0.5 to 5.6LMS

(4 to 50)

TYPICAL ENVIRONMENTAL RESISTANCE

Cured for 1 week @ 22 C

Breakloose Torque, ISO 10964, Pre-torqued to 5 Nm:

M10 zinc phosphate steel nuts and bolts:

iva

Act

9

64

r

to

Max. Prevail Torque, ISO 10964, Pre-torqued to 5 Nm:

M10 steel nuts and bolts

Nm

8 to 20

(lb.in.) (70 to 180)

Hot Strength

Tested at temperature

100

5min10min 30min 1h

3h 6h

Cure Time

24h

72h

TYPICAL PROPERTIES OF CURED MATERIAL

Physical Properties:

Coefficient of Thermal Expansion,

ISO 11359-2, K-1

Coefficient of Thermal Conductivity, ISO 8302,

W/(mK)

Specific Heat, kJ/(kgK)

8010-6

% Strength @ 22 C

% of Full Strength on Steel

Nm

(lb.in.)

Nm

(lb.in.)

Nm

(lb.in.)

Breakloose Torque, ISO 10964, Pre-torqued to 5 Nm:

M10 steel nuts and bolts

Nm

8 to 20

(lb.in.) (70 to 180)

25

0

1min

3/8 x 16 zinc nuts and bolts

40

C

75

0

1min

3/8 x 16 steel nuts (grade

2) and bolts (grade 5)

3/8 x 16 cadmium nuts and bolts

Prevail Torque, ISO 10964:

M10 steel nuts and bolts

100

22

% of Full Strength on Steel

Cure Speed vs. Temperature

The rate of cure will depend on the temperature. The graph

below shows the breakaway strength developed with time at

different temperatures on M10 steel nuts and bolts and tested

according to ISO 10964.

75

50

25

0.1

0.3

50

100

Temperature, C

150

TYPICAL PERFORMANCE OF CURED MATERIAL

Adhesive Properties

After 24 hours @ 22 C

Breakaway Torque, ISO 10964:

M10 steel nuts and bolts

Henkel Americas

+860.571.5100

Nm

(lb.in.)

3 to 9

(25 to 80)

Henkel Europe

+49.89.320800.1800

Henkel Asia Pacific

+86.21.2891.8863

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

TDS LOCTITE 222MS, October-2009

5. For Thru Holes, apply several drops of the product onto

the bolt at the nut engagement area.

6. For Blind Holes, apply several drops of the product

down the internal threads to the bottom of the hole.

7. Assemble and tighten as required.

8. For Sealing Applications, apply a 360 bead of product

to the leading threads of the male fitting, leaving the first

thread free. Force the material into the threads to

thouroughly fill the voids. For bigger threads and voids,

adjust product amount accordingly and apply a 360

bead of product on the female threads also.

% Initial Strength @ 22 C

Heat Aging

Aged at temperature indicated and tested @ 22 C

125

120 C

100

75

50

150 C

25

0

1000

2000

3000

Exposure Time, hours

4000

5000

Chemical/Solvent Resistance

Aged under conditions indicated and tested @ 22 C.

% of initial strength

Environment

100 h

500 h

1000 h

5000 h

Motor oil

125

100

95

90

85

Leaded Petrol

22

95

95

95

95

Brake fluid

22

95

95

95

90

Water/glycol 50/50

87

80

80

80

80

Acetone

22

100

90

90

90

Ethanol

22

95

95

90

90

GENERAL INFORMATION

This product is not recommended for use in pure oxygen

and/or oxygen rich systems and should not be selected as

a sealant for chlorine or other strong oxidizing materials

For safe handling information on this product, consult the

Material Safety Data Sheet (MSDS).

Where aqueous washing systems are used to clean the

surfaces before bonding, it is important to check for

compatibility of the washing solution with the adhesive. In

some cases these aqueous washes can affect the cure and

performance of the adhesive.

This product is not normally recommended for use on plastics

(particularly thermoplastic materials where stress cracking of

the plastic could result). Users are recommended to confirm

compatibility of the product with such substrates.

