Académique Documents

Professionnel Documents

Culture Documents

Saudi Aramco Inspection Checklist: Pre-Application Inspection of Castable & Brick Refractory SAIC-N-2024 15-Dec-09 Mech

Transféré par

aamirapiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Saudi Aramco Inspection Checklist: Pre-Application Inspection of Castable & Brick Refractory SAIC-N-2024 15-Dec-09 Mech

Transféré par

aamirapiDroits d'auteur :

Formats disponibles

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

Pre-Application Inspection of Castable & Brick Refractory

PROJECT TITLE

SAIC-N-2024

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

REFERENCE

General Requirements (Both SAES-N-110 & SAES-N-120 Applications, See Note 1)

Refractory systems for specific equipment meet requirements

specified in SAES-N-100 Table 3 "Mandatory Refractory Systems" :

A) Refractory Anchor (Material, Sizes & Types) selection is correct

B) Refractory Material (Type, Weight % of Needles,

Application Method) selection is correct. See Note 3 (Make Field Copy).

SAES-N-100,

Para. 9.1

A2

Checklist SAIC-N-2022 is completed & accepted. Anchorage, supports

& hexsteel installations are welded. All inspection & testing is complete.

as referenced

A3

Checklist SAIC-N-2023 has been completed & accepted & both

applicators & application techniques are fully qualified.

as referenced

A4

Post-weld Heat treatment (PWHT) & hardness testing after welding is

completed & accepted.

See Note 2

SAES-N-110,

Para. 6.2.2

A5

Materials have been stored off the ground & properly covered with tarps

to protect against damage from water or moisture.

See Note 2.

SAES-N-110,

Para. 7.2

B.

Pre-Application Requirements for Castable Refractories (SAES-N-110 Procedure)

B1

All surfaces are clean, dry & free from oil, grease, weld slag & mill scale

prior to installation of refractory.

SAES-N-110,

Para. 8.1

B2

Prior to application of refractory, all metallic surfaces have been grit

blasted in accordance with SSPC SP 6, "Commercial Blast Clean".

SAES-N-110,

Para. 8.2

B3

Surfaces previously coated with a vapor barrier or that are heavily

corroded (such as tie-ins to existing equipment or repairs) are brush

blasted in accordance with SSPC SP 7, "Brush Blasting".

SAES-N-110,

Para. 8.3

B4

Application of hydraulic-setting refractory is by gunning, casting, or

vibration casting (as previously qualified by test sample).

SAES-N-110,

Para. 9.1.1

B5

Testing procedures (test panel & production sample) were performed

per SAES-N-110, Section 11.2 requirements with all testing conducted

by a fully qualified & Company approved independent lab. (Note 4)

SAES-N-110,

Para. 9.1.2

B6

Surfaces to be lined were inspected prior to refractory installation & SA

authorized Refractory Inspector has given approval for lining application.

SAES-N-110,

Para. 9.1.3

B7

Linings backing surface temperatures are monitored & do not exceed

32C for application.

SAES-N-110,

Para. 9.1.4

B8

Protective Steps are taken are maintain a maximum temperature of

32C for a minimum of 24 hours after installation. Linings are protected

from heat-induced accelerated setting by protective measures. Note 5.

SAES-N-110,

Para. 9.1.5

Page 1 of 12

PLANT NO.

EC / PMCC / MCC NO.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

CONTRACTOR INSPECTION LEVEL

A1

MECH-

SYSTEM ID.

QUANTITY INSP.

SAUDI ARAMCO INSPECTION LEVEL

ACCEPTANCE CRITERIA

QR NUMBER

CONTRACTOR / SUBCONTRACTOR

PURCHASE ORDER NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

A.

15-Dec-09

EQPT CODE

SAUDI ARAMCO TIP NUMBER

ITEM

No.

30-Jun-08

DATE APPROVED

WORK PERMIT REQUIRED?

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Application Inspection of Castable & Brick Refractory

PROJECT TITLE

ITEM

No.

SAIC NUMBER

SAIC-N-2024

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

B9

Linings & lining materials are kept above 10C during the lining

application and for a period 24 hours after the lining application.

SAES-N-110,

Para. 9.1.7

B10

Linings shall be applied in a manner that will ensure minimal shrinkage.

Manufacturer specific instruction's to minimize shrinkage are followed.

SAES-N-110,

Para. 9.1.8

B11

Water used to mix refractory (certificate) complies with the following:

A) The pH is within a range of 5.8-8.6.

B) Water quality (All Impurities < 1000 ppm, Iron < 500 ppm,

Calcium & Magnesium, both < 300 ppm, Chlorine & Sulfur, both < 200

ppm).

SAES-N-110,

Para. 9.1.9

B12

Admixtures are not used during refractory mixing operations.