Directions for use:

For Assembly

1. For best results, clean all surfaces (external and

internal) with a LOCTITE cleaning solvent and allow to

dry.

2. If the material is an inactive metal or the cure speed is

too slow, spray all threads with and allow to dry.

3. Shake the product thoroughly before use.

4. To prevent the product from clogging in the nozzle, do

not allow the tip to touch metal surfaces during

application.

Henkel Americas

+860.571.5100

For Disassembly

1. Remove with standard hand tools.

2. In rare instances where hand tools do not work because

of excessive engagement length, apply localized heat to

nut or bolt to approximately 250 C. Disassemble while

hot.

For Cleanup

1. Cured product can be removed with a combination of

soaking in a Loctite solvent and mechanical abrasion

such as a wire brush.

Loctite Material SpecificationLMS

LMS dated December-7, 1999. Test reports for each batch are

available for the indicated properties. LMS test reports include

selected QC test parameters considered appropriate to

specifications for customer use. Additionally, comprehensive

controls are in place to assure product quality and

consistency. Special customer specification requirements may

be coordinated through Henkel Quality.

Storage

Store product in the unopened container in a dry location.

Storage information may be indicated on the product container

labeling.

Optimal Storage: 8 C to 21 C. Storage below 8 C or

greater than 28 C can adversely affect product properties.

Material removed from containers may be contaminated during

use. Do not return product to the original container. Henkel

Corporation cannot assume responsibility for product which

has been contaminated or stored under conditions other than

those previously indicated. If additional information is required,

please contact your local Technical Service Center or

Customer Service Representative.

Conversions

(C x 1.8) + 32 = F

kV/mm x 25.4 = V/mil

mm / 25.4 = inches

m / 25.4 = mil

N x 0.225 = lb

N/mm x 5.71 = lb/in

N/mm x 145 = psi

MPa x 145 = psi

Nm x 8.851 = lbin

Nm x 0.738 = lbft

Nmm x 0.142 = ozin

mPas = cP

Henkel Europe

+49.89.320800.1800

Henkel Asia Pacific

+86.21.2891.8863

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

TDS LOCTITE 222MS, October-2009

Note

The data contained herein are furnished for information only

and are believed to be reliable. We cannot assume

responsibility for the results obtained by others over whose

methods we have no control. It is the user's responsibility to

determine suitability for the user's purpose of any production

methods mentioned herein and to adopt such precautions as

may be advisable for the protection of property and of persons

against any hazards that may be involved in the handling and

use thereof. In light of the foregoing, Henkel Corporation

specifically disclaims all warranties expressed or implied,

including warranties of merchantability or fitness for a

particular purpose, arising from sale or use of Henkel

Corporations products. Henkel Corporation specifically

disclaims any liability for consequential or incidental

damages of any kind, including lost profits. The discussion

herein of various processes or compositions is not to be

interpreted as representation that they are free from

domination of patents owned by others or as a license under

any Henkel Corporation patents that may cover such

processes or compositions. We recommend that each

prospective user test his proposed application before repetitive

use, using this data as a guide. This product may be covered

by one or more United States or foreign patents or patent

applications.

Trademark usage

Except as otherwise noted, all trademarks in this document

are trademarks of Henkel Corporation in the U.S. and

elsewhere. denotes a trademark registered in the U.S.

Patent and Trademark Office.

Reference 1.1

Henkel Americas

+860.571.5100

Henkel Europe

+49.89.320800.1800

Henkel Asia Pacific

+86.21.2891.8863

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

Vous aimerez peut-être aussi

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyD'EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinPas encore d'évaluation

- Loctite 243Document4 pagesLoctite 243ablemathew173974Pas encore d'évaluation

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingD'EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingPas encore d'évaluation

- Loctite 243™: Technical Data SheetDocument4 pagesLoctite 243™: Technical Data SheetRadu_ISPas encore d'évaluation

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesD'EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášPas encore d'évaluation

- Loctite 242: Product Description TechnologyDocument3 pagesLoctite 242: Product Description TechnologyRuiPas encore d'évaluation

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Loctite 262: Product Description TechnologyDocument3 pagesLoctite 262: Product Description TechnologyrajaramPas encore d'évaluation

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesD'EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Loctite 567Document3 pagesLoctite 567Nandani MangaleePas encore d'évaluation

- Advances in Solid Oxide Fuel Cells and Electronic CeramicsD'EverandAdvances in Solid Oxide Fuel Cells and Electronic CeramicsPas encore d'évaluation

- Product 243: Technical Data SheetDocument3 pagesProduct 243: Technical Data SheetRuiPas encore d'évaluation

- Loctite 2701: Technical Data SheetDocument3 pagesLoctite 2701: Technical Data SheethendrabudimanPas encore d'évaluation

- TDS Loctite 3355 PDFDocument3 pagesTDS Loctite 3355 PDFffincher4203Pas encore d'évaluation

- Loctite 518 2011Document3 pagesLoctite 518 2011Boss_enqPas encore d'évaluation

- Loctite 567 Thread Sealant Data SheetDocument3 pagesLoctite 567 Thread Sealant Data SheetJoseph BernardPas encore d'évaluation

- 4105 DatasheetDocument2 pages4105 DatasheetAsad NaeemPas encore d'évaluation

- Loctite 518™: Technical Data SheetDocument3 pagesLoctite 518™: Technical Data Sheetsaurabhjerps231221Pas encore d'évaluation

- Physical Properties: % of Initial Strength Environment °C 100 HR 500 HR 1000 HRDocument1 pagePhysical Properties: % of Initial Strength Environment °C 100 HR 500 HR 1000 HRAlberto GutierrezPas encore d'évaluation

- Loctite 5182Document3 pagesLoctite 5182ccorp0089Pas encore d'évaluation

- Loctite 648: Technical Data SheetDocument3 pagesLoctite 648: Technical Data SheetRuiPas encore d'évaluation

- Loctite 2700™: Product DescriptionDocument4 pagesLoctite 2700™: Product DescriptionvuvuvuvPas encore d'évaluation

- Loctite 542: Product Description Technology Cure Speed vs. Bond GapDocument4 pagesLoctite 542: Product Description Technology Cure Speed vs. Bond GapbabshuagPas encore d'évaluation

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoPas encore d'évaluation

- 4011 TDDocument2 pages4011 TDFernando HalaburaPas encore d'évaluation

- SONLOK_3243Document2 pagesSONLOK_3243robinPas encore d'évaluation

- SB Drill CollarDocument51 pagesSB Drill CollarJeff ZhangPas encore d'évaluation

- Heat Transfer OilDocument2 pagesHeat Transfer OilDony LiePas encore d'évaluation

- Loctite 2432: Technical Data SheetDocument2 pagesLoctite 2432: Technical Data SheetFabio ParceroPas encore d'évaluation

- Loctite 324™: Technical Data SheetDocument3 pagesLoctite 324™: Technical Data SheetUgan Git PadayacheePas encore d'évaluation

- Loctite 641: Technical Data SheetDocument3 pagesLoctite 641: Technical Data SheetRuiPas encore d'évaluation

- Dow Corning® 895 Structural Glazing Sealant: Product InformationDocument1 pageDow Corning® 895 Structural Glazing Sealant: Product Informationjaga67Pas encore d'évaluation

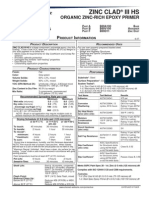

- Zinc Clad IIIDocument4 pagesZinc Clad IIIScott Van PeltPas encore d'évaluation

- Loctite 592™: % of Initial Strength Environment °C 720 HDocument2 pagesLoctite 592™: % of Initial Strength Environment °C 720 HAndy ChongPas encore d'évaluation

- Loctite 5699™: Technical Data SheetDocument3 pagesLoctite 5699™: Technical Data Sheetgazwang478Pas encore d'évaluation