SAES-N-110,

Para. 9.1.10

B13

Water ratios specified by Refractory Manufacturer are available & mixing

containers used have accurate level markings to assure mix accuracy.

SAES-N-110,

Para. 9.1.11

B14

Temperature Controls (water & refractory) exist to keep mixed refractory

between 10C and 32C.

SAES-N-110,

Para. 9.1.12

B15

Additives to linings have been approved by Saudi Aramco Engineer

(Supervisor, Piping & Valves Unit, Consulting Services Dept, Dhahran).

SAES-N-110,

Para. 9.1.13

B16

Piping & equipment is supported to prevent distortion during lining.

SAES-N-110,

Para. 9.1.14

B17

Threaded attachments on equipment are protected from lining during

application & Protection does not interfere with the application of lining.

SAES-N-110,

Para. 9.1.15

B18

Equipment nozzle extensions were properly coated with grease to

prevent refractory from bonding to them.

SAES-N-110,

Para. 9.1.16

B19

All openings in equipment are closed & tapered hardwood plugs & sheet

metal sleeves extend beyond the final thickness of the lining.

SAES-N-110,

Para. 9.1.17

B20

These plugs or sleeves are coated with grease, fit snugly into openings,

& shall remain in place until the refractory has set.

SAES-N-110,

Para. 9.1.17

B21

Refractory Manufacturer's recommended time limits (for lining

settlement) are available. The application is well-planned to ensure use

within specified time limits.

SAES-N-110,

Para. 9.1.18

B22

A minimum gap (Cut Back) of 100 mm is provided at the ends of each

section for refractory installed in piping or vessel sections to be

connected by welding.

SAES-N-110,

Para. 9.1.19

B23

The second layer in Double-layer linings is applied after the first layer

has cured for 24 hour minimum and the first layer is thoroughly wetted

just before 2nd layer application.

SAES-N-110,

Para. 9.1.20

B24

Linings of each type of refractory are installed to full thickness in a single

application & are not built up in layers.

SAES-N-110,

Para. 9.1.21

B25

When necessary to apply lining in sections to achieve full thickness in a

single application, edge forms are beveled 10 for keying of adjoining

sections. Construction Joint provisions exist. (Detailed Drawings).

SAES-N-110,

Para. 9.1.21

B26

Anchors were installed per SASD AC-036397.

See Attachment 1.

SAES-N-110,

Para. 9.2.1

Page 2 of 12

30-Jun-08

DATE APPROVED

15-Dec-09

QR NUMBER

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Application Inspection of Castable & Brick Refractory

PROJECT TITLE

ITEM

No.

SAIC NUMBER

SAIC-N-2024

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

30-Jun-08

DATE APPROVED

15-Dec-09

PASS

FAIL

Nozzle & manway opening details in refractory lined pressure vessels

& piping were installed per SASD AB-036914.

See Attachment 2.

SAES-N-110,

Para. 9.2.2

B28

Hexsteel was installed per SASD AB-036396.

See Attachment 3.

SAES-N-110,

Para. 9.2.3

B29

Inspector reviews the following procedure before production work:

"Mixing Refractory for Pneumatic Applications" .

See Note 6.

SAES-N-110,

Section 9.3

B30

Inspector reviews the following procedure before production work:

"Application of Pneumatically Applied Refractory". See Note 6.

SAES-N-110,

Section 9.4

B31

Inspector reviews the following procedure before production work:

"Mixing Refractory for Casting Applications" .

See Note 6.

SAES-N-110,

Section 9.5

B32

Inspector reviews the following procedure before production work:

"Application of Cast Refractory".

See Note 6.

SAES-N-110,

Section 9.6

B33

Inspector reviews the following procedure before production work:

"Application of Vibration Casting".

See Note 6.

SAES-N-110,

Section 9.7

C.

SAES-N-110 Procedure Figure 1 Checklist for Castable Refractory (Section A, Prior to Installation)

C1

MATERIALS are checked as follows:

A) Types of materials supplied are correct

B) Data sheets & mixing instructions are available

C) MSDS sheets are available

SAES-N-110,

Figure 1, Sect. A

C2

DOCUMENTS include approved detail drawings

SAES-N-110,

Figure 1, Sect. A

C3

INSPECTION includes the following:

A) Inspect surface preparation

B) Inspect anchor layout and welding

C4

C5

C6

C7

C) Review

welding procedures

WEATHER PROTECTION exists as follows:

A) Materials are properly stored

B) Equipment to be lined is prepared for inclement

weather

EQUIPMENT - MIXERS is checked as follows:

A) Number and type are adequate

B) Back up mixer is

available

C) Location relative to work

D) Cleanliness

GUNNITE RIGS are checked as follows:

A) Number & Type of Rigs is adequate

B) Operating Condition &

Cleanliness is adequate

C) Hose is sufficient

F) Nozzle type is

correct

VIBRATORS are checked as follows:

A) Number & Type of vibrators is adequate

B) Attachment method

C) Operating condition

D) Backup

Page 3 of 12

SAES-N-110,

Figure 1, Sect. A

SAES-N-110,

Figure 1, Sect. A

SAES-N-110,

Figure 1, Sect. A

SAES-N-110,

Figure 1, Sect. A

MECH-

CONTRACTOR / SUBCONTRACTOR

B27

SAES-N-110,

Figure 1, Sect. A

QR NUMBER

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Application Inspection of Castable & Brick Refractory

PROJECT TITLE

ITEM

No.

C8

SAIC-N-2024

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

CURING COMPOUND APPLICATORS are checked as follows:

A) Type and size

B) Cleanliness

C) Number

D) Working

conditions

AIR COMPRESSORS are checked as follows:

A) Size

C9

C10

SAIC NUMBER

B) Operating Condition

C) Contingencies

SAMPLE MOLDS are checked as follows:

A) Cubes are adequate

B) Gunnited molds are

adequate

30-Jun-08

DATE APPROVED

15-Dec-09

PASS

SAES-N-110,

Figure 1, Sect. A

SAES-N-110,

Figure 1, Sect. A

D.

Pre-Application Requirements for Extreme Erosion-Resistant Refractory (SAES-N-120 Procedure)

D1

Material is unopened & within expiry date (Or material is rejected).

SAES-N-120,

Para. 10.1.1

D2

Water used to mix refractory (certificate) complies with the following:

A) The pH is within a range of 5.8-8.6.

B) Water quality (All Impurities < 1000 ppm, Iron < 500 ppm,

Calcium & Magnesium, both < 300 ppm, Chlorine & Sulfur, both < 200

ppm).

SAES-N-120,

Para. 10.1.3

D3

Admixtures are not used unless approved by Saudi Aramco Engineer.

SAES-N-120,

Para. 10.1.4

D4

Linings will be installed indoors except for in-situ patching & repairs.

SAES-N-120,

Para. 10.1.5

D5

Lining backing surface temperatures will not exceed 32C on application

SAES-N-120,

Para. 10.1.6

D6

Protective Steps are taken are maintain a maximum temperature of

32C for a minimum of 24 hours after installation. Linings are protected

from heat-induced accelerated setting by protective measures. Note 5.

SAES-N-120,

Para. 10.1.7

D7

Linings & lining materials will be kept above 10C during the lining

application and for a period 48 hours after the lining application.

SAES-N-120,

Para. 10.1.9

D8

Surfaces shall be kept dry before, during and after installation.

SAES-N-120,

Para. 10.1.10

D9

Refractory Manufacturer's mixing instructions, installation instructions, &

precautions are available (to be strictly followed during applications).

SAES-N-120,

Para. 10.2.1

D10

A) Hobart, Model #D-33 commercial mixer (or approved equal).

B) Two, 30-quart mixing bowls

C) A beater and a wire whip

SAES-N-120,

Para. 10.2.2

Applicators understand the following mandatory requirements:

D11

A) The Mixed quantity is only what can be applied within 15 mins after

the addition of water.

B) Any mixed refractory not used within 15 minutes is

discarded.

C) Mixing does not continue

after the plastic stage occurs.

D) All

equipment, mixing bowls & tools must be kept clean & free of foreign

material & must be cleaned thoroughly after each mix.

Page 4 of 12

SAES-N-120,

Para. 10.2.3

&

Para. 10.2.4

MECH-

CONTRACTOR / SUBCONTRACTOR

SAES-N-110,

Figure 1, Sect. A

Mandatory mixing equipment (all Stainless Steel) is available as follows:

QR NUMBER

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Application Inspection of Castable & Brick Refractory

PROJECT TITLE

ITEM

No.

D12

D13

D14

SAIC NUMBER

SAIC-N-2024

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

SAMPLE TESTING PROCEDURE (9 Steps) has been completed.

(1) Select three packages at random from each batch or lot, then take 5

lbs of dry and damp material from each batch or lot.

(2) Reseal the packages that the samples were taken from and mark

them "Package Opened for Sampling".

(3) Mix the three samples of the dry material together to give a uniform

mixture. Repeat this procedure with the damp material.

(4) Take enough of the sample mix to prepare five 50 mm cubes for the

cold crushing strength tests.

(5) Seal the remainder for possible re-test.

(6) Mix the two materials together & add required amount of water (refer

to mixing instructions in paragraph 10.2.3 above) & cast five cubes.

(7) Air cure and dryout the samples in accordance with Chapter 11.