- Epoxylite 578EB - TDS - 2008Document3 pagesEpoxylite 578EB - TDS - 2008beemer5Pas encore d'évaluation

- Scotch-W Scotch-Weld ProductDocument24 pagesScotch-W Scotch-Weld ProductAnca AnghelPas encore d'évaluation

- Hyd Oil Nuto 68 MobilDocument4 pagesHyd Oil Nuto 68 MobilHaytham RedaPas encore d'évaluation

- TDS of Metlok 703Document2 pagesTDS of Metlok 703idrees.theheroPas encore d'évaluation

- BELZONA 1111 Product Specification SheetDocument2 pagesBELZONA 1111 Product Specification Sheetsibi_s_rajPas encore d'évaluation

- Crestomer, Adhesivo Estructural de Alta ResistenciaDocument3 pagesCrestomer, Adhesivo Estructural de Alta ResistenciaTommy VargasPas encore d'évaluation

- DP B58W00610Document4 pagesDP B58W00610tangouzePas encore d'évaluation

- Product Data Energol THB: DescriptionDocument2 pagesProduct Data Energol THB: Descriptionkarim karimPas encore d'évaluation

- Duct Liner (AFICO)Document4 pagesDuct Liner (AFICO)hshoooma65Pas encore d'évaluation

- Perfecto T RangeDocument2 pagesPerfecto T RangecarmaPas encore d'évaluation

- Bitumastic 300MDocument2 pagesBitumastic 300Mtharman749781Pas encore d'évaluation

- AS 312 SealentDocument2 pagesAS 312 SealentbhavinPas encore d'évaluation

- Characteristics of Glass LiningDocument10 pagesCharacteristics of Glass LiningTushar MangratiPas encore d'évaluation

- Bpxe 9Q932NDocument2 pagesBpxe 9Q932NArthur Sanda LayukPas encore d'évaluation

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSLinnie McleodPas encore d'évaluation

- 8.hyspin AWS - VNDocument2 pages8.hyspin AWS - VNThắng Phạm NguyênPas encore d'évaluation

- Tds Atlantic Hydraulic OilsDocument1 pageTds Atlantic Hydraulic Oilsmgamal1080Pas encore d'évaluation

- TDS LSZH 4001Document2 pagesTDS LSZH 4001Rasel AhmedPas encore d'évaluation

- Perfecto T Range: DescriptionDocument2 pagesPerfecto T Range: Descriptiondforsythe639Pas encore d'évaluation

- Enhanced P L A P: Olyimide Aminate ND RepregDocument4 pagesEnhanced P L A P: Olyimide Aminate ND Repregoutra_pessoaPas encore d'évaluation

- TDS Castrol Perfecto XPG - Power VersionDocument2 pagesTDS Castrol Perfecto XPG - Power VersionTeguh SPas encore d'évaluation

- Pds Psx700 Jan 2008Document3 pagesPds Psx700 Jan 2008mjayhawk28Pas encore d'évaluation

- Klinger Borosilicate Gauge Sight Glasses 2007 PDFDocument8 pagesKlinger Borosilicate Gauge Sight Glasses 2007 PDFasifPas encore d'évaluation

- 22 Ohm ResistorDocument11 pages22 Ohm ResistorDwp BhaskaranPas encore d'évaluation

- Olyimide Aminate and Repreg: FeaturesDocument4 pagesOlyimide Aminate and Repreg: FeaturesAndy ValleePas encore d'évaluation

- Tape CIDDocument5 pagesTape CIDbabshuagPas encore d'évaluation

- J-C-145C Power Cable Weather Resistant PDFDocument6 pagesJ-C-145C Power Cable Weather Resistant PDFbabshuagPas encore d'évaluation

- A-A-59503C 2011 Technical NitrogenDocument6 pagesA-A-59503C 2011 Technical NitrogenbabshuagPas encore d'évaluation

- A-A-52080B 1998 Nylon Lacing and Tying TapeDocument5 pagesA-A-52080B 1998 Nylon Lacing and Tying TapebabshuagPas encore d'évaluation