(8) Perform cold-crushing strength and bulk density tests in accordance

with ASTM C133 and ASTM C134. The cold-crushing strength and bulk

density values are the average result obtained for the five test cubes.

(9) Any sample that does not meet the minimum published strength or

density will be cause for rejection of the complete batch.

Hand packing tools (Plastic or wooden mallets) are available to

hammer refractory into hexsteel to eliminate voids or air pockets &

increase the installed density of the material.

Extreme care prevents overlaying of lining material over hexsteel. Form

for screeding is checked for levelness (screed board, line, straightedge)

& securement. No hexsteel protrusions or depressions exist.

30-Jun-08

DATE APPROVED

15-Dec-09

QR NUMBER

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAES-N-120,

Section 10.3

SAES-N-120,

Para. 10.4.1

SAES-N-120,

Para. 10.4.2

Smooth screeding is flush to the face of the hexsteel & hexsteel

pattern must be visibly distinguishable after screeding of lining.

D15

Air curing & Dryout equipment (Ventilation equipment, furnace,

auxilliary burners, temperature measuring devices, etc) is available.

SAES-N-120,

Section 11.1

Preparations for Sample Testing before Application are as follows:

A) Enough (64-80) sample forms of 50 mm cube size exist on jobsite.

D16

B) A chart is available (Sample number, date & time taken, location).

C) Sketch & log exists to show each batch location &

samples location.

D) Approved test laboratory has been determined for sample testing.

SAES-N-120,

Section 10.5

D17

A 1-pound hammer (head weight as stamped) is available for testing

the lining.

SAES-N-120,

Section 12.2.6

E.

SAES-N-120 Procedure Figure 1 Checklist for Extreme Erosion-Resistant Refractory (Section A, Prior to Installation)

E1

MATERIALS are checked as follows:

A) Types of materials supplied are correct

B) Data sheets & mixing instructions

C) MSDS sheets are available

SAES-N-120,

Para 12.5

Check List

Sec. A

Page 5 of 12

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Application Inspection of Castable & Brick Refractory

PROJECT TITLE

ITEM

No.

SAIC NUMBER

SAIC-N-2024

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

SAES-N-120,

Para 12.5

Check List

Sec. A

E2

DOCUMENTS include approved detail assembly drawings

E3

SURFACE PREPARATION & HEXSTEEL is checked as follows:

A) Surface preparation meets specifications

B) Welding procedures

E4

WEATHER PROTECTION exists as follows:

A) Materials are properly stored

B) Equipment to be lined is prepared for inclement weather conditions

E5

EQUIPMENT - MIXERS are checked as follows:

A) Number and types are adequate

B) Back up mixer is available

C) Location relative to work & Cleanliness

SAES-N-120,

Para 12.5

Check List

Sec. A

SAMPLE MOLDS are checked as follows:

A) Cubes

SAES-N-120,

Para 12.5

Check List

Sec. A

SAES-N-120,

Para 12.5

Check List

Sec. A

E6

B) Plate for erosion testing

SAES-N-120,

Para 12.5

Check List

Sec. A

SAES-N-120,

Para 12.5

Check List

Sec. A

E7

PNEUMATIC RAMMERS are checked as follows:

A) Number of rammers is adequate

B) Operating condition

F.

Pre-Application Requirements for Fireclay Brick Refractory . (SAES-N-130 Procedures)

F1

The Refractory installation procedure incorporates the requirements of

the Refractory Manufacturer, the Equipment Manufacturer, and this

standard and is approved by the Saudi Aramco Engineer prior to

installation.

SAES-N-130

Para. 5.2

F2

Detailed engineering drawings of the refractory system are available

showing anchorage design including spacing and orientation, refractory

thicknesses, all materials, surface preparation, and welding details.

SAES-N-130

Para. 5.3

F3

Structural steel framing members and tie back are provided for

supporting the brick lining on vertical flat sections.

Note:

A) All tie members shall be austenitic alloy material.

B) A minimum of 15% of the bricks shall be tied back.

C) Tie backs are not required when the radius of the curvature of

cylindrical casing keys the brick

SAES-N-130

Para. 6.3

F4

Metal support shelves welded to the casing and centered a minimum of

8 meters vertically to support the Brick lining Note: Shelves shall be

slotted to provide for differential thermal expansion.

SAES-N-130

Para. 6.3

F5

Fireclay bricks are free from mechanical damage prior to placement.

SAES-N-130

Para. 7.1

G.