- FED-STD-595C Change Notice 1 PDFDocument2 pagesFED-STD-595C Change Notice 1 PDFbabshuagPas encore d'évaluation

- Fed STD 595 - NarrativeDocument2 pagesFed STD 595 - NarrativebabshuagPas encore d'évaluation

- Fed STD 595 NarrativeDocument24 pagesFed STD 595 NarrativebabshuagPas encore d'évaluation

- 5 3 Wes MarshallDocument35 pages5 3 Wes MarshallbabshuagPas encore d'évaluation

- Importance of Beam CircularizationDocument18 pagesImportance of Beam CircularizationbabshuagPas encore d'évaluation

- Fed STD 595 - NarrativeDocument2 pagesFed STD 595 - NarrativebabshuagPas encore d'évaluation

- Fed STD 595 - NarrativeDocument2 pagesFed STD 595 - NarrativebabshuagPas encore d'évaluation

- FED-STD-595C Change Notice 1 PDFDocument2 pagesFED-STD-595C Change Notice 1 PDFbabshuagPas encore d'évaluation

- FED-STD-595C Change Notice 1 PDFDocument2 pagesFED-STD-595C Change Notice 1 PDFbabshuagPas encore d'évaluation

- Fed STD 595 - NarrativeDocument2 pagesFed STD 595 - NarrativebabshuagPas encore d'évaluation

- 595 Color NamesDocument14 pages595 Color NamesbabshuagPas encore d'évaluation

- 595 Color NamesDocument14 pages595 Color NamesbabshuagPas encore d'évaluation

- Cfr21.1040 Table 6 AelDocument2 pagesCfr21.1040 Table 6 AelbabshuagPas encore d'évaluation

- J-C-145C Power Cable Weather Resistant PDFDocument6 pagesJ-C-145C Power Cable Weather Resistant PDFbabshuagPas encore d'évaluation

- Cfr21.1040 Table 6 AelDocument1 pageCfr21.1040 Table 6 AelbabshuagPas encore d'évaluation

- A4995 - R Laser Exmeption From Federal StandardsDocument1 pageA4995 - R Laser Exmeption From Federal StandardsbabshuagPas encore d'évaluation

- DIN 47100 Wire Color CodeDocument1 pageDIN 47100 Wire Color CodebabshuagPas encore d'évaluation

- MGMT Directive 11045 Protection of Classified National Security Information Accountability Control and Storage PDFDocument24 pagesMGMT Directive 11045 Protection of Classified National Security Information Accountability Control and Storage PDFbabshuagPas encore d'évaluation

- CFR21.1040 Table 2 Class IIDocument1 pageCFR21.1040 Table 2 Class IIbabshuagPas encore d'évaluation

- CFR 2008 Title49 Vol2 Sec172 101Document209 pagesCFR 2008 Title49 Vol2 Sec172 101babshuagPas encore d'évaluation

- Bio Stds Oct07Document194 pagesBio Stds Oct07babshuagPas encore d'évaluation

- WSQ Gray-Scale Specification Version 3Document56 pagesWSQ Gray-Scale Specification Version 3Sohaib RezaPas encore d'évaluation

- NcicDocument20 pagesNcicbabshuagPas encore d'évaluation

- Support Notes GPS OperatingParametersDocument9 pagesSupport Notes GPS OperatingParametersbabshuagPas encore d'évaluation

- MGMT Directive 11045 Protection of Classified National Security Information Accountability Control and Storage PDFDocument24 pagesMGMT Directive 11045 Protection of Classified National Security Information Accountability Control and Storage PDFbabshuagPas encore d'évaluation

- Support Notes GPS OperatingParametersDocument9 pagesSupport Notes GPS OperatingParametersbabshuagPas encore d'évaluation

- pd10196 Tetra Alsafe PDFDocument2 pagespd10196 Tetra Alsafe PDFEusebio NavarroPas encore d'évaluation

- Aesthetic FinishesDocument5 pagesAesthetic FinishesAnonymous dOdHWHg4Pas encore d'évaluation