SAES-N-130 - Checklist for Fire Clay Brick Refractory Installation. (Prior to Installation)

G1

MATERIALS are checked as follows:

A) Types of materials supplied are correct

B) Data sheets & mixing instructions are available

C) MSDS sheets are available

G2

DOCUMENTS include approved detail assembly drawings

Page 6 of 12

SAES-N-130

Para 8.3

Check List

SAES-N-120,

Para 12.5

Check List

Sec. A

30-Jun-08

DATE APPROVED

15-Dec-09

QR NUMBER

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Application Inspection of Castable & Brick Refractory

PROJECT TITLE

ITEM

No.

G3

SAIC NUMBER

SAIC-N-2024

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

EQUIPMENT - MIXERS are checked as follows:

A) Number and types are adequate

B) Back up mixer is available

C) Brick saw is available.

D) Location relative to work & Cleanliness

SAES-N-120,

Para 12.5

Check List

Sec. A

Page 7 of 12

30-Jun-08

DATE APPROVED

15-Dec-09

QR NUMBER

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

Pre-Application Inspection of Castable & Brick Refractory

PROJECT TITLE

SAIC-N-2024

WBS / BI / JO NUMBER

ITEM

No.

ACCEPTANCE CRITERIA

30-Jun-08

DATE APPROVED

REFERENCE

QR NUMBER

15-Dec-09

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

REMARKS:

REFERENCE DOCUMENTS:

1.

2.

3.

3.

SAES-N-100 -- Refractory Systems (30 Jan 2007)

SAES-N-110 -- Installation Requirements-Castable Refractories (30 Jan 2007)

SAES-N-120 -- Installation Requirements-Extreme Erosion Resistant Refractories (30 Jan 2007)

SAES-N-130 Installation Requirements Fireclay Bricks. (30 January 2007)

ATTACHMENTS:

Attachment 1 -- SASD AC-036397 (Anchoring Details for Castable Refractories)

Attachment 2 -- SASD AB-036914 (Support Details at Nozzles & Manways for Castable Refractory)

Attachment 3 -- SASD AB-036396 (Hexsteel Details)

NOTES:

1. This checklist applies to Pre-Application inspection for castable refractory systems detailed in procedures SAES-N-110 & SAES-N-120.

2. This is a requirement for both SAES-N-110 & SAES-N-120.

3. Use Table 3 Mandatory Refractory Systems of SAES-N-100 (Not Attached) for Pre-installation inspection checks of materials.

4. The standard refers to Paragraph 11. This is an error. Testing requirements are in Section 11. This will be revised upon the next standard review.

5. To achieve temperature limitations specified (Maximum 32C for 24 hours minimum), the backing surface may be shaded from direct sunlight,

the refractory lining may be applied indoors, or apply refractory lining at night with proper illumination. Cooling by water spraying is prohibited.

6. Inspector reviews a Field Copy of SAES-N-110, Section 9, Installation. (This is not attached to this checklist & a field copy will be needed). The

Inspector uses the procedure as a checklist for equipment (mixing, application), consumables (air, water, materials), & set-up (formwork) checks.

Contractor / Third-Party

Saudi Aramco

Construction Representative*

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

Name, Initials and Date:

QC Inspector

PID Representative

Performed Inspection

Work / Rework May Proceed

Name, Initials and Date:

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

Y = YES

Page 8 of 12

N = NO F = FAILED

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Application Inspection of Castable & Brick Refractory

SAIC NUMBER

SAIC-N-2024

30-Jun-08

DATE APPROVED

QR NUMBER

15-Dec-09

MECH-

Attachment 1 -- SASD AC-036397

(Anchoring Details for Castable Refractories)

Note: Use this Attachment on Layout (Pre-Welding) & Final Inspections

Page 9 of 12

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Application Inspection of Castable & Brick Refractory

SAIC NUMBER

SAIC-N-2024

30-Jun-08

DATE APPROVED

15-Dec-09

QR NUMBER

MECH-

Attachment 2 -- SASD AB-036914

(Support Details @ Nozzles & Manways for

Castable Refractory)

Note: Use this Attachment on Layout (Pre-Welding) & Final Inspections

Page 10 of 12

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Application Inspection of Castable & Brick Refractory

Page 11 of 12

SAIC NUMBER

SAIC-N-2024

30-Jun-08

DATE APPROVED

15-Dec-09

QR NUMBER

MECH-

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Application Inspection of Castable & Brick Refractory

SAIC-N-2024

30-Jun-08

DATE APPROVED

15-Dec-09

QR NUMBER

MECH-

Attachment 3 -- SASD AB-036396 (Hexsteel Details)

Note: Use this Attachment on Layout (Pre-Welding) & Final Inspections

Page 12 of 12

Vous aimerez peut-être aussi

- Architectural SymbolsDocument34 pagesArchitectural SymbolsNiallburke100% (4)

- Saudi Aramco Inspection Checklist: Review of Refractory Installation Procedure SAIC-N-2018 25-May-05 MechDocument4 pagesSaudi Aramco Inspection Checklist: Review of Refractory Installation Procedure SAIC-N-2018 25-May-05 MechAnonymous S9qBDVky100% (1)

- 16 JRTP 02 ITP - Rev01Document13 pages16 JRTP 02 ITP - Rev01khsaeed100% (1)

- Bronzino's Styles in ContextDocument239 pagesBronzino's Styles in ContextYnnodusPas encore d'évaluation

- Painting ReportDocument1 pagePainting Reportbaidu1980Pas encore d'évaluation

- KP-00+++-CQ712-G0011 - Rev.0 - ITP For For Cathodic Protection WorksDocument7 pagesKP-00+++-CQ712-G0011 - Rev.0 - ITP For For Cathodic Protection WorksUtku Can KılıçPas encore d'évaluation

- GEMSS-M-35 Rev 01 Painting & Coating Protection SystemDocument12 pagesGEMSS-M-35 Rev 01 Painting & Coating Protection SystemKaramSobhy100% (1)

- Chevron Pre-Inspection ChecklistDocument2 pagesChevron Pre-Inspection ChecklistosersPas encore d'évaluation

- G-Dragon's Coup D' Etat MV SymbolismsDocument32 pagesG-Dragon's Coup D' Etat MV Symbolismstalkaboutkpop90% (20)

- Saic N 2031Document4 pagesSaic N 2031aamirapi100% (1)

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistaamirapi100% (2)

- Saic N 2028Document4 pagesSaic N 2028aamirapi100% (1)

- Saic N 2029Document6 pagesSaic N 2029aamirapi100% (1)

- Saic N 2033Document5 pagesSaic N 2033aamirapiPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechDocument5 pagesSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiPas encore d'évaluation

- Insulation QAP for Boiler ApplicationsDocument4 pagesInsulation QAP for Boiler ApplicationsMukesh DakPas encore d'évaluation

- Saudi Aramco Refractory Receiving ChecklistDocument4 pagesSaudi Aramco Refractory Receiving ChecklistphilipyapPas encore d'évaluation

- Standard Specification FOR Pipeline Internal CoatingDocument2 pagesStandard Specification FOR Pipeline Internal CoatingRanjan KumarPas encore d'évaluation

- 8474L-000-JSD-2310-001-4-Protective Coatings PDFDocument31 pages8474L-000-JSD-2310-001-4-Protective Coatings PDFDo Quynh100% (2)

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistaamirapi100% (1)

- Work Method Statement FOR HSS PQTDocument6 pagesWork Method Statement FOR HSS PQTenels77Pas encore d'évaluation

- SATIP-N-001-02 Rev. 4Document2 pagesSATIP-N-001-02 Rev. 4Anonymous 4e7GNjzGW100% (1)

- Saic N 2036Document6 pagesSaic N 2036aamirapiPas encore d'évaluation

- Saic N 2037Document5 pagesSaic N 2037aamirapiPas encore d'évaluation

- 8474l-000-Jsd-2310-001-2-Protective CoatingDocument31 pages8474l-000-Jsd-2310-001-2-Protective Coatinglebienthuy100% (1)

- Cold Thermal Insulation SpecificationDocument13 pagesCold Thermal Insulation SpecificationCameliaPas encore d'évaluation

- Refractory Inspection: Prepared by Integrity EngineeringDocument17 pagesRefractory Inspection: Prepared by Integrity EngineeringAhmedPas encore d'évaluation

- Mfy 003Document4 pagesMfy 003Le TuanPas encore d'évaluation

- Concrete Works Inspection & TestingDocument9 pagesConcrete Works Inspection & Testingkbldam100% (2)

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsDocument2 pagesSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyPas encore d'évaluation

- Approved Itp-Dss - 28 Sep 2016Document4 pagesApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Vent Piping Connection SAIC-S-4041 18-May-05 PlumbDocument2 pagesSaudi Aramco Inspection Checklist: Vent Piping Connection SAIC-S-4041 18-May-05 PlumbUzair AhmadPas encore d'évaluation

- Pew 105.04 (P)Document174 pagesPew 105.04 (P)Raj BindasPas encore d'évaluation

- API936 Apr13Document4 pagesAPI936 Apr13traja4Pas encore d'évaluation

- C1729 Is A New ASTM Standard For Aluminum JacketingDocument2 pagesC1729 Is A New ASTM Standard For Aluminum JacketingTushar Arekar100% (2)

- Qc Manager, Oil and Gas ExperienceDocument25 pagesQc Manager, Oil and Gas ExperienceniranjanvengadPas encore d'évaluation

- J718Document4 pagesJ718Gatot KecePas encore d'évaluation

- HGP Insulation ProcedureDocument22 pagesHGP Insulation ProcedureShamas TabraizPas encore d'évaluation