- Alarm ValveDocument6 pagesAlarm ValveAnonymous ZPTCAz9Pas encore d'évaluation

- Chap 4 PDFDocument35 pagesChap 4 PDFKamarul Nizam100% (1)

- YOKOGAWA Exa Fc400g (Ing)Document91 pagesYOKOGAWA Exa Fc400g (Ing)biotech666Pas encore d'évaluation

- SF026a-Flow Chart Portal Frame Apex ConnectionDocument3 pagesSF026a-Flow Chart Portal Frame Apex ConnectiondvelchevPas encore d'évaluation

- Confort 125 - Aluminium Sliding Doors - Sapa Building SystemDocument12 pagesConfort 125 - Aluminium Sliding Doors - Sapa Building SystemSapa Building SystemPas encore d'évaluation

- 31000, 32000 Proximity Probe Housings: DescriptionDocument9 pages31000, 32000 Proximity Probe Housings: Descriptionmehdi227Pas encore d'évaluation

- 980a0675 PDFDocument43 pages980a0675 PDFMichael DavenportPas encore d'évaluation

- Trouble With Paint Blistering of Paint Films On Metal Part 1 Osmotic BlisteringDocument10 pagesTrouble With Paint Blistering of Paint Films On Metal Part 1 Osmotic Blisteringandreathome100% (1)

- Fire Detector PlacementDocument32 pagesFire Detector Placementawadalmekawy100% (2)

- AISI S913-13 - SDocument18 pagesAISI S913-13 - SEdison BecerraPas encore d'évaluation

- Gas Chromatography Troubleshooting GuideDocument12 pagesGas Chromatography Troubleshooting GuideAbhishek Banerjee100% (1)

- Technical Manual - EASICOOL - EZRE (Air Edale)Document146 pagesTechnical Manual - EASICOOL - EZRE (Air Edale)Tong Hong LapPas encore d'évaluation

- Cranes, Rigging and BanksmanDocument61 pagesCranes, Rigging and BanksmanAdelCh100% (3)

- Maintenance Solutions For Hvac Systems: Belzona Protective Coatings and Engineering CompositesDocument12 pagesMaintenance Solutions For Hvac Systems: Belzona Protective Coatings and Engineering CompositesSUHEL NEVREKARPas encore d'évaluation

- Simulation of SOI PIN Diode for Space Radiation DetectionDocument12 pagesSimulation of SOI PIN Diode for Space Radiation Detectionzuraixoz7967Pas encore d'évaluation

- Steel Coil AlignmentDocument1 pageSteel Coil AlignmentBalluff SensorsPas encore d'évaluation

- MyDocument61 pagesMynvnrev0% (1)

- SS2205 Material SpecificationDocument4 pagesSS2205 Material SpecificationCh FaiPas encore d'évaluation

- QCVN 162019BXD National Technical Regulation On Products, Goods of Building Materials (Eng)Document41 pagesQCVN 162019BXD National Technical Regulation On Products, Goods of Building Materials (Eng)lwin_oo2435Pas encore d'évaluation

- Materials Question PackDocument20 pagesMaterials Question PackSuper Dila12Pas encore d'évaluation

- Dyneon PTFE BrochureDocument0 pageDyneon PTFE BrochureXray UandPas encore d'évaluation

- Arcelor High Yield IfDocument4 pagesArcelor High Yield IfJayDadrassPas encore d'évaluation

- Blanco Ku 0099M 13094 DATA 1 PDFDocument96 pagesBlanco Ku 0099M 13094 DATA 1 PDFCm EtcmPas encore d'évaluation

- KD-213 TDSDocument3 pagesKD-213 TDSalpesh.samruddhigroupPas encore d'évaluation

- Pellets TechnologyDocument8 pagesPellets TechnologyRajesh Chaudary APas encore d'évaluation

- Vogel - Operating InstructionsDocument45 pagesVogel - Operating InstructionsAbelardo MuñozPas encore d'évaluation

- Basement ConstructionDocument12 pagesBasement Constructionfgfghhffgh100% (2)