- 14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFDocument11 pages14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFVladimir Rodriguez LeonPas encore d'évaluation

- CORR-CON INSPECTION SERVICES COATING PROCEDURE TEST REPORTDocument4 pagesCORR-CON INSPECTION SERVICES COATING PROCEDURE TEST REPORTArun Prasad100% (1)

- MineralWoolInsulation Data SheetDocument18 pagesMineralWoolInsulation Data SheetAnonymous MB5YbaLrBEPas encore d'évaluation

- BTE Dome Brochure Jun 10Document2 pagesBTE Dome Brochure Jun 10م.ذكى فضل ذكىPas encore d'évaluation

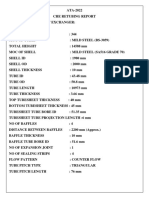

- CHE Retubing ReportDocument29 pagesCHE Retubing ReportRajesh KtrPas encore d'évaluation

- RFI For 18.03.2014 Piping, Welding at SESA FabDocument4 pagesRFI For 18.03.2014 Piping, Welding at SESA Fabmuhammedemraan100% (1)

- DRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFDocument36 pagesDRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFrodman823Pas encore d'évaluation

- Procedure of Apcs-113cDocument8 pagesProcedure of Apcs-113cNoman AhmedPas encore d'évaluation

- Sigmacover™ 620: Product Data SheetDocument5 pagesSigmacover™ 620: Product Data SheetMahmoud TahaPas encore d'évaluation

- 18B. Protegol UR 32.55R Data SheetDocument3 pages18B. Protegol UR 32.55R Data SheetClarkFedele27Pas encore d'évaluation

- Weld Built-Up ProcedureDocument1 pageWeld Built-Up ProcedureMohd Shafuaaz KassimPas encore d'évaluation

- MESC SPE 74-018 - 2010 - Nickel Alloy Pipe To Astm b167Document7 pagesMESC SPE 74-018 - 2010 - Nickel Alloy Pipe To Astm b167sathi11189Pas encore d'évaluation

- Objective 2. Reference Documents 3. Procedure 4. Painting System 5. Inspection 6. Repairs 7. Safety AnnexuresDocument11 pagesObjective 2. Reference Documents 3. Procedure 4. Painting System 5. Inspection 6. Repairs 7. Safety AnnexuresChethanPas encore d'évaluation

- Guard House Monkey Ladder 01Document5 pagesGuard House Monkey Ladder 01razi khanPas encore d'évaluation

- ICorr Insulation InspectorDocument31 pagesICorr Insulation Inspector22238.spoPas encore d'évaluation

- MST Gravity Test OwsDocument5 pagesMST Gravity Test OwsJenson T VPas encore d'évaluation

- Marathon XHBDocument4 pagesMarathon XHBeskim00Pas encore d'évaluation

- Inspection Cleaning Flushing TestingDocument8 pagesInspection Cleaning Flushing Testingadel rihanaPas encore d'évaluation

- Saudi Aramco Refractory Repair InspectionDocument4 pagesSaudi Aramco Refractory Repair InspectionaamirapiPas encore d'évaluation

- Saudi Aramco furnace dryout inspection checklistDocument4 pagesSaudi Aramco furnace dryout inspection checklistAnonymous S9qBDVky0% (1)

- Saudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 Mechரமேஷ் பாலக்காடுPas encore d'évaluation

- SAIC N 2034 InspofRepairstoExtErosResistRefractInst EL RevDocument3 pagesSAIC N 2034 InspofRepairstoExtErosResistRefractInst EL RevAnonymous S9qBDVkyPas encore d'évaluation

- Saudi Aramco CP Accessories InspectionDocument3 pagesSaudi Aramco CP Accessories InspectionaamirapiPas encore d'évaluation

- SAIC-X-3001 Rev 5Document3 pagesSAIC-X-3001 Rev 5aamirapiPas encore d'évaluation

- Saes N 130Document5 pagesSaes N 130aamirapiPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechDocument5 pagesSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistaamirapiPas encore d'évaluation

- Saic N 2040Document4 pagesSaic N 2040aamirapiPas encore d'évaluation

- SATIP-X-400-01 Rev 5Document3 pagesSATIP-X-400-01 Rev 5aamirapiPas encore d'évaluation

- Saic A 1001rev 5Document2 pagesSaic A 1001rev 5aamirapiPas encore d'évaluation

- Refractory Dry-Out Procedure For SRU Train 5 (MC-P06) Rev-ADocument107 pagesRefractory Dry-Out Procedure For SRU Train 5 (MC-P06) Rev-Aaamirapi100% (2)

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechDocument5 pagesSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiPas encore d'évaluation

- Saes N 140Document10 pagesSaes N 140aamirapiPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechDocument1 pageSaudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechaamirapiPas encore d'évaluation

- Saic N 2039Document1 pageSaic N 2039aamirapiPas encore d'évaluation

- Saic N 2035Document9 pagesSaic N 2035aamirapiPas encore d'évaluation

- Saic N 2036Document6 pagesSaic N 2036aamirapiPas encore d'évaluation

- Saudi Aramco Refractory Repair InspectionDocument4 pagesSaudi Aramco Refractory Repair InspectionaamirapiPas encore d'évaluation

- Saic N 2037Document5 pagesSaic N 2037aamirapiPas encore d'évaluation

- Saudi Aramco Refractory Repair InspectionDocument4 pagesSaudi Aramco Refractory Repair InspectionaamirapiPas encore d'évaluation

- Saic N 2033Document5 pagesSaic N 2033aamirapiPas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saic N 2030Document6 pagesSaic N 2030aamirapi100% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Group 2 BSN 2D Module 2 Workshop 2Document1 pageGroup 2 BSN 2D Module 2 Workshop 2Jashtine JingcoPas encore d'évaluation

- 08XTzF9mSWqwQHobTirO 7 TIPS For Painting With Acrylic MediumsDocument6 pages08XTzF9mSWqwQHobTirO 7 TIPS For Painting With Acrylic MediumsSanda Ionescu100% (1)

- DIY ChandelierDocument6 pagesDIY ChandelierBrassyApple67% (3)

- VRB TS1Document448 pagesVRB TS1MangBedjo100% (1)

- Bekesi Poster FinalDocument1 pageBekesi Poster Finalapi-3192736220% (1)

- Mixtec Rulership Colonial TimesDocument32 pagesMixtec Rulership Colonial TimesEmiliano GarciaPas encore d'évaluation

- Dust Test Data SheetDocument4 pagesDust Test Data Sheetjorgenorth100% (1)

- 1912-Problems in Furniture MakingDocument82 pages1912-Problems in Furniture MakingMaton de GongoraPas encore d'évaluation

- Details of Waste PaperDocument3 pagesDetails of Waste PapershivleeaggarwalPas encore d'évaluation

- Business Plan Cozy House 06Document9 pagesBusiness Plan Cozy House 06rabiyam100% (1)

- Louis MacNeice's Autumn Journal Explores Practical IdealsDocument8 pagesLouis MacNeice's Autumn Journal Explores Practical IdealsAhren WarnerPas encore d'évaluation

- Sketch Your Dreams Lesson PlanDocument5 pagesSketch Your Dreams Lesson Planapi-356117490100% (1)

- Haiku Poem AnalysisDocument3 pagesHaiku Poem Analysisapi-295870083100% (1)

- Crochet Patterns Painting Ideas and More 15 New DIY CraftsDocument73 pagesCrochet Patterns Painting Ideas and More 15 New DIY Craftsmessapos100% (4)

- CRETAzDocument53 pagesCRETAzFelipe Santiago Vega Fermin100% (1)

- Color in Feng ShuiDocument7 pagesColor in Feng ShuiSandrina PatrascanPas encore d'évaluation

- The Belles - Letters StyleDocument2 pagesThe Belles - Letters StyleslnkoPas encore d'évaluation

- How To Use These Guidesheets: X-Height SpaceDocument7 pagesHow To Use These Guidesheets: X-Height Spacespringrose983917Pas encore d'évaluation

- The History and Practice of Production DesignDocument8 pagesThe History and Practice of Production DesignKissBalázsPas encore d'évaluation

- Fundamentals of Art - Learn the Building Blocks and RulesDocument64 pagesFundamentals of Art - Learn the Building Blocks and Rulesjag0% (1)

- Fourth Grade - Aminah RobinsonDocument7 pagesFourth Grade - Aminah Robinsonapi-528337063Pas encore d'évaluation

- IKEA Catalogue 2011Document189 pagesIKEA Catalogue 2011Ahmed SamiPas encore d'évaluation

- CPAR Q1 W4v2Document19 pagesCPAR Q1 W4v2bert jacob tropicalesPas encore d'évaluation

- The Great Beauty of BogotaDocument3 pagesThe Great Beauty of BogotaDwightDemar DemarPas encore d'évaluation

- CaduceusDocument2 pagesCaduceusBryan Baynosa ArabianaPas encore d'évaluation

- Linda VFDocument21 pagesLinda VFAcro PaintsPas encore d'évaluation

- Bernstein - 99 PoetsDocument277 pagesBernstein - 99 PoetsJulián Herbert100% (2)

- Modernism: Anti-Realism in TheatreDocument109 pagesModernism: Anti-Realism in TheatreJetlogzzszszsPas encore d'évaluation